Method for improving thermoelectric properties of bismuth sulfide polycrystal

A technology of thermoelectric properties and bismuth sulfide, applied in chemical instruments and methods, polycrystalline material growth, crystal growth, etc., can solve problems such as high electrical conductivity and low thermal conductivity, and achieve high electrical conductivity, low thermal conductivity, and high migration The effect of rate sum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

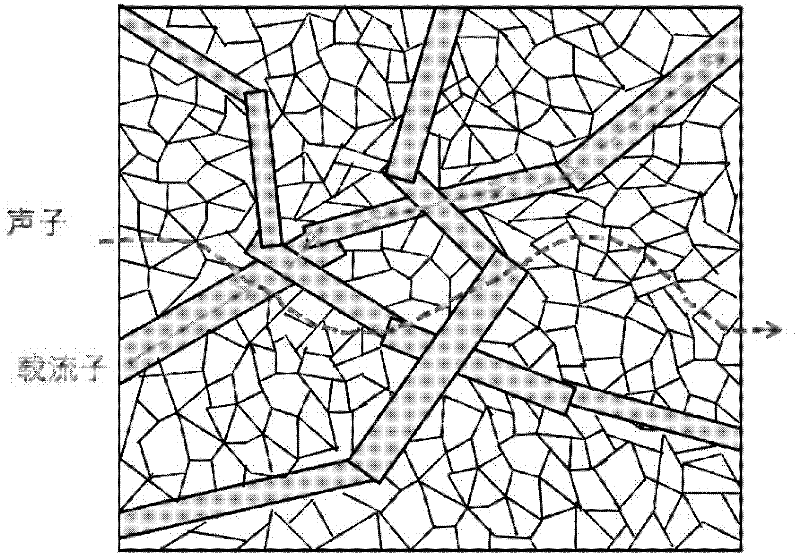

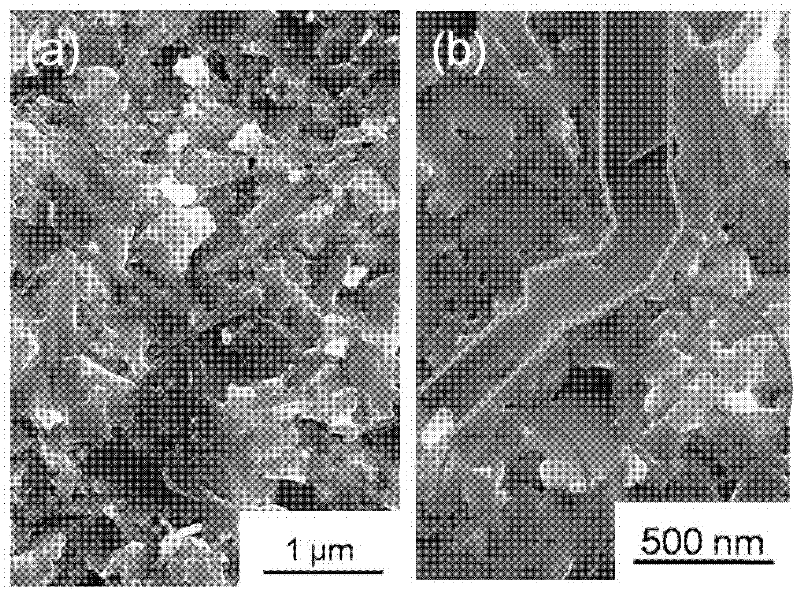

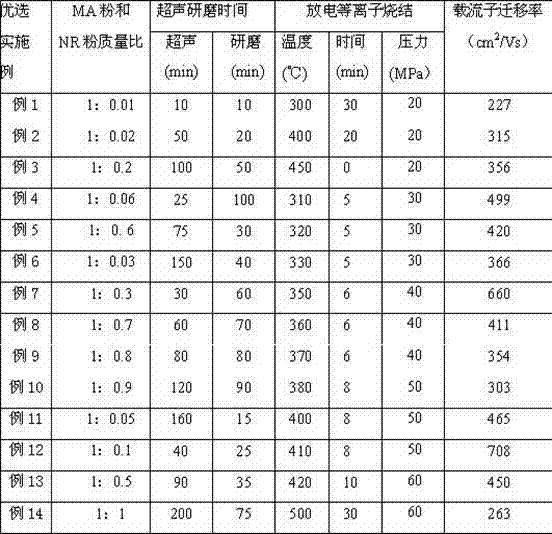

[0015] Bismuth sulfide nanopowder (MA powder) prepared by mechanical alloying method and (001) oriented single crystal bismuth sulfide nanorod (NR powder) synthesized by hydrothermal method were mixed in mass ratio, ultrasonically dispersed in absolute ethanol for 1 minute, Dry at 30-150°C for 30-300 minutes and grind by hand in an agate mortar. The ground powder is placed in a graphite mold, and a polycrystalline bismuth sulfide block is prepared by a spark plasma sintering process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com