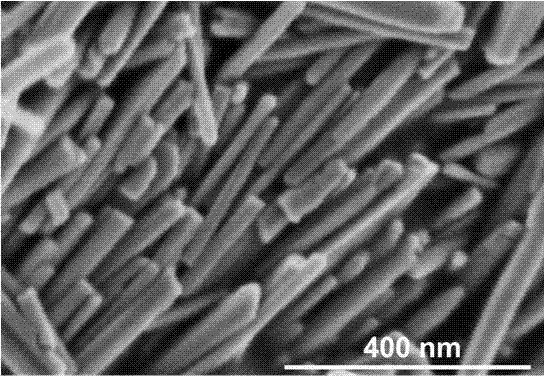

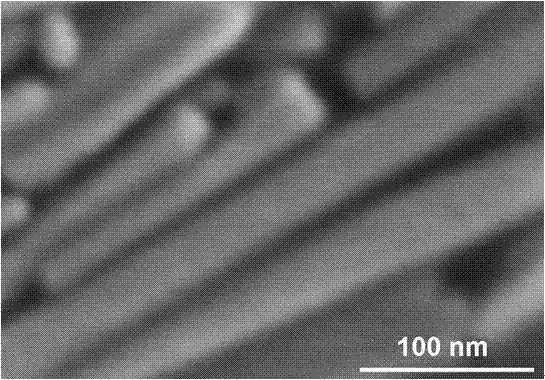

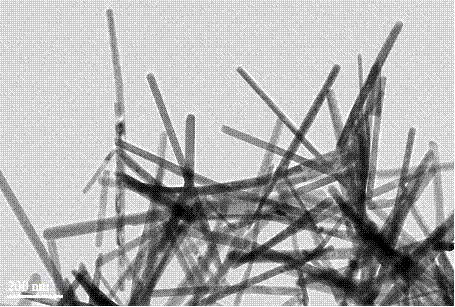

Preparation method of novel bismuth sulfide nanorods

A technology of bismuth sulfide and nanorods, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems that hinder the large-scale application of titanium dioxide, low quantum efficiency, etc., achieve improved catalytic effect, simple preparation process, and reduce usage cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A, take by weighing 0.465g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), it was added to 194mL of methanol, stirred continuously, then 1.6g of concentrated hydrochloric acid (HCl) was added, and 0.307g of glutathione (GSH) was added to the clarified solution to obtain a transparent solution;

[0035] B. Transfer the above mixed solution to a high-pressure reactor, heat it to 150°C under the protection of 1MPa nitrogen, keep it for 30min, then raise the temperature to 240°C and keep it for 1h;

[0036] C. Finally, the solvent was discharged by supercritical drying and cooled to 20-25° C., and the bismuth sulfide nanorods were taken out. The quality of the obtained product was 0.51 g, and the yield was 99.81%.

[0037] The methanol in the test is analytically pure, with a high content of main components, high purity, and low interfering impurities, which is suitable for industrial analysis and chemical experiments.

Embodiment 2

[0039] A, take by weighing 0.465g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), it was added to 200mL of methanol, stirred continuously, then 1.6g of concentrated hydrochloric acid (HCl) was added, and 0.307g of glutathione (GSH) was added to the clarified solution to obtain a transparent solution;

[0040] B. Transfer the above mixed solution to a high-pressure reactor, heat it to 150°C under the protection of 1MPa nitrogen, keep it for 45min, then raise the temperature to 240°C and keep it for 2h;

[0041] C. Finally, the solvent was discharged by supercritical drying and cooled to 20-25° C., and the bismuth sulfide nanorods were taken out. The quality of the obtained product was 0.48 g, and the yield was 99.1%.

[0042] The methanol in the test is analytically pure, with a high content of main components, high purity, and low interfering impurities, which is suitable for industrial analysis and chemical experiments.

Embodiment 3

[0044] A, take by weighing 0.465g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), it was added to 200mL ethanol, stirred continuously, then 1.6g concentrated hydrochloric acid (HCl) was added, and 0.307g glutathione (GSH) was added to the clarified solution to obtain a transparent solution;

[0045] B. Transfer the above mixed solution to a high-pressure reactor, heat it to 150°C under the protection of 1MPa nitrogen, keep it for 60min, then raise the temperature to 240°C and keep it for 3h;

[0046] C. Finally, discharge the solvent through supercritical drying and cool to 20-25° C., then take out the bismuth sulfide nanorods. The quality of the obtained product is 0.50 g, and the yield is 99.5%.

[0047] The ethanol in the test is analytically pure, with a high content of main components, high purity, and low interfering impurities, and is suitable for industrial analysis and chemical experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com