Bismuth sulfide nanorod with CT (computed tomography) angiography function, nano-composite material and preparation thereof

A nanocomposite material, bismuth sulfide technology, applied in X-ray contrast agent preparation, nanotechnology, bismuth compounds, etc., can solve the problems of uncontrollable shape of bismuth sulfide nanoparticles, limit the application of bismuth sulfide, harsh reaction conditions, etc., to achieve The effect of controllable shape, uniform size and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

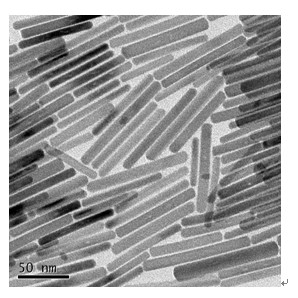

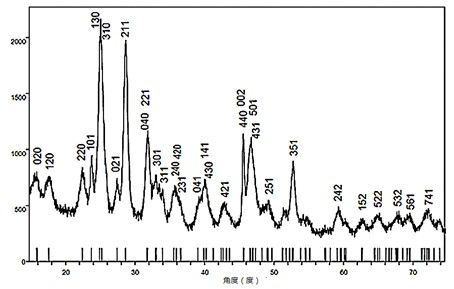

[0027] 80mL of oleylamine was added into the reaction flask, the temperature was raised to 170°C under the protection of argon, and kept at this temperature for 20min. 1.26g BiCl 3 Ultrasonic dissolved in 20mL oleylamine and 0.5g sulfur powder or 1.5g thioacetamide ultrasonically dissolved in 20mL oleylamine and added to a three-necked flask in turn, stirred for 30min. Remove the heating device, cool to room temperature, add ethanol and centrifuge, then wash the precipitate three times, and dry at room temperature. figure 1 is the TEM image of the obtained product, figure 2 It is an XRD pattern, which proves that bismuth sulfide nanorods are obtained, and the molar ratio of Bi to S is 2:3.

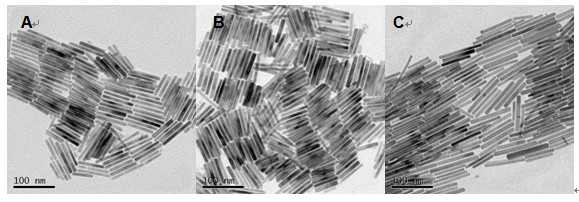

[0028] image 3 It is the TEM figure (A) 10min, (B) 20min, (C) 30min of the bismuth sulfide nanorod obtained in embodiment 1 at different reaction times. It can be seen from the figure that the bismuth sulfide nanorods synthesized in the oleylamine phase increase in length (~70nm, ~80...

Embodiment 2

[0031] Add 80mL of ethylene glycol and 8g of PVP (15K) into the reaction flask, raise the temperature to 170°C under the protection of argon, and keep at this temperature for 20min. 1.26g BiCl 3 Ultrasonic dissolved in 20mL of ethylene glycol and 1.5g of thioacetamide ultrasonically dissolved in 20mL of ethylene glycol and added to a three-necked flask in turn, stirred and reacted for 30min. Remove the heating device, cool to room temperature, add ethanol and centrifuge, then wash the precipitate three times, and dry at room temperature.

Embodiment 3

[0033] 80 mL of glycerin and 8 g of PVP (15K) were added to the reaction flask, and the temperature was raised to 170° C. under the protection of argon, and kept at this temperature for 20 min. 1.26g BiCl 3 Ultrasonic dissolving in 20mL glycerin and 1.5g thioacetamide ultrasonically dissolving in 20mL glycerin were added to a three-necked flask in turn, and stirred for 30min. Remove the heating device, cool to room temperature, add ethanol and centrifuge, then wash the precipitate three times, and dry at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com