Method for preparing cobaltous hydroxide/bismuth sulfide composite nanowire electrode material of super-capacitor

A supercapacitor electrode, cobalt hydroxide technology, used in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology and other directions, can solve problems such as high cost and limit industrial applications, and achieve high capacity and good cycle stability. , the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the cobalt hydroxide / bismuth sulfide composite nanowire supercapacitor electrode material in this embodiment includes the following steps: 1) using a titanium sheet as an electrode substrate, polishing the titanium sheet with ordinary sandpaper, and then polishing the titanium sheet in 4% dilute hydrochloric acid Ultrasonic cleaning for 15 minutes to remove impurities and titanium oxide on the surface of the titanium sheet, and finally wash with deionized water; then prepare a layer of bismuth sulfide seed layer on the titanium sheet: first, weigh 0.51g of bismuth nitrate and 0.21g of sulfur Dissolve urea in 50mL of ethylene glycol, stir for 1 hour, then take a few drops of the above solution and drop it on the titanium sheet, scrape it evenly with a blade, and heat it on a magnetic heating table at 140°C for 5 minutes;

[0031] 2) The titanium sheet with the seed layer obtained in step 1) was annealed in air at a heating rate of 5°C / min to 350°...

Embodiment 2

[0035] The difference between this example and Example 1 is that when the cobalt hydroxide nanosheets are modified on the bismuth sulfide nanowires by electrodeposition, the electrodeposition temperature is 25°C.

Embodiment 3

[0037] The difference between this embodiment and the embodiment 1 is that when the cobalt hydroxide nanosheets are modified on the bismuth sulfide nanowires by electrodeposition, the electrodeposition temperature is 90°C.

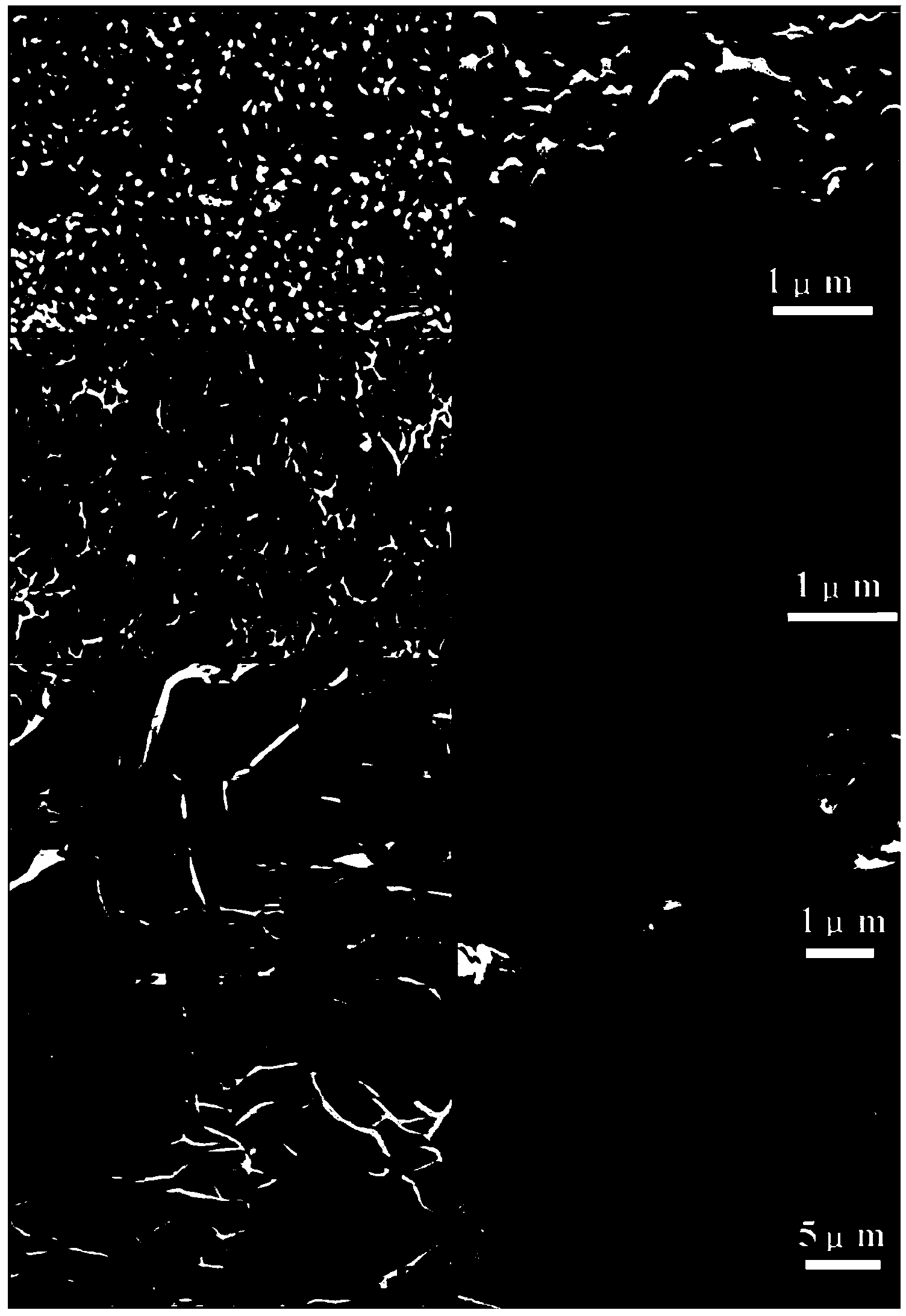

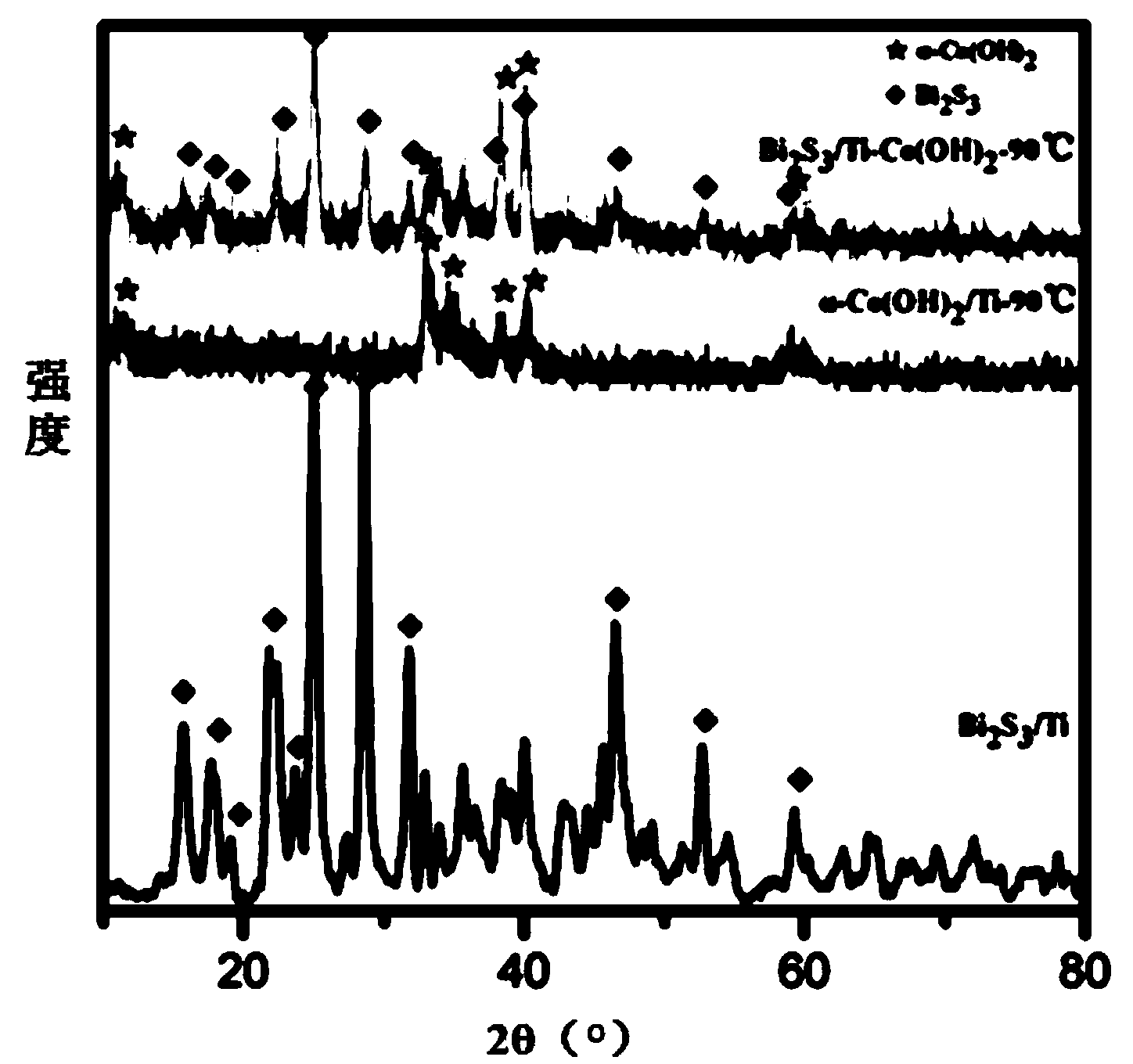

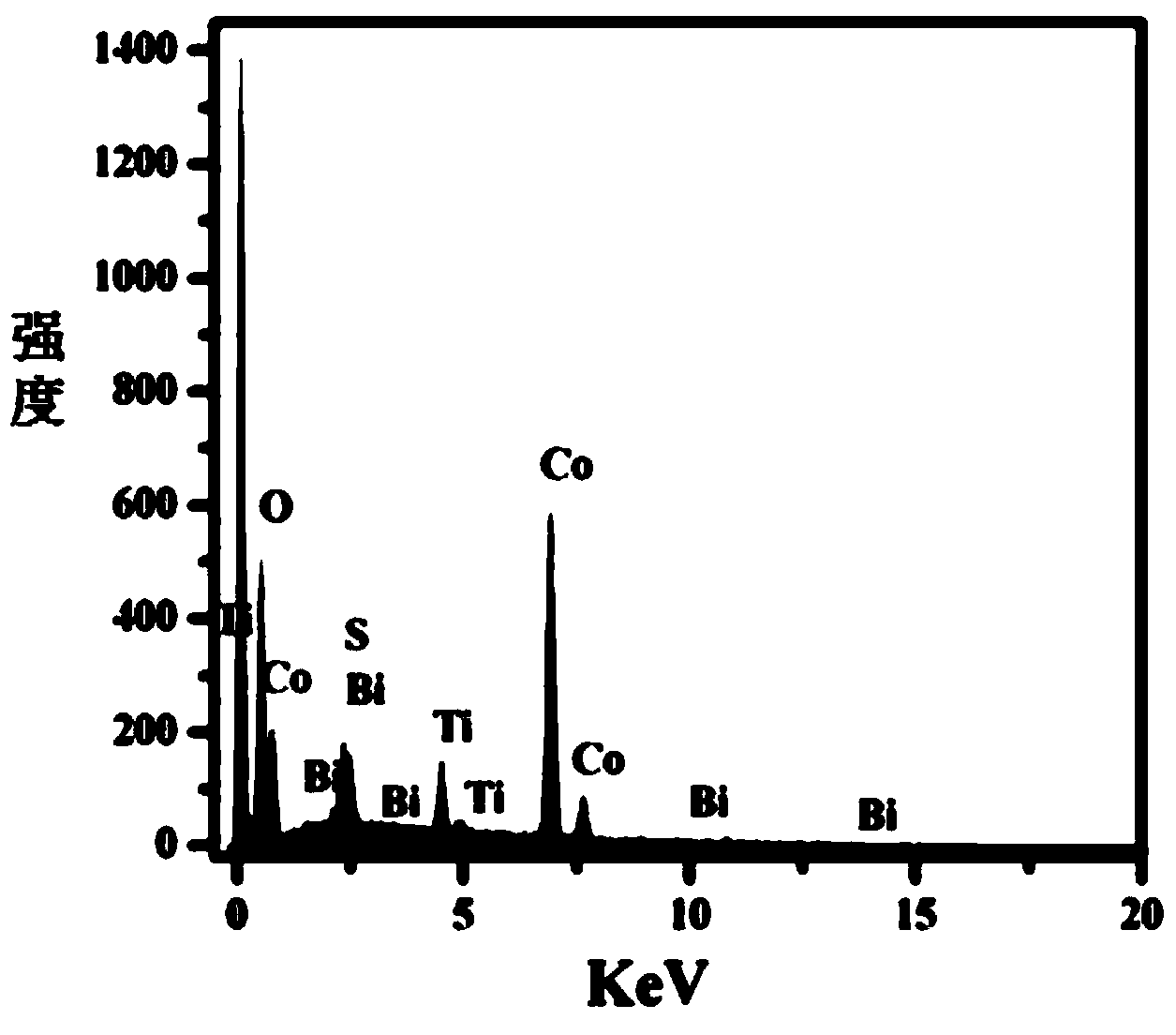

[0038] figure 1It is the SEM figure of the bismuth sulfide nanowire and the cobalt hydroxide / bismuth sulfide composite nanowire material obtained in the preparation process of Examples 1 to 3, wherein (a), (a') are the plane view and cross section of the bismuth sulfide nanowire respectively Figures, (b), (b') are plan view and cross-sectional view of the cobalt hydroxide / bismuth sulfide composite nanowire material obtained by electrodepositing cobalt hydroxide at 10°C in Example 1, respectively, (c), (c') They are the plane view and cross-sectional view of the cobalt hydroxide / bismuth sulfide composite nanowire material obtained by electrodepositing cobalt hydroxide at 25°C in Example 2, respectively, (d) and (d') are respectively electrodeposited at 90°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com