Bismuth-based nano material as well as preparation method and application thereof

A nanomaterial, bismuth-based technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of limiting electrocatalytic reduction efficiency, low concentration, improvement, etc., and achieve good electrocatalytic CO2 reduction performance, preparation method Simple, well-stabilized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

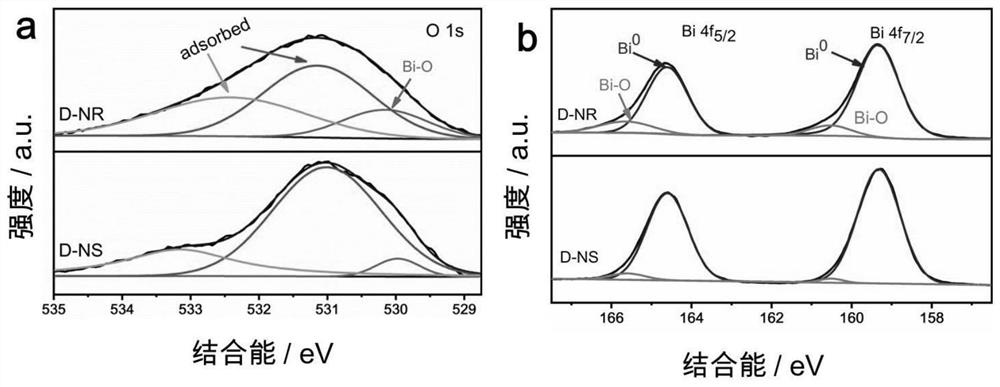

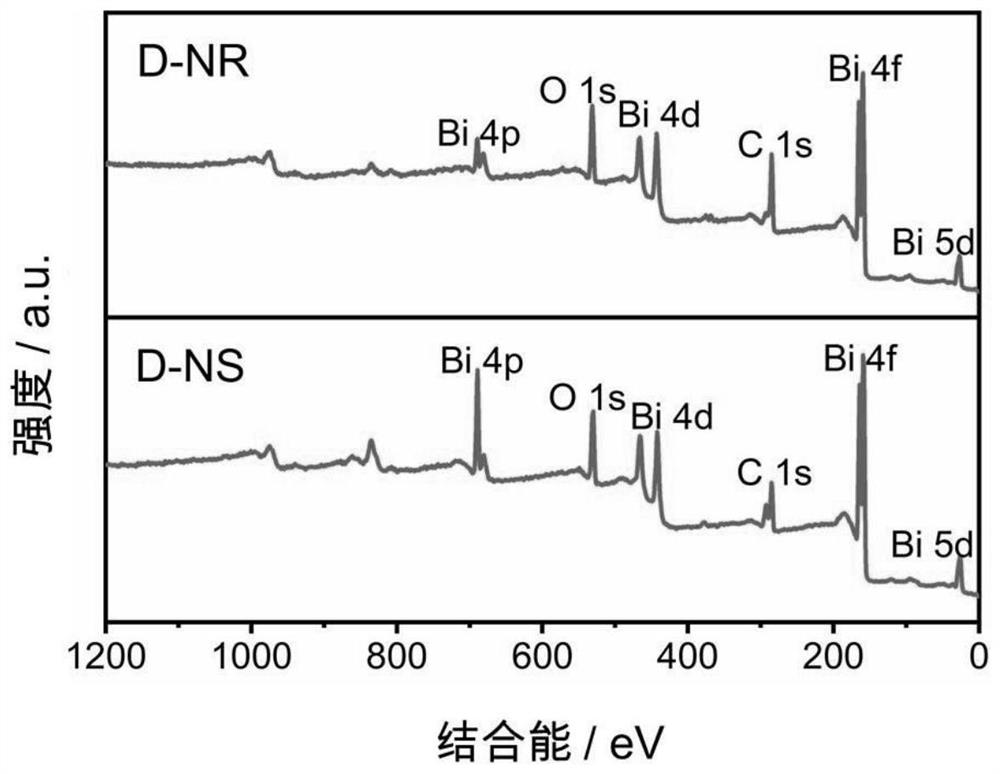

[0042] Preparation of bismuth-based materials with high concentration subsurface solvent oxygen nanosheets

[0043]Step (1): the solution containing 2g bismuth nitrate pentahydrate is added dropwise in the sodium diethyldithiocarbamate solution, the molar ratio of bismuth nitrate and sodium diethyldithiocarbamate is 1:3, both The concentration of each was 0.1mol / L, and stirred at room temperature for 1 hour. Washing and drying to obtain Bi(S 2 CNEt 2 ) 3 powder;

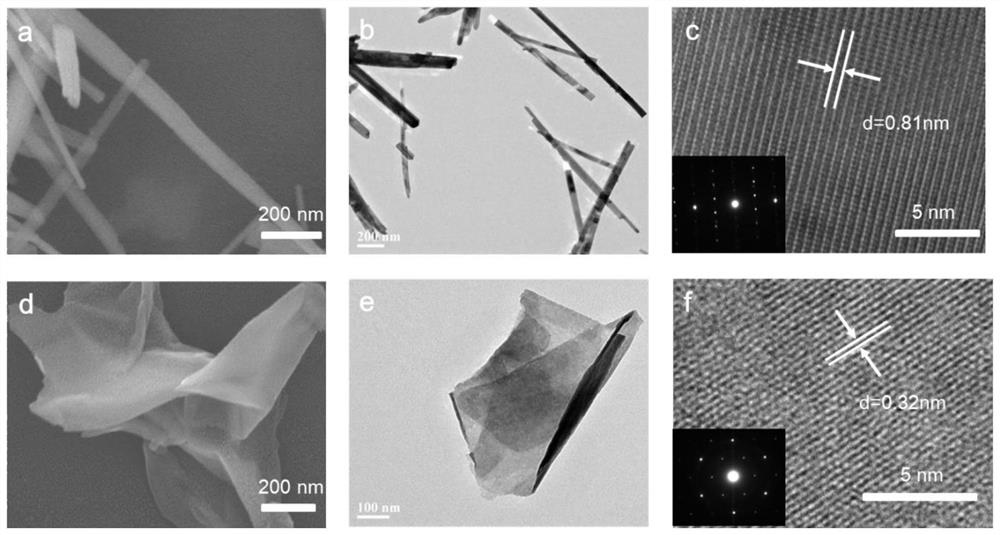

[0044] Step (2): 0.65g Bi(S 2 CNEt 2 ) 3 Add 10 mL of deionized water, heat at 140°C for 10 hours, wash and dry to obtain nanorod-shaped bismuth sulfide (referred to as NR);

[0045] Step (3): 10 mg of the prepared NR powder and 40 μL of Nafion solution (5wt%) were dispersed in 1 mL of ethanol, and after ultrasonication for 30 minutes, they were uniformly drop-coated on hydrophobic carbon paper as a working electrode (the drop-coating area was 1 × 1 cm 2 ). Using the above electrode as the working electrode,...

Embodiment 2

[0048] Preparation of bismuth-based materials with high concentration subsurface solvent oxygen nanosheets

[0049] Step (1): the solution that will contain 2g bismuth chloride is added dropwise in the sodium diethyldithiocarbamate solution, the consumption molar ratio of bismuth chloride and sodium diethyldithiocarbamate is 1:1, both The concentration of the solution was 0.2M, and stirred at room temperature for 1 hour. Washing and drying to obtain Bi(S 2 CNEt 2 ) 3 powder;

[0050] Step (2): 0.4g Bi(S 2 CNEt 2 ) 3 Add 10 mL of deionized water, heat at 120°C for 24 hours, wash and dry to obtain nanorod-shaped bismuth sulfide (referred to as NR2);

[0051] Step (3): The prepared NR2 powder 10mg and 100μL Nafion solution (5wt%) were dispersed in 10mL ethanol, after ultrasonication for 20 minutes, evenly drop-coated on the hydrophobic carbon paper as the working electrode (the drop-coating area was 1×1cm 2 ). Using the above electrode as the working electrode, Ag / AgCl (...

Embodiment 3

[0053] Preparation of bismuth-based materials with high concentration subsurface solvent oxygen nanosheets

[0054] Step (1): the solution that will contain 2g bismuth nitrate is added dropwise in the sodium diethyldithiocarbamate solution, the consumption molar ratio of bismuth nitrate and sodium diethyldithiocarbamate is 1:5, the concentration of both to 0.05M and stirred at room temperature for 2 hours. Washing and drying to obtain Bi(S 2 CNEt 2 ) 3 powder;

[0055] Step (2): 1g Bi(S 2 CNEt 2 ) 3 Add 10 mL of deionized water, heat at 160°C for 6 hours, wash and dry to obtain nanorod-shaped bismuth sulfide (referred to as NR3);

[0056] Step (3): The prepared NR3 powder 20mg and 10μL Nafion solution (5wt%) were dispersed in 0.5mL ethanol, after ultrasonication for 60 minutes, evenly drop-coated on the hydrophobic carbon paper as the working electrode (the drop-coating area was 1× 1cm 2 ). Using the above electrode as the working electrode, Ag / AgCl (3M KCl) as the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com