Bismuth sulfide graded nanoflower supercapacitor electrode material and preparation method

A technology for supercapacitors and electrode materials, applied in the fields of hybrid capacitor electrodes, chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, etc., can solve problems that are rarely reported, achieve good size, increase capacitance, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

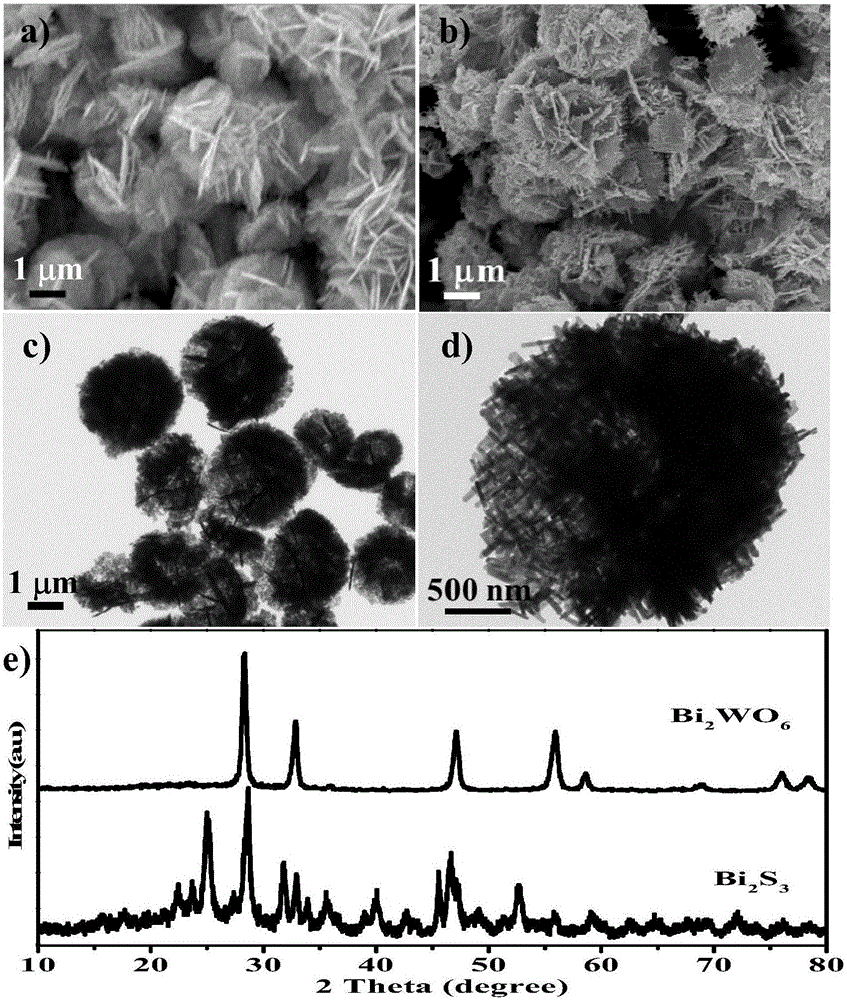

[0018] Example 1: Bi 2 S 3 Preparation of Hierarchical Nanoflowers

[0019] The specific method is: weigh the prepared Bi 2 WO 6 Add 0.1 g of graded nanoflowers to 20 mL of deionized water, stir evenly, add 0.03 g of thioacetamide, continue stirring for 30 minutes, transfer the mixture to a 30 mL hydrothermal reactor, and react at 180°C for 24 hours. After the reaction kettle was naturally lowered to room temperature, the black solid precipitate was collected, and the product was washed by centrifugation with deionized water and ethanol alternately, and dried at 60°C. Finally, the black powder obtained is Bi 2 S 3 Graded nanoflowers.

Embodiment 2

[0020] Embodiment 2: electrical performance test

[0021] The specific method is:

[0022] (1) Electrode preparation: Bi 2 S 3 The electrode material, acetylene black, and polyvinyldiene were mixed uniformly in a mass ratio of 8:1:1, evenly scraped and coated on the foamed nickel current collector, and dried at 60°C to obtain a composite electrode.

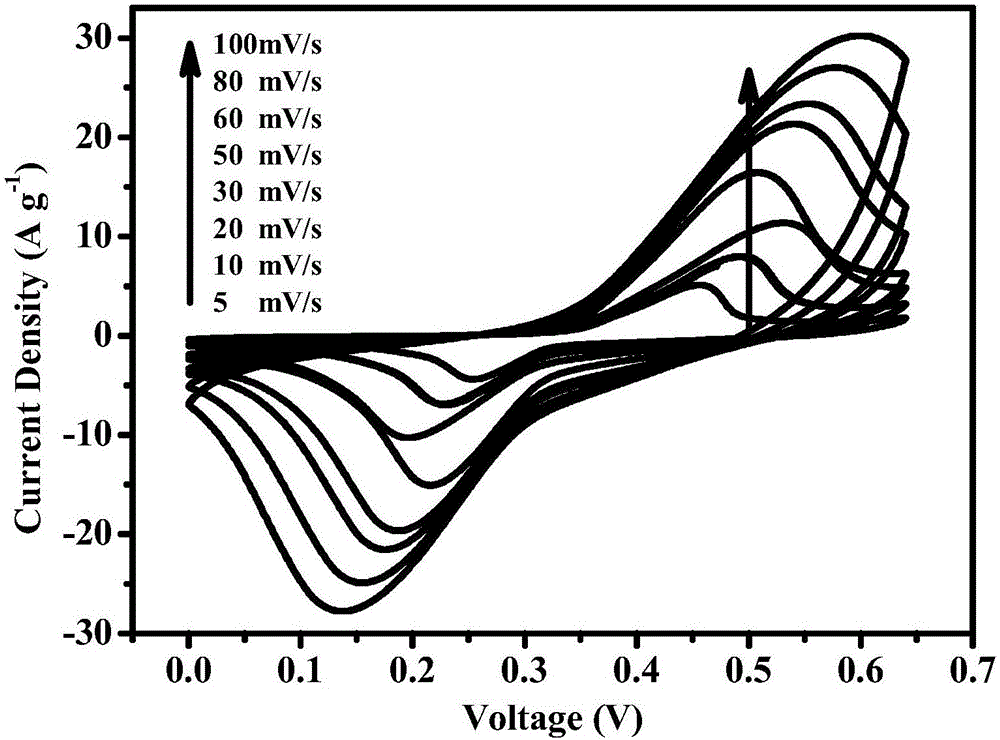

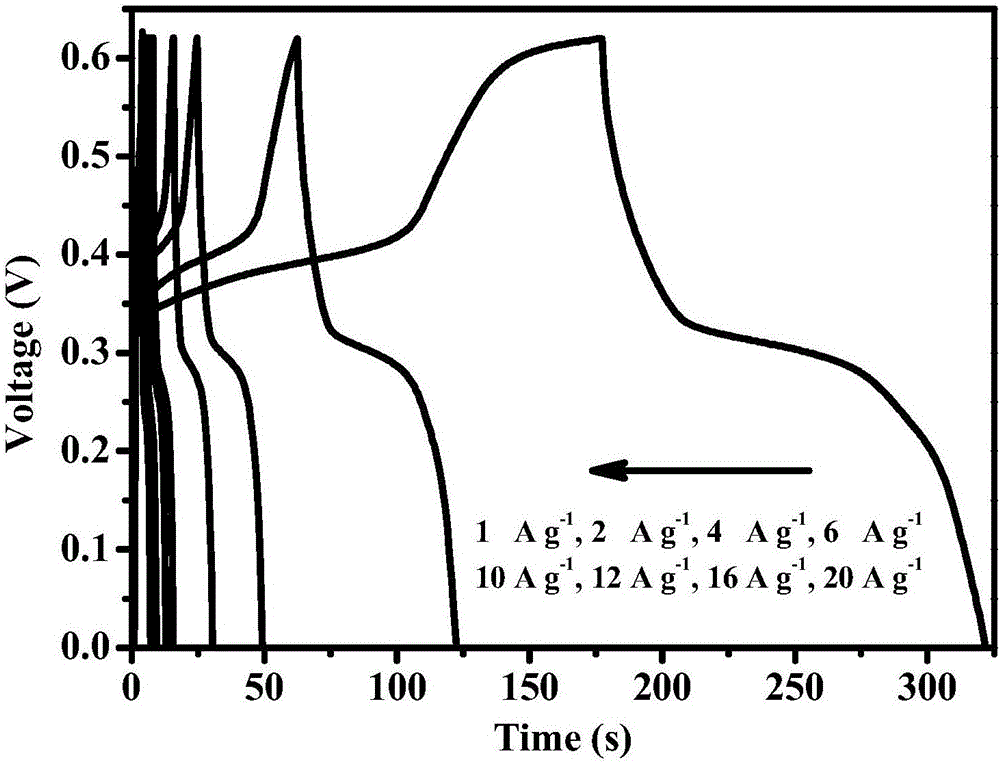

[0023] (2) Electrochemical test: the active material is used as the working electrode, nickel foam is used as the counter electrode, and Pt is used as the reference electrode for three-electrode testing. All electrochemical performance tests are carried out in 6M KOH solution on the electrochemical workstation. Perform cyclic voltammetry, constant current charge and discharge tests.

[0024] (3) The electrochemical test results are attached Figure 2-5 shown. It can be seen from the figure that the prepared Bi 2 S 3 The capacitance of hierarchical nanoflowers is a pseudocapacitance, which has good redox reaction reversibili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com