Room-temperature water phase preparation method of bismuth sulfide nanospheres

A technology of nanospheres and bismuth sulfide, which is applied in the field of preparation of sulfide nanomaterials, can solve the problems of unfavorable late application, easy agglomeration into large pieces, and unstable product morphology, etc., and achieves short preparation cycle, simple preparation equipment and good shape. good looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

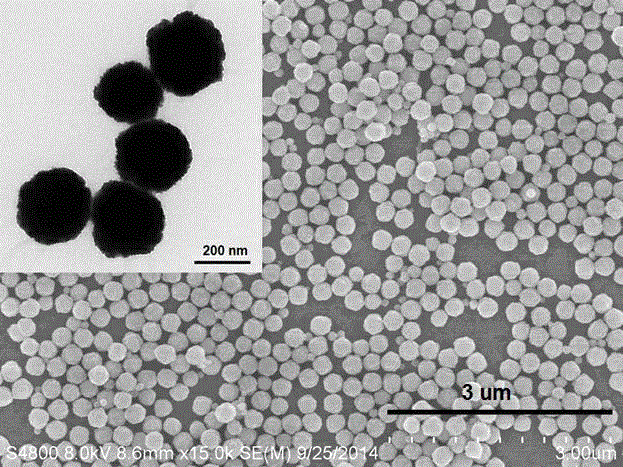

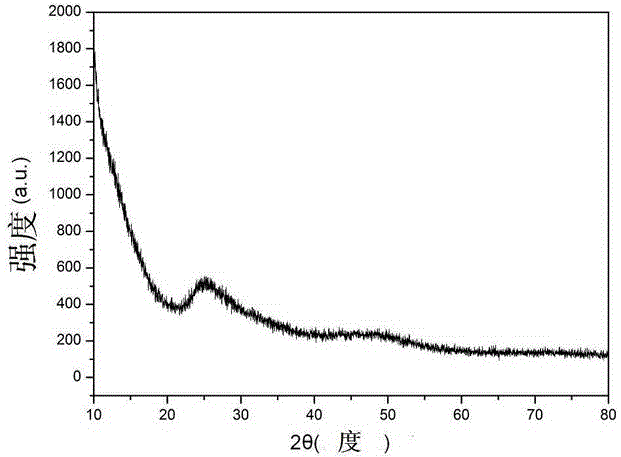

Embodiment 1

[0027] Step 1: Add 4.5 mmol of mannitol to 45 mL (20 mg / mL) polyvinyl alcohol (PVA) aqueous solution, stir and dissolve at room temperature, add 0.5 mmol of bismuth nitrate pentahydrate particles, stir and dissolve at room temperature for 10 min, forming a solution containing bismuth ions;

[0028] Step 2: Slowly add 10 mL (75 mmol / L) thioacetamide solution dropwise into the bismuth ion solution, and stir for 5 min at room temperature to form a bismuth-sulfur mixture;

[0029] The third step: heat the bismuth-sulfur mixture in a water bath at 25°C for 2 h, then perform centrifugation, wash the black solid obtained by centrifugation with deionized water and ethanol three times in turn, and dry it in vacuum at 20°C for 12 h, Fabricated bismuth sulfide nanospheres.

Embodiment 2

[0031] Step 1: Add 0.5 mmol of bismuth nitrate pentahydrate particles to 45 mL (20 mg / mL) polyvinyl alcohol aqueous solution, stir and dissolve at room temperature for 10 min;

[0032] The second step: slowly drop 10 mL (75 mmol / L) thioacetamide solution into the above solution, and stir at room temperature for 5 min to form a bismuth-sulfur mixture.

[0033] The experimental results show that in the absence of a chelating agent, bismuth ions are easily hydrolyzed to form white insoluble precipitates, which cannot be followed by subsequent reactions.

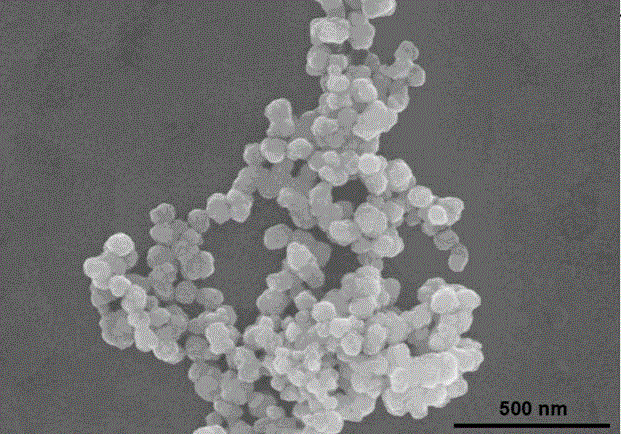

Embodiment 3

[0035] Step 1: Add 2 mmol of nitrilotriacetic acid to 45 mL (20 mg / mL) polyvinyl alcohol aqueous solution, adjust the pH of the solution with sodium hydroxide solution until the solution is clear and transparent, add 0.5 mmol of bismuth nitrate pentahydrate Particles were stirred and dissolved at room temperature for 10 min to form a solution containing bismuth ions;

[0036] Step 2: Slowly add 10 mL (75 mmol / L) thioacetamide solution dropwise into the bismuth ion solution, and stir for 5 min at room temperature to form a bismuth-sulfur mixture;

[0037] The third step: heat the bismuth-sulfur mixture in a 25°C water bath for 8 h, and then perform centrifugation, wash the black solid obtained by centrifugation with deionized water and ethanol three times in turn, and dry it in vacuum at 20°C for 12 h, made bismuth sulfide nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com