Fine grain strong acid type molecular sieve and method for synthesizing same

A synthesis method and molecular sieve technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve problems such as product loss, affecting product yield, and difficulty in the filtration process, so as to simplify the production process and shorten the production process. The effect of synthesis cycle and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

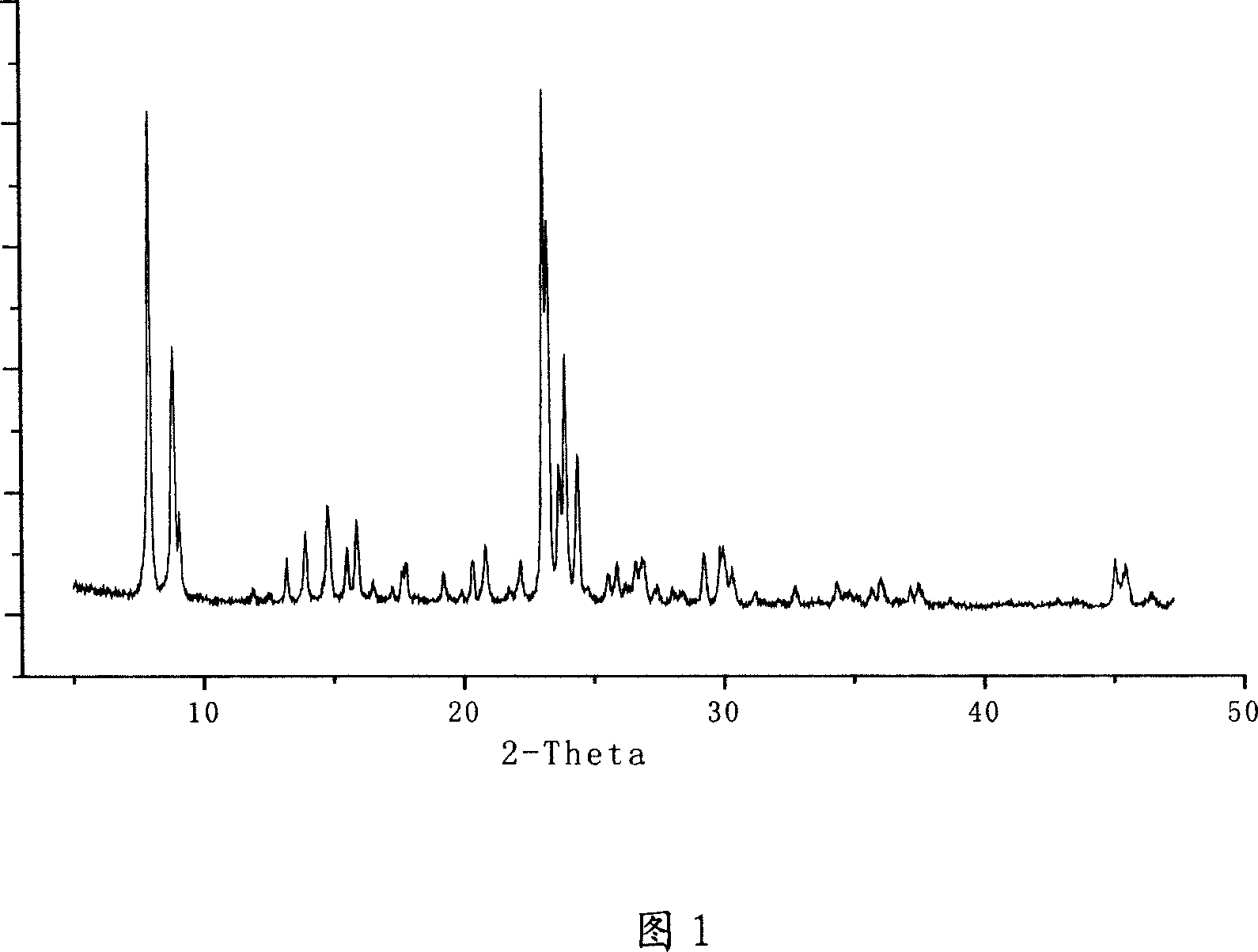

[0027] 20.3 kg of water glass (SiO 2 : 27.2% Na 2 O: 6.1%) and 22 kilograms of deionized water are mixed evenly, and the solution formulated by 1.5 kilograms of aluminum sulfate, 40 kilograms of deionized water and 0.16 kilograms of sulfuric acid is added under stirring, and ultrasonic pretreatment is carried out for 1 hour, and the treatment temperature is controlled at room temperature to 70°C. Then the autoclave was sealed and kept at a constant temperature of 170° C. for 20 hours. The reaction mixture was cooled, and then the molecular sieves were washed and concentrated by filtration with a ceramic filter element, and then ion exchange was performed with 1 mol / L nitric acid at room temperature for 6 hours. Finally, after fully washing until the solution is neutral, it is dried at 120° C. for 4 hours to obtain product A. It can be clearly seen that the product is a ZSM-5 molecular sieve through its X-ray diffraction pattern (Fig. 1). Analysis of its SiO by other 2 / Al...

Embodiment 2

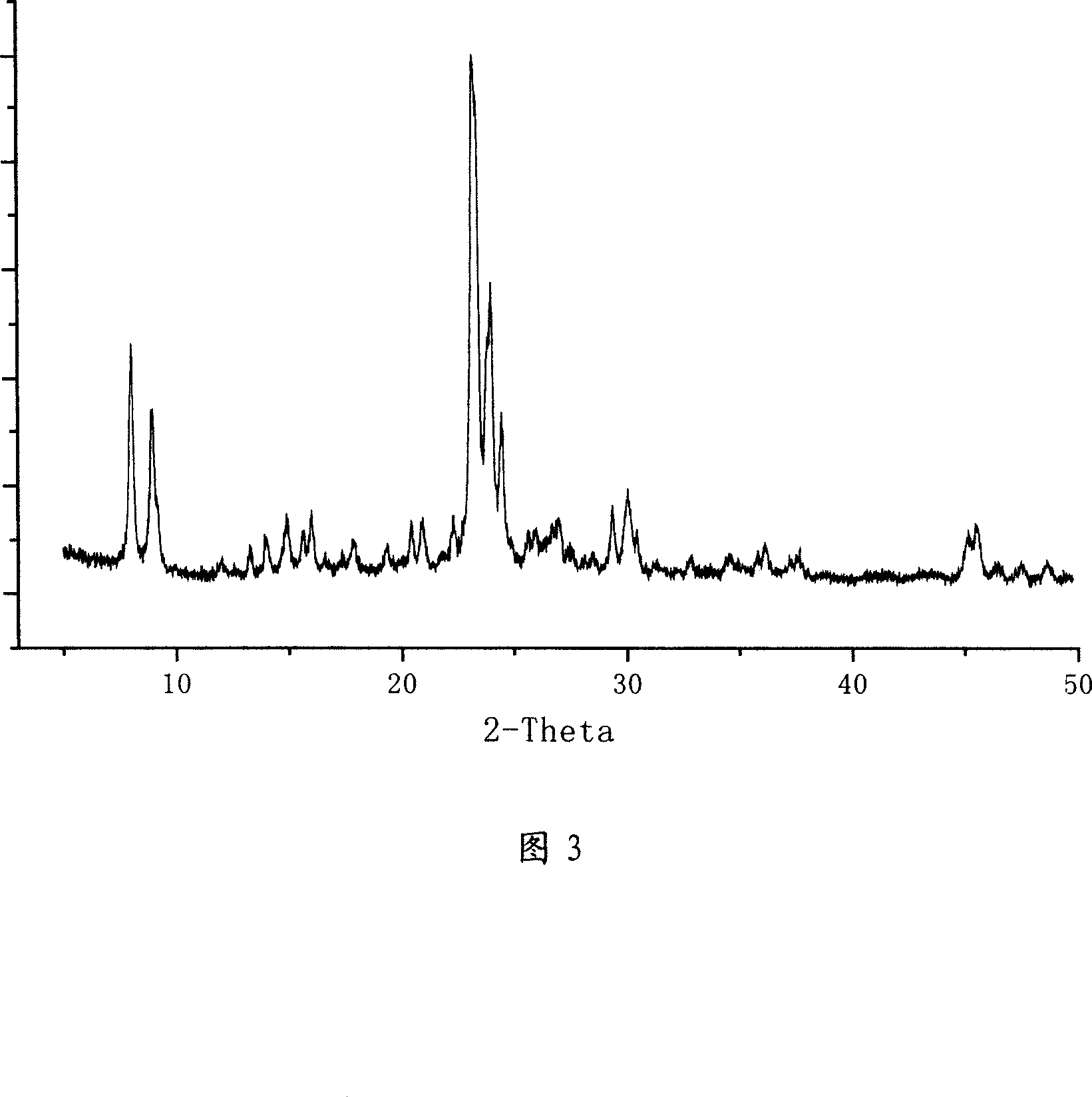

[0029] 22.0 kg of water glass (SiO 2 : 27.2% Na 2O: 6.1%) was mixed evenly with 28 kilograms of deionized water, and a solution prepared by 2.3 kilograms of aluminum sulfate, 40 kilograms of deionized water and 2.6 kilograms of phosphoric acid was added under stirring, and ultrasonic pretreatment was carried out for 5 hours, and the treatment temperature was controlled at room temperature to 70°C. Then, the autoclave was sealed and kept at a constant temperature of 180° C. for 10 hours. The reaction mixture was cooled, and then the molecular sieve was washed and concentrated by filtration with a ceramic filter element, followed by ion exchange with 1 mol / L hydrochloric acid at 60° C. for 4 hours. Finally, after fully washing until the solution is neutral, it is dried at 110° C. for 5 hours to obtain product B. It can be clearly seen that the product is a ZSM-5 molecular sieve through its X-ray diffraction pattern (Fig. 3). Analysis of its SiO by other 2 / Al 2 o 3 =25, t...

Embodiment 3

[0031] 18.9 kg of water glass (SiO 2 : 27.2% Na 2 O: 6.1%) mixes evenly with 20 kilograms of deionized water, adds the solution prepared by 1.2 kilograms of aluminum sulfate, 20 kilograms of deionized water and 0.77 kilograms of sulfuric acid under stirring, mixes 35 kilograms of filtrates (solid matter) in other examples content of about 4%), ultrasonic pretreatment was carried out for 3 hours, and the treatment temperature was controlled at room temperature to 70°C. Then, the autoclave was sealed and kept at a constant temperature of 190° C. for 5 hours. The reaction mixture was cooled, and then the molecular sieves were washed and concentrated by filtration with a ceramic filter element, followed by ion exchange with 1 mol / L sulfuric acid at 70° C. for 3 hours. Finally, after fully washing until the solution is neutral, it is dried at 130° C. for 4 hours to obtain product C. It can be clearly seen that the product is a ZSM-5 molecular sieve through its X-ray diffraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com