Preparation method of nano-silver loaded porous silicon dioxide

A technology of porous silica and silica, applied in the direction of silica, silica, chemical instruments and methods, etc., can solve the problems of highly toxic modified solvent and complicated modification process, and achieve the integrity of the block, Simple preparation process and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

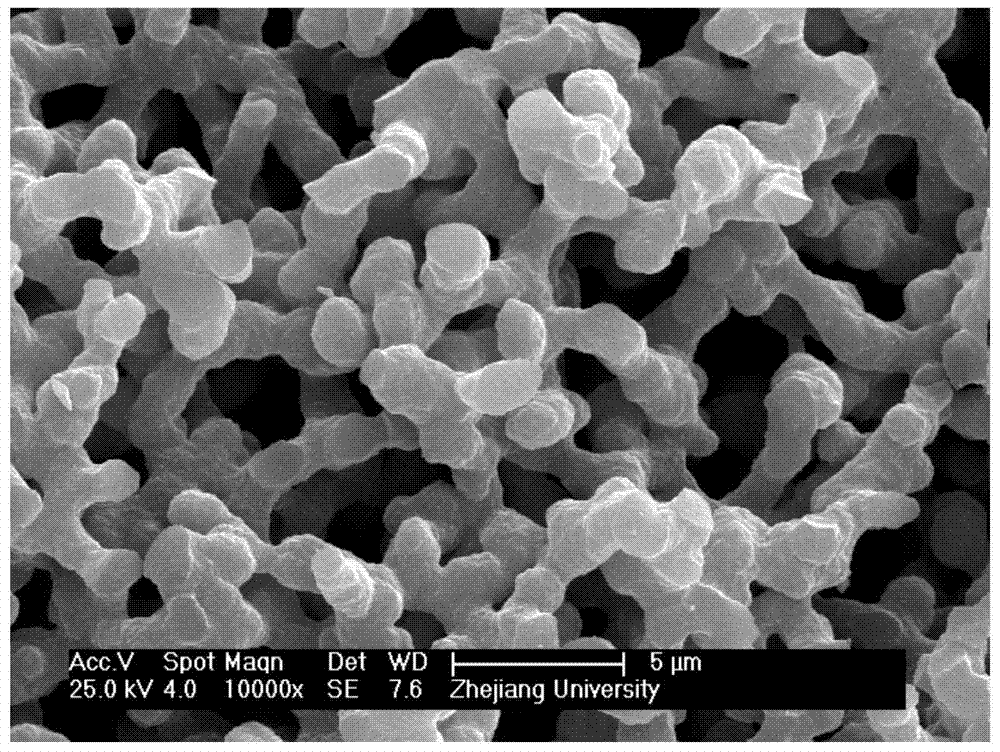

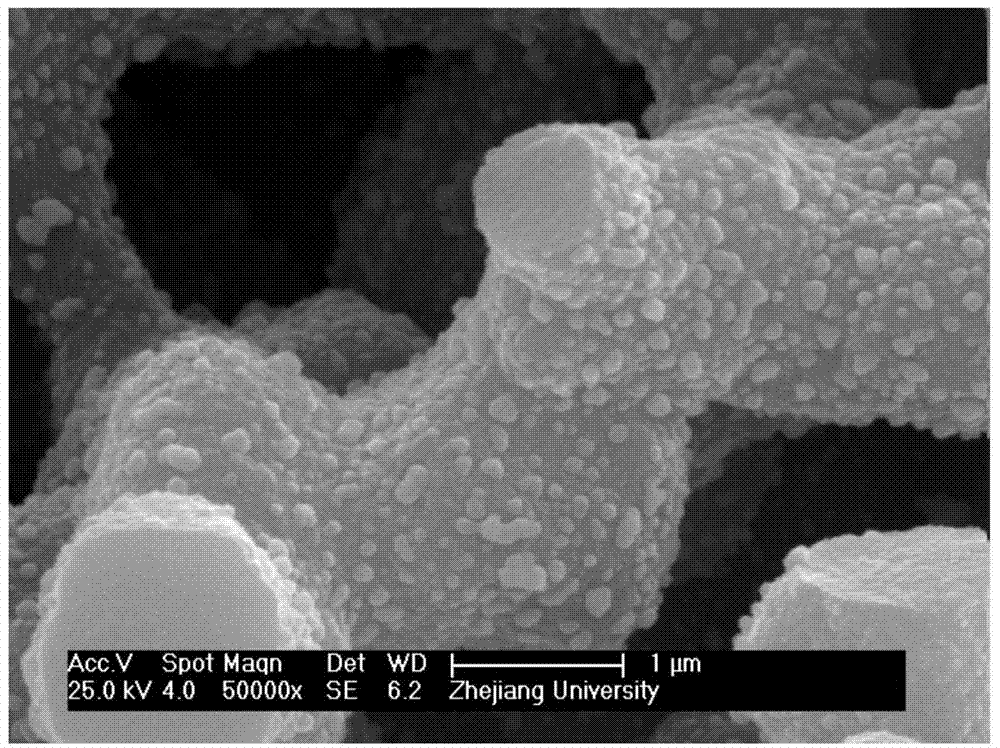

Image

Examples

Embodiment 1

[0032] Embodiment 1, a kind of preparation method of nano-silver supported porous silica, carries out following steps successively:

[0033] 1) Add 0.363g of polyethylene oxide with a molecular weight of 10000 and 3ml of methyl orthosilicate to 7.2ml of 0.01mol·L -1 In the hydrochloric acid solution, after magnetic stirring, add 1.375ml of propylene oxide and stir for 50-70min, then put it in a 40℃ oven for 3 days (so as to achieve gelation and aging);

[0034] Replace the liquid on the surface of the formed gel with absolute ethanol (replaced 3 times), so as to obtain the gel after the replacement of absolute ethanol;

[0035] After replacing the absolute ethanol, the gel was dried in an oven at 60°C for 4 days to obtain hierarchical porous silica (SiO 2 hierarchical porous blocks).

[0036] 2) Using aminopropyltriethoxysilane as a modifier and absolute ethanol as a modifying solvent to modify the prepared hierarchical porous silica, specifically:

[0037] Add 2ml of amino...

Embodiment 2

[0046] Embodiment 2, a kind of preparation method of nano-silver supported porous silica,

[0047] Compared with Example 1, only step 2 is changed):

[0048] 2) Add 2.5ml of aminopropyltriethoxysilane as a modifier to 50ml of absolute ethanol, add 0.5g of the prepared hierarchical porous silica, and modify it in an oven at 40°C for 24h; Hierarchical porous silica.

[0049] All the other contents are equal to embodiment 1.

[0050] The scanning electron micrographs of the prepared silver-loaded hierarchical porous silica bulk are the same as figure 2 .

[0051] The silver loading rate in this embodiment 2 is 28.81wt%.

Embodiment 3

[0052] Embodiment 3, a kind of preparation method of nano-silver supported porous silica,

[0053] Compared with Example 1, only step 2 is changed):

[0054] 2) Add 5ml of aminopropyltriethoxysilane as a modifier to 50ml of absolute ethanol, add 0.5g of the prepared hierarchical porous silica, and modify it in an oven at 40°C for 24h; the modified Post-hierarchical porous silica.

[0055] All the other contents are equal to embodiment 1.

[0056] The scanning electron micrographs of the prepared silver-loaded hierarchical porous silica bulk are the same as figure 2 .

[0057] The silver loading rate in this embodiment 3 is 30.81wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com