Powder metallurgical method for IN718 alloy

A technology of IN718 and powder metallurgy, which is applied in the field of alloy spherical powder preparation, can solve the problems of decreased mechanical properties of alloys, ineffective effects, increased processing costs, etc., and achieves the effect of improving mechanical properties of alloys and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A powder metallurgy method for IN718 alloy, comprising the following steps:

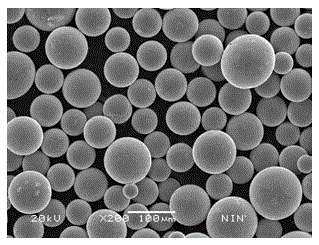

[0021] Step 1, using the plasma rotating electrode method (PREP method) to prepare spherical powder of IN718 alloy, the particle size of the spherical powder of IN718 alloy ranges from 0 to 45 μm, the content of O in the spherical powder of IN718 alloy is 0.003%, and the content of C is 0.025%. The preparation, storage and transportation of spherical powder are all carried out under vacuum;

[0022] Step 2, put the spherical powder of IN718 alloy into the stainless steel sheath, at a temperature of 800°C and a vacuum of 5×10 -2 Vacuum degassing at Pa for 8 hours, sealing and welding the mouth of the bag;

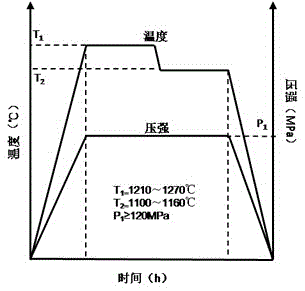

[0023] Step 3, carry out hot isostatic pressing treatment on the sheath after sealing and welding. The treatment process is: first heat preservation and pressure at 1270°C and 120MPa pressure for 4 hours, then lower the temperature to 1160°C under the condition of constant pressure, and con...

Embodiment 2

[0026] A powder metallurgy method for IN718 alloy, comprising the following steps:

[0027] Step 1, using the plasma rotating electrode method (PREP method) to prepare spherical powder of IN718 alloy, the particle size of the spherical powder ranges from 45 to 105 μm, the O content in the spherical powder is 0.002%, and the C content is 0.02%. The preparation, storage and transportation of the spherical powder The process is carried out under the protection of inert gas;

[0028] Step 2, put the spherical powder of IN718 alloy into the stainless steel sheath, at a temperature of 600°C and a vacuum of 5×10 -2 Vacuum degassing at Pa for 6 hours, sealing and welding the mouth of the sheath;

[0029] Step 3: Carry out hot isostatic pressing treatment on the envelope after sealing and welding. The treatment process is as follows: first heat preservation and pressure at 1240°C and 130MPa pressure for 3 hours, then lower the temperature to 1130°C under the condition of constant pres...

Embodiment 3

[0032] A powder metallurgy method for IN718 alloy, comprising the following steps:

[0033] Step 1, using the plasma rotating electrode method (PREP method) to prepare spherical powder of IN718 alloy, the particle size of the spherical powder ranges from 105 to 150 μm, the O content in the spherical powder is 0.001%, and the C content is 0.015%. The preparation, storage and transportation of the spherical powder The process should be carried out under the protection of inert gas;

[0034] Step 2, put the spherical powder of IN718 alloy into the stainless steel sheath, at a temperature of 400°C and a vacuum of 5×10 -2 Vacuum degassing at Pa for 4 hours, sealing and welding the mouth of the bag;

[0035] Step 3: Carry out hot isostatic pressing treatment on the envelope after sealing and welding. The treatment process is as follows: first heat preservation and pressure at 1210°C and 120MPa pressure for 2 hours, then lower the temperature to 1100°C under the condition of constan...

PUM

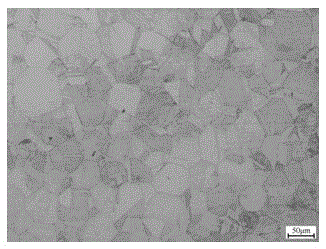

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com