Lithium ion battery positive electrode material with adjustable crystalline grain size and preparation method thereof

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of undescribed grain size, better cycle performance, and increased discharge capacity, and achieve excellent room temperature and high temperature Cyclic performance, easy industrial production, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

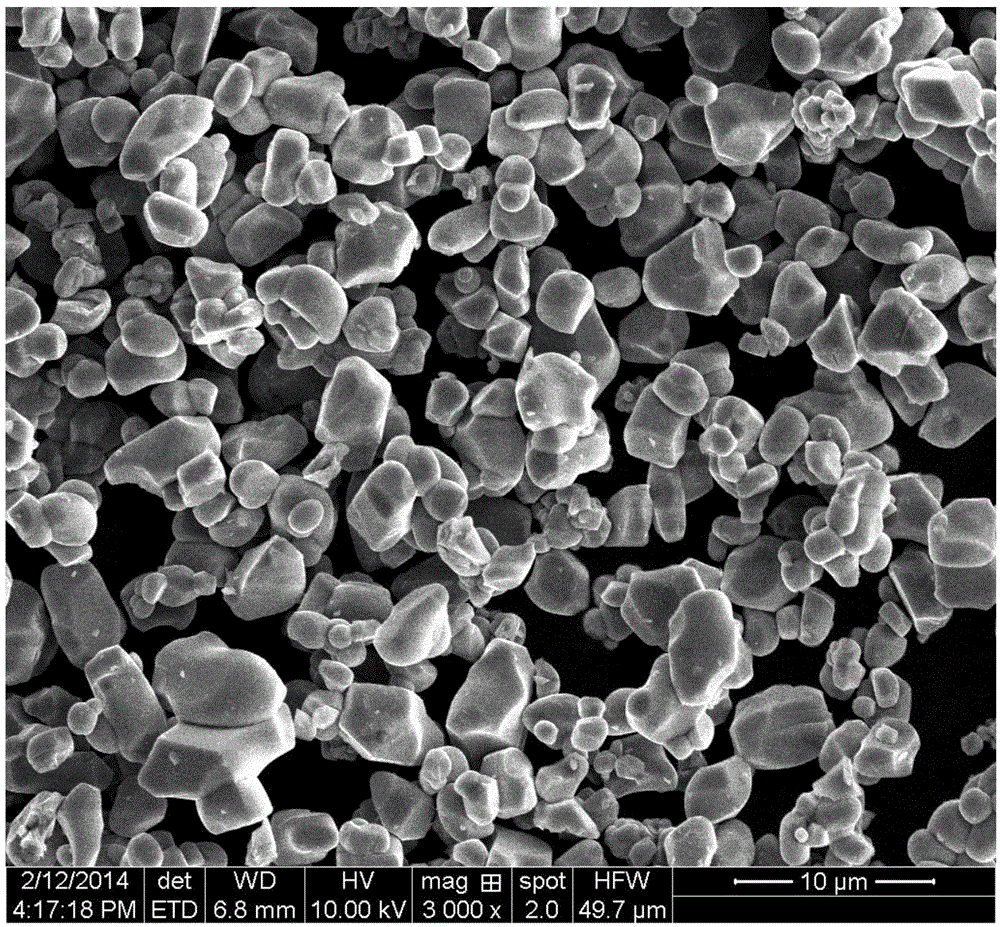

[0027] 91.1 g of precursor Ni with a median particle size of 8 μm 0.5 co 0.20 mn 0.3 (OH) 2 Mix with 36.8g lithium carbonate, 0.2gMgO ball mill, put above-mentioned material in sintering furnace after mixing and sinter at 920 ℃ for 5 hours, the sintered material passes through 200 mesh sieve after crushing, obtains Li(Ni 0.5 co 0.20 mn 0.3 ) 0.995 Mg 0.005 o 2 . The primary particle size of the obtained positive electrode material is 0.5-0.8 μm, the median particle size of the secondary particle is 8.6 μm, and the BET is 0.6 m 2 / g.

Embodiment 2

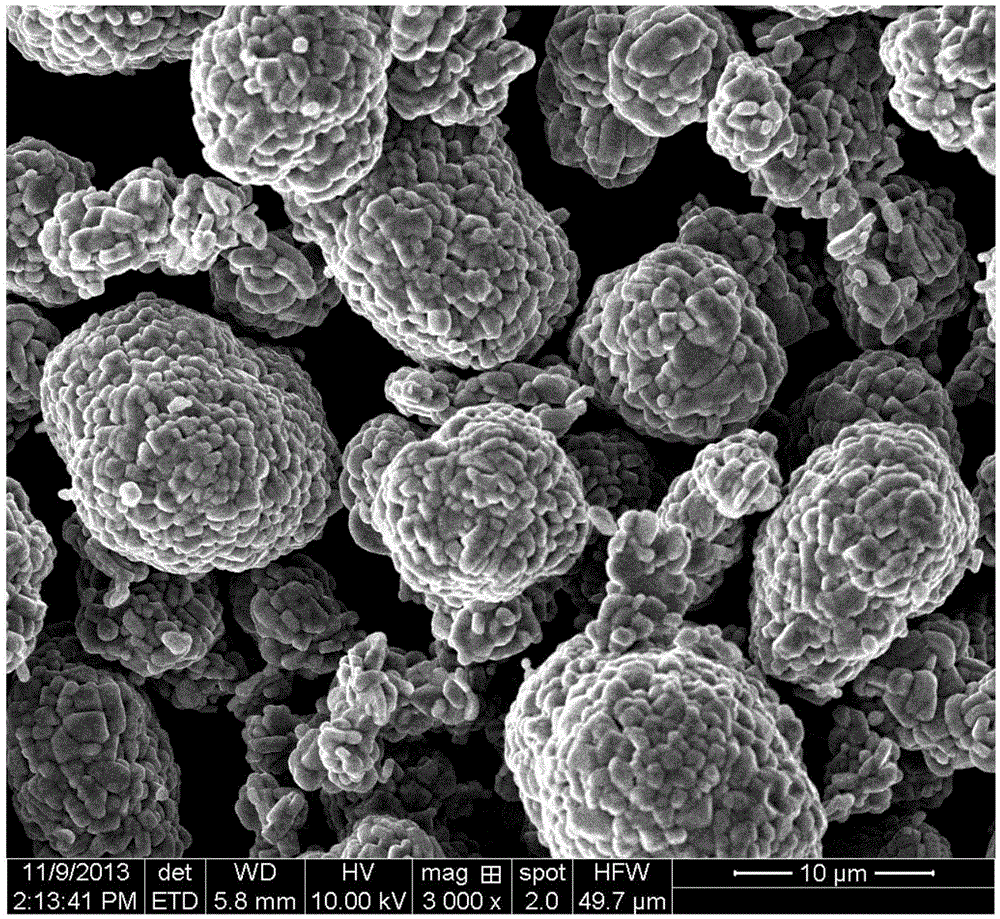

[0029] 90.2 g of precursor Ni with a median particle size of 10 μm 0.5 co 0.2 mn 0.3 (OH) 2 With 36.3g lithium carbonate, 0.174gB 2 o 3 , 1g of lithium acetate ball milling and mixing, after the mixing is completed, the above materials are placed in a sintering furnace and sintered at 900°C for 15 hours, and the sintered materials are crushed and passed through a 200-mesh sieve to obtain Li(Ni 0.5 co 0.20 mn 0.3 ) 0.98 Li 0.015 B 0.005 o 2 . The primary particle size of the obtained positive electrode material is 0.5-0.8 μm, the median particle size of the secondary particle is 9.8 μm, and the BET is 0.5 m 2 / g.

[0030] The SEM of the above positive electrode materials is shown in figure 1 .

Embodiment 3

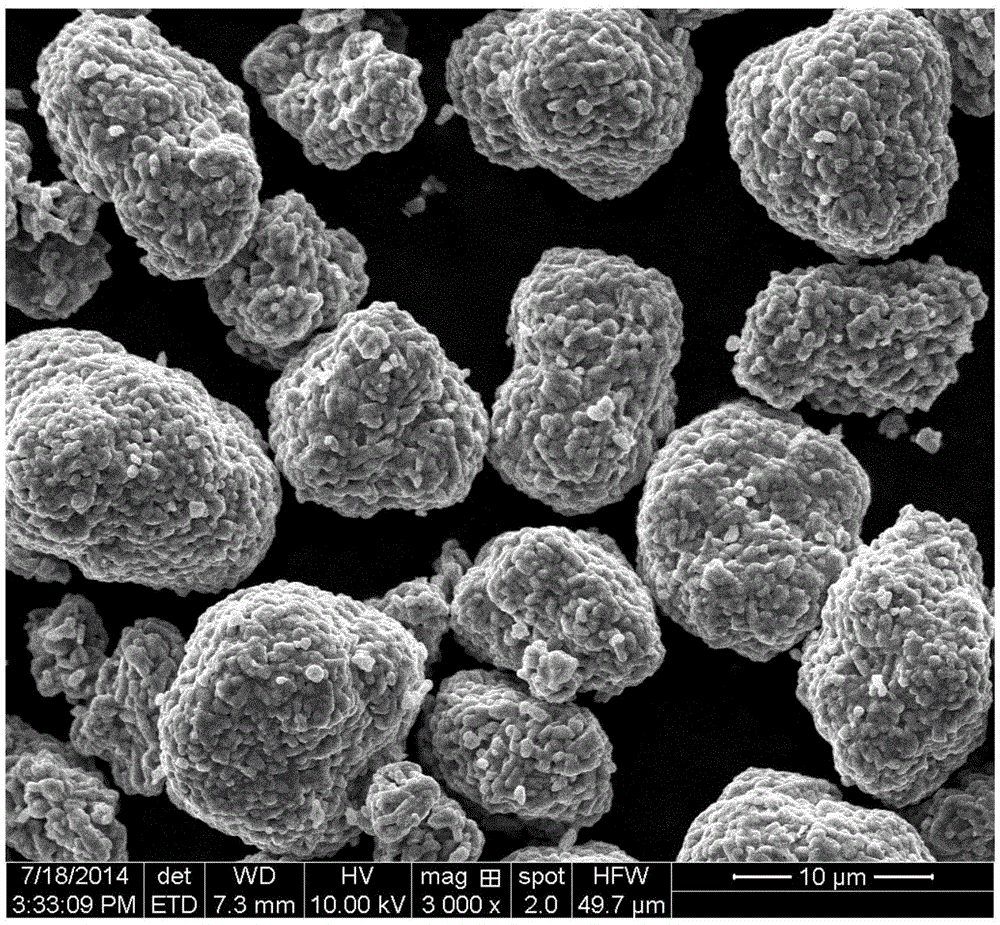

[0032] 91.0 g of precursor Ni with a median particle size of 5 μm 0.80 co 0.10 mn 0.10 (OH) 2 With 37g lithium carbonate, 0.66gNb 2 o 5 Mix by ball milling. After mixing, place the above materials in a sintering furnace under an oxygen atmosphere and sinter at 750°C for 25 hours. The sintered materials are crushed and passed through a 200-mesh sieve to obtain LiNi 0.796 co 0.0995 mn 0.0995 Nb 0.005 o 2 . The primary particle size of the obtained positive electrode material is 0.1-0.3 μm, the median particle size of the secondary particle is 6.0 μm, and the BET is 0.7 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com