Pigment dispersing agent and pigment composition containing the same dispersing agent

A pigment dispersant, pigment composition technology, applied in the field of pigment composition, or unsubstituted alkylene, pigment dispersant, can solve the problem of reduced tinting strength, reduced gloss of ink or coating coating, viscosity Elevation and other problems to achieve the effect of preventing flocculation, excellent gloss and clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

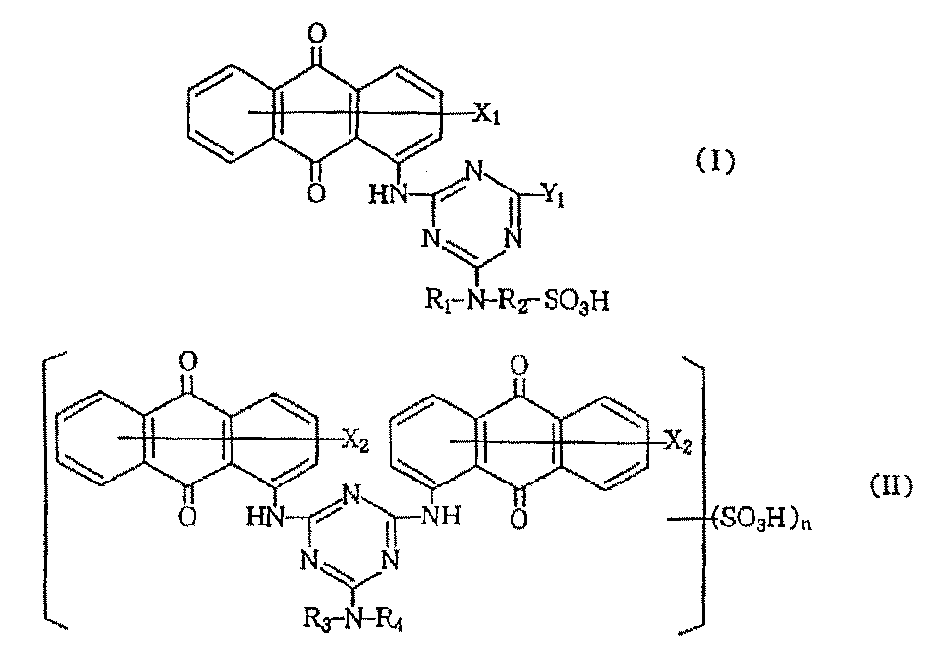

[0032] 1-Aminoanthraquinone (72 parts) and cyanuric chloride (30 parts) were added to nitrobenzene (1000 parts), followed by stirring at 170° C. for 5 hours. After cooling the reaction mixture, taurine (41 parts) and potassium carbonate (23 parts) were further added, and the resulting mixture was stirred at 180°C for 8 hours. The reaction mixture was cooled, then filtered. The solid matter was washed with ethanol, then with water, and thereafter dried, whereby the following dispersant (A) (94 parts) was obtained:

Synthetic example 2

[0034] 1-Aminoanthraquinone (72 parts) and cyanuric chloride (30 parts) were added to nitrobenzene (1000 parts), followed by stirring at 170° C. for 5 hours. After the reaction mixture was cooled, sulfanilic acid (56 parts) and potassium carbonate (23 parts) were further added, and the resulting mixture was stirred at 180° C. for 12 hours. The reaction mixture was cooled, then filtered. The solid matter was washed with ethanol, then with water, and thereafter dried, whereby the following dispersant (B) (101 parts) was obtained:

Synthetic example 3

[0036] 1-Aminoanthraquinone (73 parts) and cyanuric chloride (30 parts) were added to o-dichlorobenzene (1100 parts), followed by stirring at 170° C. for 5 hours. After cooling the reaction mixture, o-toluidine (35 parts) was further added, and the resulting mixture was stirred at 180°C for 5 hours. The reaction mixture was cooled, then filtered. The solid matter was washed with ethanol, then with water, and thereafter dried, whereby 2,4-bis(1-anthraquinonylamino)-6-tolylamino-1,3,5-triazine (94 parts) was obtained. To this compound (94 parts) was then added 5% oleum (800 parts) at 10°C or lower, followed by reaction at 30°C for 5 hours. The reaction mixture was cooled and then precipitated into ice water (2500 parts). The filtrate was collected by filtration, and then washed with water, whereby the following dispersant (C) (102 parts) was obtained. As a result of elemental analysis of sulfur, it was confirmed that an average of 0.9 sulfonic acid groups were introduced per ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com