Vehicle plate surface galling defect inducing device

An automobile sheet and defect technology, which is applied in the field of automobile sheet surface roughening defect inducing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

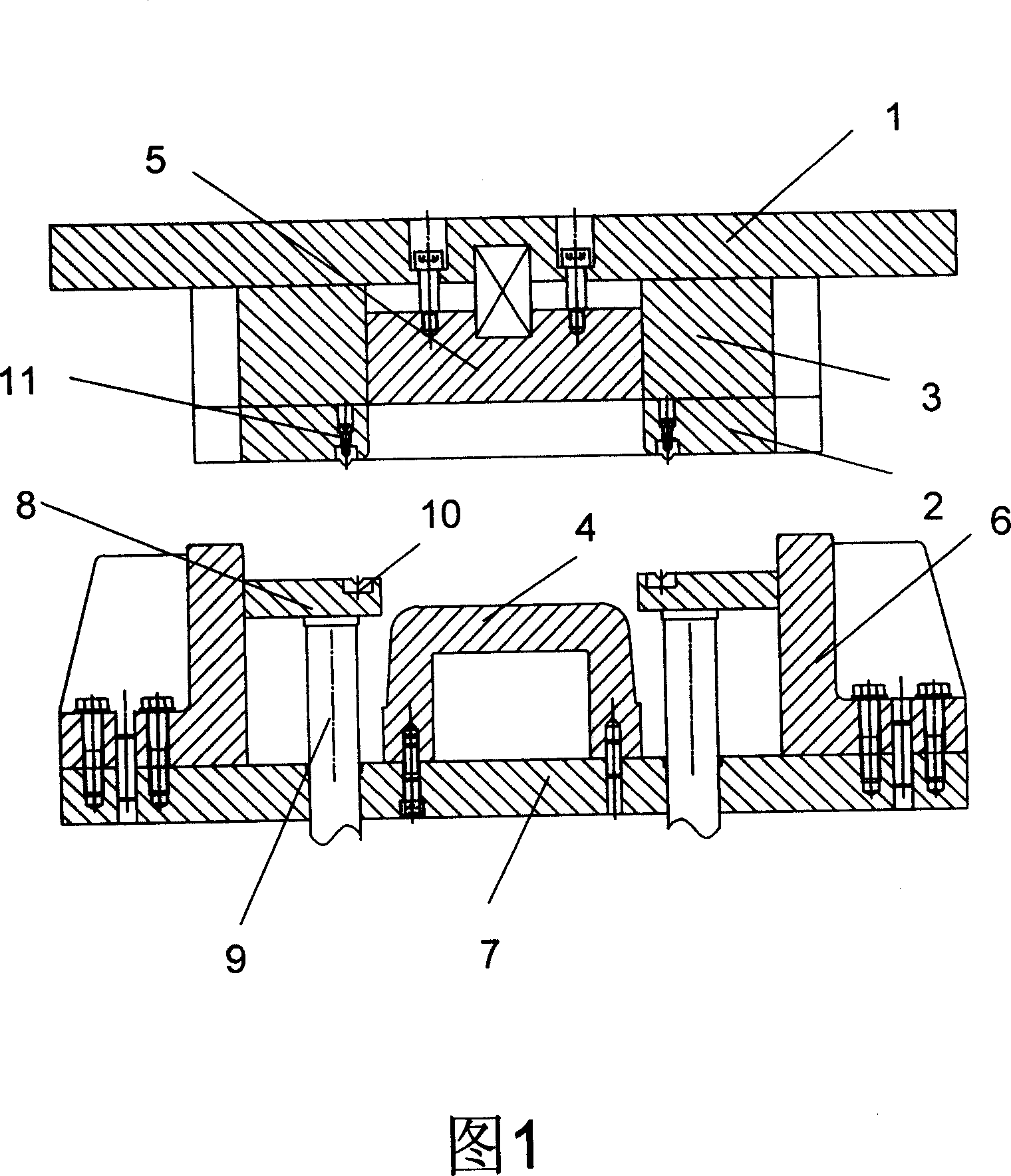

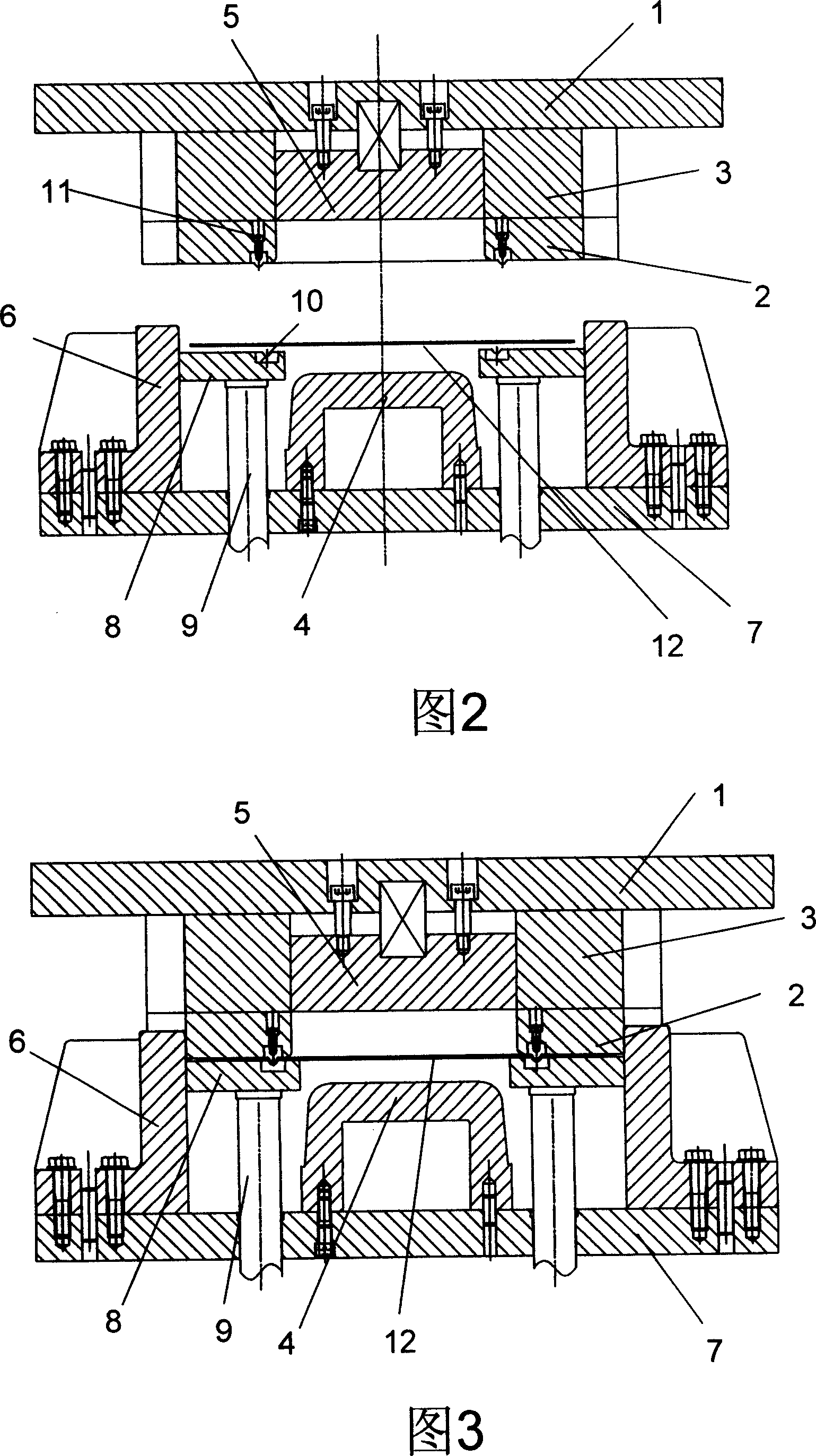

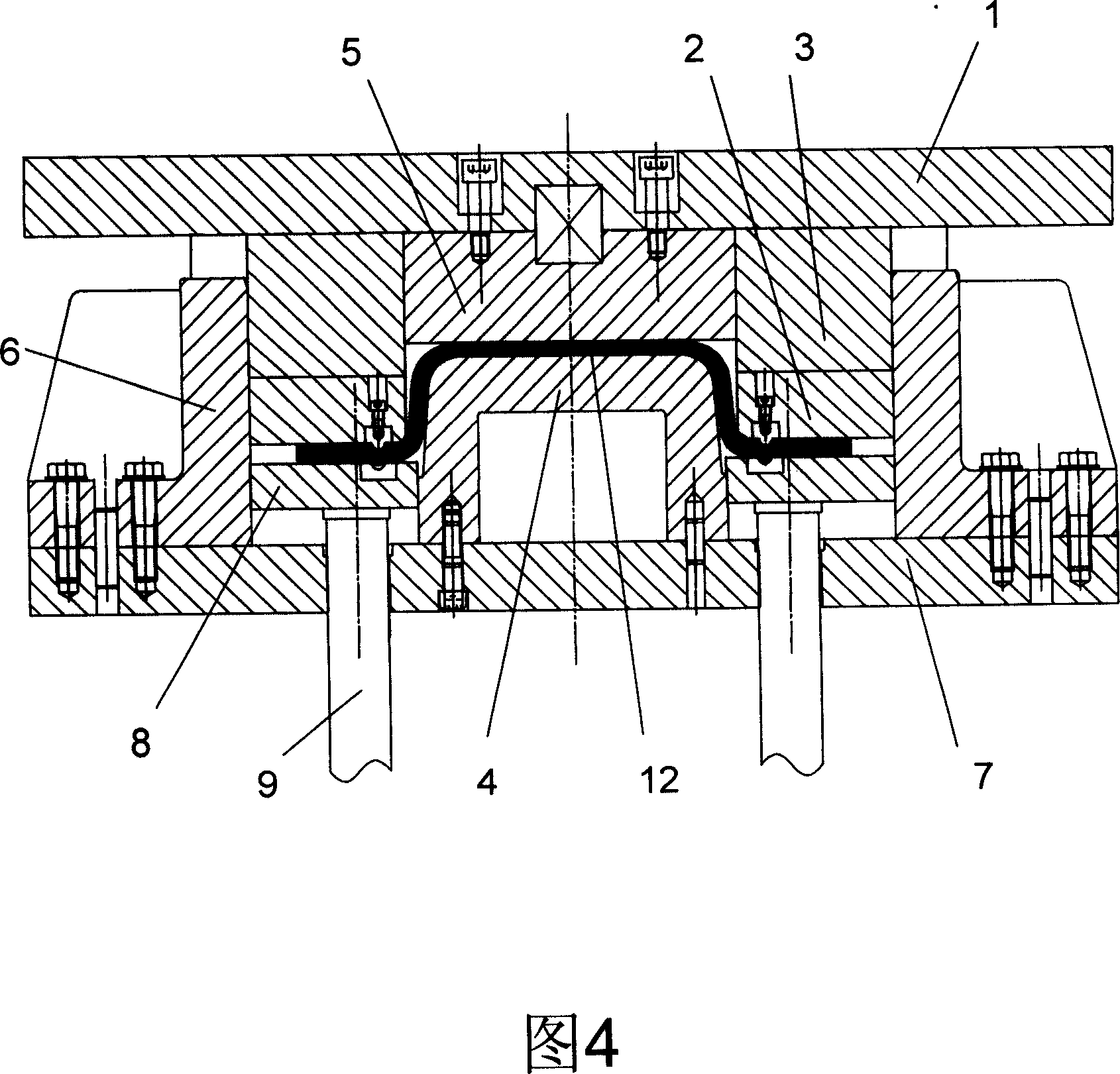

[0021] As shown in Figure 1, the napping induction device of the present invention includes a press, a die part and a punch part, specifically including an upper base plate 1, a die 2, a die pad 3, a punch 4, and a punch pad 5 , the back guide block 6, the lower bottom plate 7, the blank holder 8, the ejector pin 9, the blank holder draw bead concave rib 10, the die draw bead convex rib 11.

[0022] The upper base plate 1 is connected with a component in the press machine (not shown in the figure), and the upper base plate 1 is driven by the press machine to move up and down. Die spacer 3 is fixed on the upper base plate 1 by hexagon socket head cap screws and internal thread cylindrical pins, convex die spacer 5 is fixed on the upper base plate 1 by unloading screws, and die 2 is inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com