Flying shear type high-speed wire cutting device

A flying shear type, high-speed technology, applied in the direction of shearing device, shearing machine equipment, manufacturing tools, etc., can solve the problems of unreasonable stress mode of spare parts, high labor intensity of workers, and low labor production efficiency, so as to improve labor efficiency. Productivity, reduced maintenance downtime, simple and easy adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

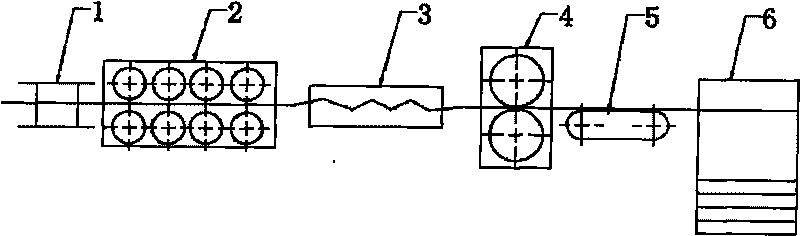

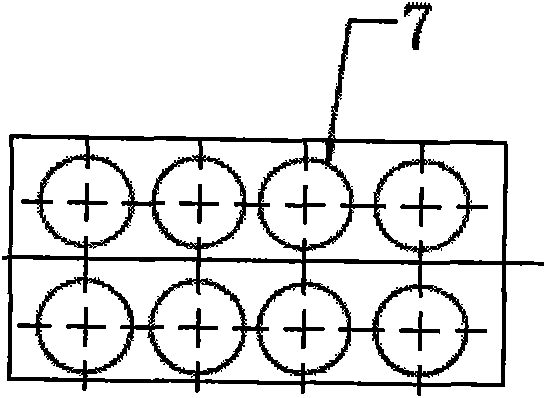

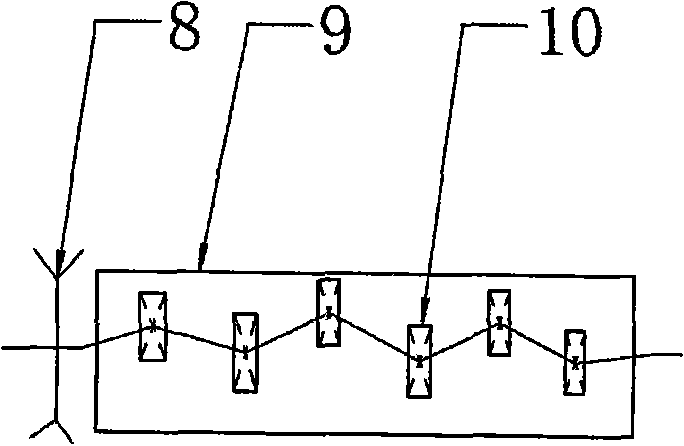

[0019] A flying shear type high-speed wire cutting device, which is composed of an auxiliary wire feeding mechanism 1, a high-speed wire cutting mechanism, a feeder 5 and a storage tank 6. The high-speed wire cutting mechanism includes a wire feeder 2, a straightening machine 3 and a flying knife Shearing machine 4; wire feeding machine 2 is composed of 8 wire feeding rollers 7 with the same rotating speed and opposite directions, and the cutting speed is determined by the diameter and rotating speed of wire feeding roller 7; straightening machine 3 is composed of belt transmission mechanism 8 and rotating The hub 9 is composed of a hub 9; the hub 9 is driven to rotate by a belt transmission mechanism 8, and the hub 9 is provided with 6 hole dies 10 that rotate together with the hub 9 and are arranged in a staggered manner relative to the center line of the silk material. Arbitrary adjustment, the hole die 10 is concave and open for easy replacement; the flying knife shearing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com