Improved structure of thermal insulation textile

A technology for improving structure and fabric, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of pilling, thin air layer, and the heat retention rate cannot adapt to harsh weather, so as to improve the heat retention rate and improve the skin tactile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

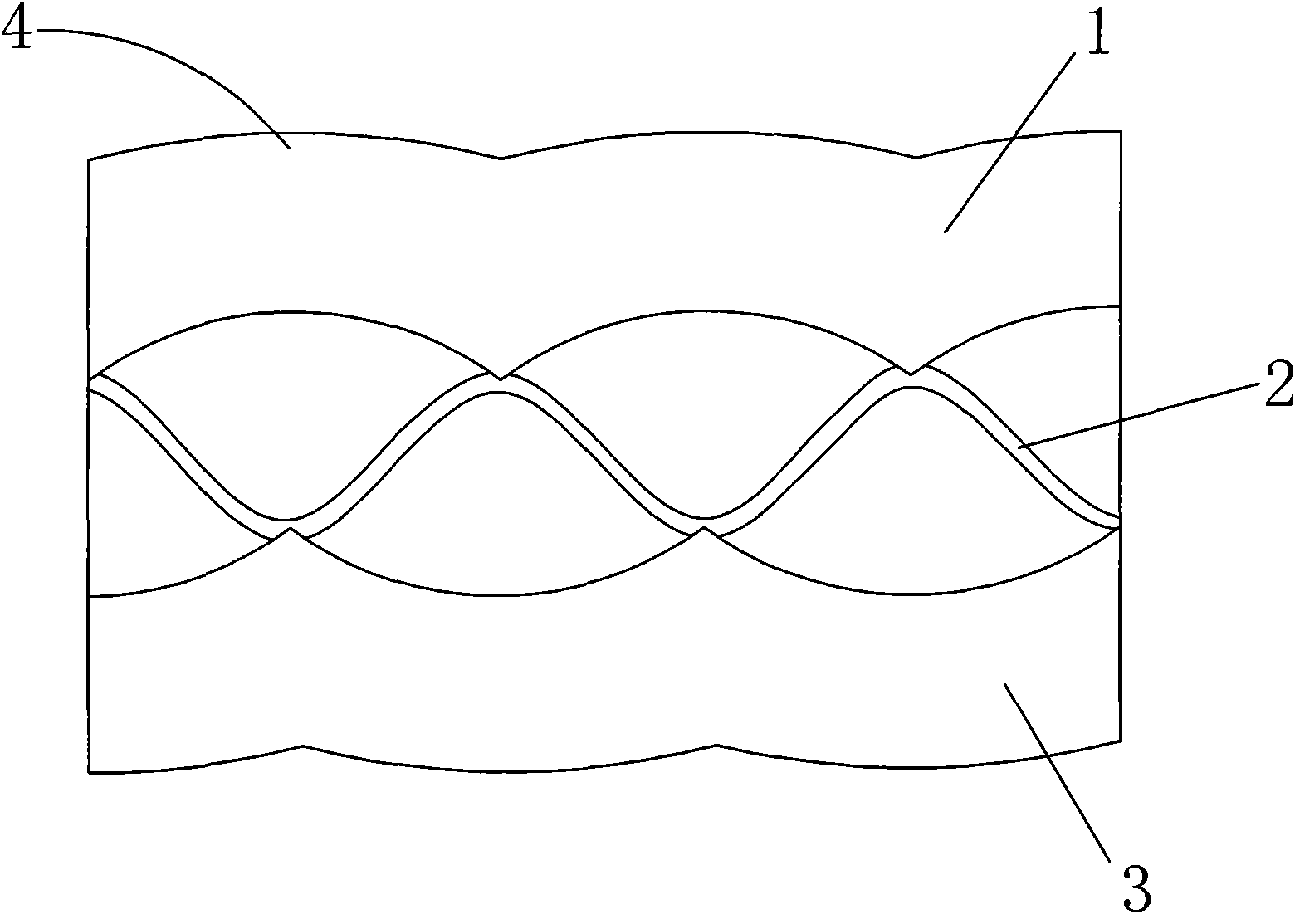

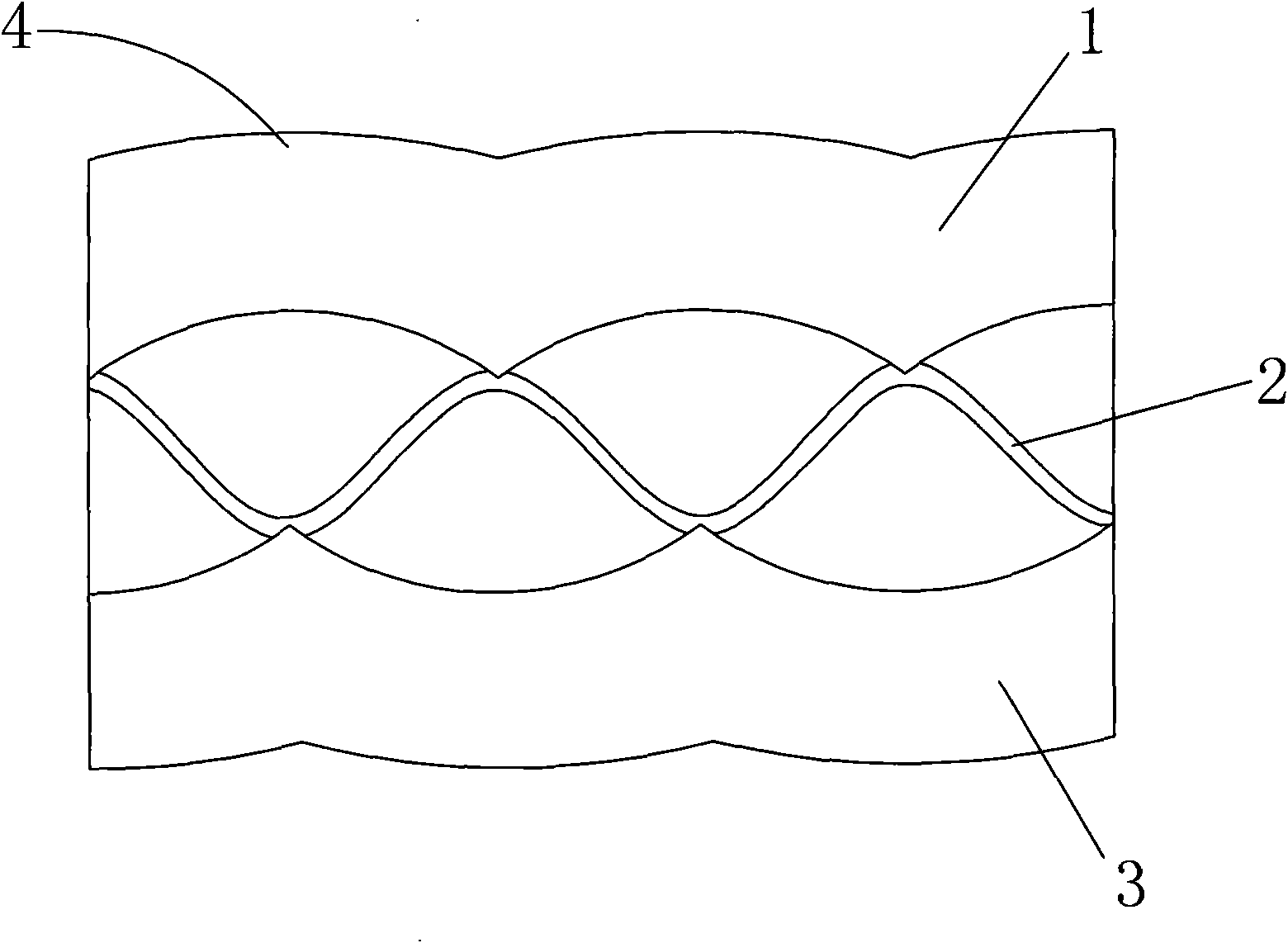

[0009] Embodiment: a kind of heat-retaining fabric improved structure, fabric top layer is cotton weaving layer 1, and fabric inner layer is the ultra-fine denier polyester stretch yarn layer 3 (the fiber below 0.55dtex in the industry is ultra-fine denier silk, dtex is dtex, refers to the gram of 10,000 meters long fiber bundle), the fabric middle layer is a silk layer 2 with elastic traction, the fabric surface layer and the fabric inner layer fabric structure are weft flat knitting structure, the fabric surface layer and the fabric inner layer pass through The middle layer of the fabric is woven together, and the surface layer of the fabric and the inner layer of the fabric are under the elastic traction of the polyester-coated yarn in the middle layer of the fabric, and the surfaces of the surface layer of the fabric and the inner layer of the fabric are spaced to form a number of raised longitudinal strips 4, thereby forming a thicker air layer , and the ultra-fine denier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com