A kind of production technology of durable easy-absorbent soft towel

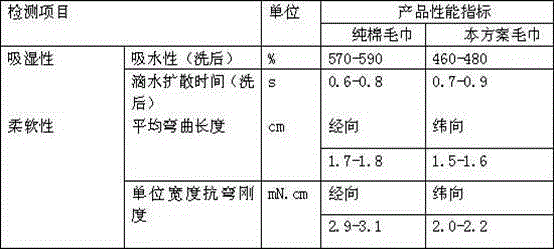

A production process and durability technology, applied in the direction of textile, yarn, fabric, etc., can solve the problems that cannot meet the needs of users, reduce the use effect of cotton towels, and reduce fiber friction, so as to achieve strong practicability and increase Effect of improving service life and softness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of production technology of durable easy water-absorbing soft towel, comprises the following steps:

[0020] (1) Spinning: 1.5D, hollow hydrophilic polyester fiber with a hollow rate of 17.5% and long-staple cotton fiber with a fiber length greater than 35mm are selected to form 16 s and 20 s Yarn, its ratio is 67.5%: 32.5%;

[0021] (2) Weaving: Weave the blended yarn in step (1) into bottom warp * bottom weft * circle warp 20 s / 2 *20 s / 1 *16 s / 1, 124*290*124 pieces / 10cm, the specification is 35cm*77cm*120g;

[0022] (3) Dyeing and finishing process, the process steps are:

[0023] Desizing: Desizing is carried out in hot water at a temperature of 90°C. During this process, 100% caustic soda 4g / l is used for 30 minutes;

[0024] Scouring: scouring in hot water at a temperature of 95°C, using 100% caustic soda 4g / l for 30 minutes;

[0025] Bleaching: Bleaching is carried out in a bleaching solution with a temperature of 99°C, a content of 30% hydrog...

Embodiment 2

[0030] A kind of production technology of durable easy water-absorbing soft towel, comprises the following steps:

[0031] (1) Spinning: 1.5D, hollow hydrophilic polyester fiber with a hollow rate of 15% and long-staple cotton fiber with a fiber length greater than 35mm are selected to be blended into 16 s and 20 s Yarn, its ratio is 65%: 30%;

[0032] (2) Weaving: Weave the blended yarn in step (1) into bottom warp * bottom weft * circle warp 20 s / 2 *20 s / 1 *16 s / 1, 124*290*124 pieces / 10cm, the specification is 35cm*77cm*120g. ;

[0033] (3) Dyeing and finishing process, the process steps are:

[0034] Desizing: Desizing is carried out in hot water at a temperature of 85°C. During this process, 100% caustic soda 3g / l is used for 25 minutes;

[0035] Scouring: scouring in hot water at a temperature of 90°C, using 3g / l of 100% caustic soda for 25 minutes;

[0036] Bleaching: Bleaching is carried out in a bleaching solution with a temperature of 98°C, a content of...

Embodiment 3

[0041] A kind of production technology of durable easy water-absorbing soft towel, comprises the following steps:

[0042] (1) Spinning: 1.5D, hollow hydrophilic polyester fiber with a hollow rate of 15-20% is blended with long-staple cotton fiber with a fiber length greater than 35mm to form 16 s and 20 s Yarn, its ratio is 70%: 35%;

[0043] (2) Weaving: Weave the blended yarn in step (1) into bottom warp * bottom weft * circle warp 20 s / 2 *20 s / 1 *16 s / 1, 124*290*124 pieces / 10cm, the specification is 35cm*77cm*120g;

[0044] (3) Dyeing and finishing process, the process steps are:

[0045] Desizing: Desizing is carried out in hot water at a temperature of 95°C. During this process, 100% caustic soda 5g / l is used for 35 minutes;

[0046] Scouring: scouring in hot water at a temperature of 100°C, using 100% caustic soda 5g / l for 35 minutes;

[0047] Bleaching: Bleaching is carried out in a bleaching solution with a temperature of 100°C, a content of 30% hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com