Heat-resistant anti-static sizing finishing agent and sizing process of pure dehair angora fabrics and related equipment

A velvet fabric and finishing agent technology, applied in the field of high-temperature sterilization and shaping cabinets, can solve the problems of lack of heat resistance and antistatic function, no recycling of hot air, affecting the surrounding environment, etc., and achieve the effect of avoiding fading, beautiful colors, and short heat preservation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of heat-resistant antistatic finishing agent for pure rabbit wool fabric, is formulated by conventional method by following raw material of percentage by weight: ethyl acrylate 4%; Butyl acrylate 4%; Ethylene vinyl acetate polymerization Distyrene 7%; Acrylic acid 12%; Cyclotetraoctamethylsiloxane 5%; Sodium polystyrene sulfonate 3%; Polyethylene benzyl trimethyl quaternary ammonium salt 4%; Emulsifier 43 %; defoamer 10%.

Embodiment 2

[0029] Embodiment 2, a kind of shaping technology of pure rabbit down fabric, its processing step is:

[0030] (1) Impregnation: use the heat-resistant and antistatic finishing agent prepared in Example 1, dilute it at a ratio of 1:5~10, soak the pure rabbit wool fabric in the diluent, and soak for 20~30 minutes at room temperature;

[0031] (2) Dehydration and drying: dehydrate the impregnated pure rabbit wool fabric in a dehydrator, and then dry it in a dryer at 70°C~80°C for 20~30 minutes;

[0032] (3) Styling: Hang the dried pure rabbit wool fabric on a hanger, put it in a high-temperature disinfection and shaping cabinet, keep it for 5 minutes when the temperature rises to 125°C, evaporate excess water, and then rise to 210°C , and then keep warm for 1-2 minutes, so that the finishing agent resin cross-links and bonds with the rabbit down to shape it. At the same time, the disinfection process is also completed.

Embodiment 3

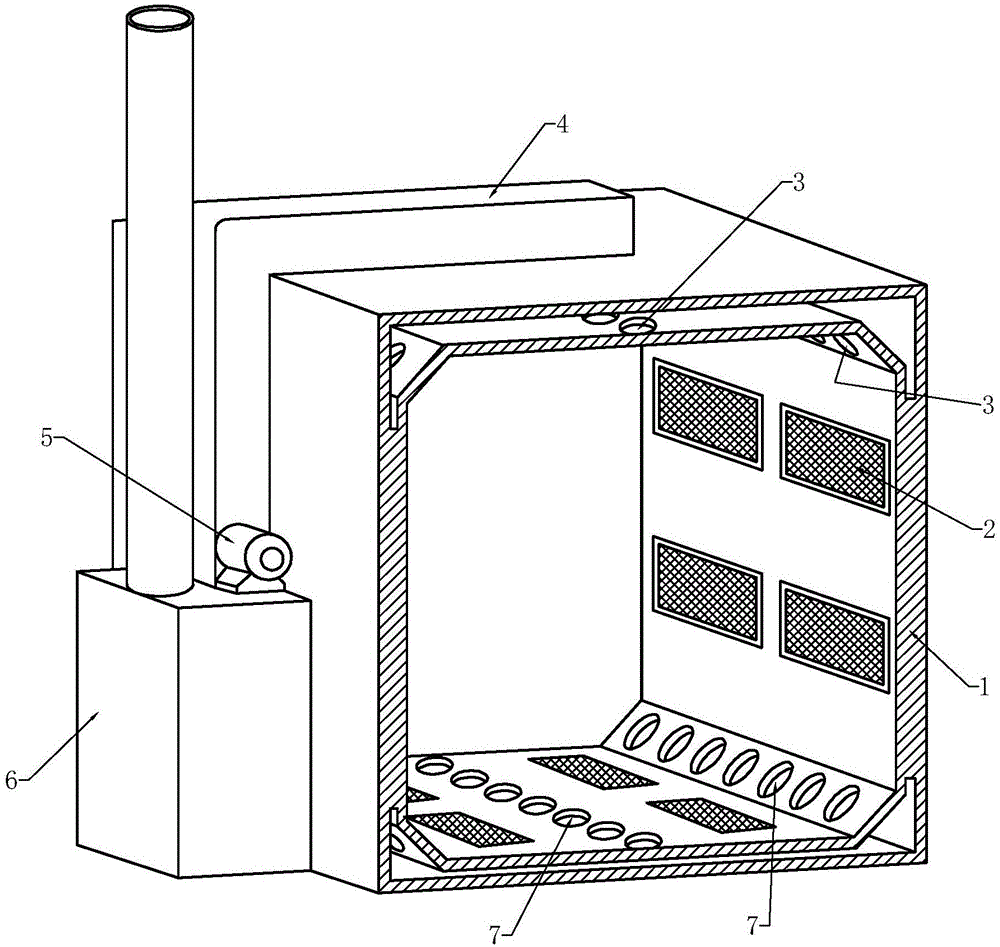

[0033] Embodiment 3, with reference to figure 1 , a high-temperature disinfection and shaping cabinet for pure rabbit down fabrics, including a box body 1, a hot air circulation device and an infrared light emitting device are arranged on the box body 1, and the hot air circulation device includes an air supply hole arranged above the box body 1 3 and the return air hole 7 arranged under the box body 1. On the outside of the box body, there is a hot air circulation channel 4 connecting the air supply hole 3 and the return air hole 7. On the hot air circulation channel 4, there is an indirect heating by fuel Device 6 and high temperature resistant blower 5. The infrared light-emitting device is composed of a plurality of infrared light-emitting panels 2 arranged on the inner wall of the box body 1 (including two side walls, a top wall and a bottom wall), and each infrared light-emitting panel 2 is respectively connected to a power source. During implementation, all infrared lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com