Drum Dyeing Machine

A dyeing machine and drum-type technology, which is applied to the processing of textile material drums, textiles and papermaking, and textile material processing. It can solve problems such as fuzzing, inconsistent product quality, and pilling, and achieve reduced use, simple structure, and easy use. The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

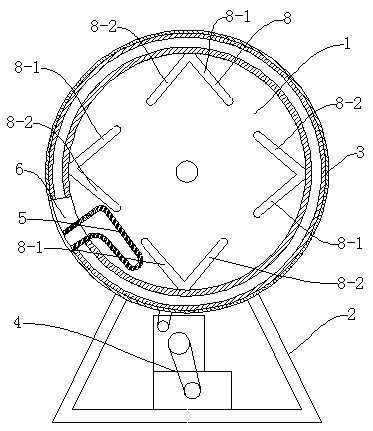

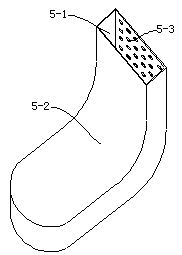

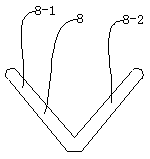

[0026] like figure 1 , image 3 , Figure 4 As shown, the drum dyeing machine described in this embodiment includes a frame 2, a drum 1 is arranged on the frame 2, the two ends of the drum 1 are rotationally connected with the frame 2, and the outer coating of the drum 1 One layer of outer casing 3, the drum 1 and the outer casing 3 are fixedly connected, and there is a gap between the two; The dye device 5, the air pressure balance mechanism and the steam heating mechanism; the dye adding device 5 and the air pressure balance mechanism are all communicated with the inside of the drum 1, and the steam heating mechanism is located between the drum 1 and the outer shell 3; in the drum 1 A driving rod 8 is arranged on the peripheral wall, and the horizontal plane where the outer tangent line of the contact point between the driving rod 8 and the inner peripheral wall of the drum is at an angle of 40 degrees with the driving rod, a part of the driving rod 8-1 and another part of...

Embodiment 2

[0028] The difference between the drum dyeing machine described in this embodiment and Embodiment 1 is that the driving rod 8-1 and the driving rod 8-2 are U-shaped, and the specific structure is as follows: Figure 5 , Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com