Threaded joint for steel pipes

A technology for threaded joints and steel pipes, applied in threaded connections, pipes/pipe joints/fittings, drill pipes, etc., can solve problems such as scratches and difficulty in providing sufficient lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

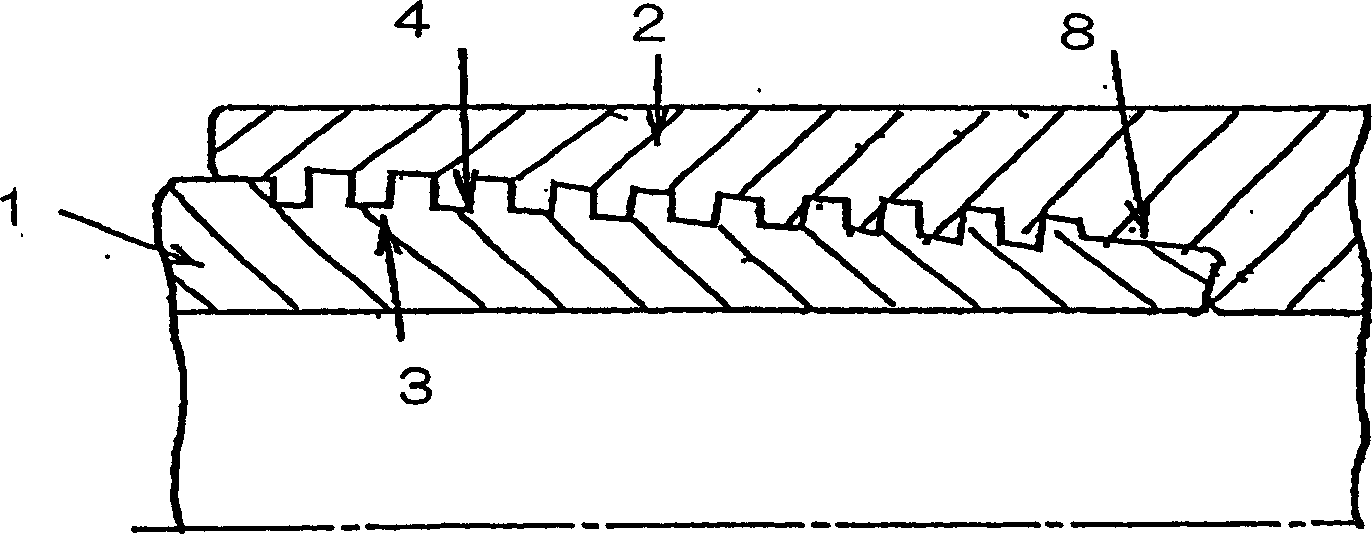

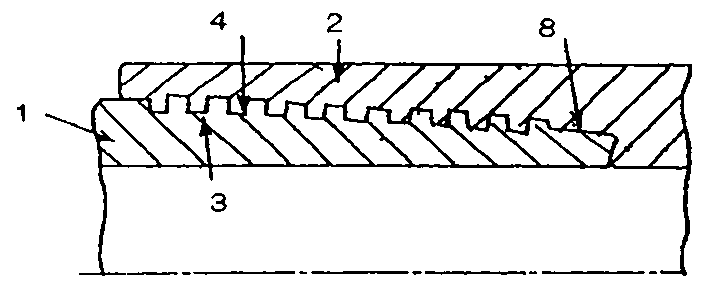

[0089] This example illustrates a threaded joint made of 13Cr steel according to the first embodiment of the present invention, which has a lubricating coating including a lower liquid layer and an upper solid layer formed on the female thread surface of the joint.

[0090] The male thread surface of the joint is not treated.

[0091] The surface of the female thread was preliminarily treated by shot blasting. From then on, within one hour, the surface of the female thread was coated with a lubricating coating with a lower liquid layer and an upper solid layer in the manner outlined in Table 1.

[0092] In Table 1, the viscosity of the substance used in the liquid layer is a value measured at 40°C. In the case where the liquid layer is made of an alkaline metal salt of an organic acid (barium sulfonate or calcium sulfonate), it is diluted with a volatile solvent (xylene) and then coated. In the case where the solid layer is made of mica powder, the powder is dispersed in a nitroce...

Embodiment 2

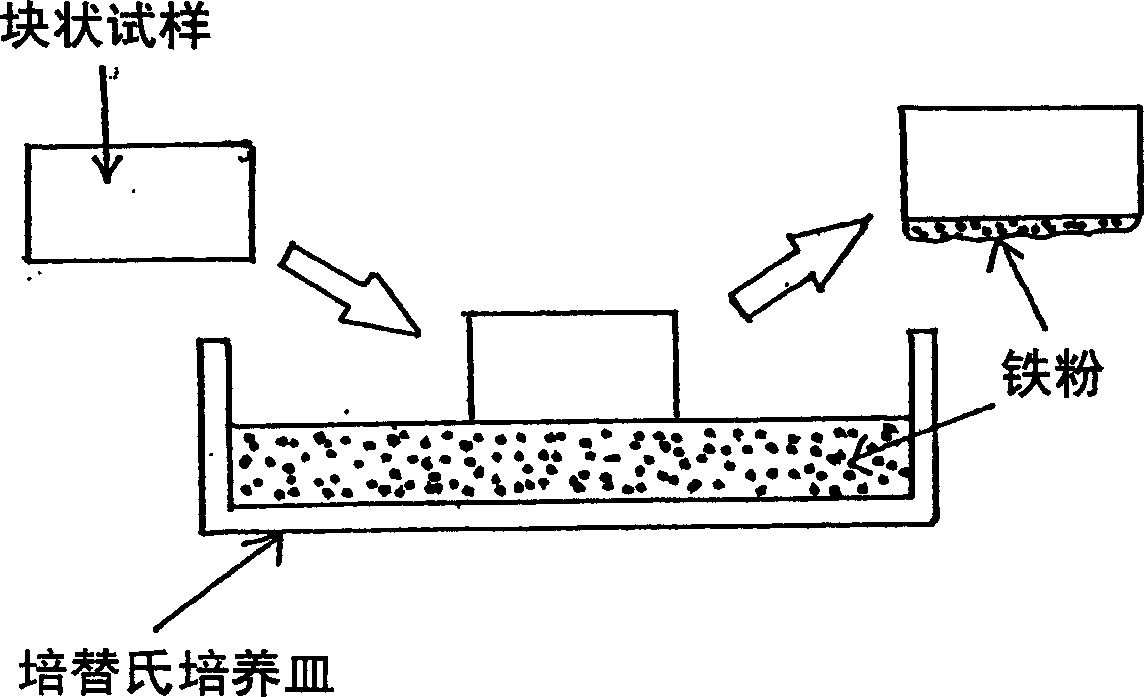

[0104] This example illustrates: according to the second embodiment of the present invention, a threaded joint made of 13Cr steel or carbon steel has a lubricating coating containing a mixture of lubricating oil and wax formed on the surface of the female thread.

[0105] Preliminary surface treatment is performed on the male thread surface of the joint without a lubricating coating, in which the male thread made of carbon steel is chemically surface treated with manganese phosphate, or the male thread made of 13Cr steel is copper plating.

[0106] The surface of the female thread was preliminarily treated in the same manner as in Example 1 (by shot blasting), and within 1 hour from then, the method outlined in Table 3 was used to contain lubricating oil, wax and optional solids. Lubricant coating of a mixture of additives. After heating the mixture to a liquefied mixture (liquefied wax) or after diluting the solvent to prepare a mixture liquid, coating of the mixture is performed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com