Corrosion-resistant self-damping energy-saving aluminum conductor steel reinforced

A steel-cored aluminum stranded wire and self-damping technology, which is applied in the field of electric wires, can solve the problems of no self-damping characteristics, no energy-saving performance, large outer diameter of stranded wires, etc., and achieve improved service life, safe and reliable use, and conductive performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

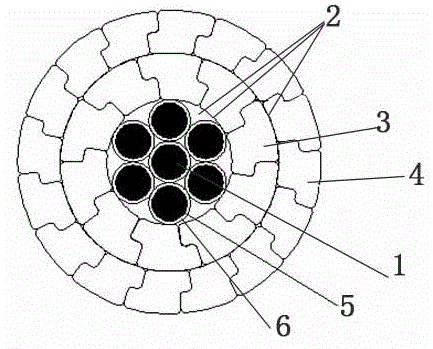

[0019] like figure 1 A super-corrosion-resistant self-damping energy-saving steel-cored aluminum stranded wire is shown, including a cable core. The central aluminum-clad steel wire 1 and the gap between the aluminum-clad steel wire layer are twisted with anti-corrosion grease 2; the inner aluminum wire layer 3 and the outer aluminum wire layer 4 are arranged in sequence outside the cable core, and the cable core and the outer aluminum wire layer are arranged in sequence. Anti-corrosion ointment 2 is filled between the contact surfaces of the inner aluminum wire layers 3 and between the inner and outer aluminum wire layers 3 and 4 contact surfaces.

[0020] Among them, the inner layer of the aluminum-clad steel wire is steel wire, the outer layer is aluminum, the inner aluminum wire layer is composed of 10 Z-shaped inner aluminum wires, and the outer aluminum wire layer is composed of 16 Z-shaped or S-shaped outer aluminum wires. Such a structure makes there is no potential d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com