Oil gas damping ant-galloping device

An anti-dancing device and damping technology, which is applied in the direction of overhead lines/cable equipment, mechanical vibration attenuation devices, etc., can solve the problems of aggravating galloping to transmission lines, the inapplicability of multi-split conductors, and galloping of transmission lines, etc., to reduce the annual Stress equalization, galloping prevention, and excessive sag prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] Embodiment 2 prepares hydrophobic insulating coating:

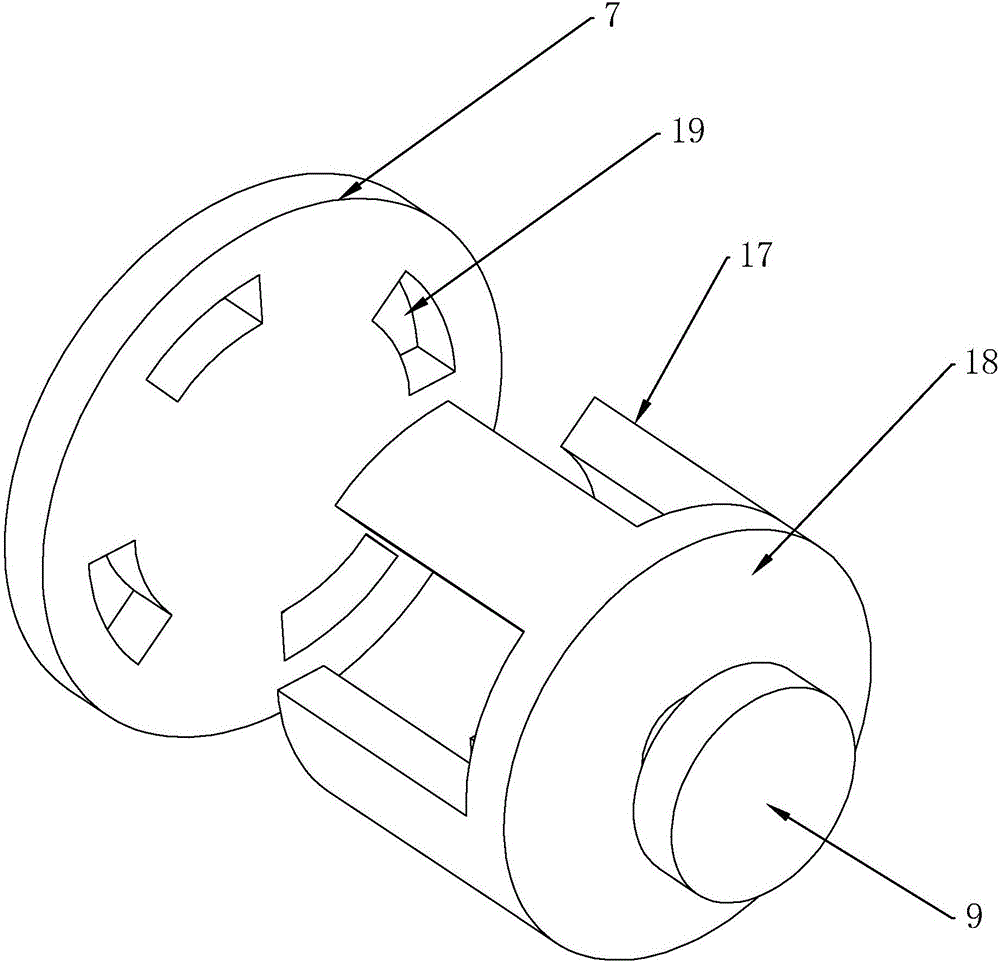

[0044] A. Put the sleeve 1, the outer cylinder 3 and the hanging plate 8 in sequence at room temperature in absolute ethanol and deionized water for ultrasonic cleaning, and place them in an oven to dry after cleaning to obtain the sleeve 1, which has a clean surface. Outer cylinder 3 and hanging plate 8;

[0045] B, 80 parts by weight of nano-SiO 2 and 10 parts by weight of tetraethoxysilane were added to 200 parts by weight of N-methylpyrrolidone solution, heated and stirred at 80°C for 4h, and after naturally cooling to room temperature, the above mixture was filtered and dried to obtain a modified hydrophobic SiO 2 , the modified hydrophobic SiO 2 Mix and stir evenly with 50 parts by weight of dimethylformamide solvent at room temperature to configure a viscous solution, apply the above viscous solution to the surface of sleeve 1, outer cylinder 3 and hanging plate 8, and let it stand at room temperature Cur...

Embodiment 3

[0048] Embodiment 3 prepares hydrophobic insulating coating:

[0049] A. Put the sleeve 1, the outer cylinder 3 and the hanging plate 8 in sequence at room temperature in absolute ethanol and deionized water for ultrasonic cleaning, and place them in an oven to dry after cleaning to obtain the sleeve 1, which has a clean surface. Outer cylinder 3 and hanging plate 8;

[0050] B, 90 parts by weight of nano-SiO 2 and 15 parts by weight of phenyltriethoxysilane were added to 260 parts by weight of N-methylpyrrolidone solution, heated and stirred at 90°C for 6 hours, and after naturally cooling to room temperature, the above mixture was filtered and dried to obtain a modified hydrophobic SiO 2 , the modified hydrophobic SiO 2 Mix and stir evenly with 80 parts by weight of dimethylformamide solvent at room temperature to configure a viscous solution, apply the above viscous solution to the surface of sleeve 1, outer cylinder 3 and hanging plate 8, and let it stand at room temper...

Embodiment 4

[0053] Embodiment 4 prepares hydrophobic insulating coating:

[0054] A. Put the sleeve 1, the outer cylinder 3 and the hanging plate 8 in sequence at room temperature in absolute ethanol and deionized water for ultrasonic cleaning, and place them in an oven to dry after cleaning to obtain the sleeve 1, which has a clean surface. Outer cylinder 3 and hanging plate 8;

[0055] B, with 100 parts by weight of nano-SiO 2 and 20 parts by weight of ethyltriethoxysilane were added to 300 parts by weight of N-methylpyrrolidone solution, heated and stirred at 100°C for 8 hours, and after naturally cooling to room temperature, the above mixture was filtered and dried to obtain a modified hydrophobic SiO 2 , the modified hydrophobic SiO 2 Mix and stir evenly with 100 parts by weight of dimethylformamide solvent at room temperature to configure a viscous solution, apply the above viscous solution to the surface of sleeve 1, outer cylinder 3 and hanging plate 8, and let it stand at room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com