Reinforcement system for substation outlets

A technology for substations and wire jumpers, which is applied in the directions of busbar/line layout, cable space arrangement/configuration, etc. It can solve problems such as long length of down conductors, twisted and broken spacers, broken strands of down conductors, etc., to reduce lateral Effects of wind pressure, preventing strand breakage, and increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

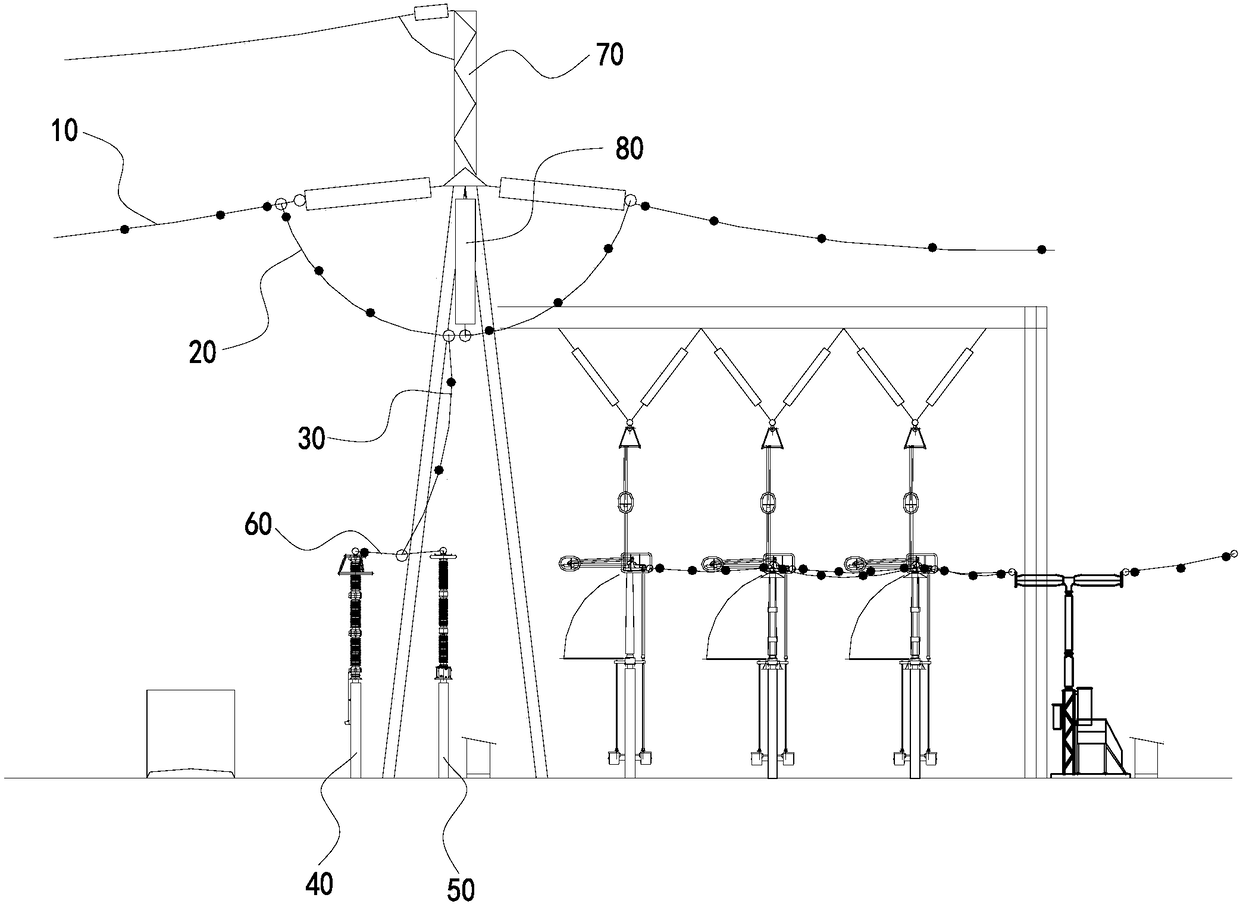

[0019] Such as figure 1 As shown, a substation outgoing line reinforcement system includes an outgoing wire 10, a jumper wire 20, a down conductor 30, a lightning arrester 40 and a voltage transformer 50 located below the outgoing wire 10, and the two ends are respectively connected to the lightning arrester 40 and the voltage transformer 50. The two ends of the jumper wire 20 are respectively connected to the outgoing wire 10, one end of the down conductor 30 is connected to the jumper wire 20, and the other end is connected to the connecting wire 60.

[0020] One end of the down conductor 30 is connected to the jumper wire 20, and the other end is connected to the connecting wire 60. Compared with the traditional wiring method, the length of the down conductor 30 is shortened, the lateral wind pressure of the down conductor 30 is reduced, and the jumper wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com