Airflow control assembly and air pump

A technology of airflow control and components, applied to pumps with flexible working elements, pumps, pump components, etc., can solve the problems of high noise in the operation of the air pump, reduce the service life of the air pump, and affect the service life of the one-way valve, so as to reduce noise, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

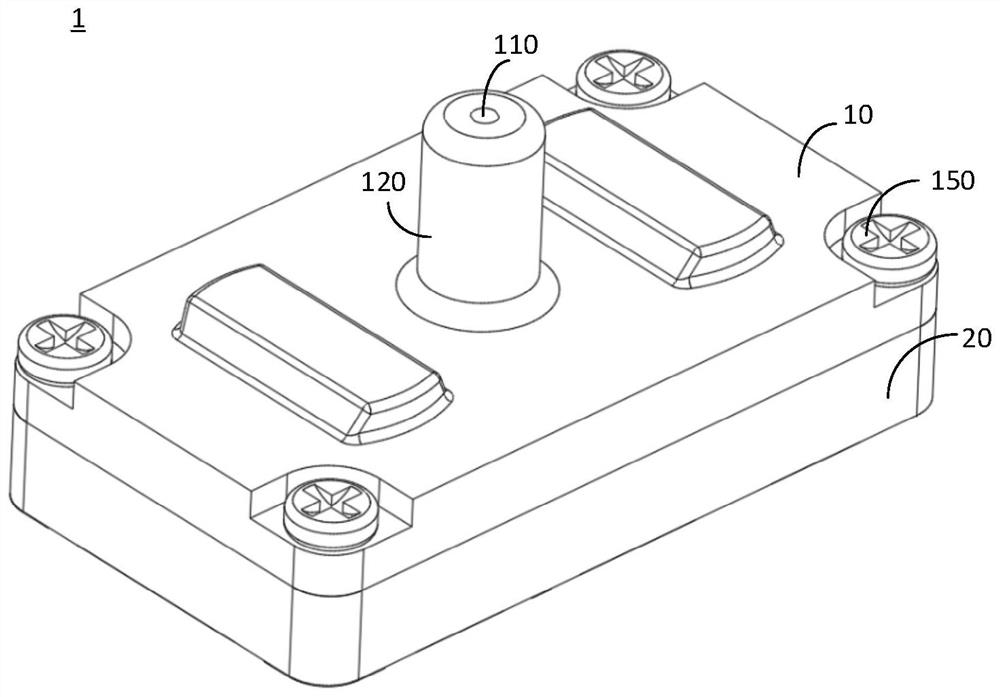

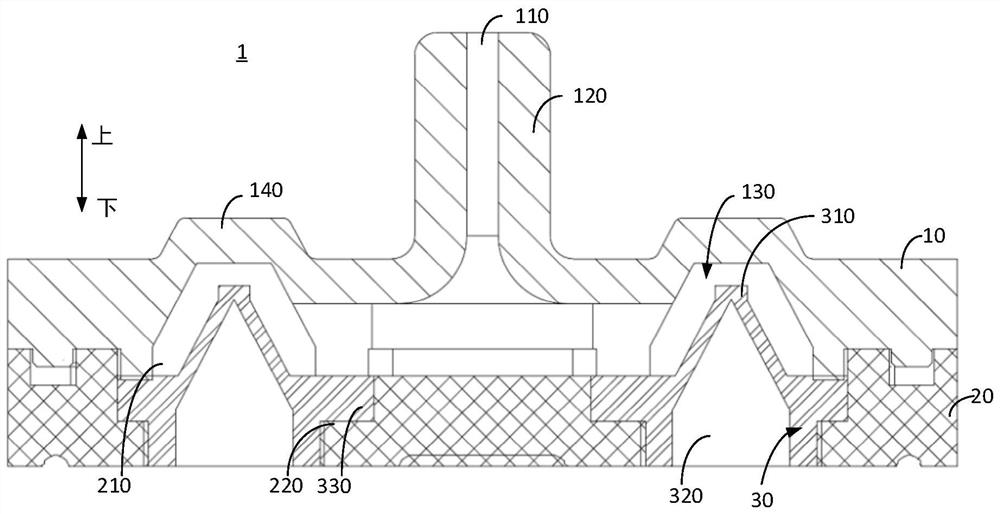

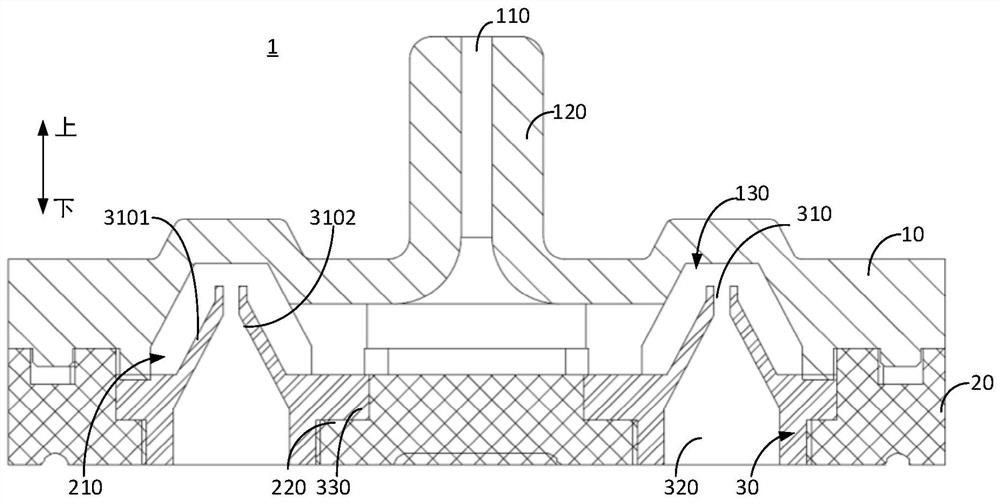

[0055] In order to solve the problems in the prior art that the air pump is noisy and the service life of the one-way valve in the air pump is short, as Figure 1-Figure 3 As shown, this embodiment discloses an airflow control assembly 1, wherein the airflow control assembly 1 can be used in an air pump, or in other pneumatic systems, as a gas flow direction limiting device in the pneumatic system. Specifically, the airflow control assembly 1 includes: an end cover 10 , a connecting plate 20 and a one-way valve 30 .

[0056] Wherein, a first air port 110 is opened on the end cover 10 . Specifically, combined with figure 1 and Figure 4 As shown, in a feasible implementation, the first air port 110 and the end cover 10 are formed in such a way that the end cover 10 extends toward the side away from the one-way valve 30 to form an extension end 120 , and at the extension end The first air port 110 is formed on the part 120, so that when the one-way valve 30 is opened, the air...

Embodiment 2

[0093] refer to Figure 4-Figure 6 As shown, this embodiment provides an air pump 2 , including: an air pump body 21 and an airflow control assembly 1 . The airflow control assembly 1 is arranged on the air pump body 21 , and an air chamber 27 is formed on the air pump body 21 .

[0094] Wherein, the airflow control assembly 1 in this embodiment has the same structure as the airflow control assembly 1 provided in the first embodiment, and can bring about the same or similar technical effects, and will not be described here one by one. For details, please refer to the first embodiment description of.

[0095]In this embodiment, when the ventilation end 310 of the one-way valve 30 is opened, the air cavity 27 of the air pump body 21 communicates with the second air port 210 and the first air port 110 to form an air flow channel. Since in this embodiment, the one-way valve 30 is installed on the second air port 210 of the connecting plate 20, and the open end 320 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com