Preparation method of Al-Zr-RE alloy round aluminum rod

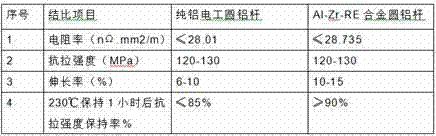

The technology of a round aluminum rod and a preparation method is applied in the field of aluminum alloy materials, which can solve the problems of low tensile strength, large cable sag, and self-heavy weight, and achieves the advantages of improving utilization rate, small sag and saving construction cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

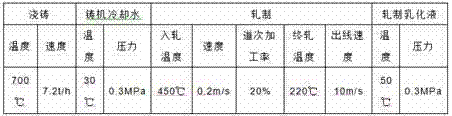

[0031] A preparation method of an Al-Zr-RE alloy round aluminum rod, comprising the steps of:

[0032] (1) Install aluminum liquid with a mass fraction of more than 99.60% of aluminum in the aluminum smelting furnace according to the production demand, so that the temperature is controlled at 750-780°C;

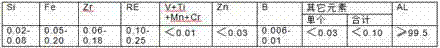

[0033] (2) Add zirconium agent and rare earth alloy when calculating the concentration, so that the mass fraction of zirconium is controlled between 0.06 and 0.18%, and the mass fraction of rare earth is controlled between 0.10 and 0.25%. In order to ensure that the aluminum alloy is fully alloyed, Keep the furnace temperature at 750-780°C for more than 1 hour, and carry out electromagnetic stirring at the same time, and determine that the content of zirconium and rare earth meets the requirements by sending the "samples before the furnace" to analyze the chemical composition.

[0034] (3) After the zirconium and rare earth are fully melted, add industrial silicon, iron and a...

Embodiment 2

[0045] A preparation method of an Al-Zr-RE alloy round aluminum rod, comprising the steps of:

[0046] (1) Install aluminum liquid with a mass fraction of more than 99.60% aluminum in the aluminum smelting furnace according to the production demand, so that the temperature is controlled at 750-760 °C;

[0047](2) Add zirconium agent and rare earth alloy when calculating the concentration, so that the mass fraction of zirconium is controlled between 0.06 and 0.18%, and the mass fraction of rare earth is controlled between 0.10 and 0.25%. In order to ensure that the aluminum alloy is fully alloyed, Keep the furnace temperature at 770-780°C for more than 1 hour, and carry out electromagnetic stirring at the same time, and determine the content of zirconium and rare earths to meet the requirements by sending "samples before the furnace" to analyze the chemical composition.

[0048] (3) After the zirconium and rare earth are fully melted, add industrial silicon, iron and aluminum-b...

Embodiment 3

[0055] A preparation method of an Al-Zr-RE alloy round aluminum rod, comprising the steps of:

[0056] (1) Install aluminum liquid with a mass fraction of more than 99.60% aluminum in the aluminum smelting furnace according to the production demand, so that the temperature is controlled at 760-780 °C;

[0057] (2) Add zirconium agent and rare earth alloy when calculating the concentration, so that the mass fraction of zirconium is controlled between 0.06 and 0.18%, and the mass fraction of rare earth is controlled between 0.10 and 0.25%. In order to ensure that the aluminum alloy is fully alloyed, Keep the furnace temperature at 750-770°C for more than 1 hour, and carry out electromagnetic stirring at the same time, and determine that the content of zirconium and rare earth meets the requirements by sending the "samples before the furnace" to analyze the chemical composition.

[0058] (3) After the zirconium and rare earth are fully melted, add industrial silicon, iron and alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com