Carbon fiber compound core of power transmission circuit

A transmission line, carbon fiber technology, applied in the direction of circuits, insulated cables, power cables, etc., to achieve the effect of high conductivity, no magnetic loss and heat loss of conductivity, and advanced control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

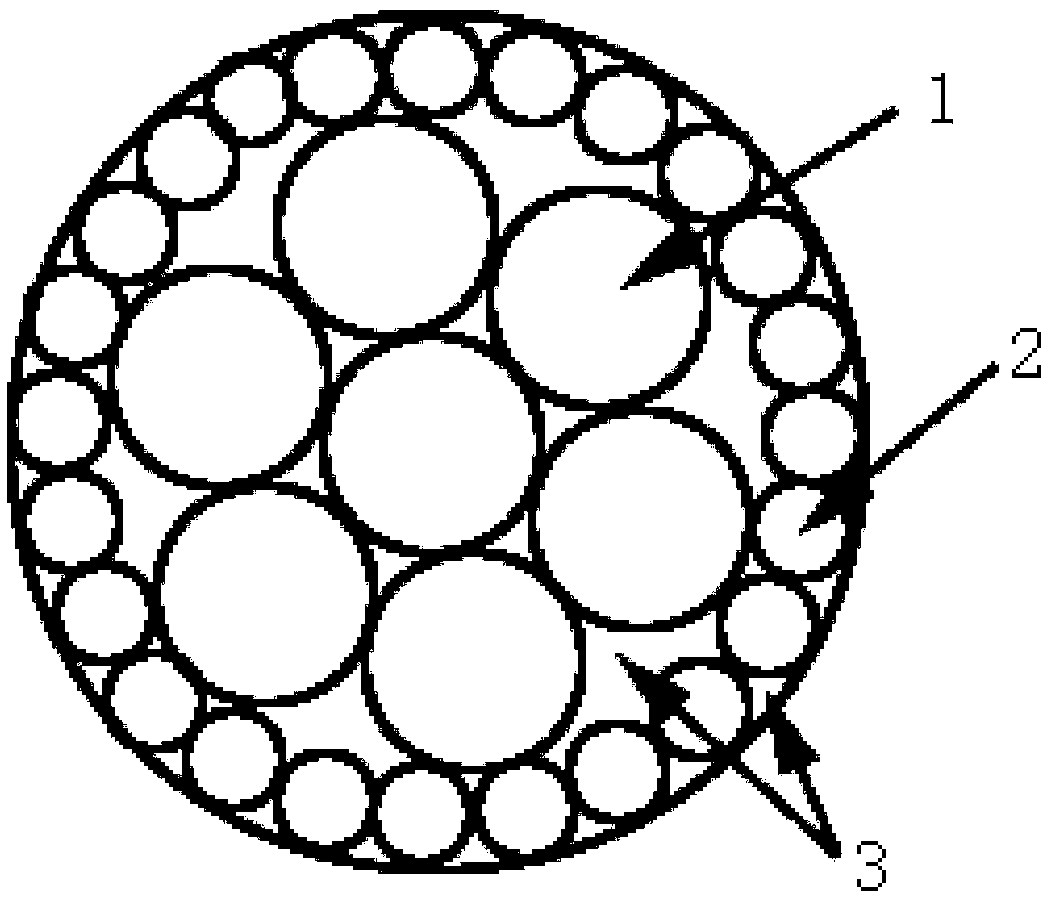

[0019] The cross-section of the transmission line carbon fiber composite core provided by an embodiment of the present invention is as follows: image 3 As shown, wherein, the carbon fiber composite core of the power transmission line includes an inner core 1, an outer core 2, and the outer core 2 is wrapped around the inner core 1, wherein the inner core is carbon fiber made by carbonizing polyacrylonitrile fibers, and the outer The core is high-strength glass fiber or basalt fiber; the inner core and outer core are heated and fixed by the cured resin 3, and the cured resin is a high-temperature-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com