Composite material reinforcing lead and production method thereof

A composite material and wire technology, used in cable/conductor manufacturing, conductors, insulated conductors, etc., can solve problems such as reducing the performance of composite core products, reduce labor costs, improve pultrusion speed, and ensure mechanical properties and service life. Effect

Inactive Publication Date: 2010-08-25

JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH +1

View PDF1 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Moreover, due to the uneven heating process from outside to inside, residual stress will be formed inside the work material, which reduces the performance of composite core products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

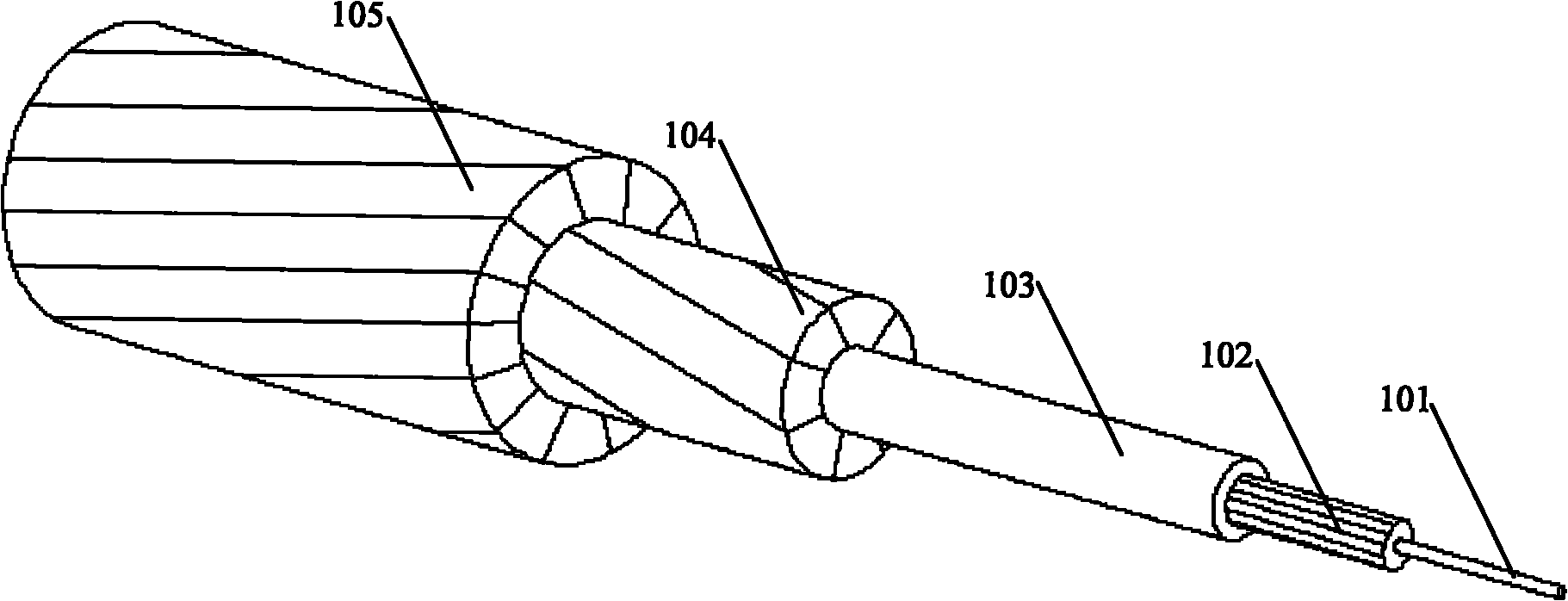

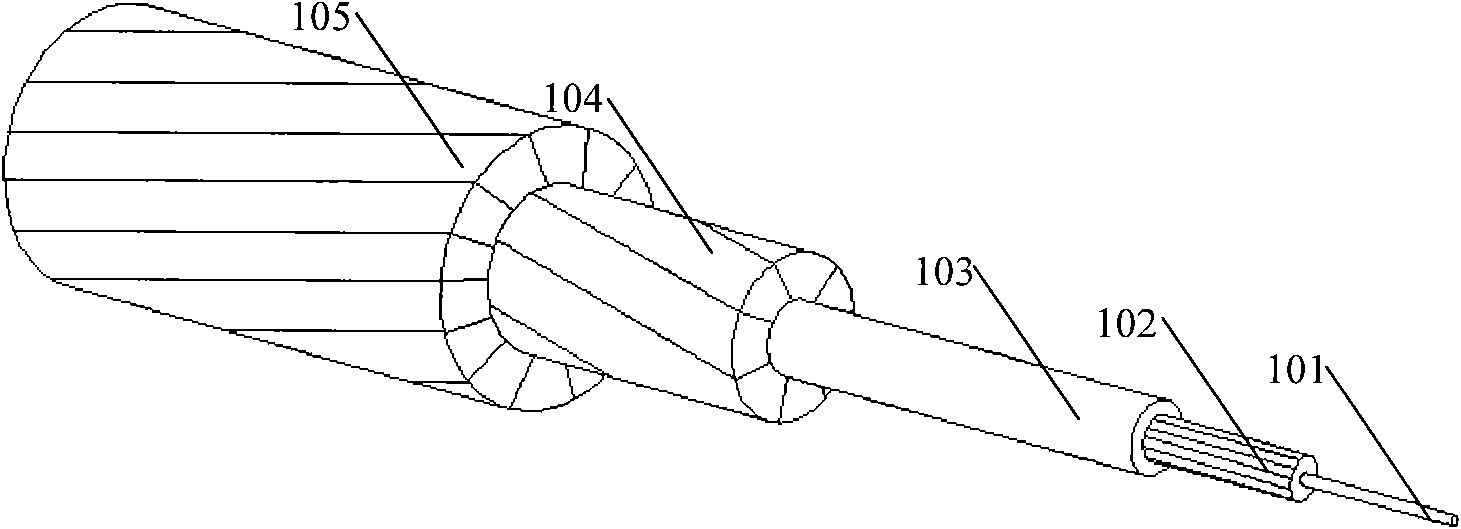

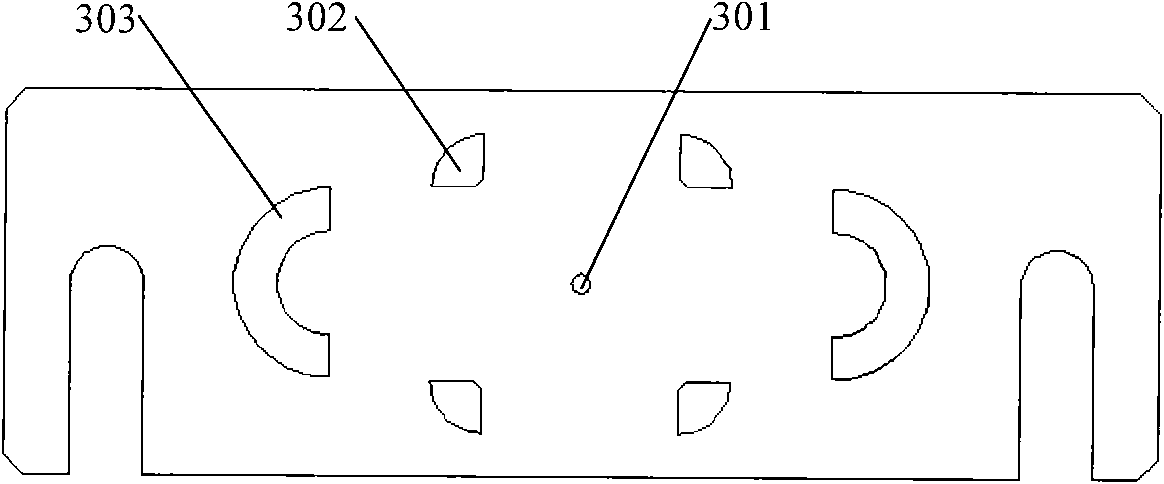

The invention relates to a composite material lead and a production method thereof, in particular to a lead for overhead power transmission and a production method thereof. The lead comprises a composite material reinforcing rib encircled by a conducting material. The production method relates to a composite material pultrusion process. The lead comprises the reinforcing rib and a long-bar shaped conductive body distributed vertically along the reinforcing rib. The reinforcing rib comprises a continuous carbon fiber reinforced composite material carrier and a glass fiber mat reinforced composite material protective body. The reinforcing rib of the invention is produced by the pultrusion process including a die opening and closing technology and an induction heating technology. The reinforcing rib is wound with the conductive body outside to form the lead which can be used for overhead power transmission. The lead provided by the invention has the advantages of long service life, low cost, low sag and high transmission efficiency. The production method of the reinforcing rib has fast pultrusion speed and even internal and external heating of materials and can eliminate residual heat stress during solidification.

Description

Composite material reinforced wire and its manufacturing method technical field The present invention relates to a composite material reinforced wire and its manufacturing method. Specifically, the present invention relates to a wire used for overhead power transmission and its manufacturing technology. The wire includes a composite material reinforcing rib surrounded by conductive materials. The manufacturing method involves Composite pultrusion manufacturing process. Background technique Due to the development needs of the power transmission network, power transmission technology is becoming an important research field for people in the industry, and the wire manufacturing technology involved is a research hotspot in recent years. In traditional overhead transmission lines, steel-cored aluminum conductors are usually used, the inner steel core is used as a carrier, and the aluminum wrapped around the steel core is used as a conductor. The steel material has low specific...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B7/18H01B5/10H01B9/02H01B3/30H01B3/48H01B3/08H01B13/00

Inventor 李建龙孟凡颢

Owner JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com