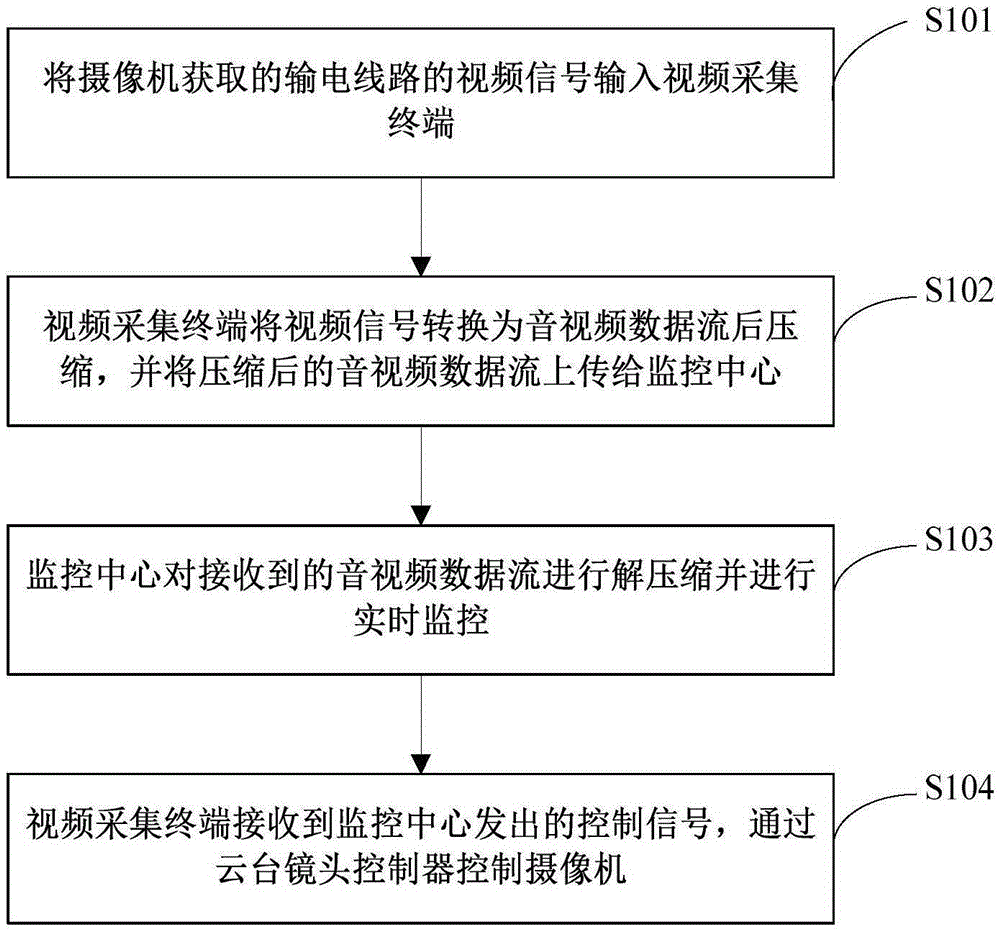

Remote monitoring method for power transmission line

A transmission line and remote monitoring technology, applied in distribution line transmission systems, televisions, electrical components, etc., can solve problems such as inconvenient viewing, improve monitoring efficiency, ensure robustness, and achieve long-term economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The alloy wire is composed of the following weight percentages: Zr: 0.04%; Cu: 0.1%; Fe: 0.96%; Mn: 0.04%; vitrified bond: 0.2%; Mg: 0.15%; Ti: 0.02%; %; B: 0.2%, the balance is Al and unavoidable impurities. RE is Ce and La, where the mass ratio of Ce to La is 1:4.

[0038] The vitrified bond is composed of the following raw materials in weight percentage: 1% boron, 25% aluminum oxide, 5% lithium oxide, 3% sodium oxide and 4% magnesium oxide, 1% copper powder, 0.5% tin powder and 1% zinc oxide, the remainder The amount is silica; the particle size of said raw materials is not more than 10 microns.

Embodiment 2

[0040]The alloy wire is composed of the following weight percentages: Zr: 0.05%; Cu: 0.15%; Fe: 0.98%; Mn: 0.04%; vitrified bond: 0.3%; Mg: 0.18%; Ti: 0.05%; %; B: 0.1%, the balance is Al and unavoidable impurities. RE is Ce, La, Nd and Ho, wherein the mass ratio of Ce, La, Nd and Ho is 1:1:2:1.

[0041] The vitrified bond is composed of the following raw materials in weight percentage: 2% boron, 20% aluminum oxide, 6% lithium oxide, 5% sodium oxide and 8% magnesium oxide, 2% copper powder, 1.5% tin powder and 0.3% zinc oxide, the remainder The amount is silica; the particle size of said raw materials is not more than 10 microns.

Embodiment 3

[0043] The alloy wire is composed of the following components in weight percentage: Zr: 0.05%; Cu: 0.12%; Fe: 0.96%; Mn: 0.045%; ceramic bond: 0.3%; Mg: 0.2%; Ti: 0.01%; %; B: 0.1%, the balance is Al and unavoidable impurities. RE is Ce, Nd and Ho, wherein the mass ratio of Ce, Nd and Ho is 1:2:2.

[0044] The vitrified bond is composed of the following raw materials in weight percentage: 1.5% boron, 22% aluminum oxide, 5% lithium oxide, 4% sodium oxide and 6% magnesium oxide, 1% copper powder, 1.0% tin powder and 0.5% zinc oxide, the remainder The amount is silica; the particle size of said raw materials is not more than 10 microns.

[0045] The electrical conductivity of the alloy wire is 65%, and the tensile strength exceeds 300MPa.

[0046] Carbon fiber composite wire is a new energy-saving capacity-enhancing wire with a new structure. Compared with conventional wires, it has light weight, high tensile strength, good heat resistance, small thermal expansion coefficient, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com