Bidirectional beam string structure of rectangular plane

A plane and rectangular technology, applied in the field of two-way string beam structure, can solve the problems of difficult processing and installation of roof units, low stiffness and stability of side string string beams, and achieve the effect of convenient processing and installation, and uniform stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

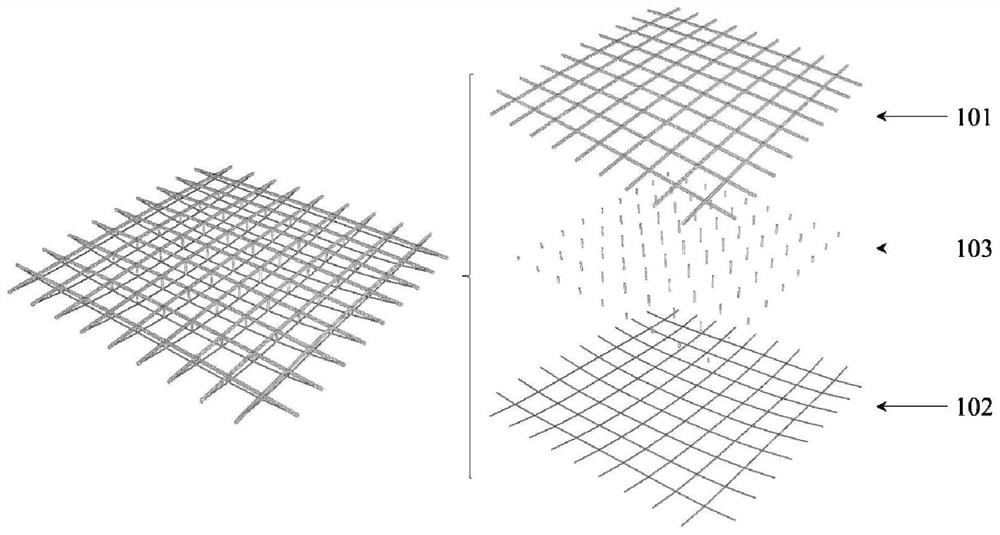

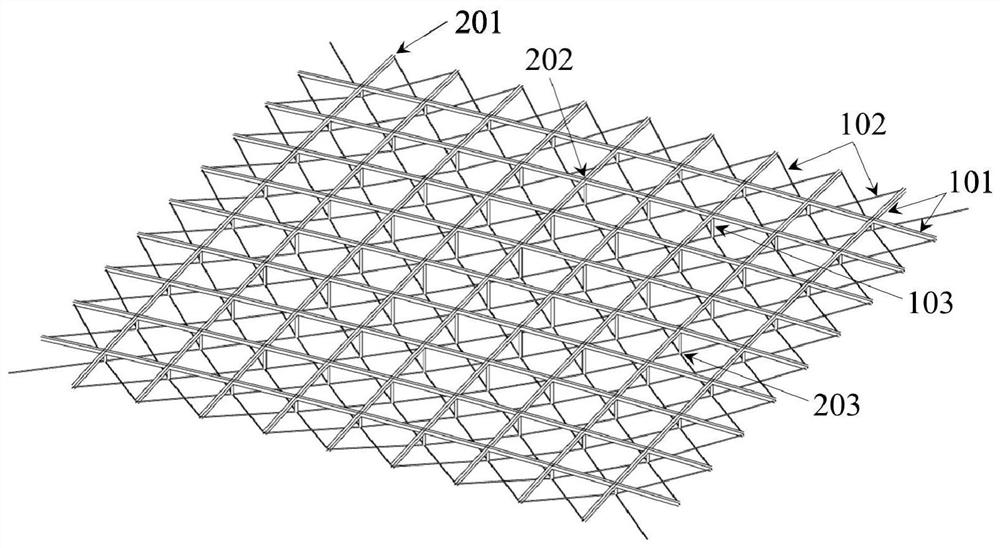

[0038] like figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 Shown is the first specific implementation of a two-way tension beam structure with a rectangular plane in the present invention. In this embodiment, the two-way tension beam structure is composed of an upper beam system 101, a lower cable system 102 and a strut 103. The horizontal projection of the structure is a square.

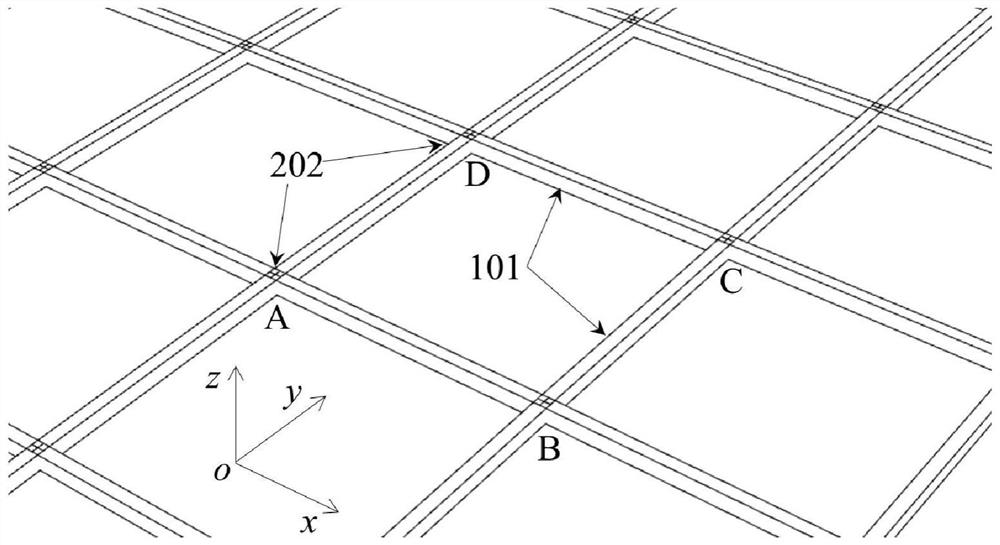

[0039] The upper beam system 101 is composed of two groups of beam systems whose horizontal projection is orthogonal and upright. The horizontal projections of the two groups of beam systems are respectively parallel to the two opposite sides of the structural square plane. The beam end nodes 201 and the upper beam system nodes 202 are located at elliptic paraboloid. A three-dimensional coordinate system is established with the center of the rectangular flat roof as the origin. The x-axis and y-axis of the three-dimensional coordinate system are respectively parallel to ...

Embodiment 2

[0056] like Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 Shown is a second specific embodiment of a rectangular plane bidirectional stretched beam structure of the present invention. The arrangement of the bidirectional stretched string beam structure in this embodiment is basically the same as that of the first embodiment, and the similarities will not be repeated here. The difference is that the horizontal projection of the structure is a rectangle, and the lower layer cable system 102 adopts the evacuation arrangement, that is, along the diagonal direction parallel to the rectangular plane, braces 103 are arranged below every other row of upper layer beam system nodes 202. and the lower cable tie 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com