Conductive silver paste for microelectronic packaging and preparation method thereof

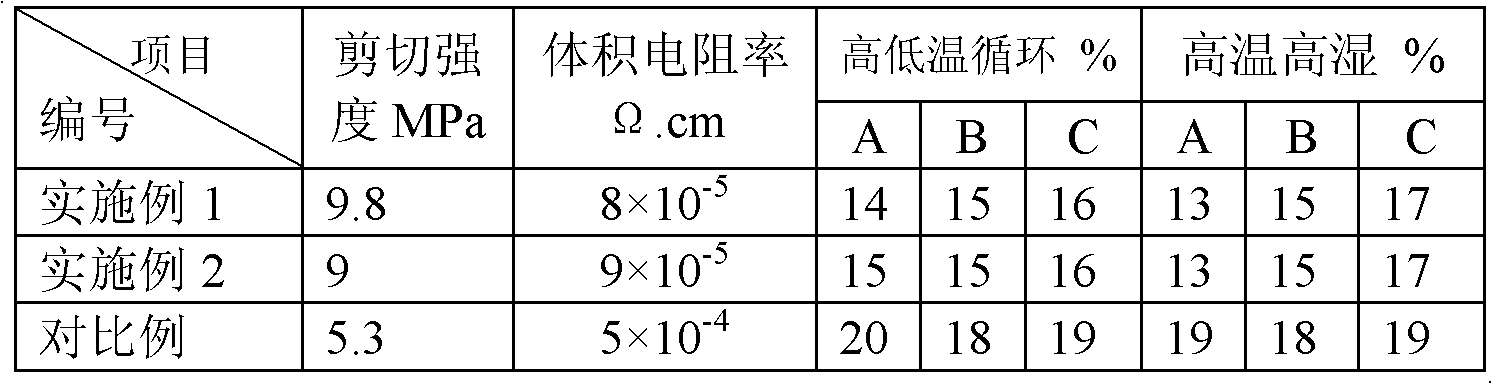

A technology of microelectronic packaging and conductive silver glue, which is applied in the field of conductive glue, can solve the problems of poor impact resistance and conductivity (unstable contact resistance) of glue joints, and achieve the effect of stable contact resistance and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, equip each component by the following mass percentages:

[0037] Liquid epoxy resin: 12 parts, using a mixture of bisphenol A diglycidyl ether and bisphenol F diglycidyl ether, and the mass ratio of bisphenol A diglycidyl ether: bisphenol F diglycidyl ether is 2:1 ;

[0038] Diluent: 10 parts, using a mixture of cyclohexyl glycidyl ether and diethylene glycol ethyl ether acetate, and the mass ratio of the two is: 2:1;

[0039] 13 parts of spherical silver powder with a particle size of 3-7 μm, and 57 parts of flake silver powder with a particle size of 5-9 μm;

[0040] Latent curing agent: 1 part, using TH-2833;

[0041] Curing accelerator: 0.3 parts, using organic urea accelerator, such as Dyhard UR200;

[0042] Coupling agent: 1.7 parts, using K-550;

[0043] Defoamer: 1 part, using lecithin;

[0044] Conduction accelerator: 1 part, using β-phenylacrolein;

[0045] Anti-aging agent: 1 part, using TNPP;

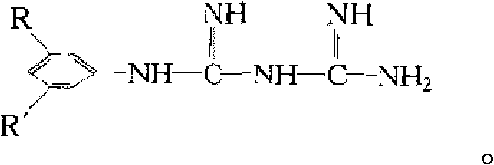

[0046] 2 parts of toughening agent, using a self-s...

Embodiment 2

[0049] First, equip each component by the following mass percentages:

[0050] Liquid epoxy resin: 12 parts, using a 1:1 mixture of epoxy acrylic resin and bisphenol A diglycidyl ether;

[0051] Diluent: 10 parts, using a mixture of 1,4 butanediol diglycidyl ether: diethylene glycol ethyl ether acetate = 2:1;

[0052] 13 parts of spherical silver powder with a particle size of 3-7 μm, and 57 parts of flake silver powder with a particle size of 5-9 μm;

[0053] Latent curing agent: 1 part, using TH-2844;

[0054] Curing accelerator: 0.3 parts, using imidazole accelerators, such as 2-ethyl-4-methylimidazole;

[0055] Coupling agent: 1.7 parts, using K-570;

[0056] Defoamer: 1 part, using lecithin;

[0057] Conduction accelerator: 1 part, using o-hydroxybenzaldehyde;

[0058] Anti-aging agent: 1 part, using TNPP;

[0059] Toughener: 2 parts, modified epoxy resin with self-shell-core structure polymer, the core is butadiene polymer, and the shell is plastic with a higher gl...

Embodiment 3

[0062] This example is a comparative example. (Whether the ratio of the comparative example can exceed the ratio of the content of the invention, such as diluent > 10 parts,)

[0063] First, equip each component by the following mass percentages:

[0064] Liquid epoxy resin: 12 parts, using a 1:1 mixture of epoxy acrylic resin and bisphenol A diglycidyl ether;

[0065] Diluent: 11 parts, using a mixture of 1,4 butanediol diglycidyl ether: diethylene glycol ethyl ether acetate = 2:1;

[0066] 13.5 parts of spherical silver powder of 3-7 μm, 59.5 parts of flake silver powder of 5-9 μm;

[0067] Latent curing agent: 1 part, using dicyandiamide;

[0068] Curing accelerator: 0.3 parts, using imidazole accelerators, such as 2-ethyl-4-methylimidazole;

[0069] Coupling agent: 1.7 parts, using K-570;

[0070] Defoamer: 1 part, using lecithin;

[0071] Conduction accelerator: 0 parts;

[0072] Anti-aging agent: 1 part, using TNPP;

[0073] Toughener: 0 parts.

[0074] Then, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com