Ice-covering-resistant film and preparation method thereof

An anti-icing and film-attaching technology, which is applied in the field of composite materials, can solve the problems of increased difficulty in de-icing, poor wear resistance of anti-icing materials, and inability to optimize ice adhesion strength of films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

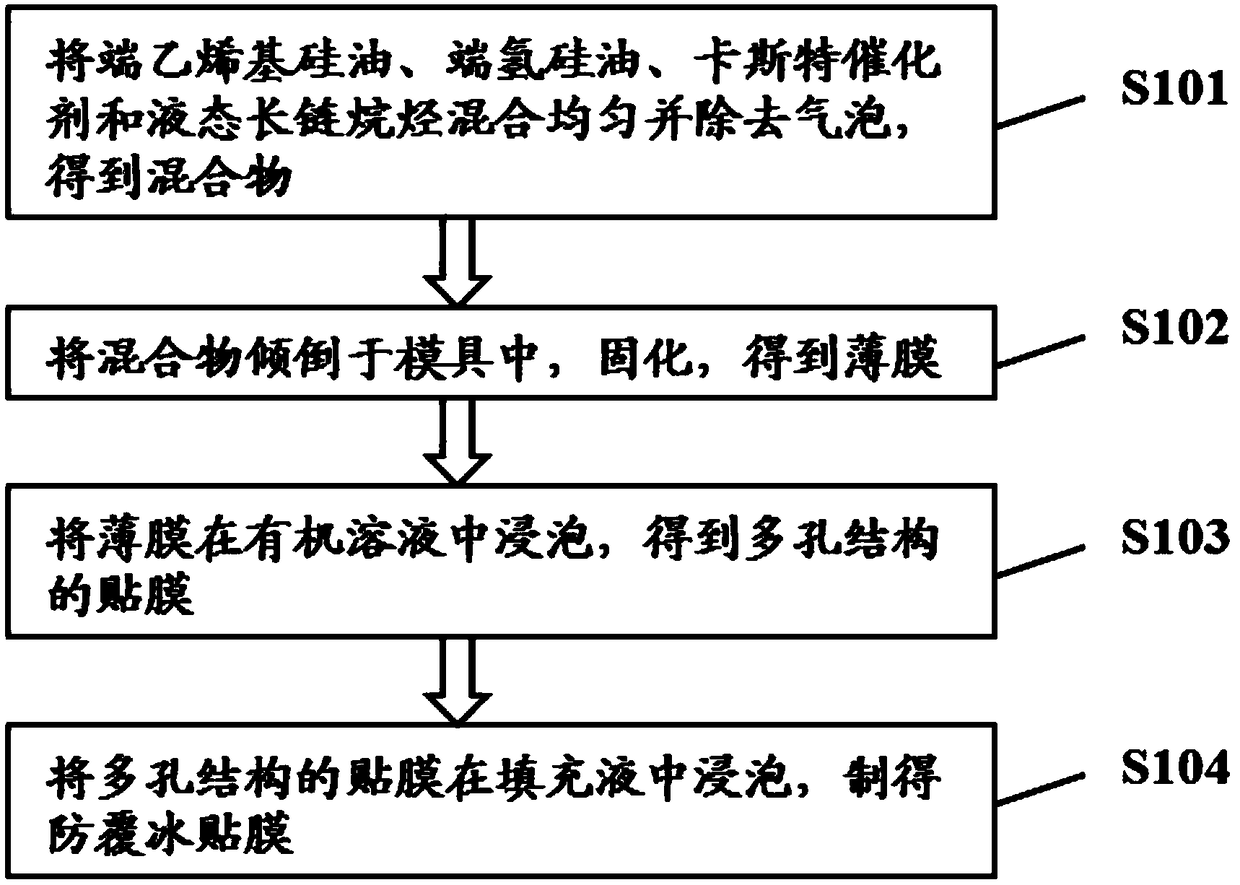

[0022] The preparation method of anti-icing film provided by the invention comprises the following steps:

[0023] Such as figure 1 The step S101 shows: the vinyl-terminated silicone oil, the hydrogen-terminated silicone oil, the castor catalyst and the liquid long-chain alkane are uniformly mixed and the air bubbles are removed to obtain a mixture. In this step, in parts by weight, mix 10-100 parts of vinyl-terminated silicone oil, 1-50 parts of hydrogen-terminated silicone oil, 0.05-0.15 parts of Castel catalyst, and 10-100 parts of liquid long-chain alkanes in a glass vessel Homogenize and remove air bubbles. Optionally, by weight, 50 parts of vinyl-terminated silicone oil, 25 parts of hydrogen-terminated silicone oil, 0.1 part of Castor catalyst, and 50 parts of liquid long-chain alkanes at a stirring rate of 1500 to 2500 rpm, Stir for 25-35 minutes to mix evenly, and remove air bubbles by vacuuming. Among them, the change of the proportion of vinyl-terminated silicone o...

Embodiment 1

[0030] In parts by weight, weigh 10 parts of vinyl-terminated silicone oil, 1 part of hydrogen-terminated silicone oil, 0.05 parts of castor catalyst, and 10 parts of liquid paraffin, and add them to glassware, stir vigorously at 2000rpm for 30 minutes, and then vacuum to remove air Bubble. Then it was poured into a mold and cured at 70° C. for 10 hours to obtain a film. Soak the film in D40 solvent for 30 minutes, remove the long-chain alkanes, and blow dry to obtain a film with a porous structure, then soak the film with a porous structure in perfluoropolyether for 30 minutes, remove the excess filling liquid after taking it out, Blow dry to obtain an anti-icing film with a thickness of 2mm.

[0031] After testing, the ice adhesion strength of the anti-icing film is 30kPa. After 100 icing / deicing cycles, the ice adhesion strength of the anti-icing film decreased by 19%.

Embodiment 2

[0033]In parts by weight, weigh 100 parts of vinyl-terminated silicone oil, 50 parts of hydrogen-terminated silicone oil, 0.15 parts of castor catalyst, and 100 parts of liquid paraffin, and add them to glassware, stir vigorously at 2000rpm for 30 minutes, and then vacuum to remove air Bubble. Then it was poured into a mold and cured at 70° C. for 10 hours to obtain a film. Soak the film in D40 solvent for 30 minutes, remove long-chain alkanes, and blow dry to obtain a film with a porous structure, then soak the film with a porous structure in F-550S for 30 minutes, remove the excess filling liquid after taking it out, and blow it Dry to obtain an anti-icing film with a thickness of 4mm.

[0034] After testing, the ice adhesion strength of the anti-icing film is 40kPa. After 100 icing / deicing cycles, the ice adhesion strength of this anti-icing film decreased by 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| ice adhesion strength | aaaaa | aaaaa |

| ice adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com