Patents

Literature

30results about How to "Low ice adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-icing composition driven by catalytic hydrogen generation under subzero temperatures

InactiveUS20170107413A1Reduce hysteresisLower surface energyOther chemical processesCoatingsHydrogenOptical transparency

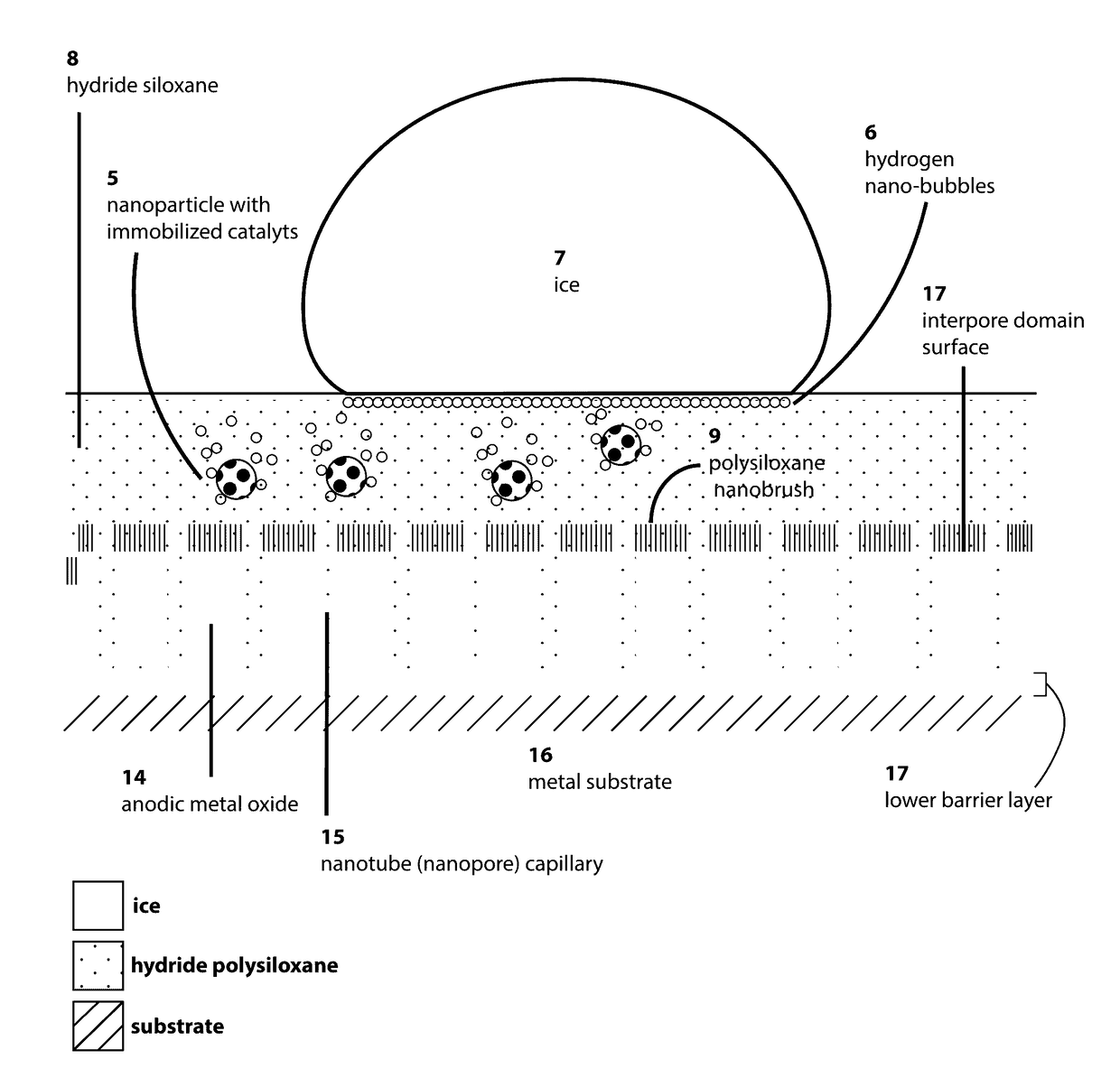

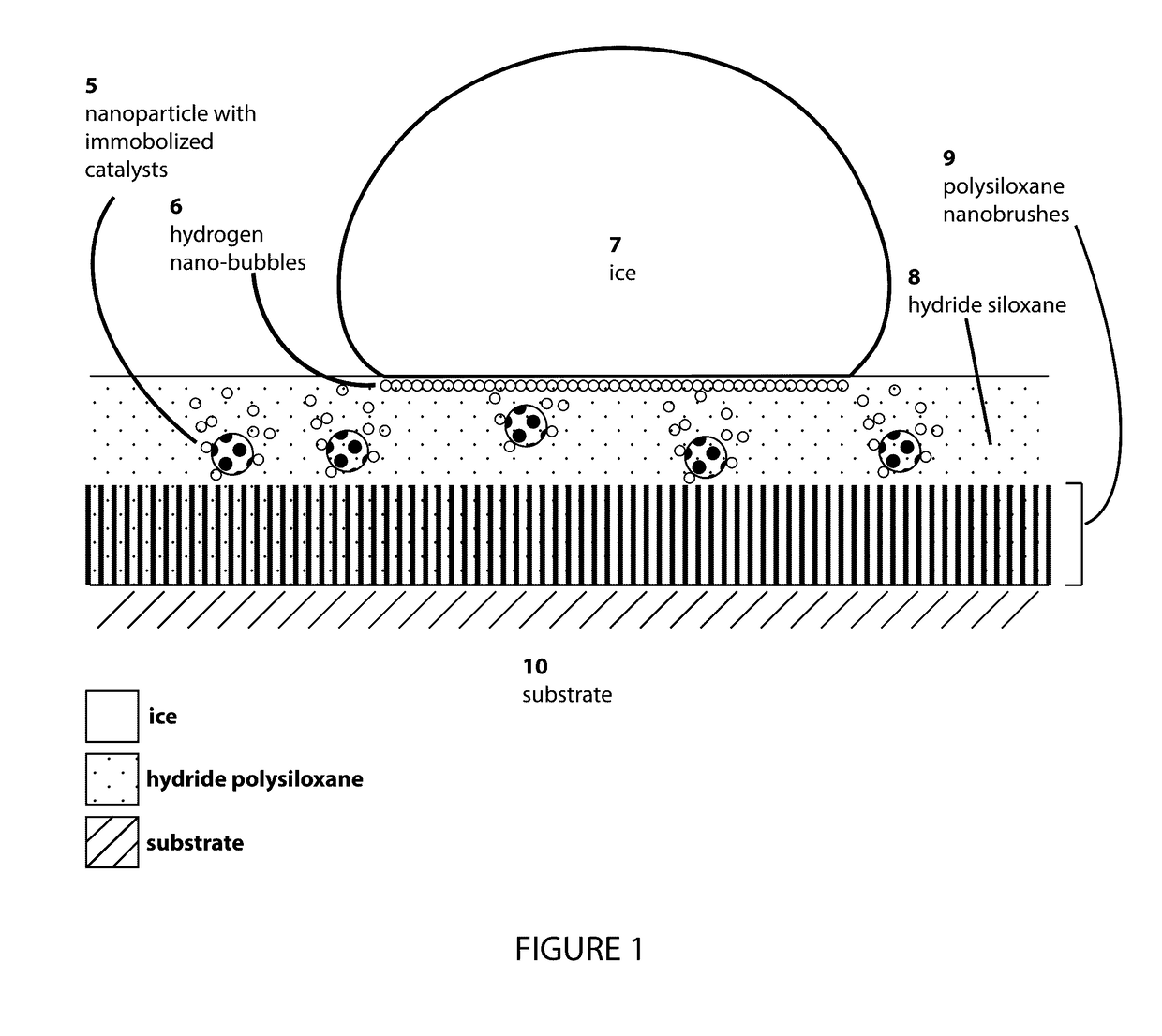

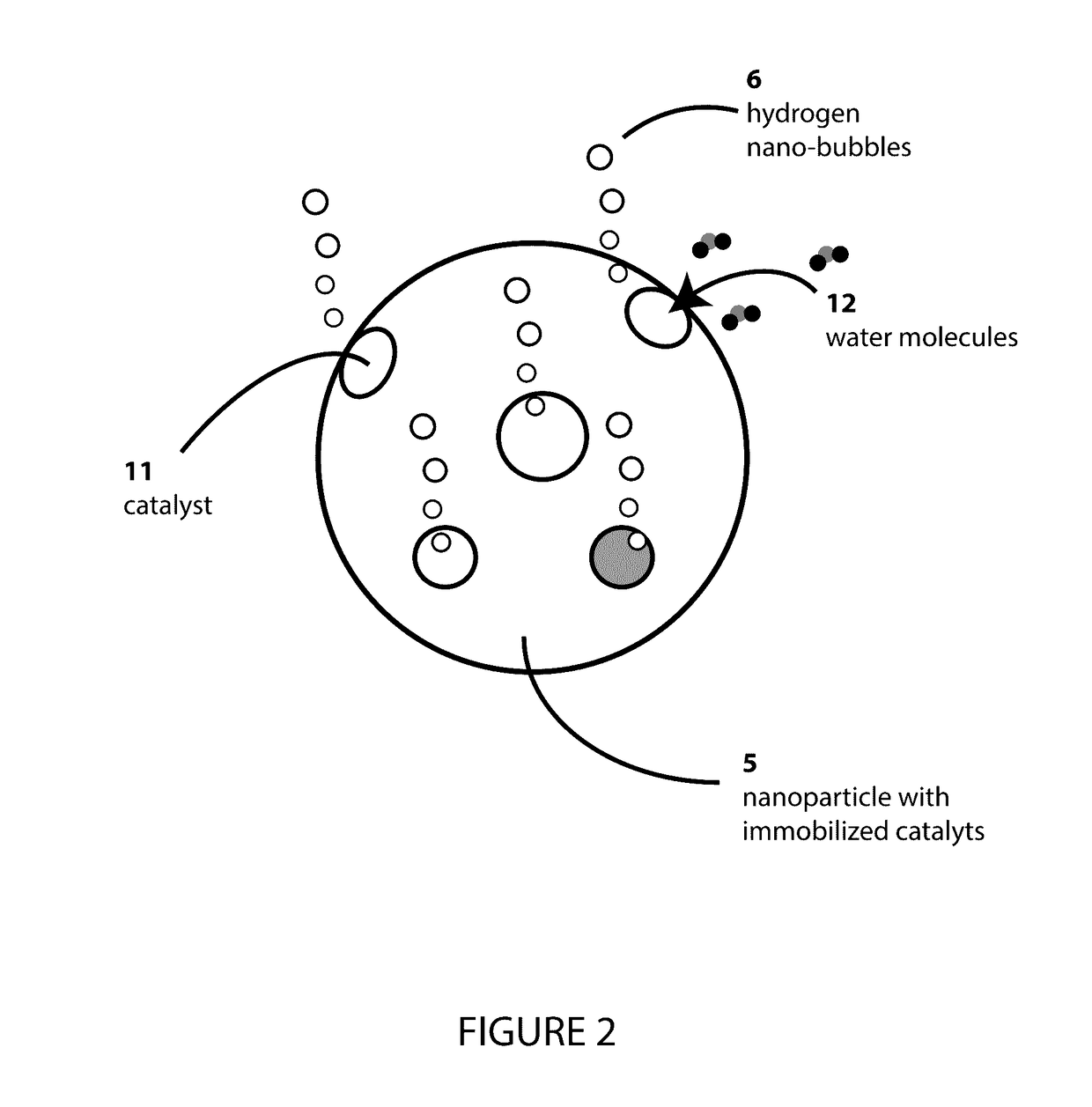

The present invention relates to a self-renewing, anti-icing composition driven by a dehydrogenative reaction of a reactive hydrogen-rich compound catalyzed by nanoparticle immobilized catalysts, which is active under subzero temperatures. The disclosed coating displays a variety of properties including, but not limited to hydrophobicity, anti-wetting, and resistance to ice formation and ice adhesion. The novel anti-icing coating can be used on glass surfaces requiring optical clarity and transparency and can also be applied to a variety of smooth, roughened, or porous surfaces.

Owner:WANG LIANG +1

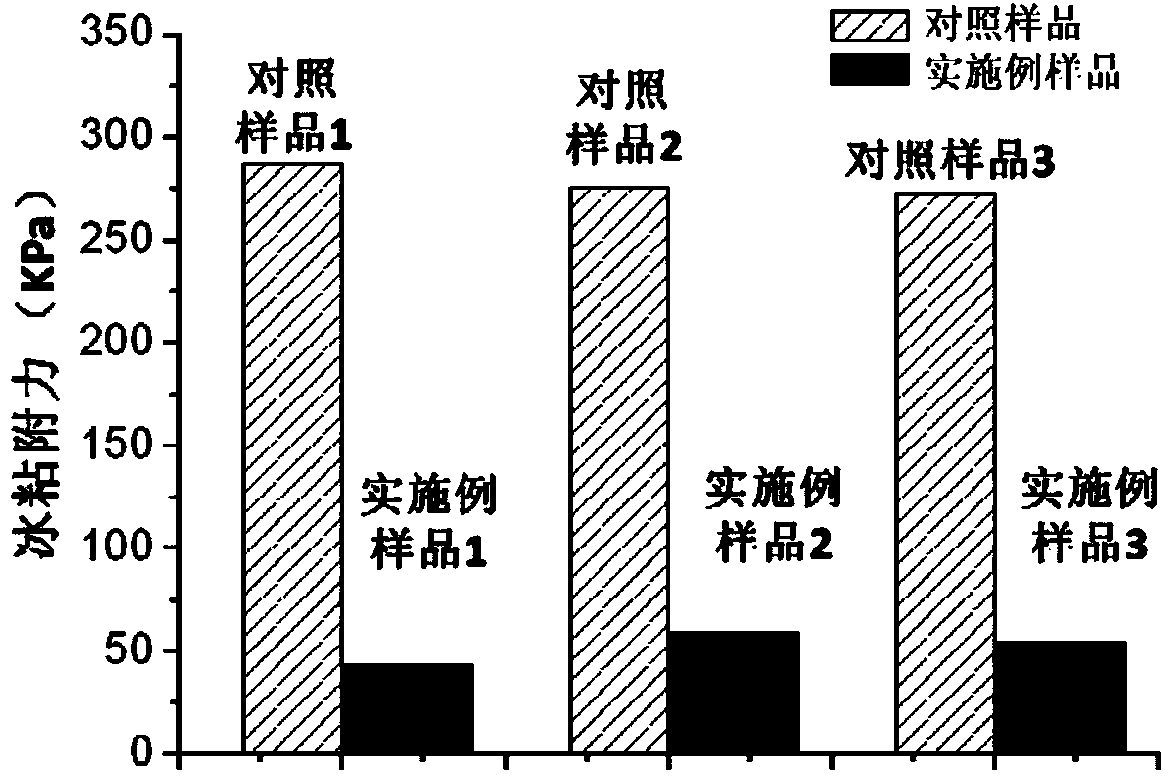

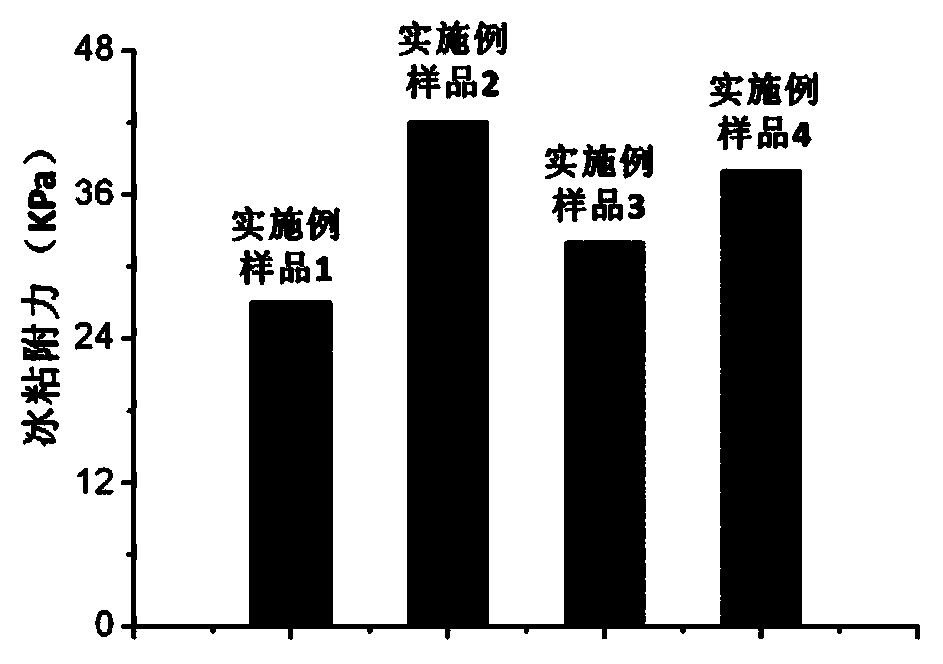

Organic silicon gel anti-ice-covering coating as well as preparation method and application thereof

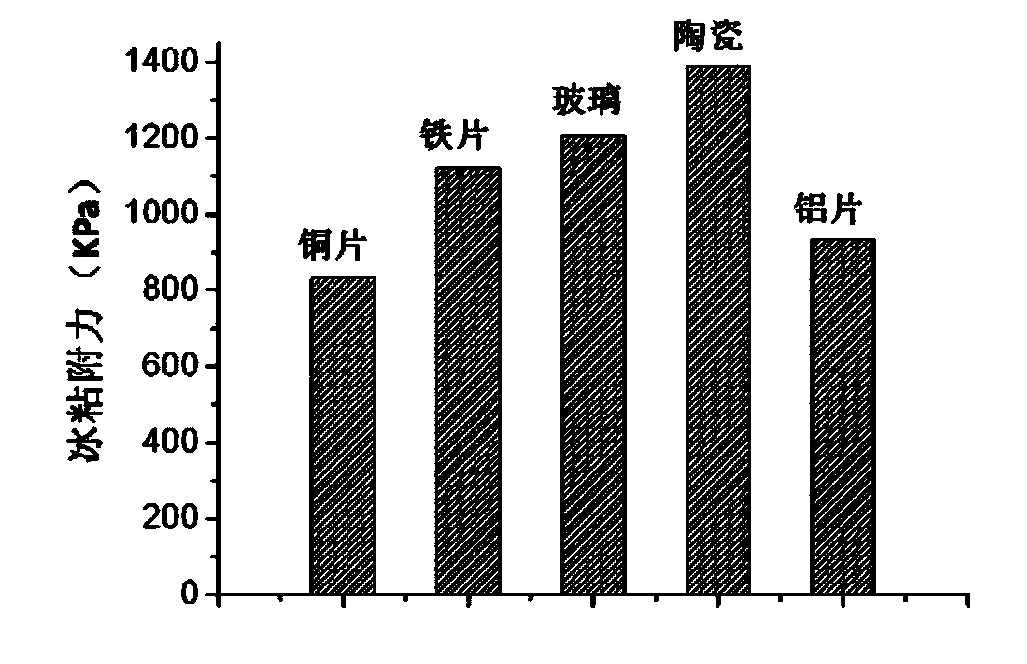

InactiveCN104212339ALow ice adhesionReduce adhesionOther chemical processesCoatingsSurface engineeringSilicon rubber

The invention belongs to the technical field of material surface engineering, and in particular relates to an organic silicon gel anti-ice-covering coating, and a preparation method and application of the organic silicon gel anti-ice-covering coating. The low-ice-adhesion organic silicon gel anti-ice-covering coating consists of crosslinkable polysiloxane, a crosslinking agent, a catalyst, a promoter, non-volatile hydrophobic liquid and an inorganic material. The preparation method comprises the following steps: performing mixing and uniform ball-milling on polysiloxane, the crosslinking agent, the catalyst, the promoter, the non-volatile hydrophobic liquid and the inorganic material, then coating on a base material, and curing to obtain an anti-ice-covering coating, wherein crosslinkable polysiloxane, the crosslinking agent, the catalyst and the promoter form an organic silicon rubber network by virtue of reaction, and the non-volatile hydrophobic liquid is effectively fixed in the anti-ice-covering coating; gel formed by the non-volatile hydrophobic liquid and the crosslinkable organic silicon rubber network is a main anti-icing functional layer which can delay the surface icing of water and reduce the binding force between an ice layer and a substrate material so as to ensure that the coating surface achieves an anti-ice-covering effect, and the mechanical performance of the anti-ice-covering coating also can be effectively improved.

Owner:STATE GRID CORP OF CHINA +2

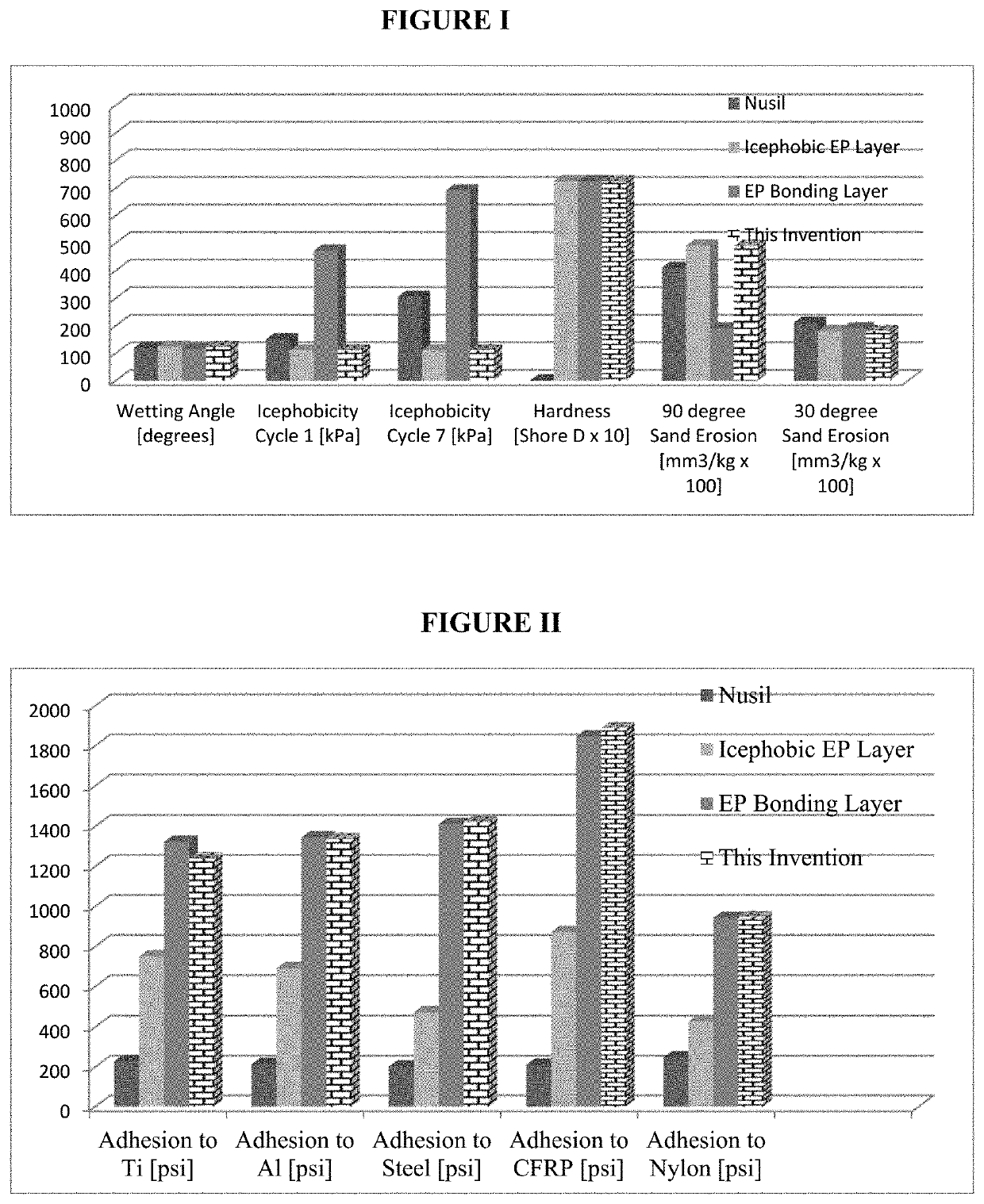

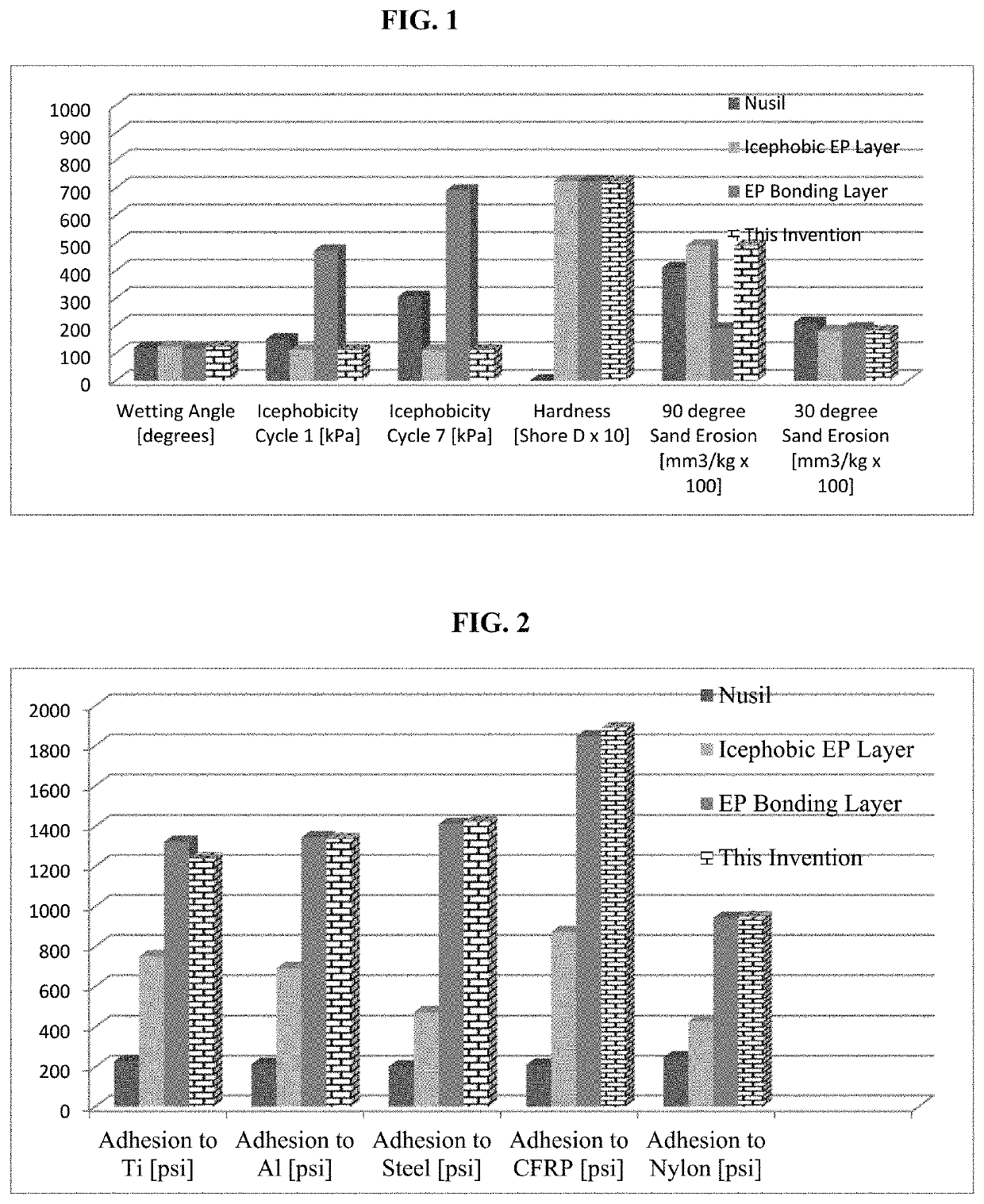

Articles comprising durable icephobic coatings

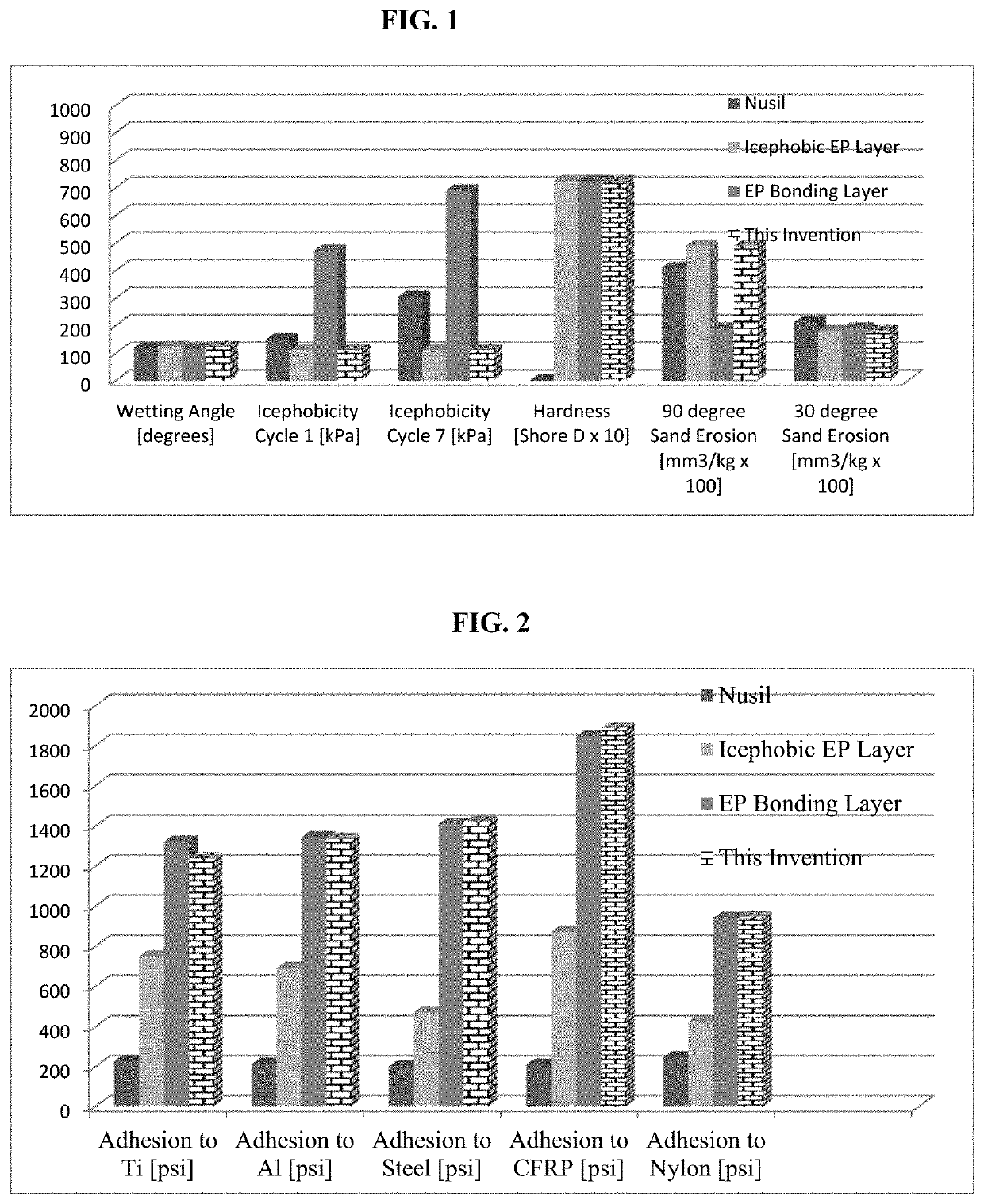

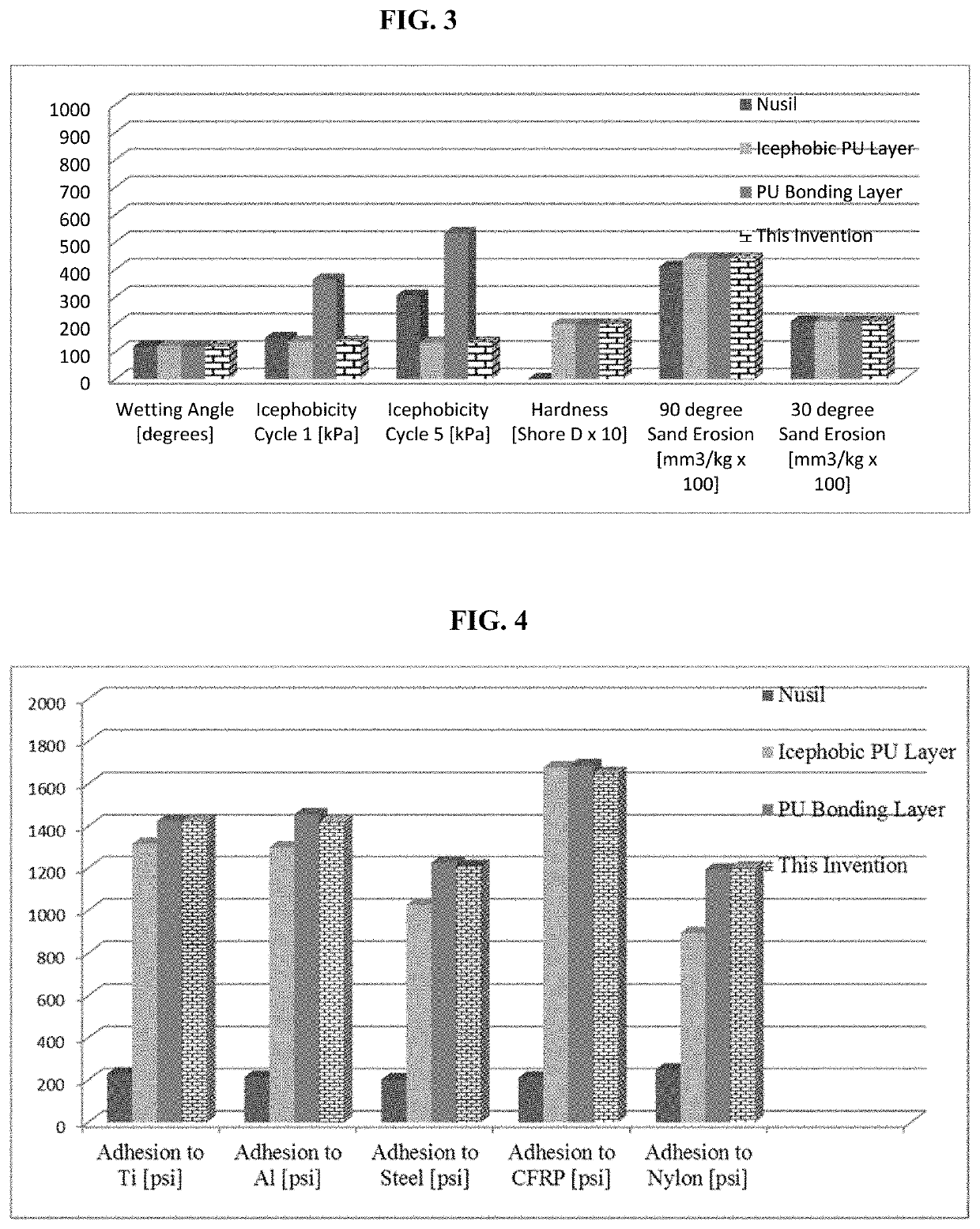

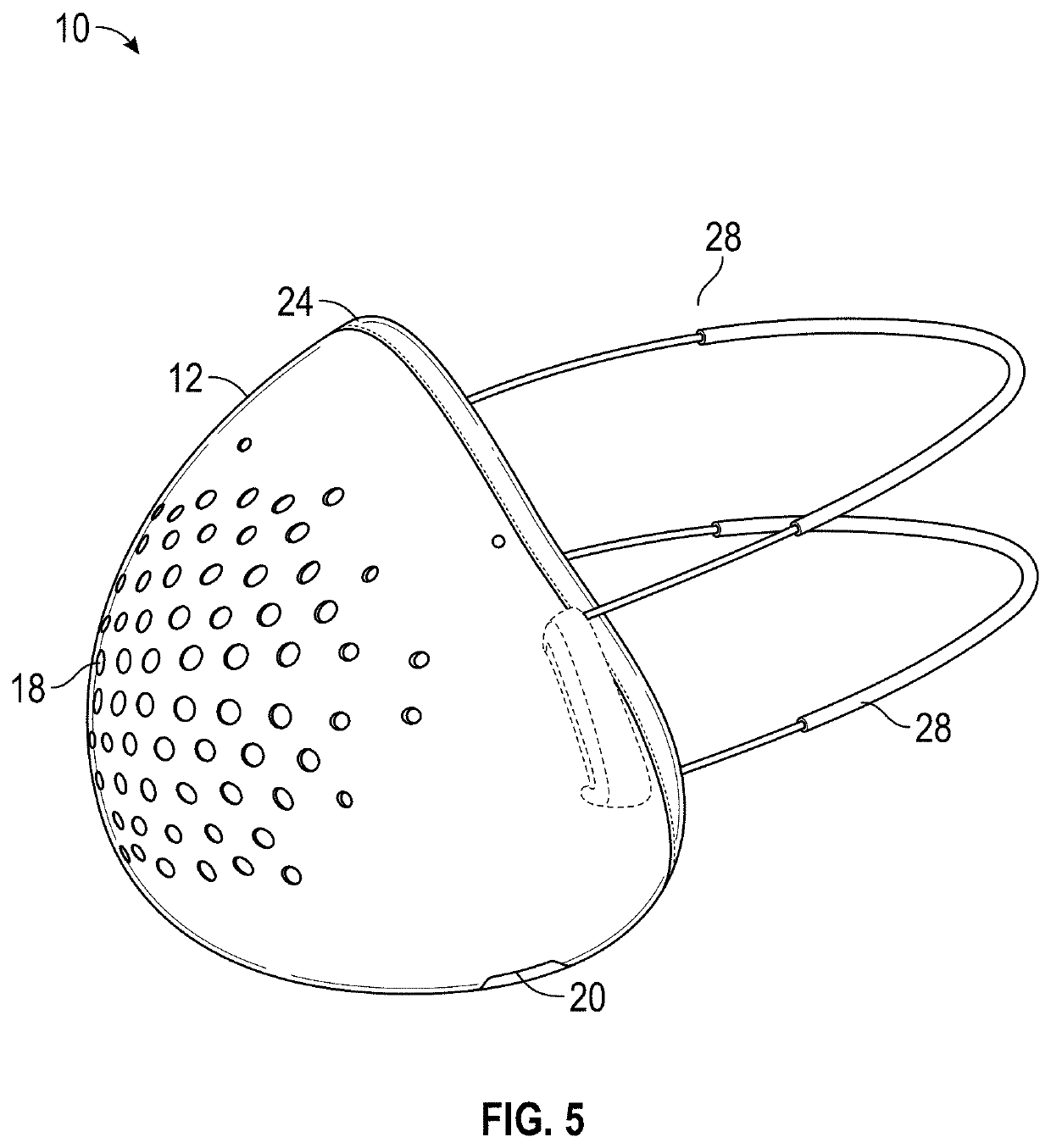

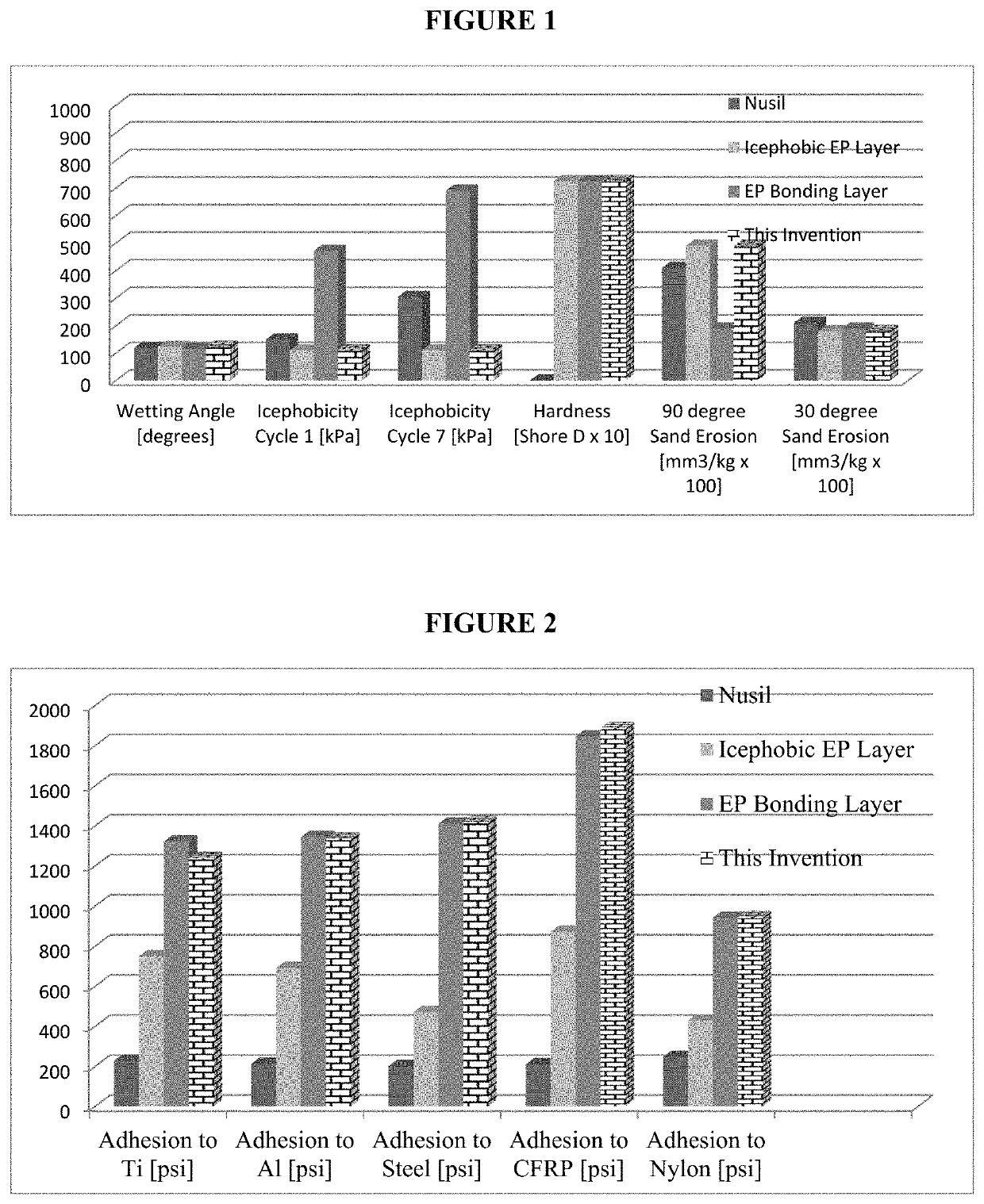

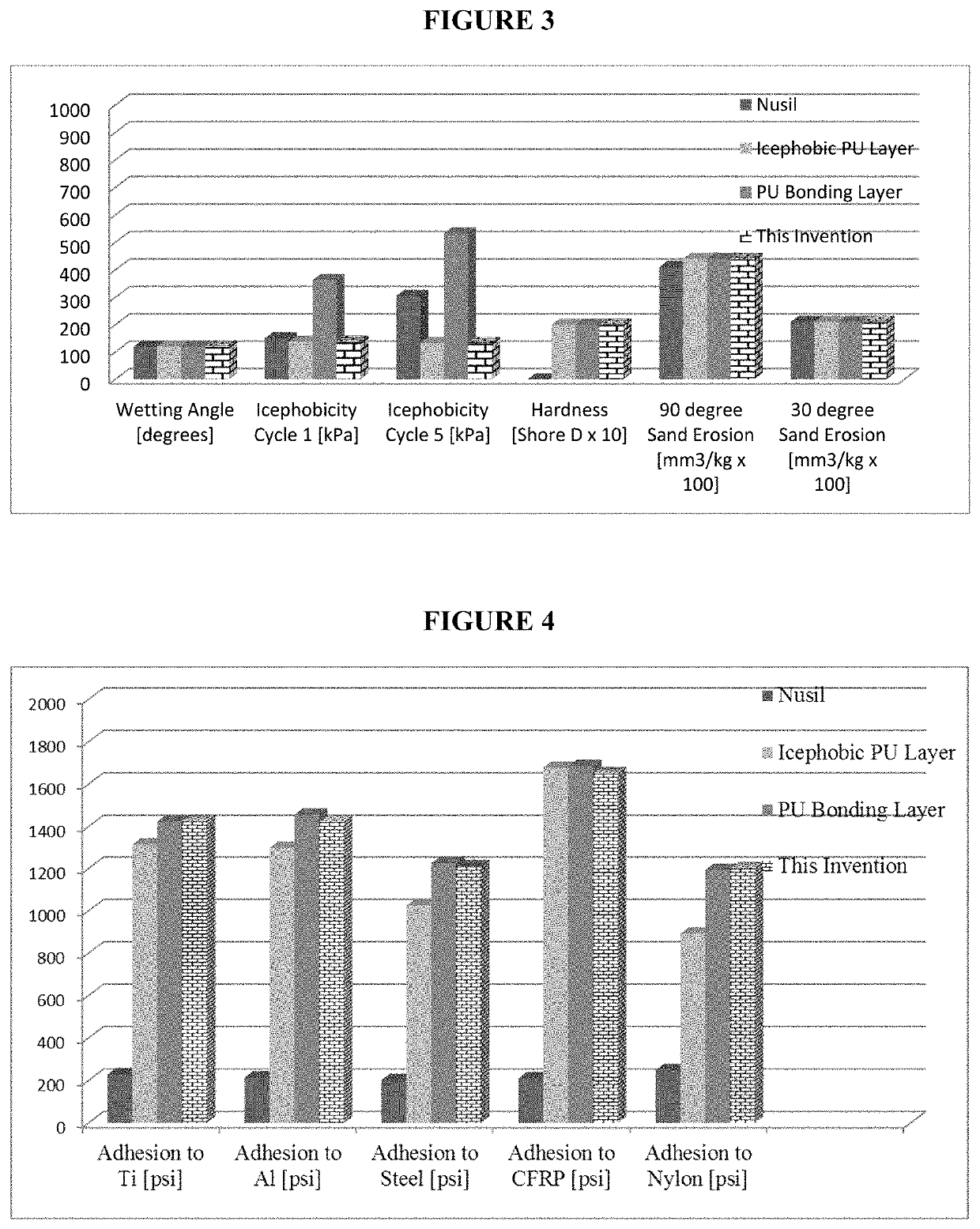

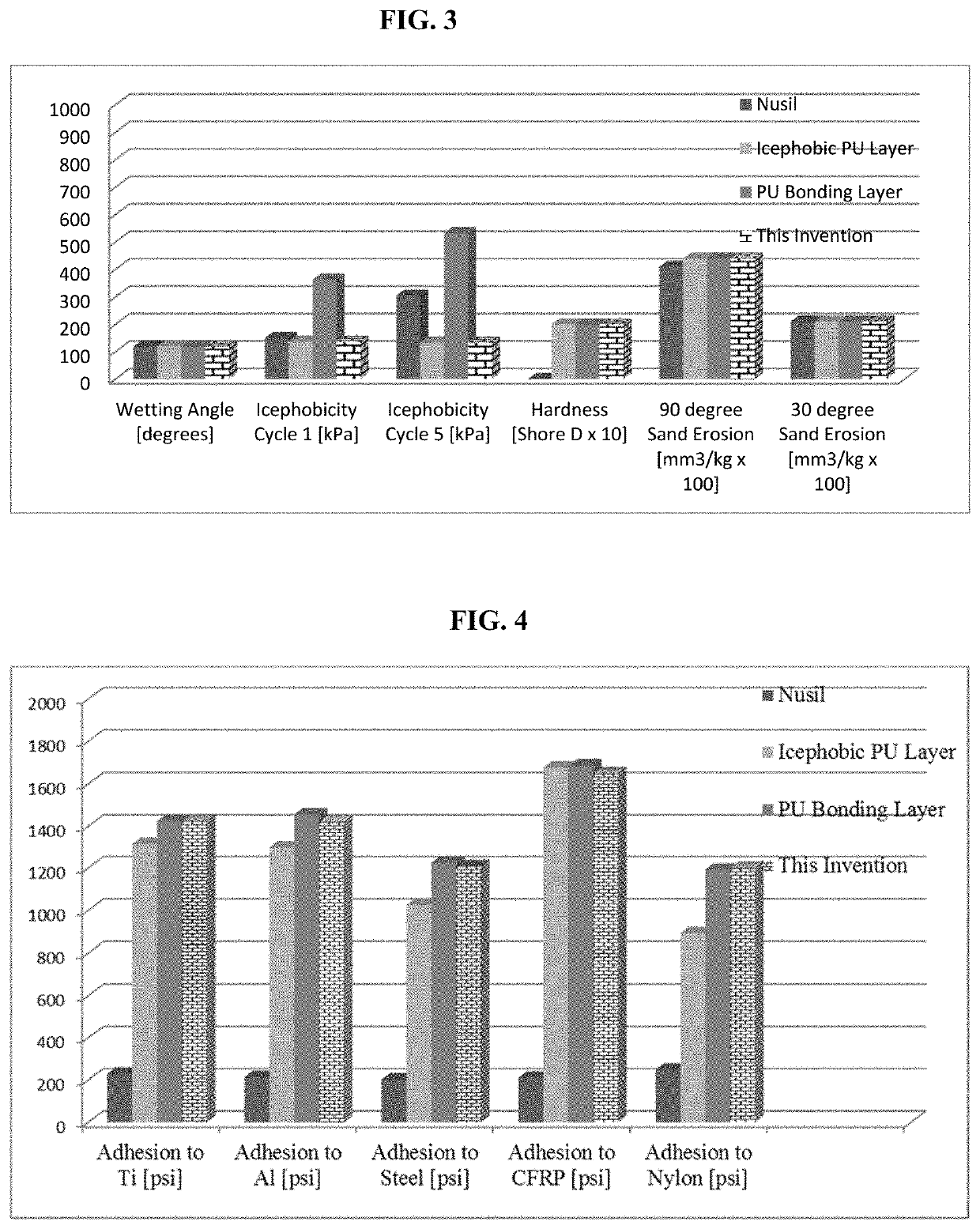

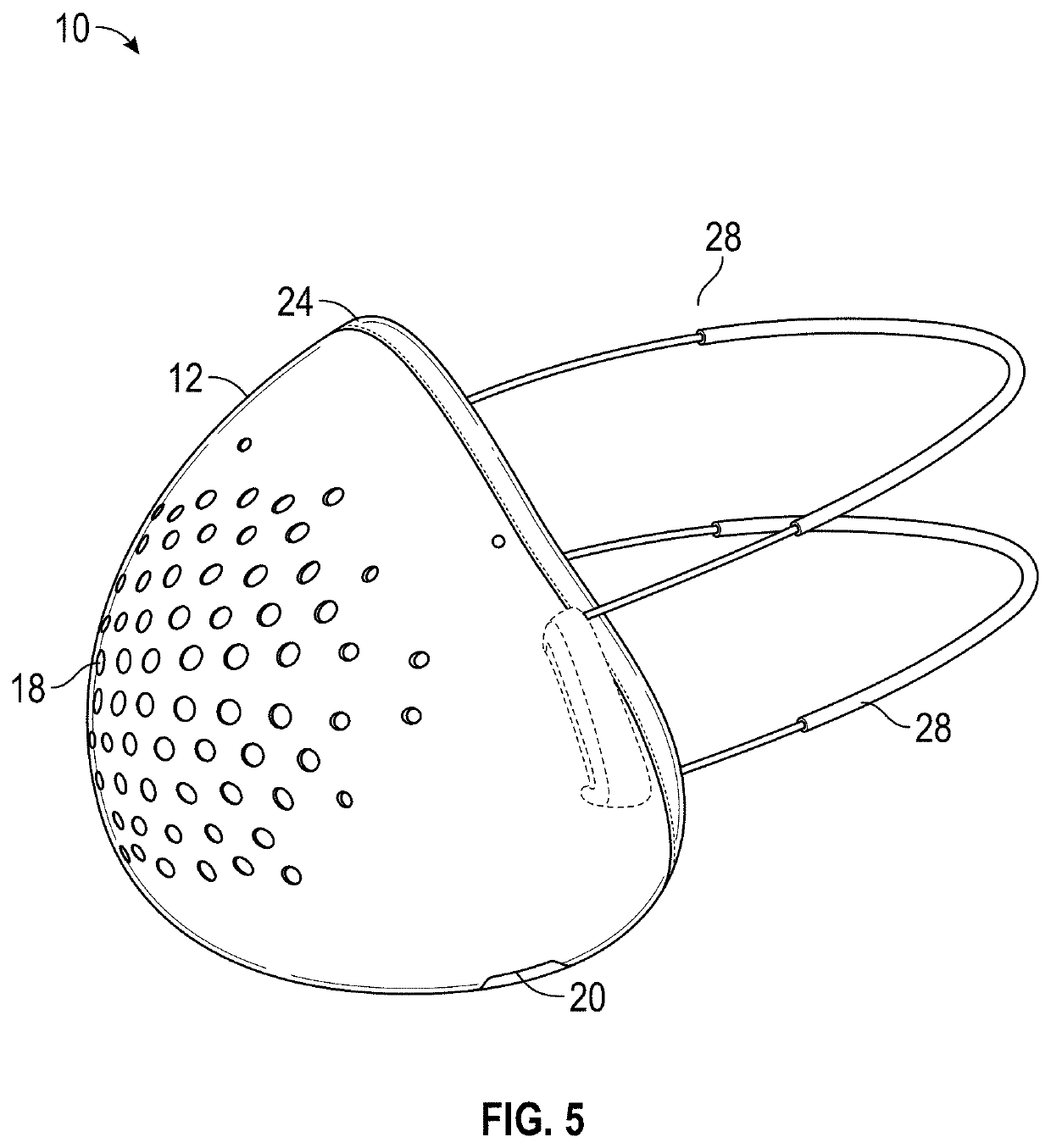

ActiveUS20210017395A1Low ice-adhesion strengthExcellent abrasion resistancePolyurea/polyurethane coatingsThin material handlingPolymer sciencePolymer resin

Articles including durable and icephobic polymeric coatings are disclosed. The polymeric coatings include a bonding layer which may contain a substantially fully cured polymeric resin providing excellent adhesion to metallic or polymer substrates. The polymeric coating further includes an outer surface layer which is smooth, hydrophobic and icephobic and, in addition to a substantially fully cured resin, contains silicone comprising additives near the exposed outer surface. The anisotropic polymeric coatings are particularly suited for strong and lightweight parts required in aerospace, automotive and sporting goods applications. A process for making the articles is disclosed as well.

Owner:INTEGRAN TECH

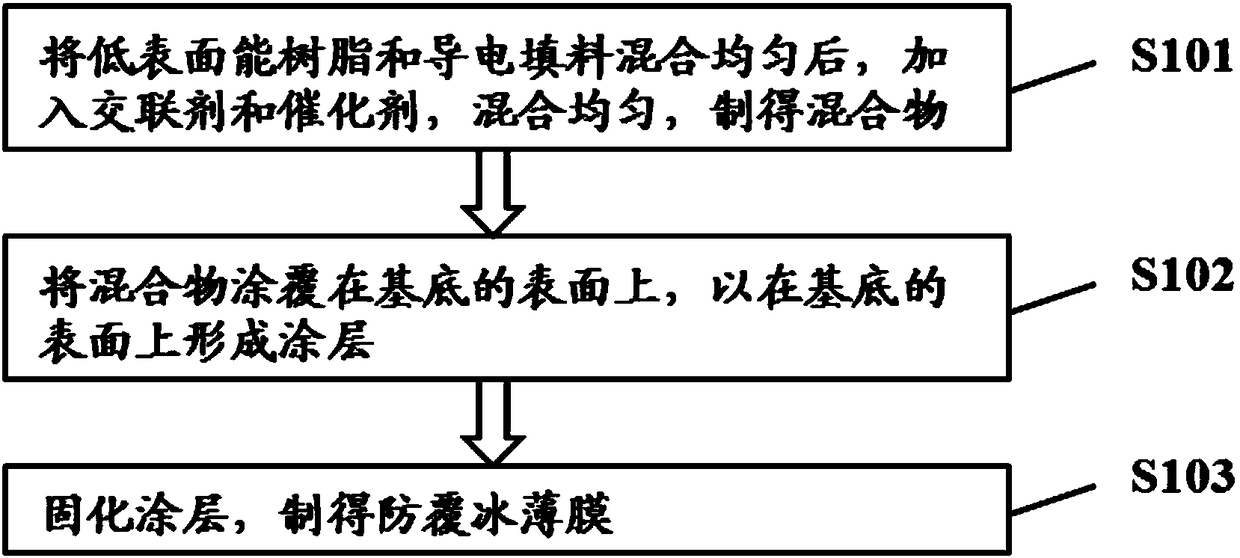

Anti-icing film and preparation method thereof

PendingCN109423197AGood deicing effectExtended service lifeOther chemical processesElectrically-conductive paintsCross-linkAviation

The invention provides an anti-icing film and a preparation method thereof. The method includes the following steps: mixing a certain proportion of low surface energy resin, conductive fillers, a cross-linking agent and a catalyst, and coating and curing to prepare the anti-icing film with low surface energy and capable of powering on to generate heat. The content of each of components is controlled to ensure that the prepared anti-icing film not only has good electrical conductivity, but also can be powered on to generate the heat to de-ice, has certain mechanical strength, and enables the service life to be prolonged. Compared with general anti-icing materials only having an anti-icing or deicing function, the anti-icing film of the invention not only has low ice adhesion strength and good anti-icing effect, but also enables the deicing effect to be achieved by powering on and heating the film after the surface of the film ices up. The preparation method provided by the invention issimple, is easy to operate and popularize, is low in cost, and can be used for an air conditioning refrigeration shell, a power transmission line, fan blades, aviation equipment, and the like.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

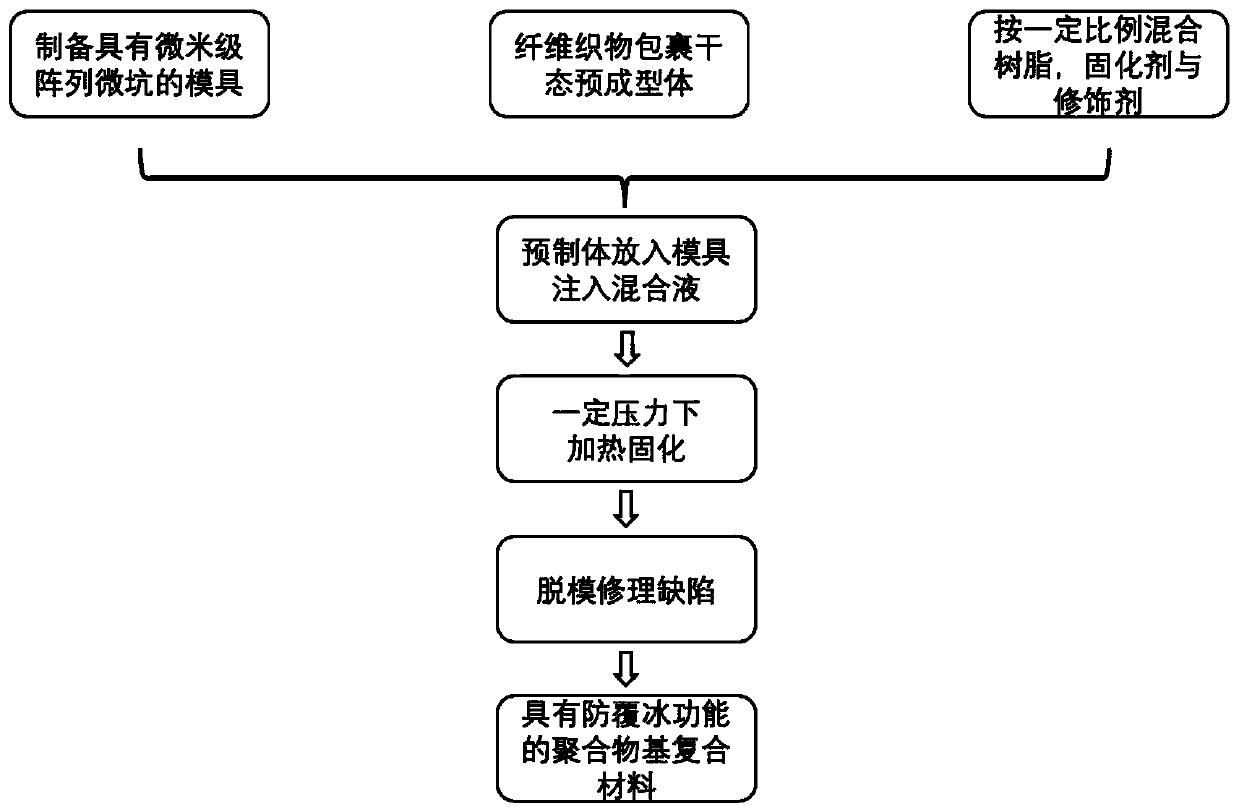

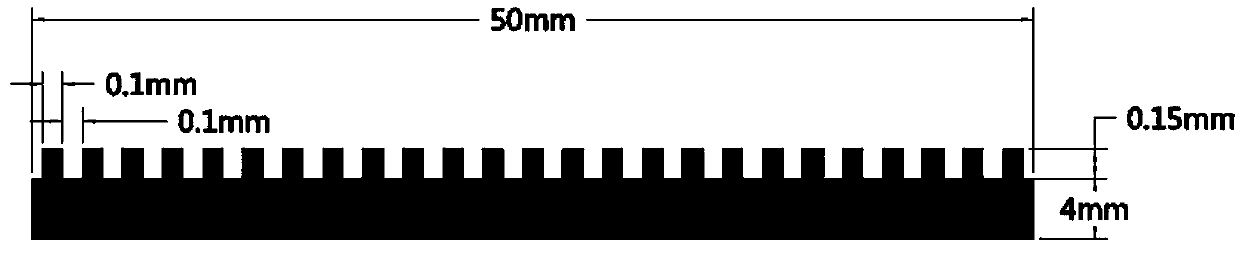

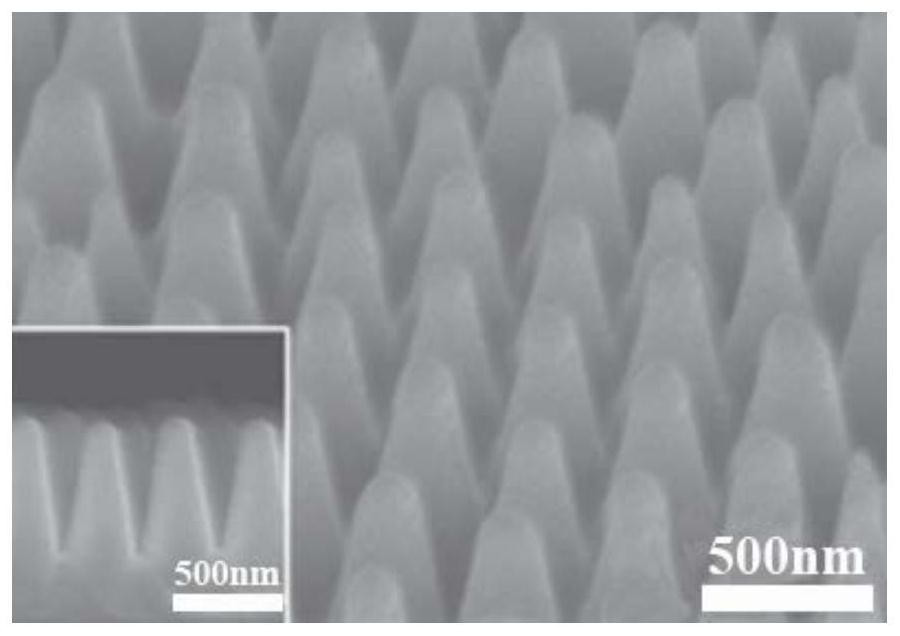

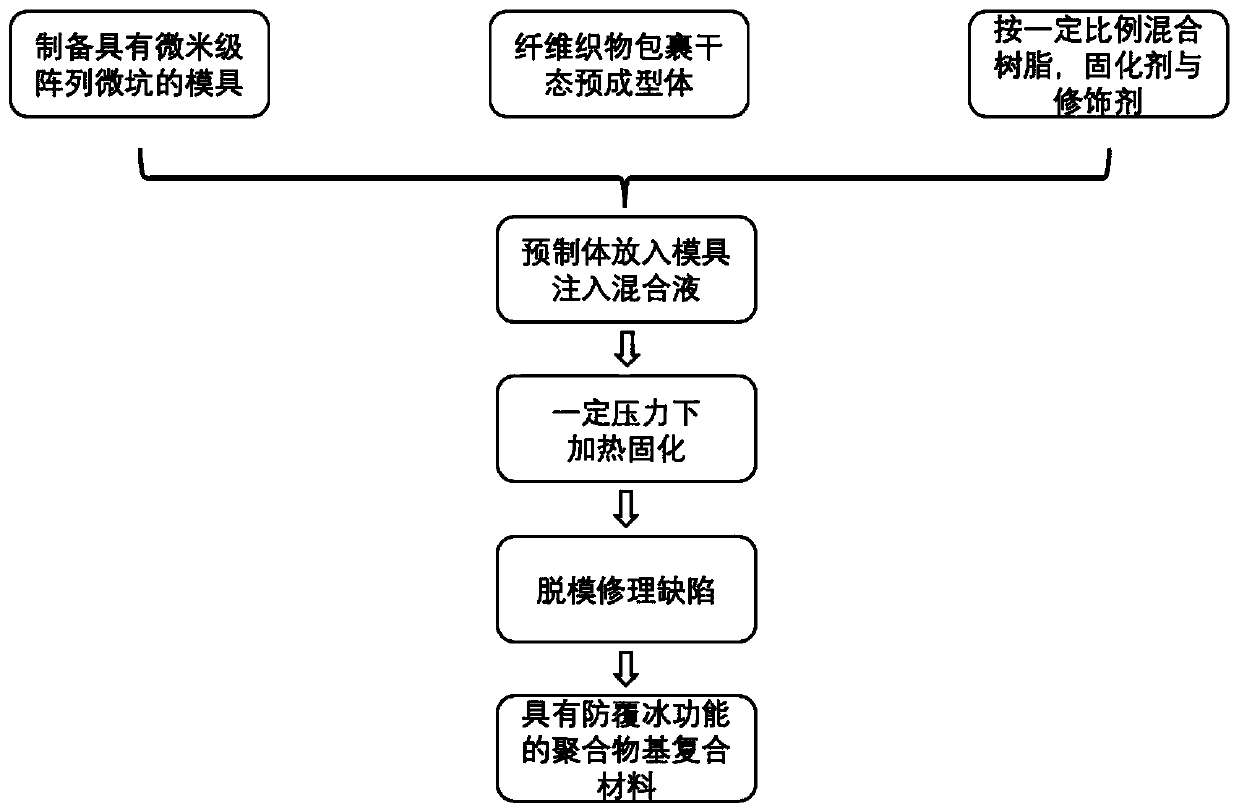

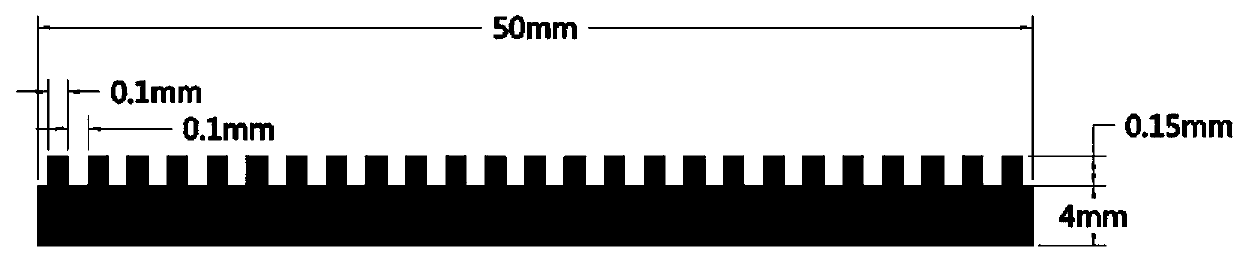

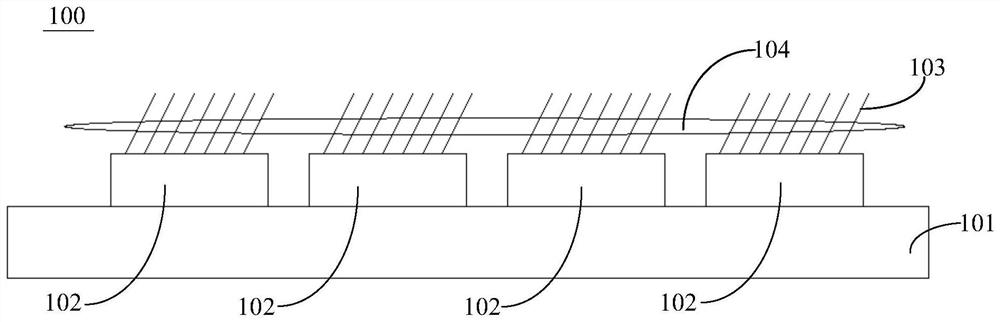

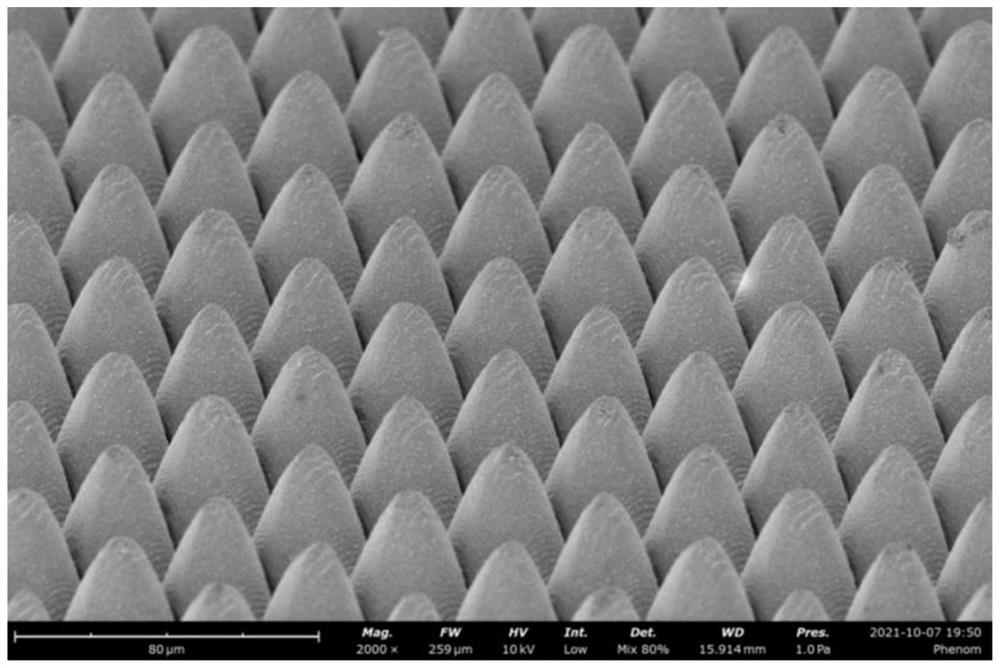

Polymer material with covering ice preventing function and integrated forming method thereof

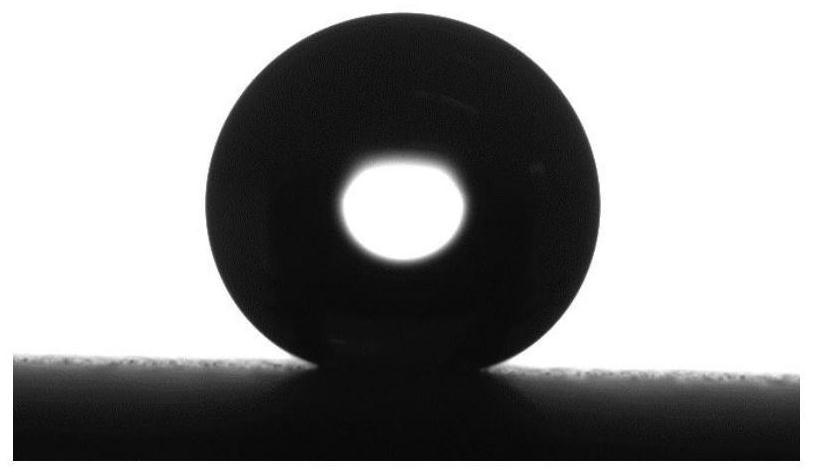

ActiveCN109822950AWith anti-icing functionEvenly distributedDomestic articlesWind forcePolymer substrate

The invention discloses an integrated forming method of a polymer material with a covering ice preventing function. By designing the mold surface structure and adjusting the forming hot-pressing parameters of a composite material, integrated forming of a covering ice preventing function structure and a polymer-based material is achieved. The polymer material with the covering ice preventing function and the integrated forming method thereof have the following advantages that the two functions of preparation of the polymer-based material and integration of the covering ice preventing micro-structure on the material are finished at the same time; compared with the traditional technology, operation is simple, the structure forming property is good, and the micro-structure distribution is uniform; the prepared polymer material has the surface with the super-hydrophobicity to the liquid-state water, the freezing time of supercooling liquid drops is prolonged remarkably, and thus the supercooling liquid drops have enough time to leave the surface; and the ice adhesion strength is extremely low, the covering ice can be separated from the material surface under the action of natural wind force or gravity, and the polymer material can be used for covering parts, which are exposed in the extreme environment, on the outer surface of machine equipment and has the important practical significance to the ice preventing and removing technological development of a wind power machine and an airplane.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

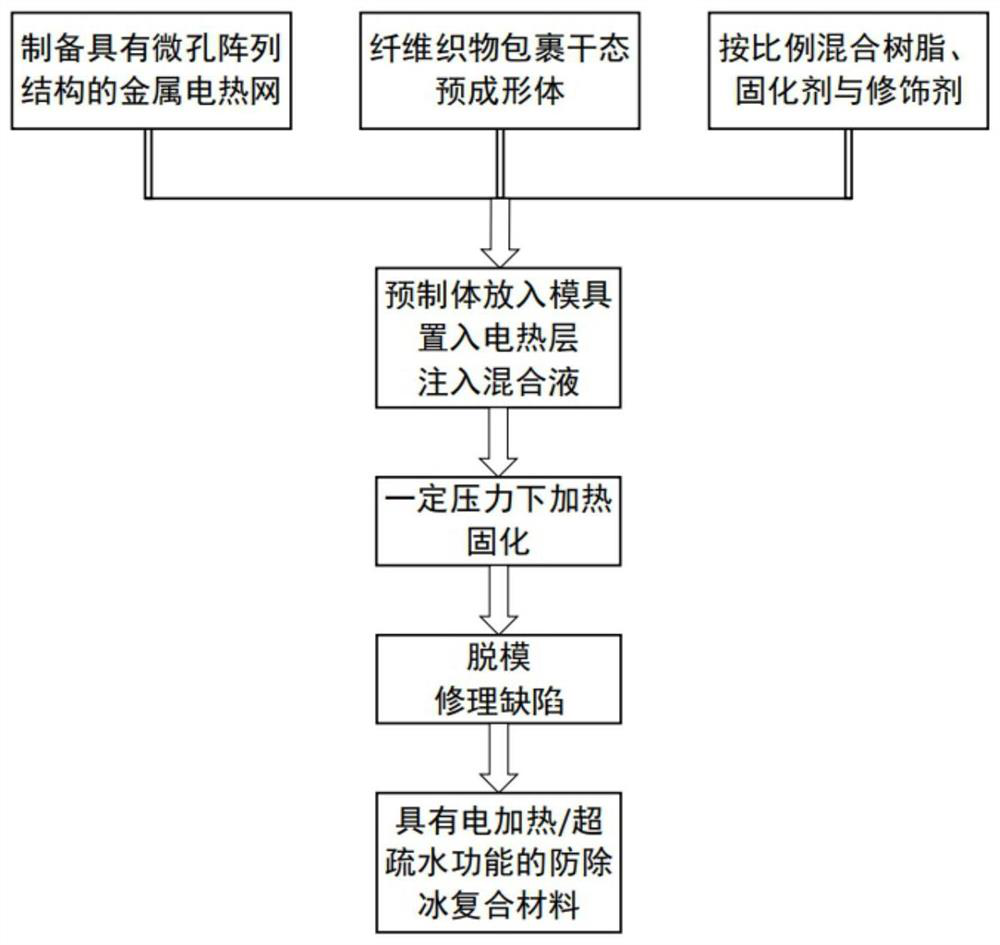

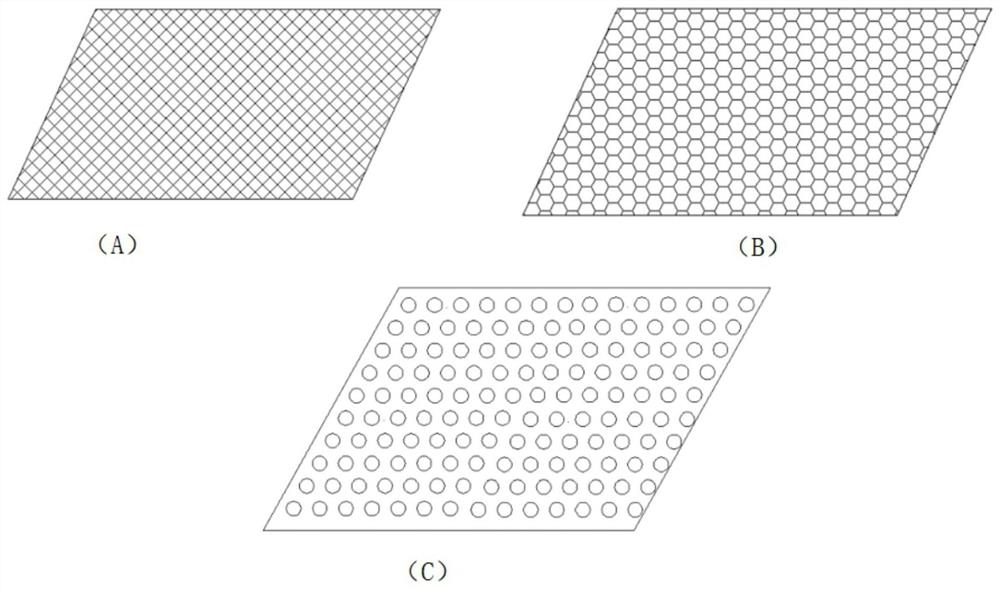

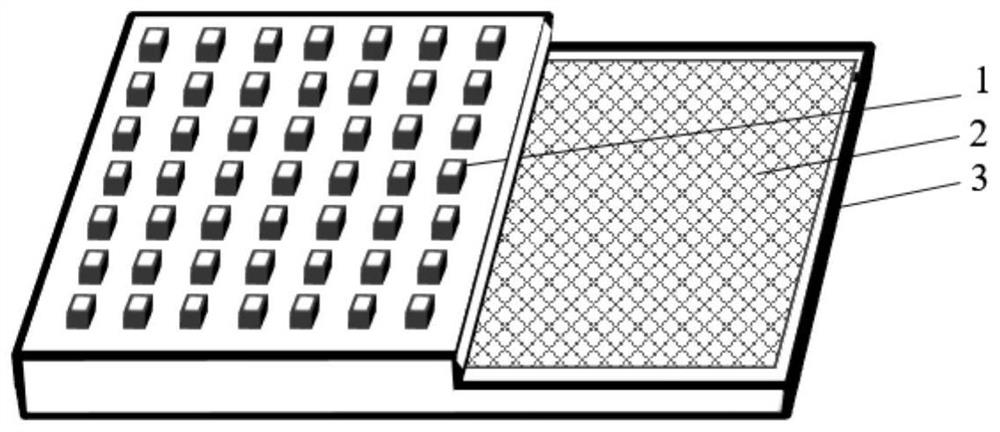

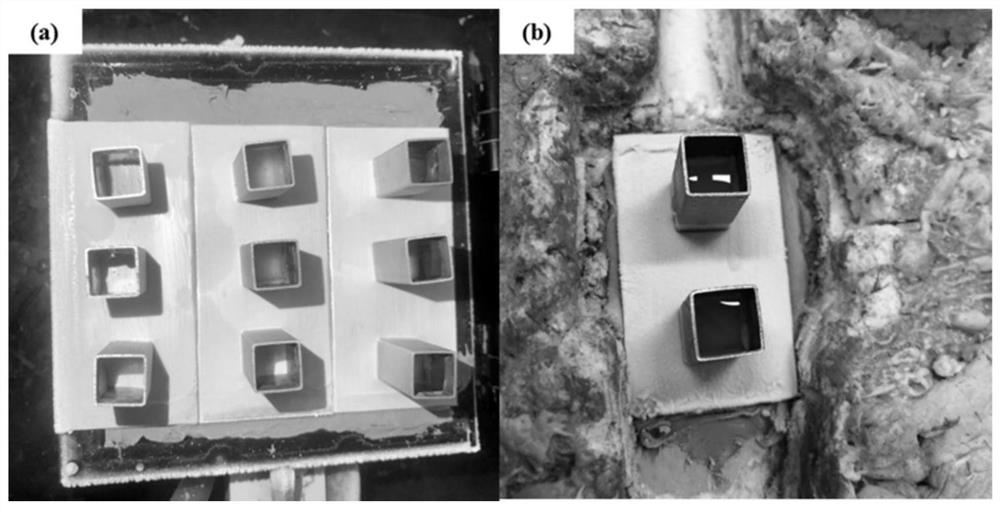

Anti-icing and de-icing composite material with electric heating/super-hydrophobic function and preparation method of anti-icing and de-icing composite material

InactiveCN113246560AEasy to operateGood structural formabilityOther chemical processesSynthetic resin layered productsHigh energyPolymer

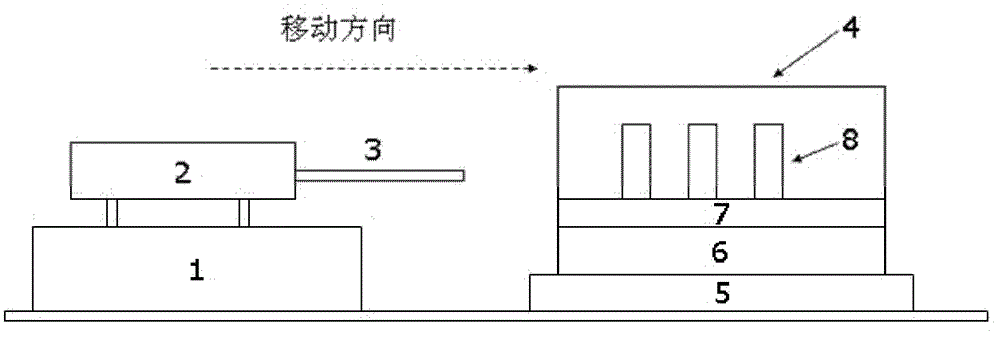

The invention provides an anti-icing and de-icing composite material with an electric heating / super-hydrophobic function and a preparation method of the anti-icing and de-icing composite material. The composite material comprises a super-hydrophobic layer (1), an electric heating grid layer (2) and a base layer (3) from top to bottom in sequence; the electric heating grid layer (2) is a mesh metal template with a micropore array; the electric heating grid layer (2) is coated in the base layer (3); and the base layer (3) is formed by a polymer mixture. The invention also relates to a preparation method of the composite material. Compared with traditional single active deicing or passive anti-icing, passive anti-icing and active anti-icing are combined, ice attached to the surface of the composite material can be rapidly removed, and the problem of high energy consumption caused by single electric heating deicing is solved. The anti-icing and de-icing composite material prepared by the method is higher in anti-icing and de-icing efficiency, can be used for covering parts on the outer surfaces of various machinery equipment in various service environments, and is of great significance to the development of an efficient anti-icing and de-icing technology.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

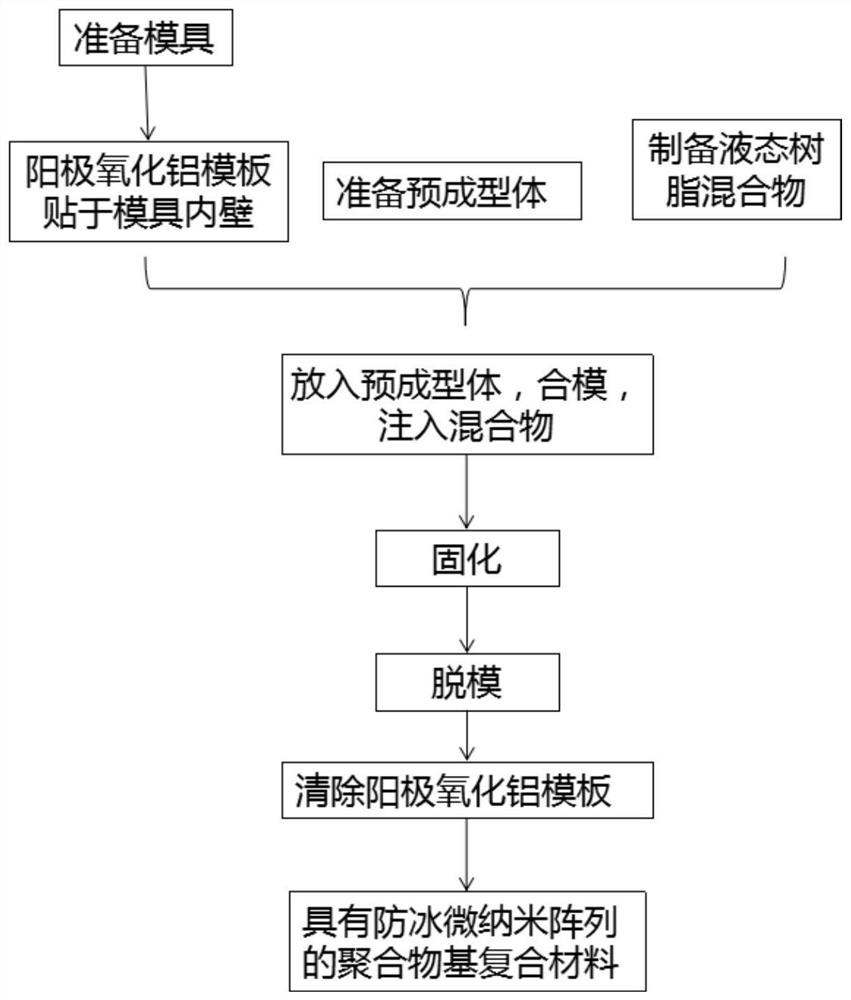

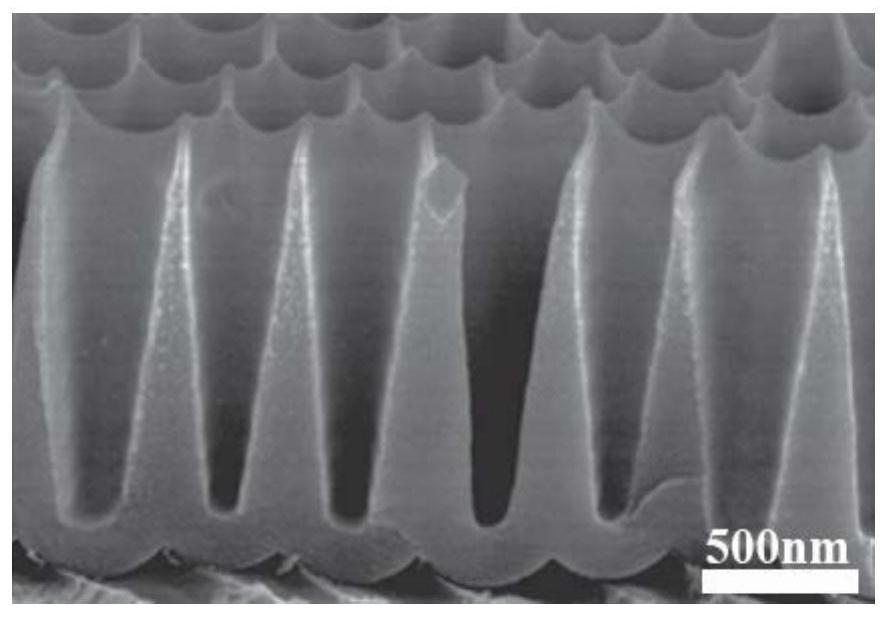

Forming method of anti-icing array structure on surface of thermosetting resin-based composite material

PendingCN111907090AWon't breakAvoid destructionFinal product manufactureDomestic articlesNano structuringLiquid water

The invention relates to a forming method of an anti-icing array structure on the surface of a thermosetting resin-based composite material. An anti-icing array on the surface of the thermosetting resin-based composite material is prepared by designing an anodic aluminum oxide template structure and adjusting forming parameters of the composite material. The forming method has the beneficial effects that the forming method of the anti-icing array structure on the surface of the thermosetting resin-based composite material is simple in manufacturing process, the manufactured composite materialis complete in surface micro-nano structure, stable in size and high in structural consistency, the super-hydrophobic characteristic is achieved on liquid water, the super-cooled liquid drop icing time can be remarkably prolonged, and supercooled liquid drops have enough time to be separated from the surface; the extremely low ice adhesion strength is achieved, and an ice coating can fall off fromthe surface under the action of natural wind or gravity; and the anti-icing array structure can be used for machine outer surfaces such as aircrafts and wind driven generator blades which are exposedin an extreme environment, and important significance on development of ice prevention and removal technologies of equipment such as wind driven generators, novel high-speed railway motor train unitsand airplanes, in particular to passive ice prevention and removal technologies is achieved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

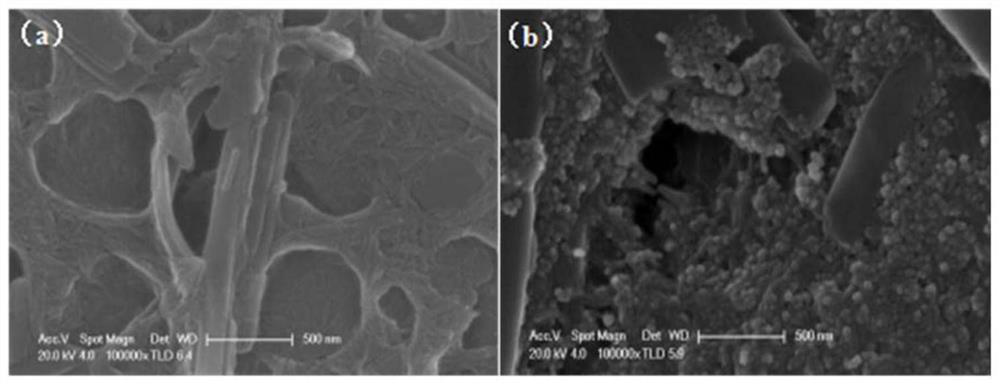

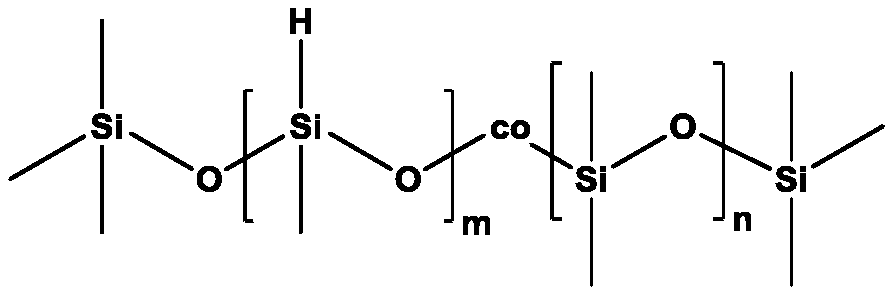

Liquid-filled porous silicon resin anti-icing material and preparation method thereof

The invention discloses a liquid-filled porous silicon resin anti-icing material and a preparation method thereof. A fluorosilane-modified porous silicon resin and fluorine-containing liquid composite layer is combined on a base material of the liquid-filled porous silicon resin anti-icing material, wherein the fluorine-containing liquid is filled in the fluorosilane-modified porous silicon resin, and the porous silicon resin is obtained by uniformly mixing an inorganic silicon or organic silicon raw material, a catalyst solution and organic nanoparticle in a solvent to form a mixed solution, directly coating the mixed solution on the surface of the base material, and removing the organic nanoparticle after drying and curing the coating; the fluorine-containing liquid is selected from one or two of liquid perfluorocarbon and liquid fluorosilicone; the fluorine-containing liquid has a viscosity range of 0.1-500cm<2> / s at the room temperature; and the average particle size of the organic nanoparticle is 50-800nm. When the environment temperature and the environment humidity can cause the base material to ice, the surface of the liquid-filled porous silicon resin can prevent subcooled water from contacting the base material, and a liquid lubricating material can be used for greatly descending the adhesive power of the ice layer and is easy to separate from the surface under the action of gravity or wind power. The liquid-filled porous silicon resin anti-icing material can be efficiently acted under the weather conditions such as the environment temperature of 0 to -40 DEG C and the environment humidity of 40%-90%.

Owner:STATE GRID CORP OF CHINA +2

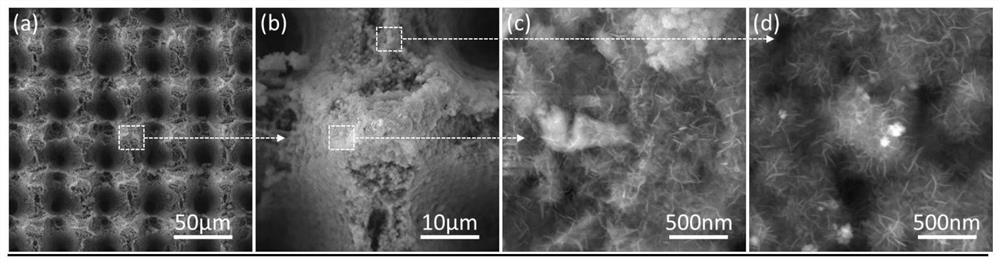

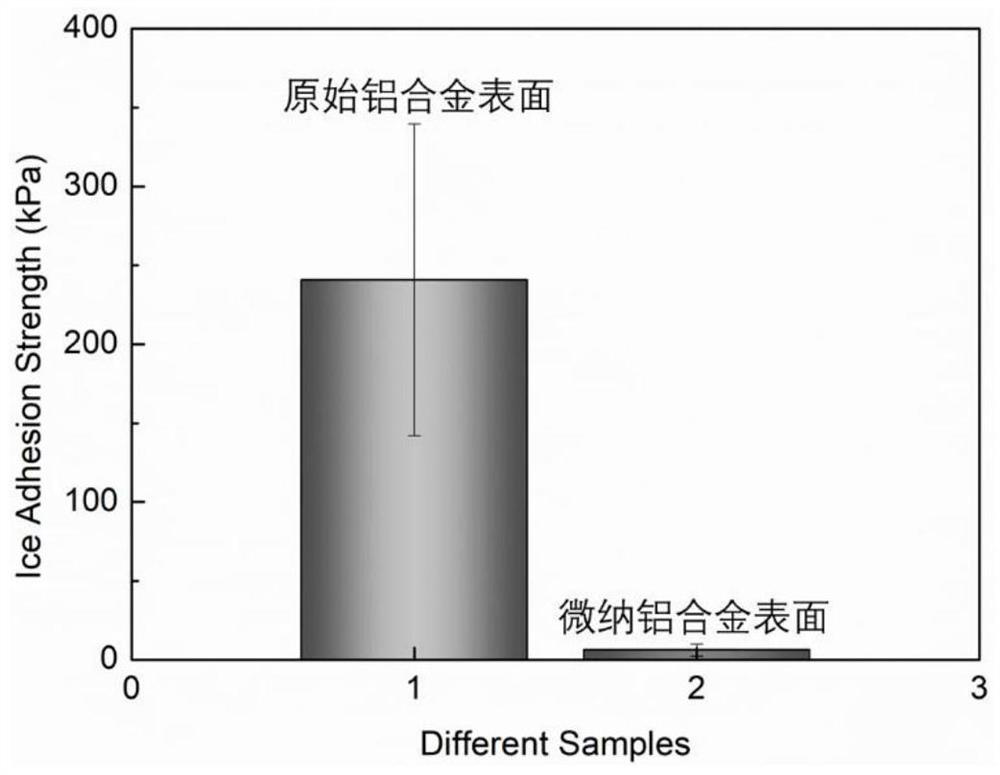

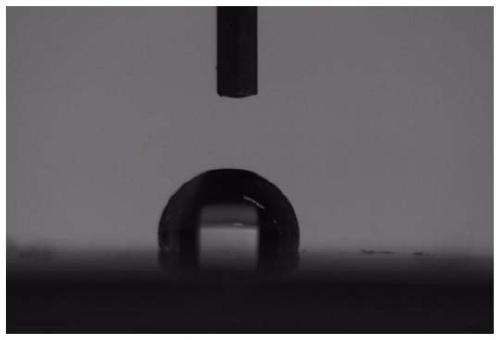

Super-hydrophobic anti-icing aviation aluminum alloy surface and production method

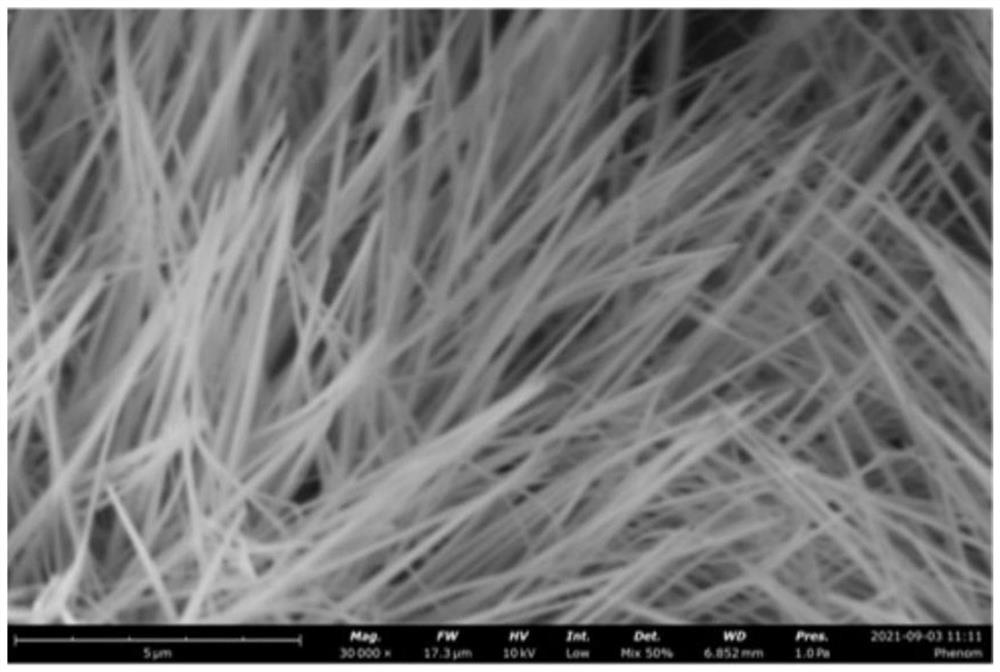

A super-hydrophobic anti-icing aviation aluminum alloy surface with ultralow ice adhesion is composed of a multi-stage micro-nano structure, the micro-nano structure is based on a three-dimensional micron cone structure periodically distributed on the surface of an aluminum alloy base material, and densely-growing nanosheets and nano flower clusters composed of the nanosheets are distributed on the surface of a micron cone; and one or two of submicron spheres and submicron flowers are dispersed and distributed on the surface of the micron cone or between the micron cones. The invention furtherdiscloses a production method of the surface, the surface is formed by combining ultrafast laser ablation and a wet chemical method and then carrying out low-free-energy surface chemical modification, and large-area efficient production can be achieved. The aviation aluminum alloy anti-icing surface has extremely low ice adhesion, adhesion strength between ice and the surface can be as low as 6 kPa, and the ice can automatically fall off under the action of self gravity or slight vibration. The surface structure can be widely applied to anti-icing fields of aviation key components, ships, ground transportation tools, refrigerators, air conditioners and the like.

Owner:TSINGHUA UNIV

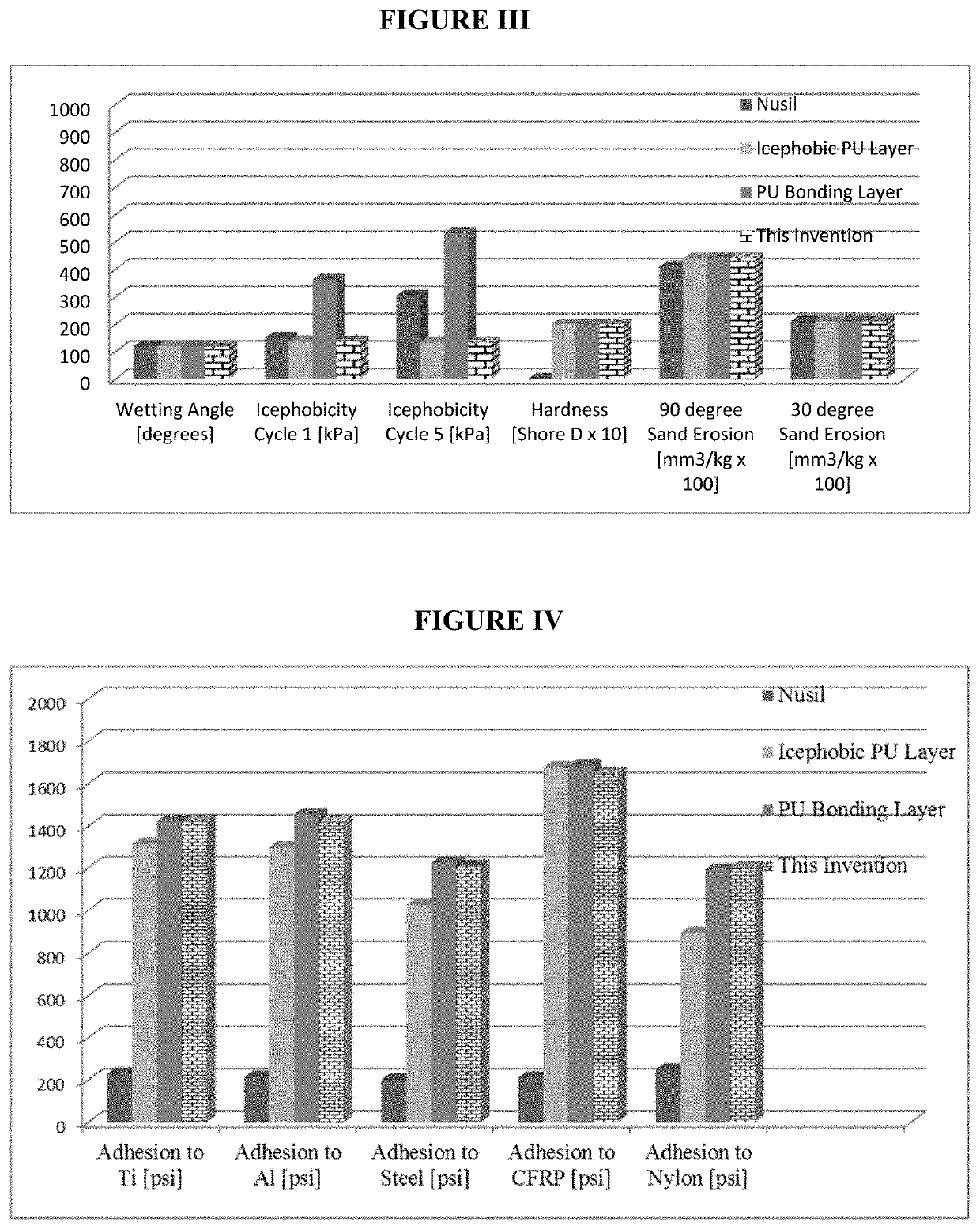

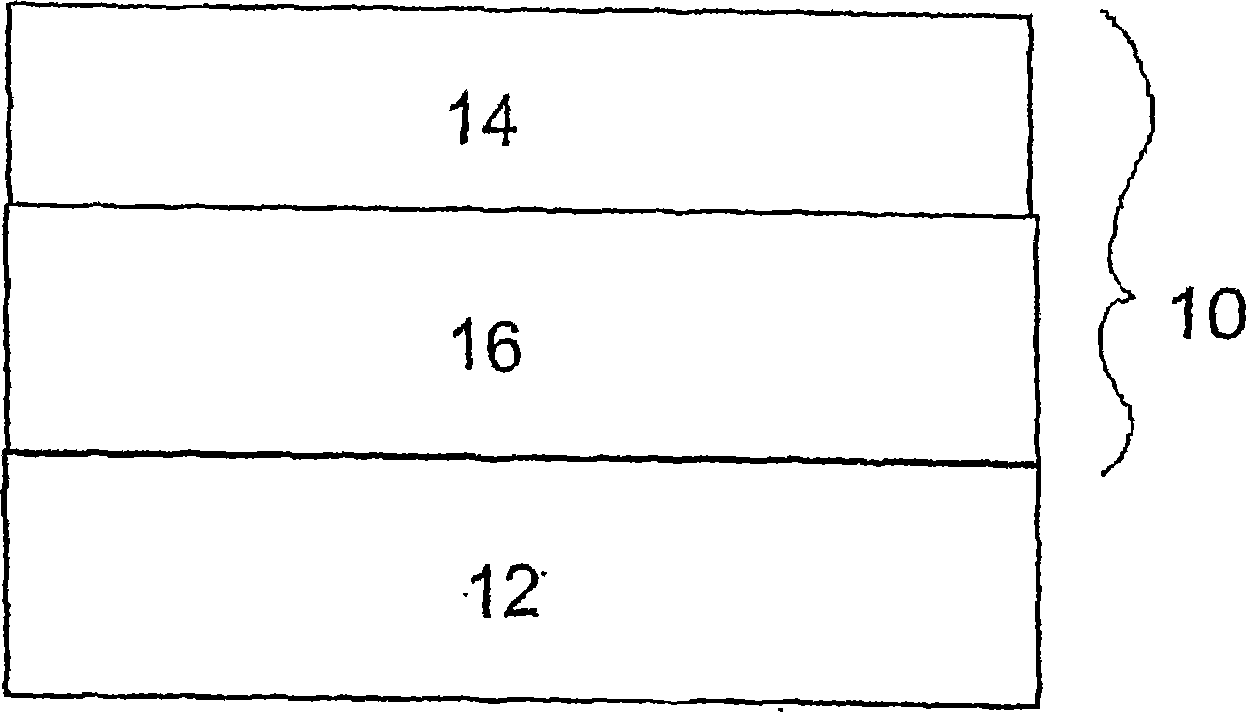

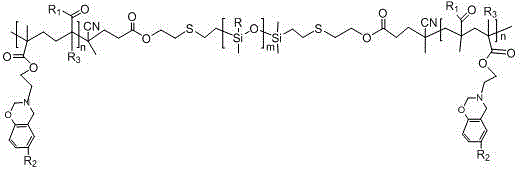

Articles comprising durable water repellent, icephobic and/or biocidal coatings

ActiveUS11312869B2Minimize adverse effectsQuick wearAntifouling/underwater paintsPaints with biocidesPolymer sciencePolymer resin

Articles including durable and icephobic and / or biocidal polymeric coatings are disclosed. The polymeric coatings can include a bonding layer which may contain a substantially fully cured polymeric resin providing excellent adhesion to metallic or polymer substrates. The polymeric coating further includes an outer surface layer which is smooth, hydrophobic, biocidal and icephobic and, in addition to a substantially fully cured resin, contains silicone comprising additives near the exposed outer surface. The anisotropic polymeric coatings are particularly suited for strong and lightweight parts required in aerospace, automotive and sporting goods applications. A process for making the articles is disclosed as well.

Owner:INTEGRAN TECH

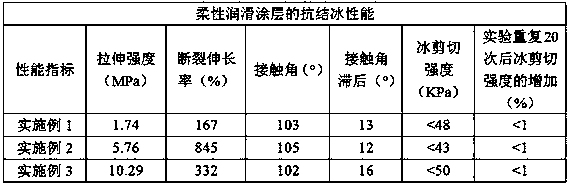

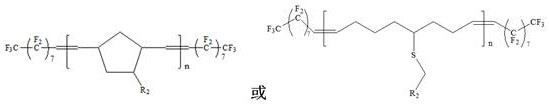

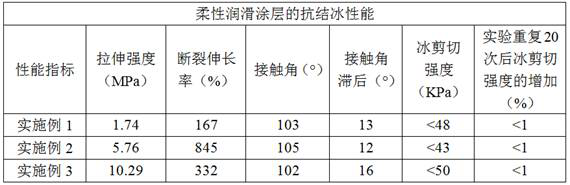

Flexible lubricating coating as well as preparation method and application of flexible lubricating coating

The invention provides a preparation method of a flexible lubricating coating, and the lubricating coating is obtained by uniformly brushing fluorine-containing / organicsilicon flexible molecules on aporous polymer surface. Meanwhile, the invention provides a coating prepared by using the preparation method, and the coating has a superhydrophobic and super-oleophylic lubricating coating with a porous structure. The preparation method of the flexible lubricating coating is simple in operation, technical requirements are low, large-scale preparation is easy to realize, and the flexible lubricating coating has good icing resistance after adsorbing lubricating oil. The invention further provides an application of the flexible lubricating coating to an icing-resistant coating.

Owner:UNIV OF JINAN

Articles comprising durable icephobic coatings

ActiveUS11319450B2Minimize adverse effectsQuick wearPolyurea/polyurethane coatingsThin material handlingPolymer sciencePolymer resin

Articles including durable and icephobic polymeric coatings are disclosed. The polymeric coatings include a bonding layer which may contain a substantially fully cured polymeric resin providing excellent adhesion to metallic or polymer substrates. The polymeric coating further includes an outer surface layer which is smooth, hydrophobic and icephobic and, in addition to a substantially fully cured resin, contains silicone comprising additives near the exposed outer surface. The anisotropic polymeric coatings are particularly suited for strong and lightweight parts required in aerospace, automotive and sporting goods applications. A process for making the articles is disclosed as well.

Owner:INTEGRAN TECH

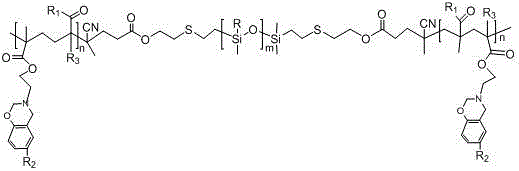

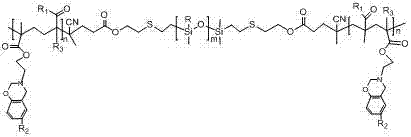

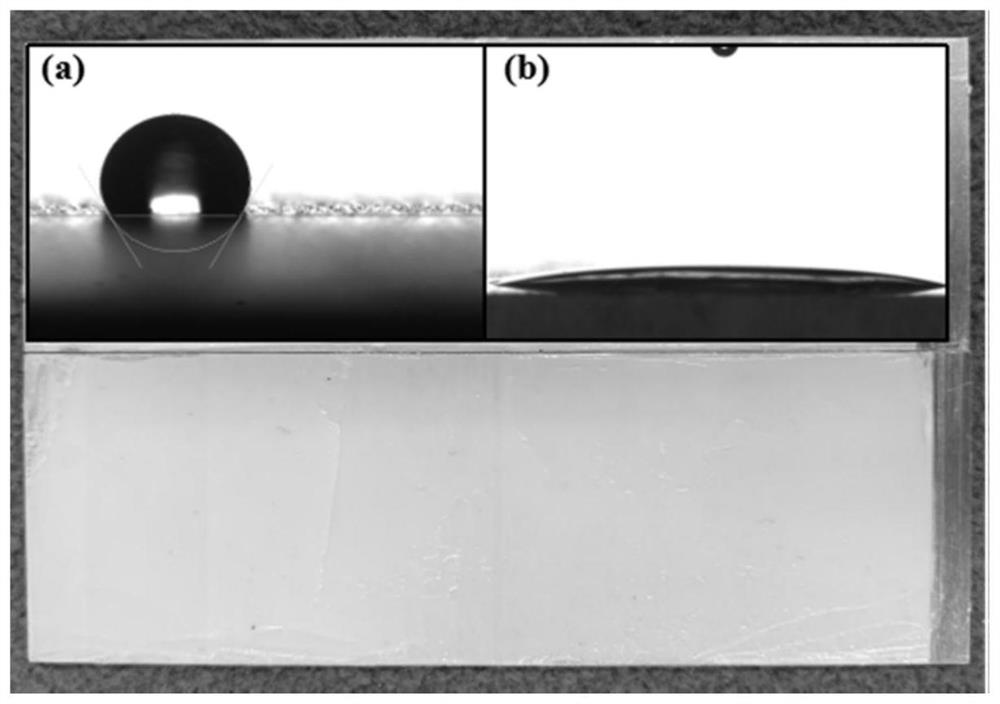

Method for preparing fluorine-containing polydimethylsiloxane anti-icing material

A method for preparing a fluorine-containing polydimethylsiloxane anti-icing material comprises the following steps: respectively adding AIBN, MMA and F-PDMS into a 50 ml round-bottom flask, dissolving above substances in tetrahydrofuran, slowly heating the obtained solution in an oil bath to 70 DEG C, performing a reaction for 8 h, naturally cooling the obtained product, precipitating the productin an n-hexane solution while stirring, performing suction filtration, and collecting obtained filter residues; dissolving the obtained crude product in purified tetrahydrofuran, washing the obtainedprecipitate 3-5 times, drying the washed precipitate in a vacuum drying box for 24 h, and collecting the obtained F-PDMS-co-PMMA product; and dispensing a prepared 3wt% F-PDMS-co-PMMA solution on a clean glass sheet, allowing the solution to naturally form a film at room temperature for 12h, and drying the film in the vacuum drying box at 50 DEG C for 24h. The material has the characteristics ofsimple preparation process and superior anti-icing performance.

Owner:XI AN JIAOTONG UNIV

Wear resistant coatings to reduce ice adhesion on air foils

InactiveCN1906329AReduce wearLow ice adhesionVacuum evaporation coatingDe-icing equipmentsDiamond-like carbonHydrogen

A hard, wear resistant and ice-phobic coating ( 10 ) can be applied to an air foil surface ( 12 ) in a single application to enhance the deicing of the surface. The coating includes a functional top layer ( 14 ) which is harder than the air foil surface and has high contact angle with water. The functional layer contains carbon (>35 atomic %) and hydrogen (0-40 atomic %) in a diamond-like carbon, glassy, or amorphous configuration, as well as incorporated silicon and oxygen (0.1-40 atomic % each).

Owner:THE TIMKEN CO

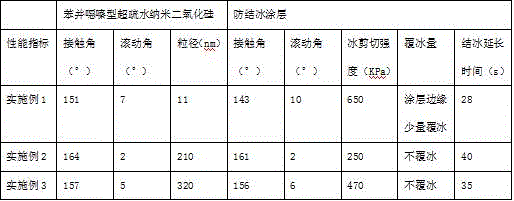

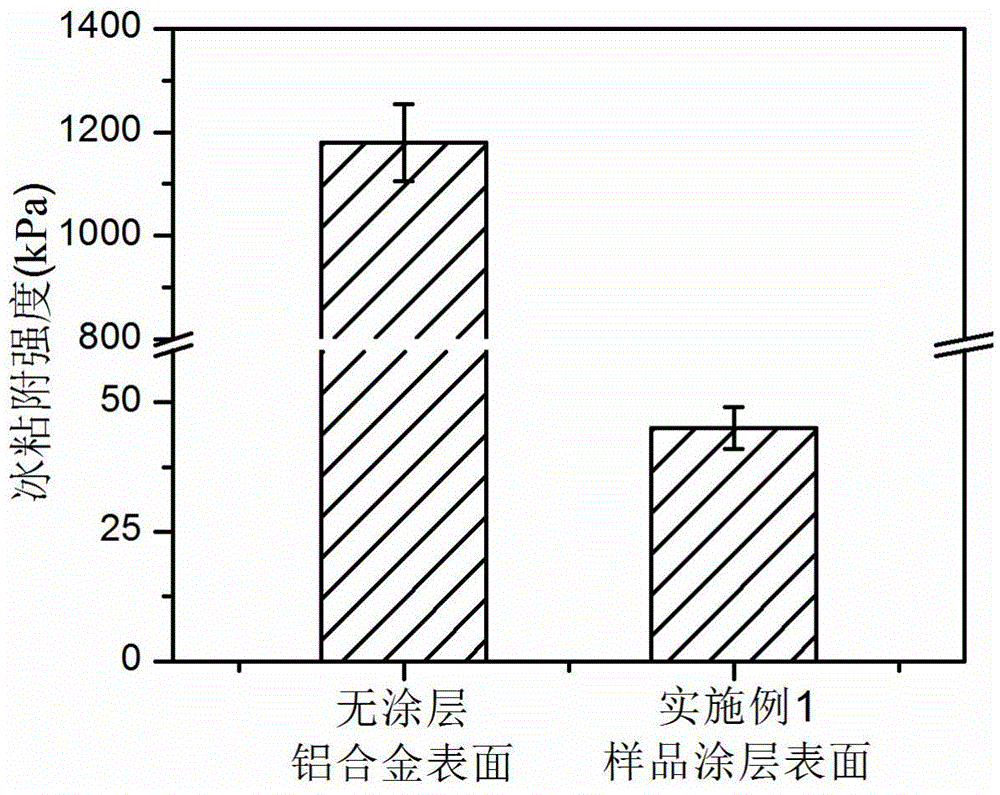

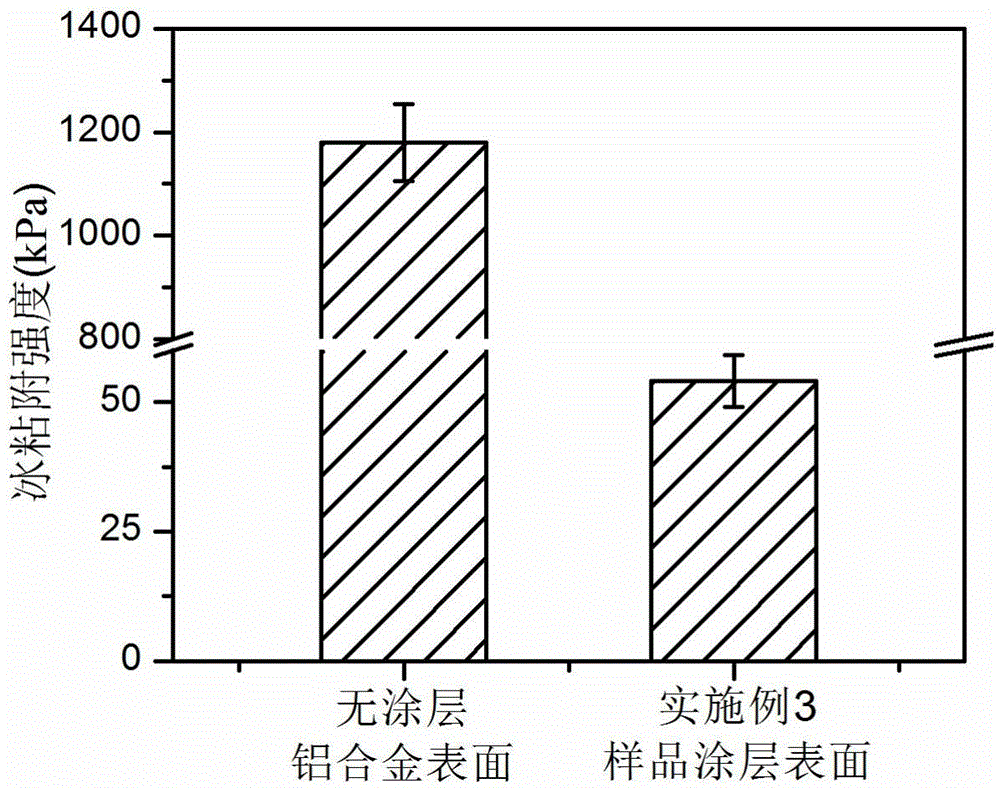

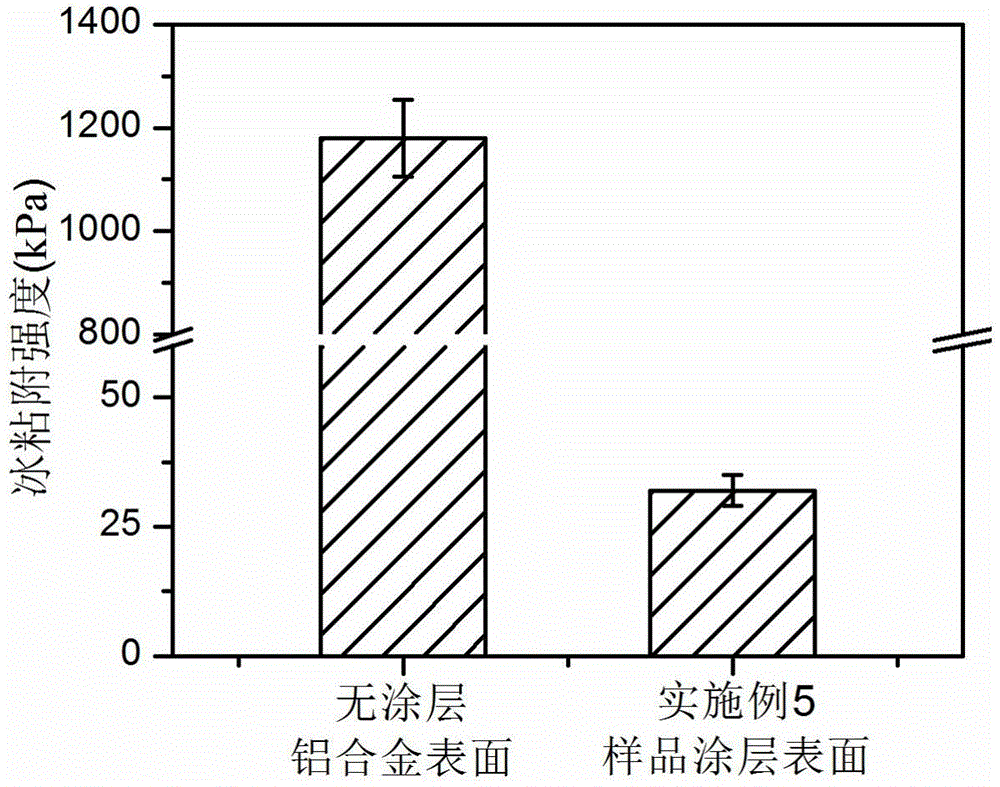

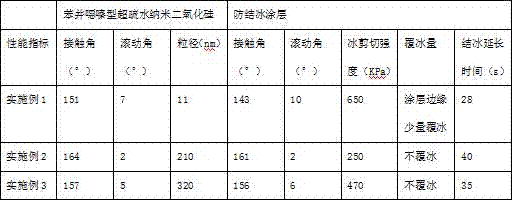

Benzoxazine type super-hydrophobic nano silicon dioxide as well as preparation method and application thereof

ActiveCN105969178AExcellent superhydrophobic propertiesThe synthesis method is simpleCoatingsPigment treatment with organosilicon compoundsMicrowaveSolvent

The invention relates to benzoxazine type super-hydrophobic nano silicon dioxide as well as a preparation method and application thereof, belonging to the technical field of nano material modification and application. The benzoxazine type super-hydrophobic nano silicon dioxide is prepared by the following step: stirring benzoxazine and a solvent thereof, silicon dioxide nanoparticles and water for 0.5-2 hours at 20-50 DEG C in microwave condition. The water contact angle of a coating prepared from the benzoxazine type super-hydrophobic nano silicon dioxide is larger than 150 degrees, and the roll angle is smaller than 10 degrees while the coating has good anti-icing performance; compared with a metal aluminum surface, the ice adhesion strength on the surface of the anti-icing coating is reduced to 50% or below; at low temperature, the ice cover is reduced to 50% or below; and the water icing delay time on the surface of the anti-icing coating is longer than 30s.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

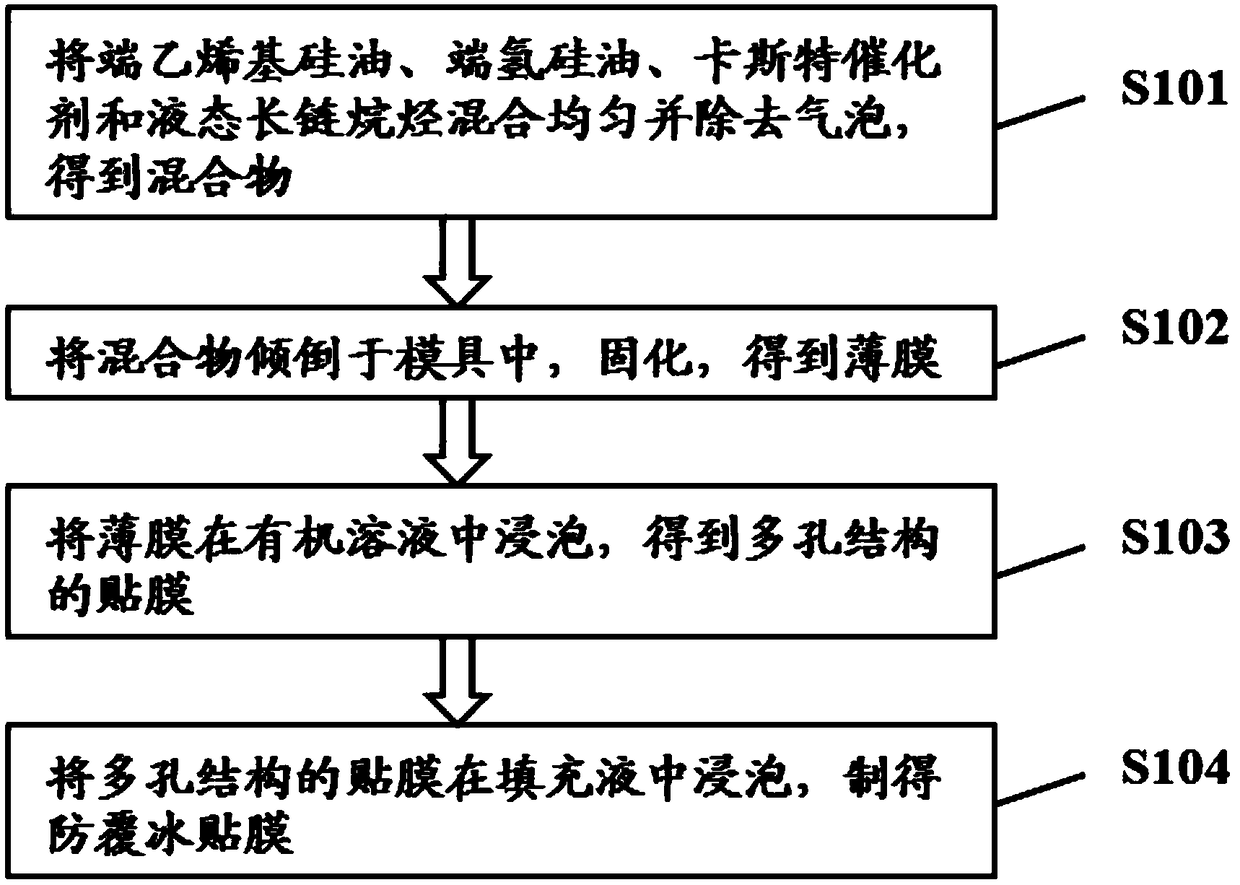

Ice-covering-resistant film and preparation method thereof

The invention provides an ice-covering-resistant film and a preparation method thereof. The preparation method comprises: uniformly mixing vinyl-terminated silicone oil, hydrogen-terminated silicone oil, a Karstedt catalyst and a liquid-state long-chain alkane, and curing to obtain a film; soaking the film in an organic solvent to obtain a film with a porous structure; and soaking the film with the porous structure in a filling liquid to obtain the ice-covering-resistant film. According to the present invention, the shear strength, the ice adhesion strength and the service life of the ice-covering-resistant film are improved by controlling the types and the ratio of the raw materials; the prepared ice-covering-resistant film has advantages of suitable shear strength, low ice adhesion strength and long service life, belongs to the active anti-icing system, can be directly attached to the surfaces of instruments and other objects requiring ice-covering resistance, has significant ice-covering resistance, and further has characteristics of simple use, simple operation and convenient maintenance at the late stage.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

Articles comprising durable water repellent, icephobic and/or biocidal coatings

ActiveUS20210017399A1Minimize adverse effectsQuick wearAntifouling/underwater paintsPaints with biocidesPolymer sciencePolymer resin

Articles including durable and icephobic and / or biocidal polymeric coatings are disclosed. The polymeric coatings can include a bonding layer which may contain a substantially fully cured polymeric resin providing excellent adhesion to metallic or polymer substrates. The polymeric coating further includes an outer surface layer which is smooth, hydrophobic, biocidal and icephobic and, in addition to a substantially fully cured resin, contains silicone comprising additives near the exposed outer surface. The anisotropic polymeric coatings are particularly suited for strong and lightweight parts required in aerospace, automotive and sporting goods applications. A process for making the articles is disclosed as well.

Owner:INTEGRAN TECH

A polymer material with anti-icing function and its integrated molding method

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

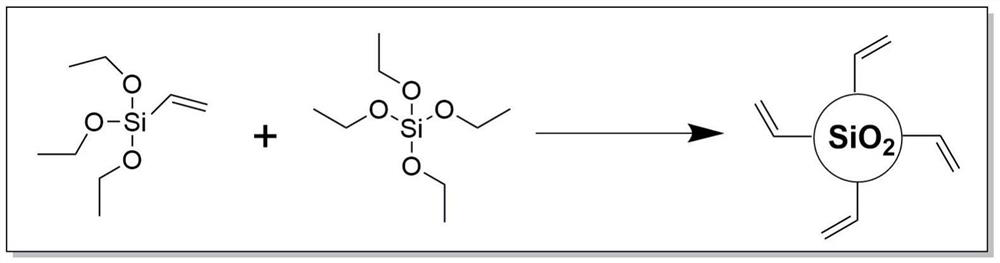

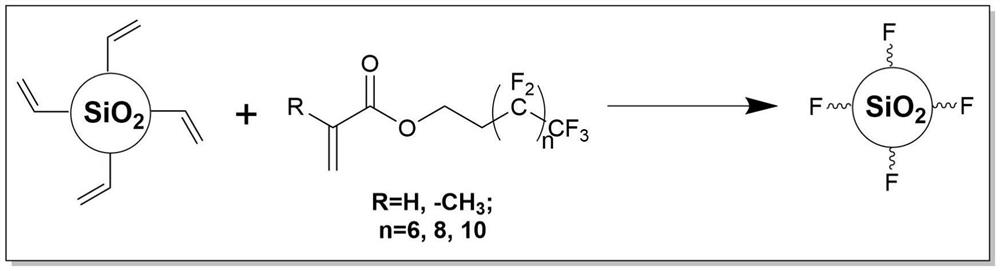

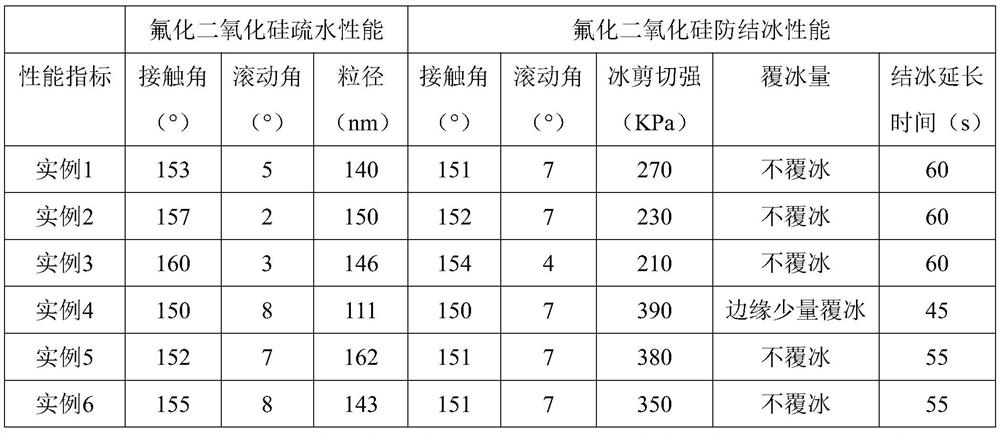

Fluorinated silicon dioxide nanoparticles and application

The invention relates to fluorinated silicon dioxide nanoparticles and application thereof. According to the technical scheme, vinyltriethoxysilane, tetraethoxysilane, alkali and a solvent are mixed, deionized water is dropwise added, the mixture is stirred at the room temperature to react for 1-24 h, and vinyl silicon dioxide is obtained; fluorine-containing acrylate, vinyl silicon dioxide, an initiator and a solvent are mixed, heating is conducted to 70-85 DEG C, and stirring is conducted to react for 2-24 hours to obtain the fluorinated silicon dioxide nanoparticles. The water contact angle of the coating prepared through copolymerization of fluorinated acrylate and vinyl silicon dioxide is larger than 150 degrees, the rolling angle is smaller than 8 degrees, and the coating has good anti-icing performance. The invention belongs to the technical field of nano material modification and application.

Owner:GUANGDONG IND TECHN COLLEGE

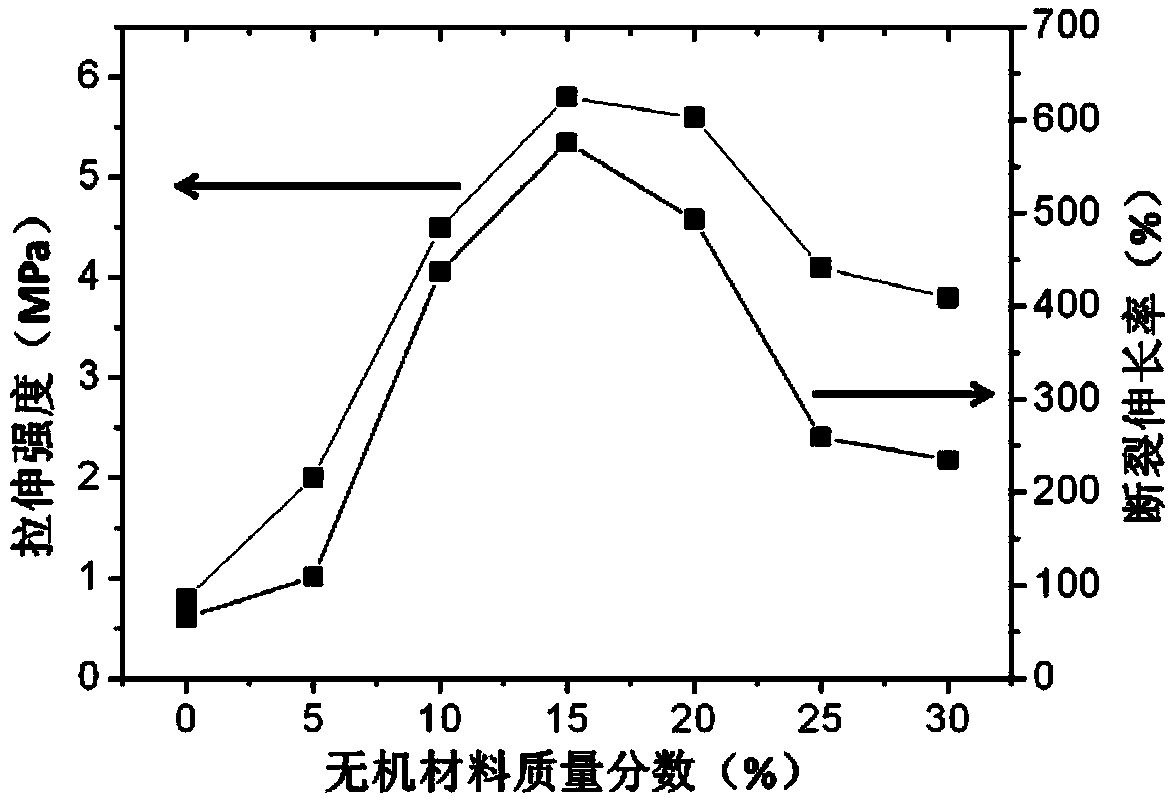

Icing-proof coating with low ice adhesion, and preparation method and application thereof

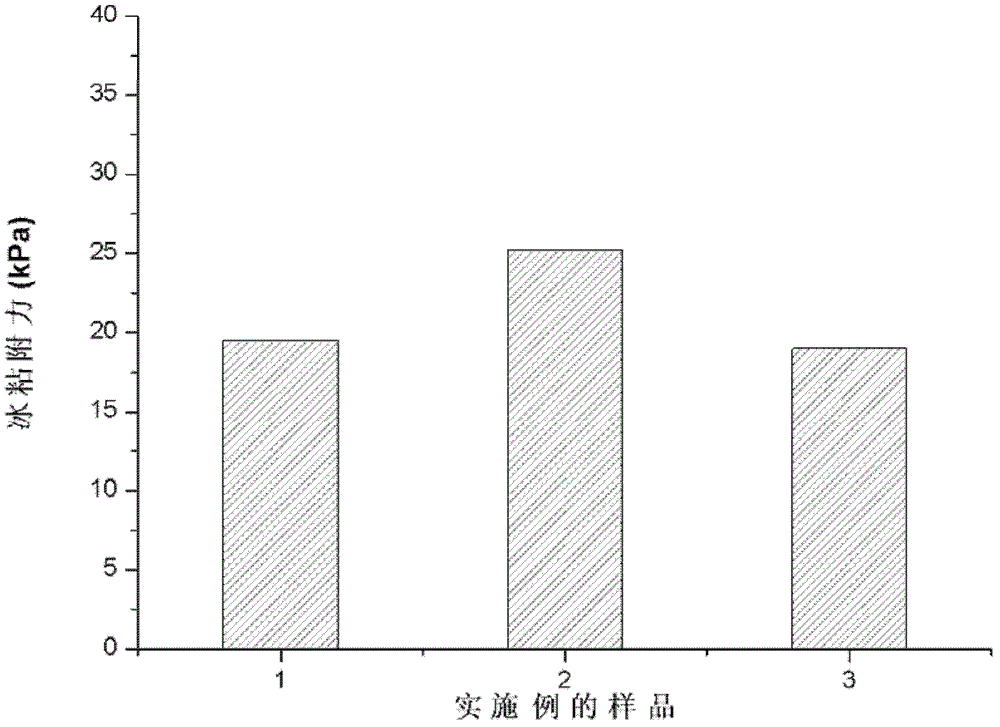

ActiveCN103194130BLow ice adhesionImprove stabilityLiquid surface applicatorsCoatingsCross-linkHigh concentration

The invention belongs to the technical fields of chemistry and chemical engineering, and relates to an icing-proof coating with low ice adhesion, and a preparation method and application thereof. The icing-proof coating provided by the invention is composed of an inorganic material and a cross-linked hydrophilic polyelectrolyte. The inorganic materials and the cross-linked hydrophilic polyelectrolyte are mixed and subjected to ball milling, and then coated on a substrate film, and cured to form the icing-proof coating. The inorganic material improves surface mechanical properties and wear resistance of the icing-proof coating, while the hydrophilic cross-linked polyelectrolyte ionizes a large amount of ions after water absorption; the ion solution with high concentration lowers the freezing point of water and enables an unfreezing water film to be formed on the surface of the icing-proof coating; therefore, a lubricating layer is introduced between ice and the surface of the icing-proof coating, so that the ice later on the substrate surface layer breaks away from the substrate surface under the action of gravity or wind to realize the icing-proof effect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

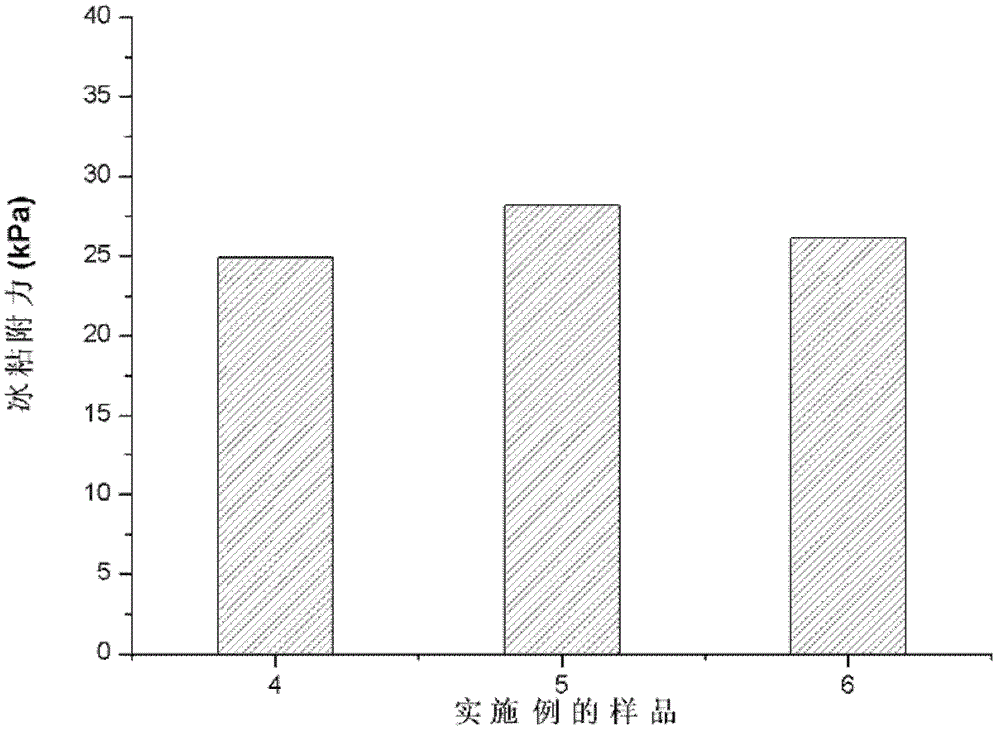

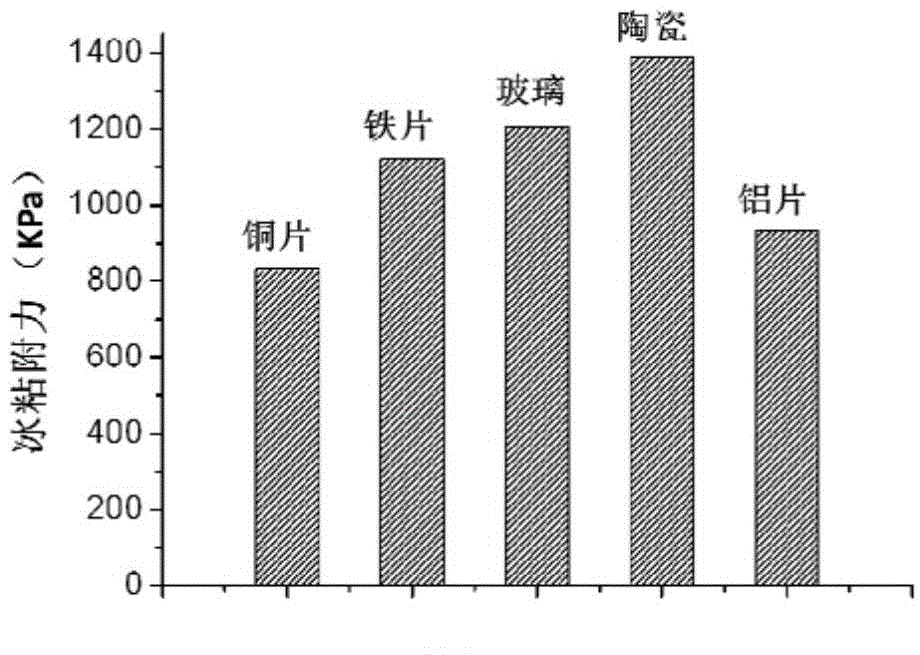

Preparation method and application of a kind of single-component hybrid waterborne anti-icing coating and its coating

ActiveCN103756550BSimple construction processSimple manufacturing processPolyurea/polyurethane coatingsEpoxy resin coatingsMechanical propertyPolymer chemistry

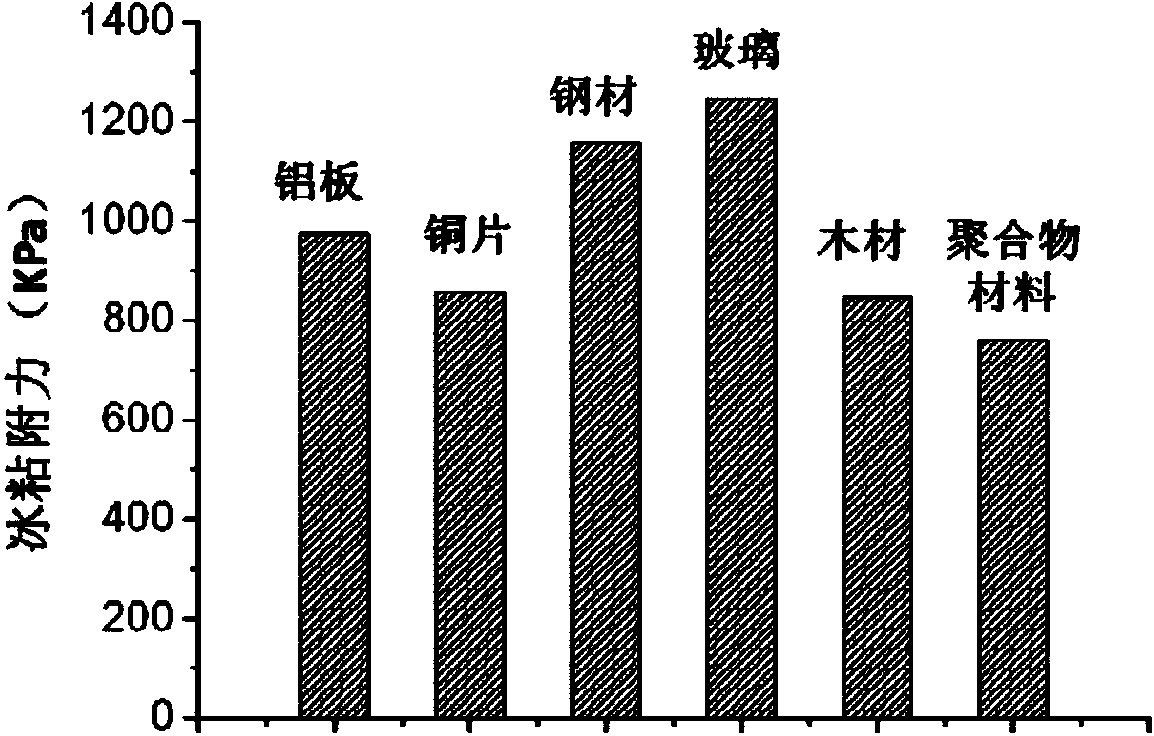

The invention provides a mono-component hybridized aqueous anti-icing coating material. The mono-component hybridized aqueous anti-icing coating material mainly contains a hybridization emulsion, wherein the hybridization emulsion is a nanoparticle modified polymer emulsion preferably. The invention further provides a coating layer containing the coating material, a preparation method of the coating material, a coating method of the coating layer and a method for forming an anti-icing coating layer on the surface of a base material. As water serves as a dispersion medium, the mono-component hybridized aqueous anti-icing coating material provided by the invention is environment-friendly; after cured to form a film, the coating layer can have excellent wear resistance and prolonged service life; through coating the surfaces of base materials, such as metal, glass and macromolecular engineering materials, with the anti-icing coating layer, the ice adhesion strength of the surfaces of the base materials can be lowered, so that compared with the other similar materials, the material has the following advantages of simple process, wide applicable range, easiness in large-area construction, excellent anti-icing performance, excellent mechanical properties and easiness in coating layer repair.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Benzoxazine-type superhydrophobic nano-silica and its preparation method and application

ActiveCN105969178BExcellent superhydrophobic propertiesThe synthesis method is simpleCoatingsPigment treatment with organosilicon compoundsMicrowaveWater contact

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

A kind of flexible lubricating coating and its preparation method and application

ActiveCN109232964BHigh tensile strengthImprove flexibilityCoatingsPolymer scienceFluorine containing

The invention provides a preparation method of a flexible lubricating coating. The flexible fluorine-containing / organic silicon molecules are uniformly brushed on the porous surface of a polymer to obtain a lubricating coating. At the same time, the coating prepared by the preparation method is provided. The coating has a super-hydrophobic and super-oleophilic lubricating coating with a porous structure. icing properties. Also provided is the use of the coating as a flexible lubricating coating in an anti-icing coating.

Owner:UNIV OF JINAN

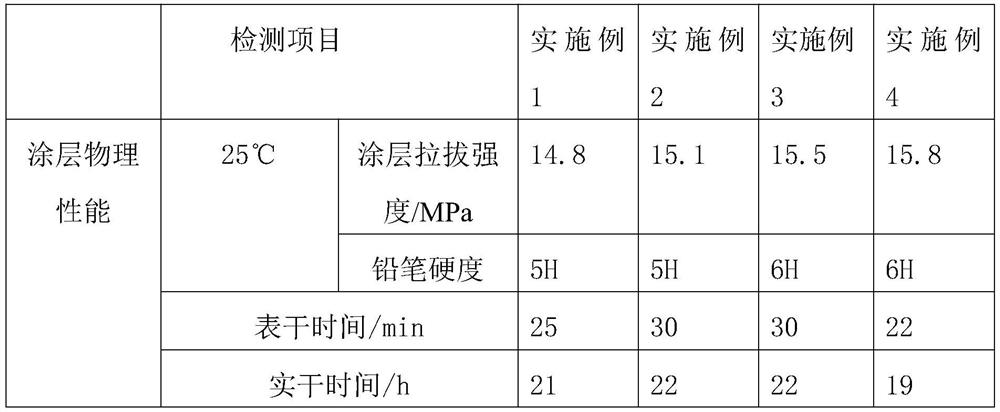

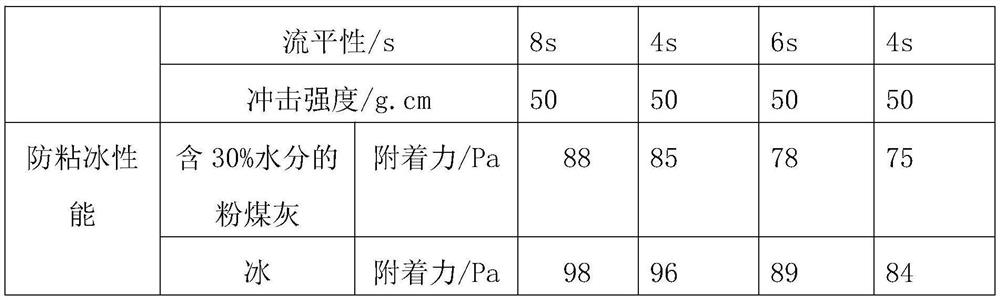

A kind of anti-sticking ice coating for mine car and preparation method thereof

Owner:SHANDONG NORTH MODERN CHEM IND

A liquid-filled porous silicone resin anti-icing material and preparation method thereof

The invention discloses a liquid-filled porous silicon resin anti-icing material and a preparation method thereof. A fluorosilane-modified porous silicon resin and fluorine-containing liquid composite layer is combined on a base material of the liquid-filled porous silicon resin anti-icing material, wherein the fluorine-containing liquid is filled in the fluorosilane-modified porous silicon resin, and the porous silicon resin is obtained by uniformly mixing an inorganic silicon or organic silicon raw material, a catalyst solution and organic nanoparticle in a solvent to form a mixed solution, directly coating the mixed solution on the surface of the base material, and removing the organic nanoparticle after drying and curing the coating; the fluorine-containing liquid is selected from one or two of liquid perfluorocarbon and liquid fluorosilicone; the fluorine-containing liquid has a viscosity range of 0.1-500cm<2> / s at the room temperature; and the average particle size of the organic nanoparticle is 50-800nm. When the environment temperature and the environment humidity can cause the base material to ice, the surface of the liquid-filled porous silicon resin can prevent subcooled water from contacting the base material, and a liquid lubricating material can be used for greatly descending the adhesive power of the ice layer and is easy to separate from the surface under the action of gravity or wind power. The liquid-filled porous silicon resin anti-icing material can be efficiently acted under the weather conditions such as the environment temperature of 0 to -40 DEG C and the environment humidity of 40%-90%.

Owner:STATE GRID CORP OF CHINA +2

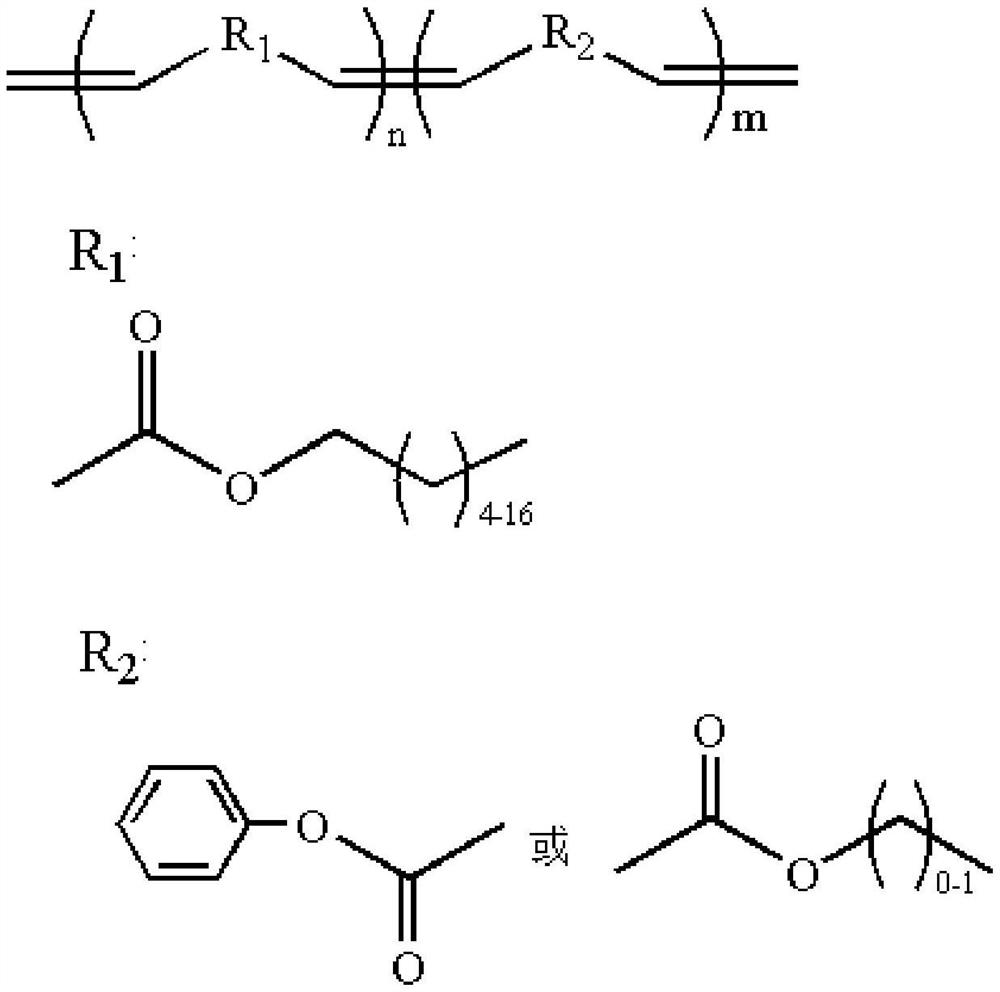

Preparation and application of olefin copolymer

InactiveCN112592635AGood anti-icing effectAdjustable mechanical propertiesCoatingsPolymer scienceAlkene

The invention provides preparation and application of an olefin copolymer. The olefin copolymer is prepared by olefin metathesis polymerization, and then a copolymer film is obtained by pouring. The prepared copolymer has good anti-icing performance.

Owner:UNIV OF JINAN

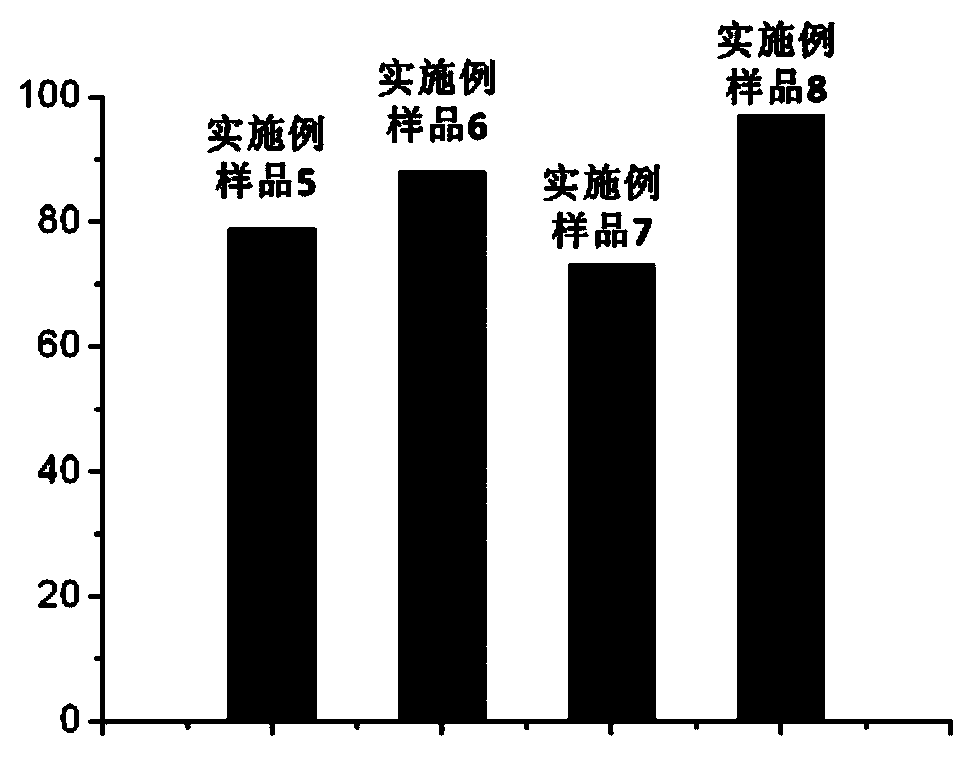

Preparation method of self-heat-absorption reshapable ice extension/deicing microarray structure

ActiveCN114473390AReduce the rate of heat exchangeReduce contact areaCleaning using liquidsNano structuringShape-memory alloy

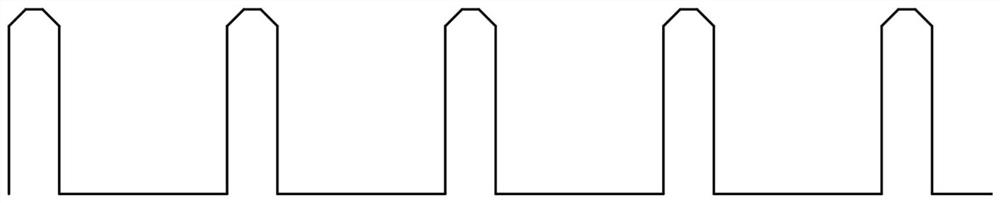

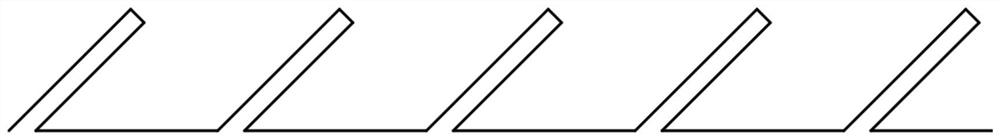

The invention discloses a preparation method of a self-heat-absorption reshaping ice extension / deicing microarray structure, and belongs to the technical field of micro-nano structure functional surface preparation. The blade-like array microstructure with the inclination angle of 30-45 degrees is prepared on the shape memory alloy, and the graphene photo-thermal coating grows on the surface of the blade-like array microstructure. After the graphene photo-thermal coating is irradiated by sunlight, a large amount of heat is generated on the surface through photo-thermal conversion, the local temperature is rapidly increased, in a low-temperature environment, the shape memory alloy coated with ice on the surface recovers to be in a high-temperature state with a large micro-structure inclination angle after being heated, an ice layer attached to the surface is promoted to fall off, and therefore the graphene photo-thermal coating is formed. And the active anti-icing and deicing process of the material surface is realized. The microstructure machined by adopting wire cut electrical discharge machining is good in shape recovery after deformation. The directional rolling of the liquid drops can be realized by regulating and controlling the form of the array microstructure, so that subsequent deicing is facilitated; the prepared microstructure can reduce the contact area between ice and the substrate so as to reduce the adhesion strength of the ice on the material surface.

Owner:CHANGCHUN UNIV OF SCI & TECH

A kind of anti-icing lubricating grease and its preparation method and application

ActiveCN111363605BExcellent wide temperature rangeImprove flame retardant performanceLubricant compositionSuperhydrophobeEmulsion

An anti-icing lubricating grease and its preparation method and application, comprising dispersing nano-silica sol, ammonia water, deionized water, tetraethyl orthosilicate, and a hydrophobic treatment agent in absolute ethanol, and continuously stirring in a water bath, namely The superhydrophobic superoleophilic coating can be obtained; the superhydrophobic superoleophilic coating is placed in an oven to dry, and then the dried block is ground to obtain a superhydrophobic superoleophilic nanoparticle aggregate powder; the superhydrophobic superlipophilic nanoparticle aggregate powder is obtained; Oil nanoparticle powder, unmodified grease and silicone oil are dispersed in an organic diluent, and then ultrasonicated in an ultrasonic cleaner to obtain a uniformly dispersed mixed emulsion; the uniformly dispersed mixed emulsion is placed in an oven to obtain a semi-solid glue After standing still at room temperature to volatilize the residual organic diluent, the modified anti-icing grease can be obtained. The anti-icing lubricating grease coating process of the present invention has low requirements on the substrate, and has no requirements on flat or curved surfaces, and can be formulated and constructed in a large area, which is beneficial to the popularization and application of the anti-icing lubricating grease.

Owner:SOUTHEAST UNIV

Super-hydrophobic surface with high durability and low ice adhesion and preparation method thereof

PendingCN114589081ALow ice adhesionPreserve surface hydrophobicityWatercraft hull designPretreated surfacesNanowireAdhesion strength

The invention relates to a super-hydrophobic surface with high durability and low ice adhesion and a preparation method thereof. The surface structure comprises a substrate, micron hillocks, nanowires and polymer connectors, the plurality of micron hills are periodically distributed on the surface of the substrate; a plurality of nanowires are arranged, the nanowires extend out of the surfaces of the micron hillocks, and a plurality of nanowires extend out of the surface of each micron hillock; and the polymer connectors are connected between the adjacent nanowires. In the surface structure, the gaps between the nanowires on the surface of the micron hills are smaller than those between the micron hills, and the polymer connectors are connected between the adjacent nanowires and show a net-shaped structure, so that lower ice adhesion strength can be obtained while the surface hydrophobicity is kept. Meanwhile, in the use process, after a melting and freezing cycle, the nanowires at the top end of the surface structure may be gradually broken and damaged, but the polymer connector can be stored, so that the durability of the surface structure can be effectively improved.

Owner:TSINGHUA UNIV

A "two-step method" preparation method of lubricious and durable silicone anti-icing coating

InactiveCN108641593BLow ice shear strengthReduced wear resistanceCoatingsPolymer sciencePtru catalyst

The invention discloses a preparation method for a durable organosilicon anti-icing coating with lubricity through a two-step process. The two-step process comprises the following two steps: step 1, formation of a brush-type graft polymer through a reaction of hydrogen-containing polydimethylsiloxane and vinyl single-terminal polydimethylsiloxane; and step 2, preparation of a uniform reaction solution with the brush-type graft polymer as a main raw material, vinyl double-terminal polydimethylsiloxane as a crosslinking agent and polydimethylsiloxane without participation in a crosslinking reaction as an additive, and preparation of the durable organosilicon anti-icing coating with lubricity under the action of a Karstedt't catalyst. The durable organosilicon anti-icing coating with lubricity prepared by using the above-mentioned two-step process provided by the invention has ultra-low ice shear strength and excellent wear resistance, wherein the lowest ice shear strength is 2.4 kPa. Thepreparation method provided by the invention is simple and convenient and has easily-available materials; and the anti-icing coating prepared by using the preparation method provided by the inventionhas good transparency and is applied in the field of hydrophobic and anti-icing coatings.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com