Super-hydrophobic surface with high durability and low ice adhesion and preparation method thereof

A super-hydrophobic surface, high-level technology, applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, etc., can solve problems such as difficult to resist icing effects, low number of icing and thawing cycles, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

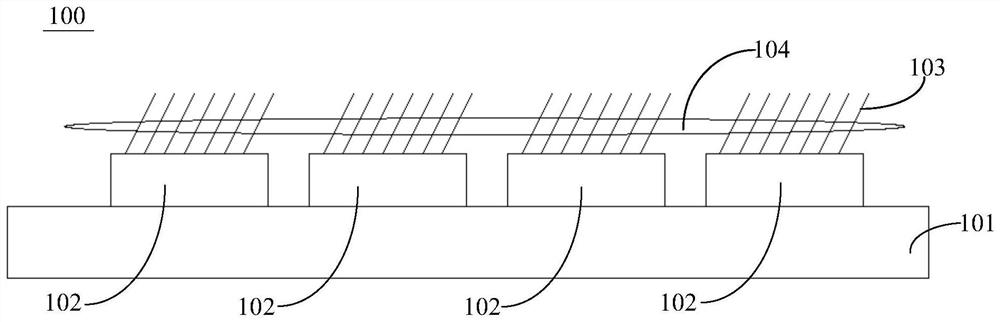

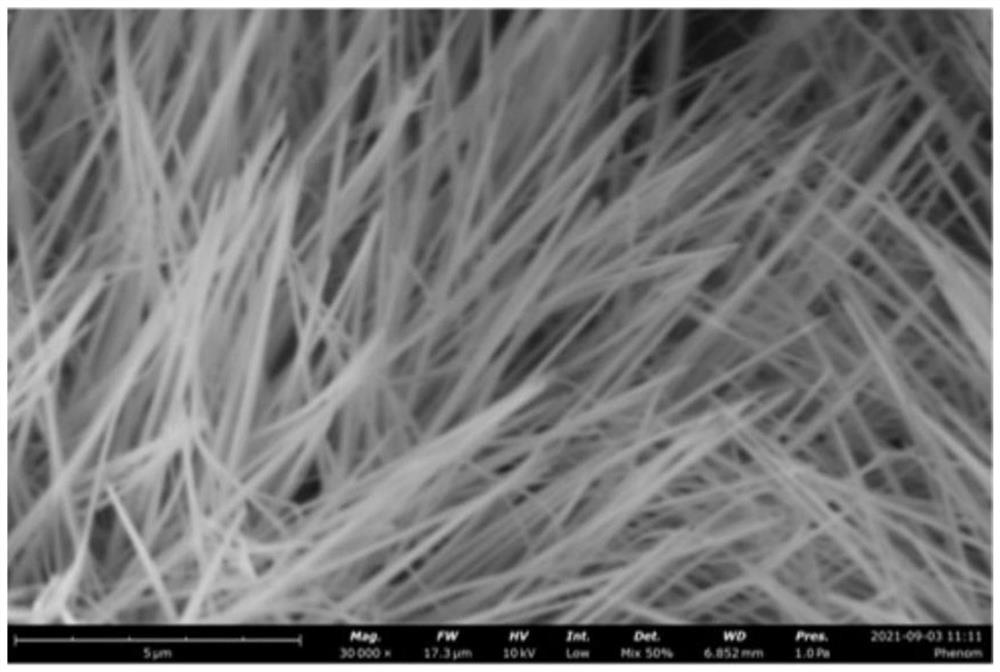

[0072] Further embodiment of the present invention provides a method for preparing a superhydrophobic surface with high durability and low ice adhesion. The preparation method comprises the following steps: a micromound is formed on the surface of the substrate to obtain a primary structure. Nanowires are formed on the surface of the micromound, resulting in a secondary structure. The polymer is rotated onto a secondary structure to form a polymer link on a nanowire, and the polymer linker is connected between adjacent nanowires.

[0073] In the preparation method of the present embodiment, microchounds, nanowires and polymer joiners are sequentially formed on the surface of the substrate. Among them, the gap between the nanowires on the surface of the micromound is smaller than the gap between the microchumular structures, and a greater additional pressure can be formed between the nanowires. At this time, when the polymer is rotated to the secondary structure, the polymer is mor...

Embodiment 1

[0098] In the present embodiment, the substrate is a copper substrate. The preparation method of the superhydrophobic surface of high durability and low ice adhesion in the present embodiment comprises the following steps:

[0099] S101: The thickness of the copper plate with a thickness of 0.2 mm is cut into a size of 20×20 mm, and after 10 min of ultrasonic cleaning in alcohol, it is purged and dried with nitrogen.

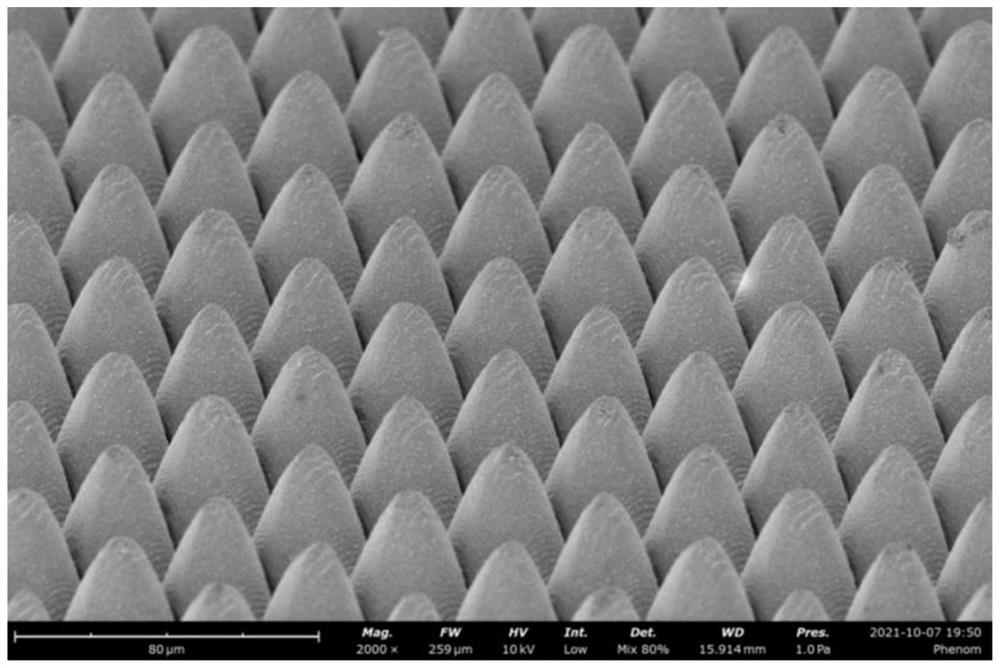

[0100] S102: Femtosecond pulsed laser ablation is used to form a matrix-arranged microchond on the surface of the copper substrate. The conditions for femtosecond pulsed laser ablation are: laser wavelength of 1030 nm, pulse width of 800 fs, repetition rate of 200kHz, average power of 6W, scanning pattern is a vertically crossed parallel line array, line-to-line spacing is 35μm, scanning speed is 500mm / s. Femtosecond pulsed laser ablation is followed by alcohol leaching, nitrogen purging and drying to obtain a primary structure. The morphology of the micromound in t...

Embodiment 2

[0106] In the present embodiment, the substrate is an aluminum substrate. The preparation method of the superhydrophobic surface of high durability and low ice adhesion in the present embodiment comprises the following steps:

[0107] S101: The aluminum plate with a thickness of 0.2 mm is cut into a size of 20×20 mm, and after 10 min of ultrasonic cleaning in alcohol, it is purged and dried with nitrogen.

[0108] S102: Nanosecond pulsed laser ablation is used to form a matrix-arranged microchond on the surface of the aluminum substrate. The conditions for nanosecond pulsed laser ablation are: laser wavelength of 1060 nm, pulse width of 250 nm, repetition rate of 200 kHz, average power of 30 W, scanning pattern vertically crossed parallel line array, line to line spacing of 60 μm, scanning speed of 400 mm / s. After nanosecond pulsed laser ablation, the primary structure is obtained by alcohol leaching, nitrogen purging and drying. The morphology of the micromound in the resulting p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com