Preparation method of self-heat-absorption reshapable ice extension/deicing microarray structure

A technology of microarray structure and microstructure, which is applied in the direction of liquid cleaning method, cleaning method and utensils, chemical instruments and methods, etc., can solve the problems of complex preparation process, difficult promotion, environmental pollution, etc., and achieve simple preparation method, Effects of reduced heat exchange rate and easy operation of the processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A method for preparing a self-absorbing heat-recoverable ice-extending / de-icing microarray structure, comprising the following steps:

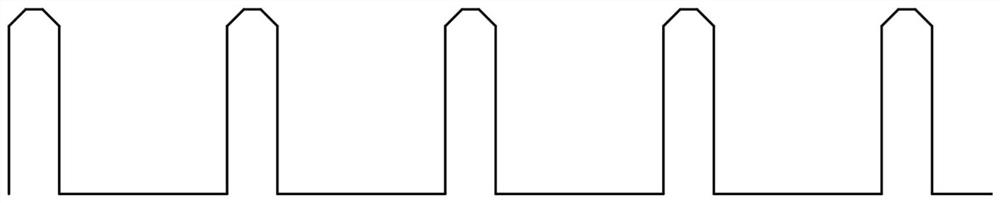

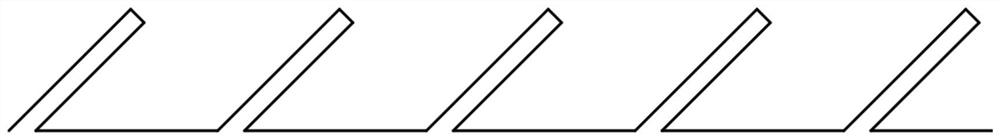

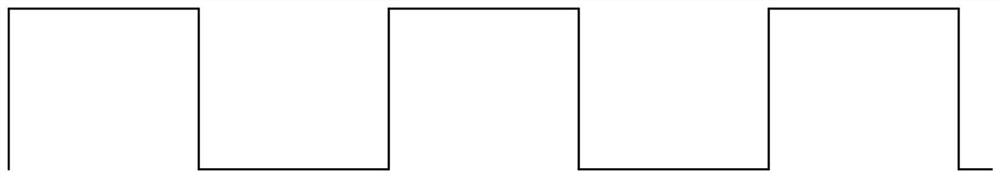

[0038] Step 1. Based on the working principle of the shape memory alloy, an array microstructure is prepared on the surface of the nickel-titanium NiTi shape memory alloy substrate 2 . Design principles such as Figure 5 As shown: the height H of the microstructure is 100-500 μm, the width D is 50 μm, and the thickness is 50 μm-200 μm. The inclination angle θ between the array structure and the substrate surface is 30° to 45°, and the array spacing W is 400 μm to 800 μm. According to the design structure, draw a two-dimensional diagram of the microstructure path of wire electric discharge machining;

[0039] Step 2. Import the 2D image, and perform WEDM processing twice:

[0040] The first wire electric discharge cutting: on the surface of the NiTi shape memory alloy substrate 2 clamped horizontally, according to figure 1 The wire-cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com