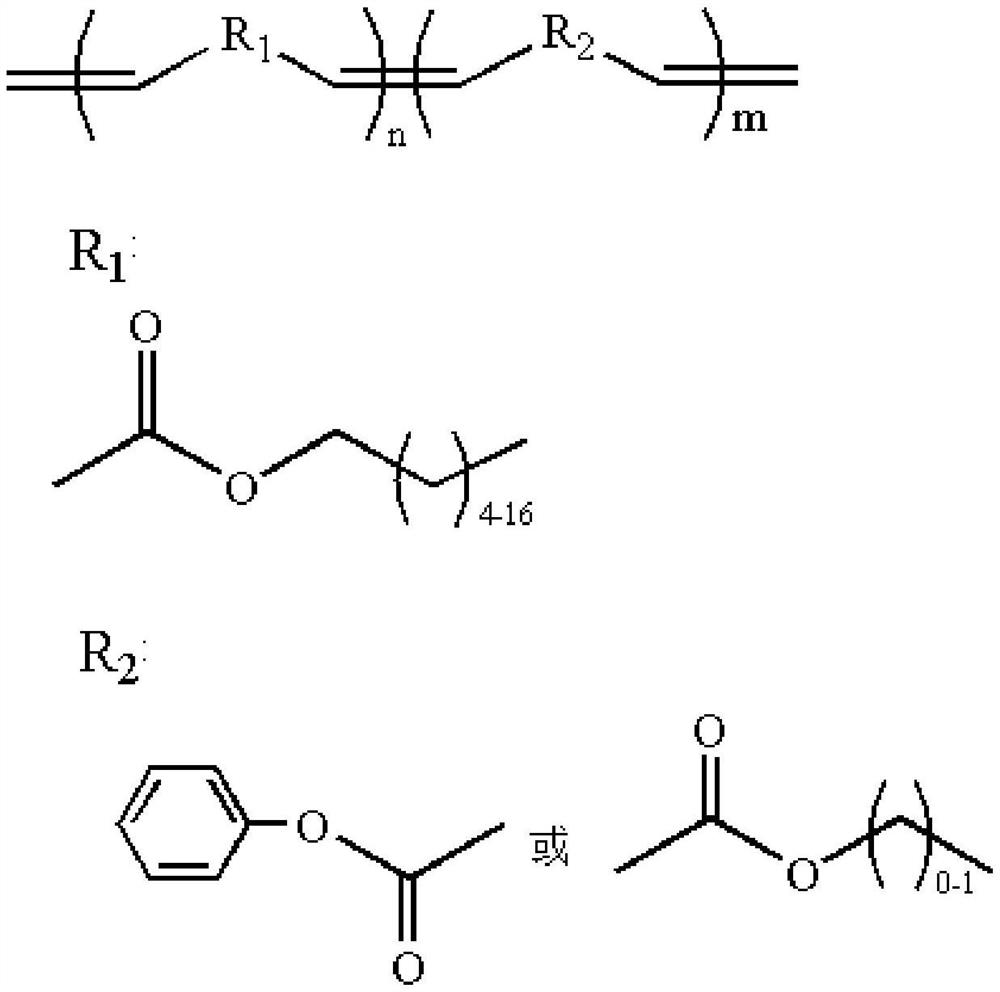

Preparation and application of olefin copolymer

A technology of olefin copolymers and polymers, applied in coatings and other directions, can solve the problems of poor adhesion and low surface energy of fluorosilicon materials, and achieve good anti-icing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of copolymers, the preparation method is: 0.15g (1mmol) norbornene carboxylate methyl ester and 1.18g (5mmol) norbornene carboxylate heptyl ester were dissolved in dichloromethane, prepared into a solution with a mass fraction of 5%, in Under nitrogen protection, Grubbs second-generation catalyst (Grubbs 2 nd , 8.49mg) was dissolved in a solvent and injected into the reaction bottle through a syringe. Then remove the ice bath and react at 15°C for 48 hours. After the reaction, a small amount of vinyl ether was added dropwise to terminate the reaction, and the copolymer was obtained by rotary evaporation and precipitation.

[0021] Prepare the copolymer film, the preparation method is: first dissolve the above-mentioned olefin copolymer (0.5g) in toluene (0.5g) to prepare a 50% polymer solution, and then apply the solution on the substrate by casting method , After drying at 60°C for 12h, the copolymer film was obtained.

[0022] The film water contact angl...

Embodiment 2

[0024] Prepare the copolymer, the preparation method is: 0.64g (3mmol) phenyl norbornene carboxylate and 0.01g (0.03mmol) hexadecyl norbornene carboxylate are dissolved in benzene, and are prepared into a solution with a mass fraction of 25%. Under nitrogen protection, Grubbs second-generation catalyst (Grubbs 2 nd , 4.33mg) was dissolved in solvent and injected into the reaction bottle through a syringe. Then remove the ice bath, react at 25°C for 12 hours, drop a small amount of vinyl ether to terminate the reaction, and obtain a copolymer by rotary evaporation and precipitation.

[0025] To prepare a copolymer film, the preparation method is as follows: firstly, the above-mentioned olefin copolymer (0.3g) is dissolved in ethyl acetate (0.7g) to prepare a 30% polymer solution, and then the solution is coated on the substrate by casting method. After drying at 30°C for 48 hours, the copolymer film was obtained.

[0026] The water contact angle of the copolymer film is 70°, ...

Embodiment 3

[0028] Prepare the copolymer, the preparation method is: 0.03g (0.01mmol) norbornene carboxylate pentafluorophenyl ester and 2.11g (6mmol) norbornene carboxylate octafluoropentyl ester are dissolved in tetrahydrofuran, and the mass fraction is 30% solution, under the protection of nitrogen, and then Grubbs second-generation catalyst (Grubbs 2 nd , 16.97mg) was dissolved in solvent and injected into the reaction vial through a syringe. Then the ice bath was removed, and the reaction was carried out at 45°C for 3 hours. After the reaction was completed, a small amount of vinyl ether was added dropwise to terminate the reaction, and the copolymer was obtained by rotary evaporation and precipitation.

[0029] To prepare the copolymer film, the preparation method is as follows: first dissolve the above olefin copolymer (0.5g) in N,N-dimethylformamide (9.5g) to prepare a 5% polymer solution, and then use the solution Coated on the substrate by casting method, and dried at 100°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com