A liquid-filled porous silicone resin anti-icing material and preparation method thereof

A porous silicon, anti-icing technology, applied in the field of materials, can solve the problems of unsuitable industrial application, high material selectivity, complicated preparation methods, etc. The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

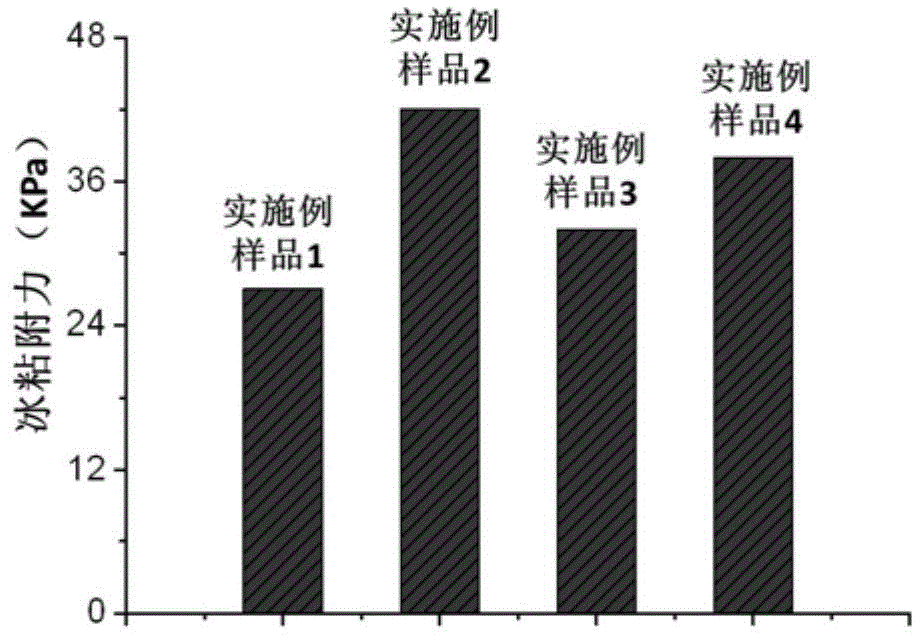

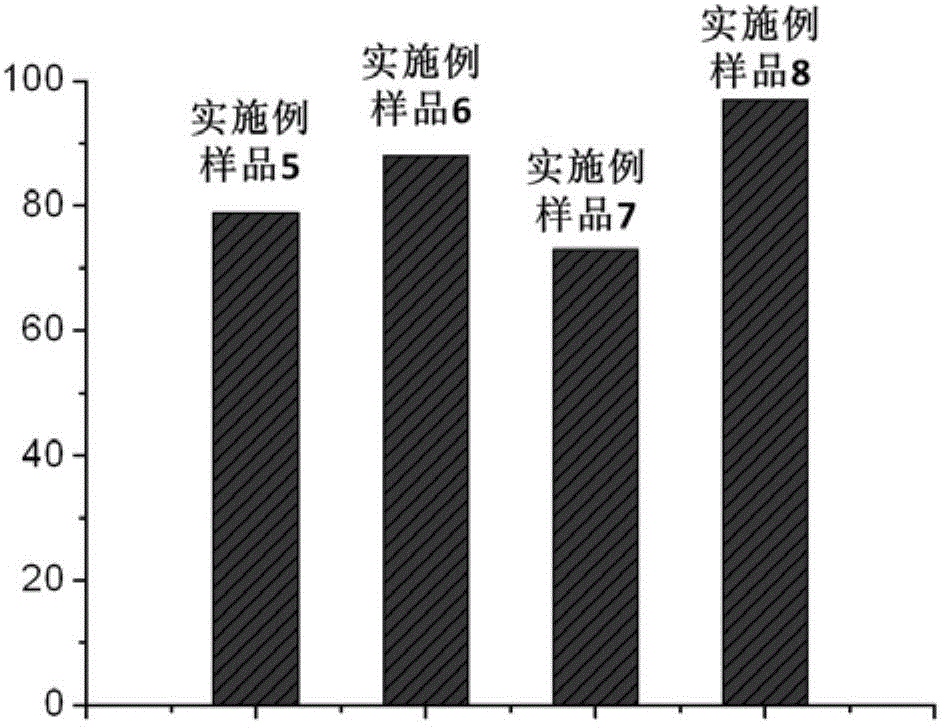

Examples

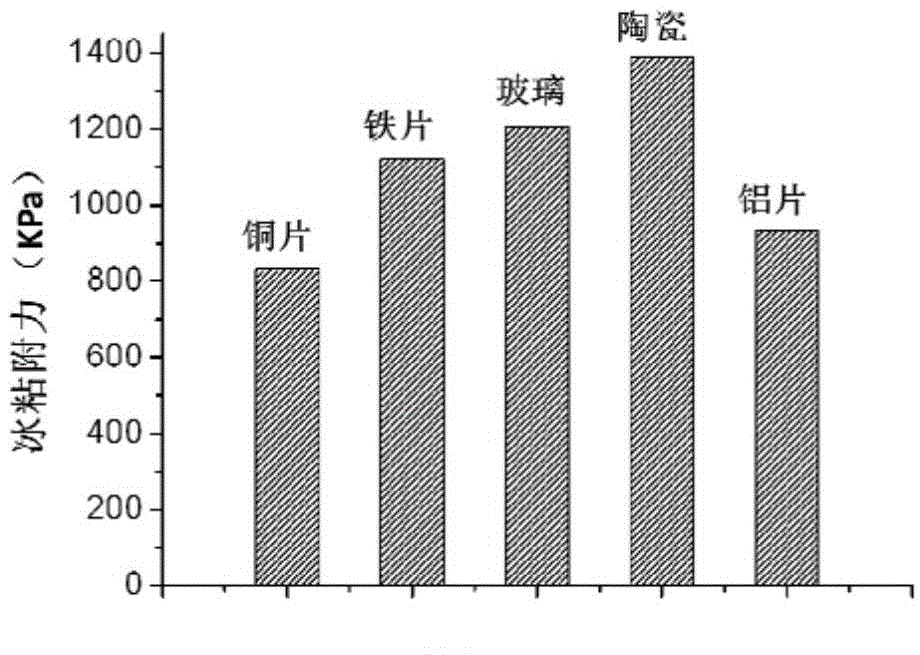

Embodiment 1

[0041] (1) Preparation of porous silicone resin

[0042] A certain mass of polystyrene nanoparticles (average particle diameter of 500nm) was added to a 10% sodium silicate aqueous solution (the mass ratio of polystyrene to sodium silicate was 1:1), and after mixing evenly, Add 0.1mol / L hydrochloric acid aqueous solution (the volume ratio of hydrochloric acid aqueous solution to the mixed solution is 1:20), and then directly coat the solution on the surface of the copper sheet. After the solution is dried and solidified, put it into a muffle furnace and raise the temperature to 800°C for ablation After 30 minutes, take out the copper sheet after cooling down to obtain a copper sheet with porous silicone resin on the surface.

[0043] (2) Surface chemical modification of porous silicone resin

[0044] The copper sheet with porous silicone resin on the surface obtained in step (1) was placed in an airtight container containing trifluoroethyltrimethoxysilane for 24 hours to obta...

Embodiment 2

[0050] (1) Preparation of porous silicone resin

[0051] A certain mass of polymethyl methacrylate nanoparticles (average particle diameter is 400nm) was added to a 20% mass fraction of methyl orthosilicate / methanol solution (polymethyl methacrylate and methyl orthosilicate The mass ratio is 1:2), after mixing evenly, add 0.3mol / L sulfuric acid aqueous solution (the volume ratio of sulfuric acid aqueous solution to the mixed solution is 1:10), and then directly coat the solution on the surface of the iron sheet, and wait for the solution to dry and solidify Put it into a muffle furnace and raise the temperature to 300°C for ablation for 1200 minutes. After cooling down, take out the iron sheet to obtain an iron sheet with porous silicone resin on the surface.

[0052] (2) Surface chemical modification of porous silicone resin

[0053] Place the copper sheet with porous silicone resin on the surface prepared in step (1) in an airtight container containing trifluoroethyltrietho...

Embodiment 3

[0058] (1) Preparation of porous silicone resin

[0059] A certain mass of nanocellulose (average particle size is 300nm) is added to a 40% tetraethyl orthosilicate / ethanol solution (the mass ratio of nanocellulose to tetraethyl orthosilicate is 1:4), After mixing evenly, add 0.5mol / L nitric acid aqueous solution (the volume ratio of nitric acid aqueous solution to the mixed solution is 1:30), then directly coat the solution on the surface of the glass sheet, and put it into the muffle furnace to heat up to Ablation at 500°C for 800 min, and after cooling down, take out the iron sheet to obtain a glass sheet with porous silicone resin on the surface.

[0060] (2) Surface chemical modification of porous silicone resin

[0061] The glass sheet with porous silicone resin on the surface prepared in step (1) is soaked in a methanol solution of 1% hexafluorobutyltrimethoxysilane by mass fraction for 6h to obtain a glass sheet of porous silicone resin with surface chemical modificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| ice adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com