Super-hydrophobic anti-icing aviation aluminum alloy surface and production method

An aluminum alloy surface, anti-icing technology, applied in the direction of the fuselage bulkhead, etc., can solve the problems of difficult to achieve ice shedding, surface ice adhesion performance reports, and super-hydrophobic surface ice adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

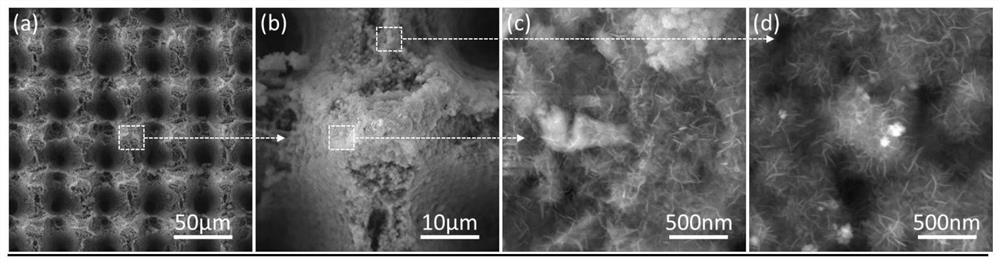

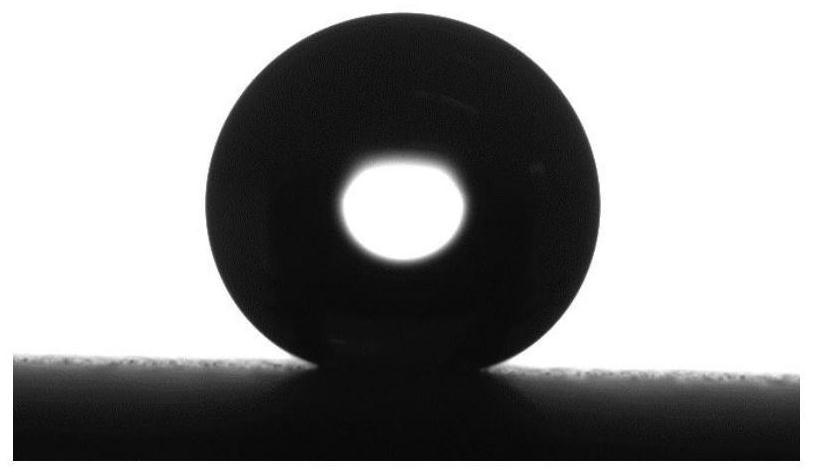

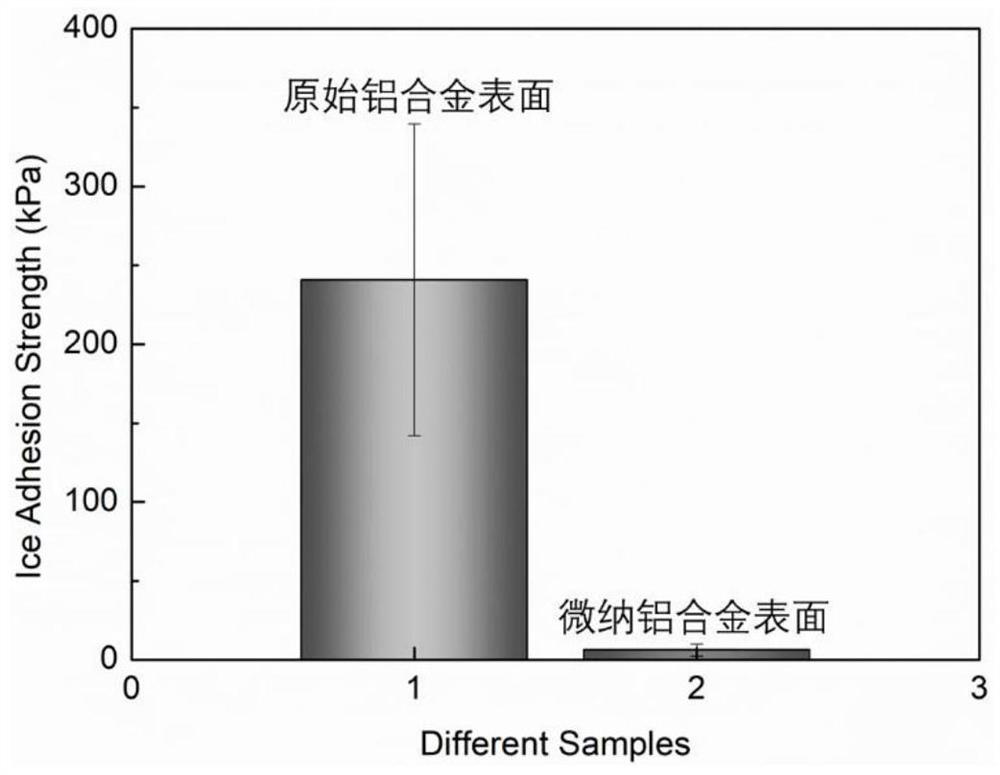

[0044] The invention discloses a micro-nano structure on the surface of a super-hydrophobic anti-icing aviation aluminum alloy with ultra-low ice adhesion. figure 1 As shown in the figure, it can be seen that the surface is composed of periodically distributed complex micro-nano tertiary structures. Among them, the nanostructure is a two-dimensional nanosheet structure, which is densely grown on the surface of the three-dimensional microcone; the submicron spherical structure is grown by stacking nanosheets. The diameter is about 500nm, dispersed on the microcone, and the whole three-dimensional three-level complex micro-nano structure has the structural characteristics of integrated interconnection. After surface chemical modification, the surface can exhibit a water droplet contact angle of about 160°, such as figure 2 shown. The ice adhesion strength of this surface is only 6kPa, compared with the untreated aluminum alloy surface (240kPa), the ice adhesion strength is red...

Embodiment 2-1

[0053] 1) Using aviation aluminum alloy foil as the base material, first use a mechanical cutting knife to obtain a sheet-shaped aluminum alloy foil sample with an area of 20mm×80mm, and then place it in absolute ethanol and acetone for ultrasonic cleaning for 10-20 minutes, After removal, dry them in a gentle stream of nitrogen gas.

[0054] 2) Perform periodic patterned ablation on the surface of the aluminum alloy sample using a high-power ultrafast laser. The laser wavelength is 1030nm, the pulse width is 800fs, the pulse repetition frequency is 200kHz, and the laser power is 6W. Processing, the distance between adjacent scanning lines is 40 μm, the scanning speed is 500 mm / s, and the height of the three-dimensional microcone unit is 60 μm, the diameter of the bottom is about 40 μm, and the period is 40 μm. After the ablation is completed, the sample is ultrasonically cleaned in absolute ethanol After 10 minutes, take it out and dry it in a gentle nitrogen stream.

[00...

Embodiment 2-2

[0060] 1) Using aviation aluminum alloy foil as the base material, first use a mechanical cutting knife to obtain a sheet-shaped aluminum alloy foil sample with an area of 20mm×80mm, and then place it in absolute ethanol and acetone for ultrasonic cleaning for 10-20 minutes, After removal, dry them in a gentle stream of nitrogen gas.

[0061] 2) Perform periodic patterned ablation on the surface of the aluminum alloy sample using a high-power ultrafast laser. The laser wavelength is 1030nm, the pulse width is 800fs, the pulse repetition frequency is 200kHz, and the laser power is 6W. Processing, the distance between adjacent scanning lines is 40 μm, the scanning speed is 500 mm / s, and the height of the three-dimensional microcone unit is 60 μm, the diameter of the bottom is about 40 μm, and the period is 40 μm. After the ablation is completed, the sample is ultrasonically cleaned in absolute ethanol After 10 minutes, take it out and dry it in a gentle nitrogen stream.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com