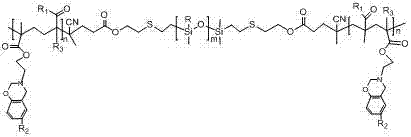

Benzoxazine-type superhydrophobic nano-silica and its preparation method and application

A technology of nano-silica and benzoxazine, which is applied in the treatment of dyed organic silicon compounds, fibrous fillers, coatings, etc., can solve the problem of dispersion (poor compatibility, easy aggregation of nanoparticles, super hydrophobic to achieve excellent super-hydrophobic performance, easy dispersion, and stable anti-icing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

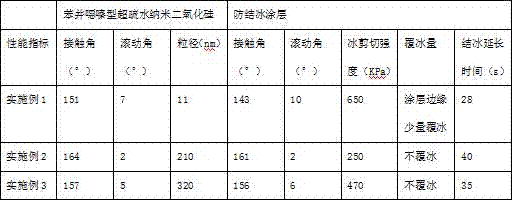

Embodiment 1

[0037] First, add 100ml of chloroform, 9g of phenol, 18g of aminopropyltriethoxysilane, and 5.8g of paraformaldehyde into the round bottom flask. After mixing evenly, heat up to the reflux temperature by microwave radiation (power 300W), and react 4 After 1 hour, the reaction was cooled to room temperature and turned into a light brown solution. The resulting solution was washed with water and dried to obtain an aminopropyltriethoxysilane-type benzoxazine. Add 3 g of the above-prepared benzoxazine to 150 ml of toluene solution, and then add 2 ml of water and 5 g of nano-silicon dioxide (with a particle size of 8 nm). Mix well, under microwave radiation (power 100W), at 20 o Stir for 0.5 hour under the condition of C, filter with suction, wash with water, and dry to obtain 6.8 g of benzoxazine-type superhydrophobic nano-silica.

[0038] 2 g of the prepared benzoxazine-type superhydrophobic nano-silica and 8 g of polymers containing benzoxazine rings were dissolved in ethyl ac...

Embodiment 2

[0040] First, add 150ml of chloroform, 15g of p-trifluoromethylphenol, 16g of aminopropyltrimethoxysilane (CAS No: 13822-56-5), and 5.8g of paraformaldehyde into the round bottom flask. Microwave radiation heating (power 400W) to reflux temperature, react for 6 hours, and cool the reactant to room temperature. The resulting solution was washed with water and dried to obtain a fluorine-containing benzoxazine. Add 1.5 g of the above-prepared fluorine-containing benzoxazine into 100 ml of trifluorotoluene solution, and then add 3 ml of water and 4 g of nano-silicon dioxide (with a particle size of 200 nm). Mix well, under microwave radiation (power 200W), at 50 o Stir for 2 hours under the condition of C, filter with suction, wash with water, and dry to obtain 4.2 g of fluorine-containing benzoxazine-type superhydrophobic nano-silica.

[0041] 1 g of the prepared benzoxazine-type superhydrophobic nano-silica and 9 g of polymers containing benzoxazine rings were dissolved in eth...

Embodiment 3

[0043] First add 120ml of chloroform, 12.9g of p-isopropylphenol, 21g of aminopropyldiisopropylethoxysilane (CAS No: 117559-36-1), 5.8g of paraformaldehyde into the round bottom flask, mix After uniformity, microwave radiation heating (power 400W) to reflux temperature, react for 3 hours, and cool the reactant to room temperature. The resulting solution was washed with water and dried to obtain benzoxazine. Add 2 g of the above-prepared benzoxazine into 50 ml of benzene solution, and then add 3 ml of water and 2 g of nano-silicon dioxide (with a particle size of 300 nm). Mix well, under microwave radiation (power 200W), at 300 o Stir for 1 hour under the condition of C, filter with suction, wash with water, and dry to obtain 3.8 g of benzoxazine-type superhydrophobic nano-silica.

[0044] 3 g of the prepared benzoxazine-type superhydrophobic nano-silica and 7 g of polymers containing benzoxazine rings were dissolved in ethyl acetate to prepare a 30% solution. The prepared s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com