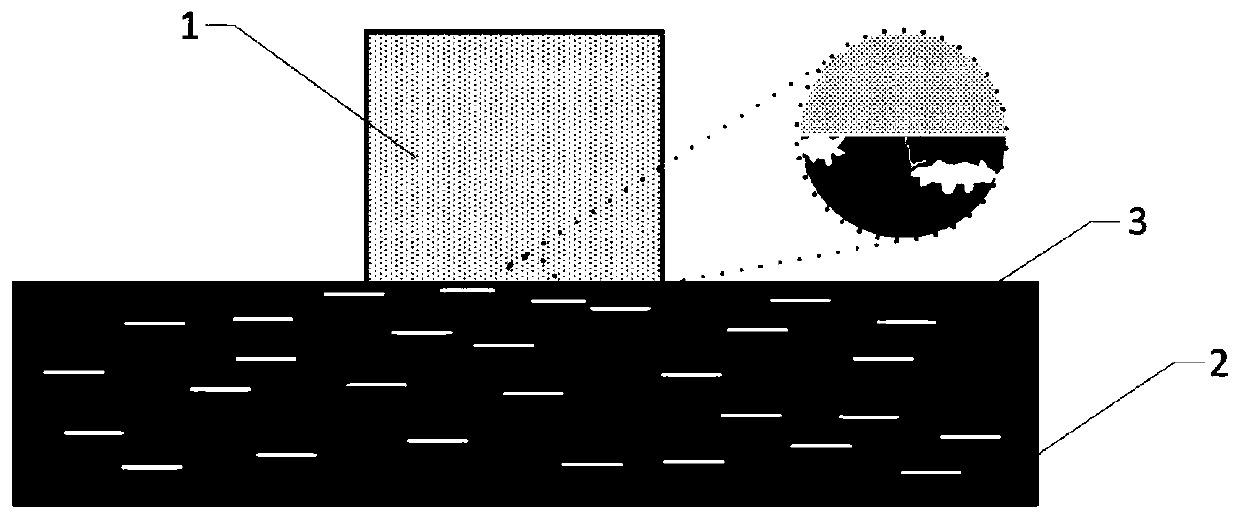

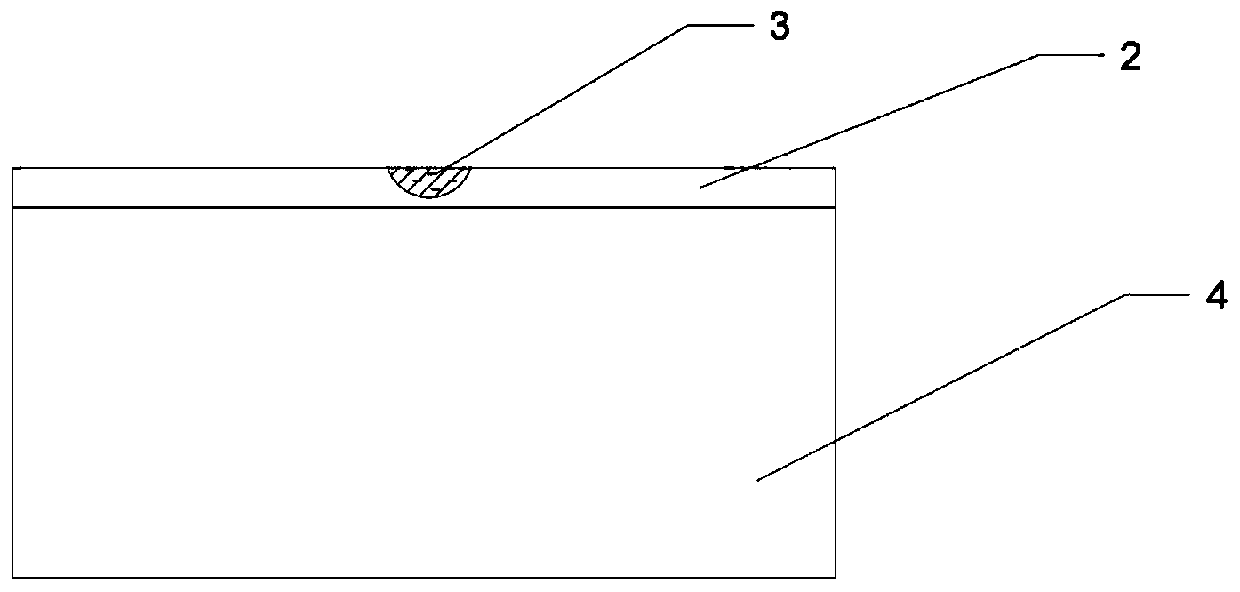

Intelligent anti-icing material, and preparation method and application thereof

An anti-icing, intelligent technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of rubber prone to aging, short service life, energy consumption, etc. The effect of adhesion and acceleration of voluntary shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method for the intelligent anti-icing material described in the above technical solution, comprising the following steps:

[0032] (1) carrying out hydroxylation treatment on the nickel-titanium alloy wire to obtain hydroxylated nickel-titanium alloy wire;

[0033] (2) coating the surface of the hydroxylated nickel-titanium alloy wire obtained in the step (1) with an adhesive to obtain the nickel-titanium alloy wire to be bonded;

[0034] (3) The nickel-titanium alloy wire to be bonded obtained in the step (2) is sequentially mixed with a hydrophobic resin for granulation and injection molding to obtain an intelligent anti-icing material.

[0035] In the present invention, the amount of each component used in the preparation method is consistent with the amount used in the technical solution of the aforementioned intelligent anti-icing material, and will not be repeated here.

[0036] In the invention, the nickel-titani...

Embodiment 1

[0050] Heat treatment: anneal a nickel-titanium alloy wire (composition of Ti-50.8Ni) with a diameter of 150 μm and a length of 0.3 cm at 650 ° C for 25 min, water quenching, and then hold at 300 ° C for 24 h to obtain a martensitic phase Nickel-titanium alloy wire with a change point temperature of -30 to -10°C;

[0051] Pretreatment: Ultrasound the heat-treated nickel-titanium alloy wire in acetone for 30 minutes at a frequency of 100 Hz, wash it with distilled water, and wash it in a mixed acid solution of hydrofluoric acid: nitric acid: water with a volume ratio of 1:5:2 for 30 seconds. N 2 blow dry;

[0052] Preparation of intelligent anti-icing material: Disperse the pretreated nickel-titanium alloy wire in Piranha solution, immerse at 90°C for 3 minutes, filter with suction, wash with distilled water and dry to obtain hydroxylated nickel-titanium alloy wire; The hydroxylated nickel-titanium alloy wire is immersed in the Schiff base metal complex / DMF solution, ultrason...

Embodiment 2

[0054] Heat treatment: anneal a nickel-titanium alloy wire (composition of Ti-58.6Ni) with a diameter of 80 μm and a length of 0.3 cm at 450 ° C for 120 min, air-cool, and then hold at 400 ° C for 24 h to obtain a martensitic transformation Nickel-titanium alloy wire with a point temperature of -30~-10°C;

[0055] Pretreatment: Ultrasound the heat-treated nickel-titanium alloy wire in acetone for 30 minutes at a frequency of 100 Hz, wash it with distilled water, and wash it in a mixed acid solution of hydrofluoric acid: nitric acid: water with a volume ratio of 1:5:2 for 15 seconds. N 2 blow dry;

[0056] Preparation of intelligent anti-icing material: Disperse the pretreated nickel-titanium alloy wire in Piranha solution, immerse at 90°C for 1.5 min, filter with suction, wash with distilled water and dry to obtain hydroxylated nickel-titanium alloy wire; The obtained hydroxylated nickel-titanium alloy wire is immersed in the Schiff base metal complex / DMF solution, ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com