A porous superhydrophobic-lubricating composite anti-icing coating and its preparation method

A technology of super-hydrophobic coating and porous structure, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of loss of anti-icing effect, increase of adhesion, etc., achieve excellent hydrophobicity, low equipment requirements, easy to obtain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of described anti-icing coating comprises the following steps:

[0020] (1) First, low molecular polybutadiene, polyacryl, water-based polyurethane, alkyl ketene dimerization, and heptane (solvent) are mixed according to the weight ratio of 1:2-5:5-6:3-6: 7-9 After mixing, heat and stir at 20-30°C for 1 hour, add toluenesulfonylhydrazide with a total mass of 20-50wt.% of the mixture, foam at 50-80°C for 1 hour, and form a film by spraying at room temperature Finally, dry at 40-60°C to obtain a superhydrophobic coating with a foamed porous structure;

[0021] (2) Next, adding nano-graphene with a particle size of 70-100nm according to the weight ratio of 1-2.5wt.% into the hyaluronic acid (HA) lubricating fluid, and obtaining the bionic joint lubricating fluid after ultrasonic dispersion;

[0022] (3) Finally, the surface of the superhydrophobic coating with a foamed porous structure is injected with a nanographene-modified biomimetic joint lubric...

Embodiment 1

[0025] (1) Mix low-molecular polybutadiene, polyacryloyl, water-based polyurethane, alkyl ketene dimer, and heptane in a mass ratio of 1:3:5:3:7, then heat and stir at 25°C After 1h, add 20wt.% of the total mass of the mixture tosylhydrazide, foam at 70°C for 1 hour, spray with a spray gun at room temperature, and dry at 50°C to obtain a superhydrophobic-lubricating composite anti-icing foam with a porous structure coating;

[0026] (2) adding nano-graphene with a particle size of 90nm into the hyaluronic acid (HA) lubricating fluid according to the weight ratio of 2wt.%, and obtaining the modified bionic joint lubricating fluid after ultrasonic dispersion;

[0027] (3) Using a micro-syringe, inject nano-graphene modified hyaluronic acid (HA) 0.3g / cm 2 Finally, a composite coating is obtained.

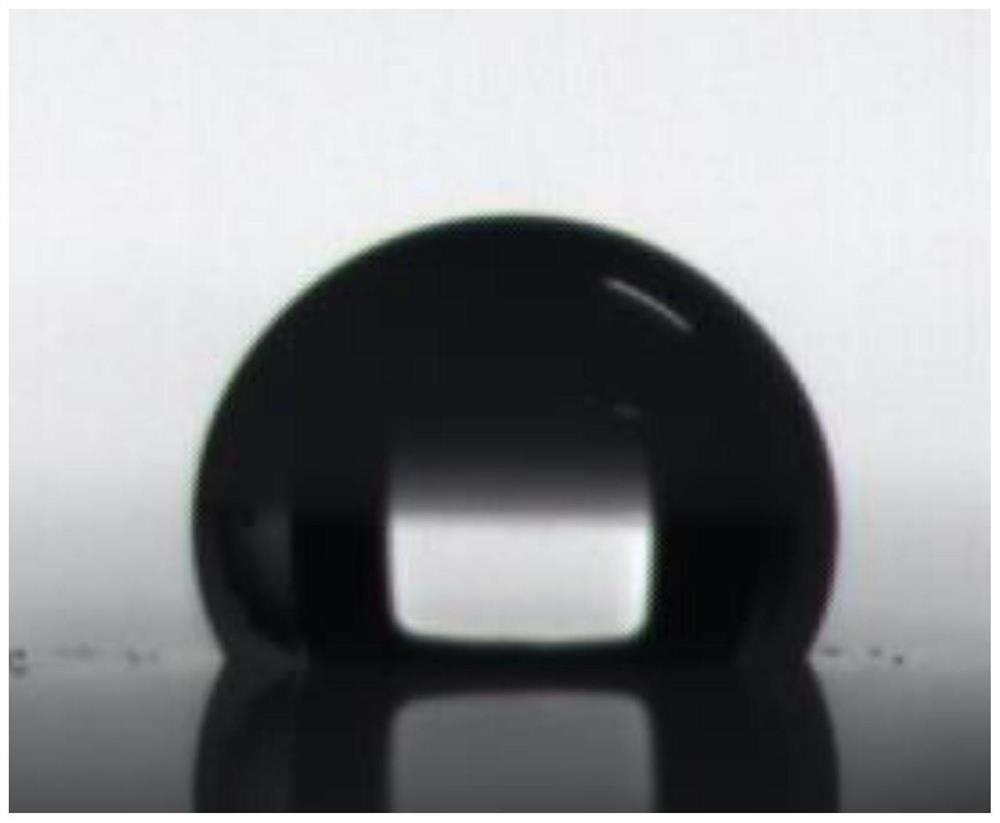

[0028] The prepared superhydrophobic-lubricating composite anti-icing coating with foamed porous structure has a water droplet contact angle of 120°, such as figure 1 Shown; The obt...

Embodiment 2

[0030] (1) Mix low-molecular polybutadiene, polyacryloyl, water-based polyurethane, alkyl ketene dimer, and heptane in a mass ratio of 1:4:6:5:8, then heat and stir at 30°C 1h, add 45wt.% of toluenesulfonylhydrazide and foam at 75°C for 1 hour, spray with a spray gun at room temperature, and dry at 40°C to obtain a superhydrophobic coating with a foamed porous structure;

[0031] (2) adding nano-graphene with a particle size of 80nm to a hyaluronic acid (HA) lubricating fluid according to a weight ratio of 1.5wt.%, and obtaining a modified bionic joint lubricating fluid after ultrasonic dispersion;

[0032] (3) Using a micro-syringe, inject nano-graphene in hyaluronic acid (HA) 0.4g / cm 2 Finally, a composite coating is obtained.

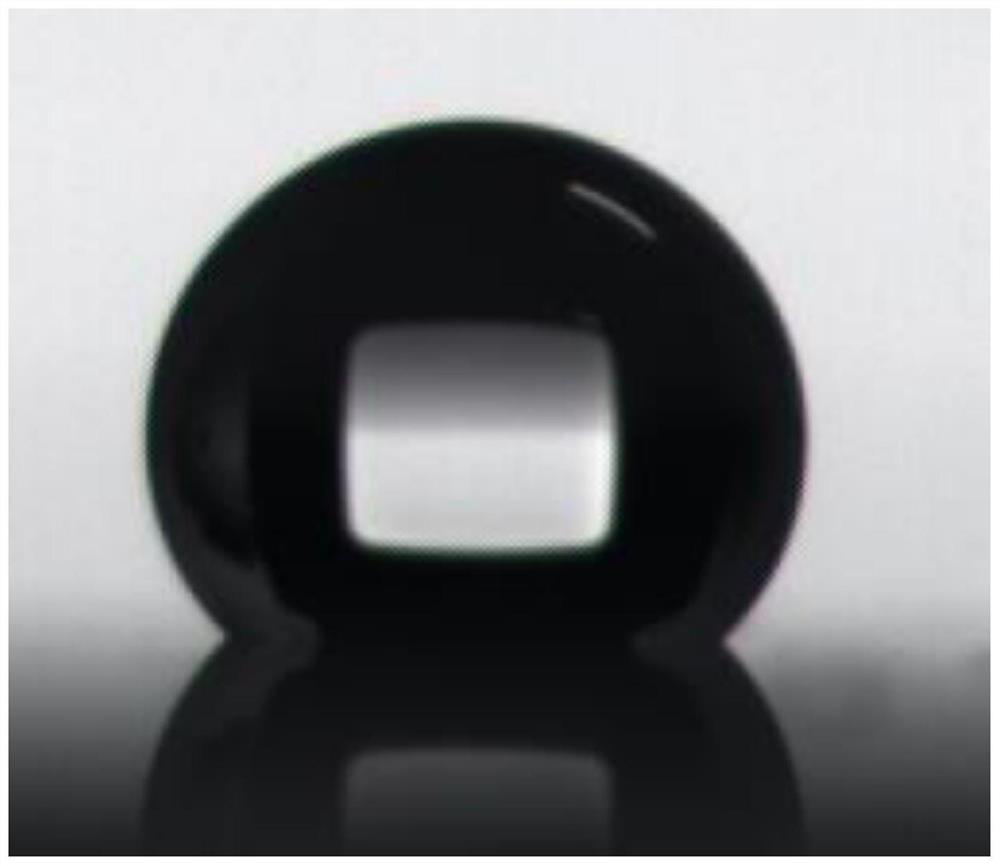

[0033] The prepared superhydrophobic-lubricating composite anti-icing coating with foamed porous structure has a water droplet contact angle of 130°, such as figure 2 Shown; the resulting synovial fluid-injected composite coating has a contact are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com