Anti-icing paint and preparation method thereof

An anti-icing and coating technology, applied in coating and other directions, can solve the problems of limited scope of application, dangerous operation, low efficiency, etc., and achieve the effects of low surface tension and surface energy, improved hydrophobicity, and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

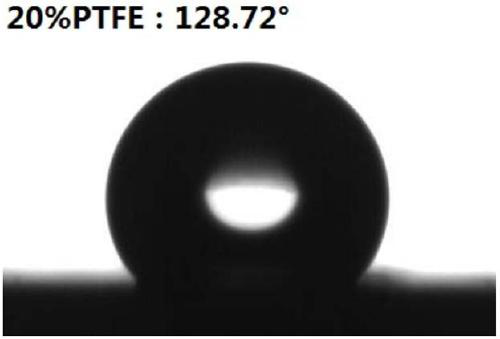

Embodiment 1

[0043] In this embodiment, the components and mass percentages of the anti-icing coating are as follows:

[0044] Polysilazane resin 40%

[0045] PTFE micropowder 20%

[0046] Nano Ceramic Particles 5%

[0047] Nano Silica 10%

[0048] Titanium dioxide 5%

[0049] Organomodified bentonite 2%

[0050] Perfluorosurfactant 2%

[0051] Alkyl acrylate-unsaturated amine copolymer 1%

[0052] Butyl acetate 15%

[0053] The preparation method of this anti-icing coating is as follows:

[0054] (1) 40 g of polysilazane resin and 20 g of polytetrafluoroethylene micropowder were mixed with a high-speed mixer at a stirring speed of 500 rpm to obtain material A1.

[0055] (2) Add the nano-ceramic particles of 5g in the material A1, the nano-silica of 10g, the pigment of 5g, the anti-sedimentation agent of 2g, the dispersant of 2g, the leveling agent of 1g and the diluent of 15g, high-speed stirring mixing Material, get material B1.

[0056] In this embodiment, the base material is...

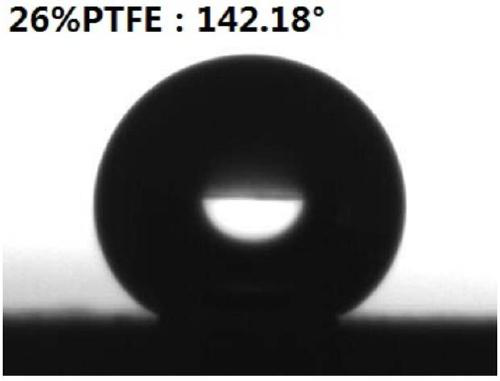

Embodiment 2

[0060] In this embodiment, the components and mass percentages of the anti-icing coating are as follows:

[0061] Polysilazane resin 34%

[0062] PTFE Micropowder 26%

[0063] Nano Ceramic Particles 5%

[0064] Nano Silica 10%

[0065] Titanium dioxide 5%

[0066] Fumed silica 2%

[0067] Perfluorosurfactant 2%

[0068] Phosphate lipid type leveling agent 1%

[0069] Di-n-butyl ether 15%

[0070] The preparation method of this anti-icing coating is as follows:

[0071] (1) 34g of polysilazane resin and 26g of polytetrafluoroethylene micropowder were mixed with a high-speed mixer at a stirring speed of 500rpm to obtain material A2.

[0072] (2) Add the nano-ceramic particle of 5g in the material A2, the nano-silica of 10g, the pigment of 5g, the anti-sedimentation agent of 2g, the dispersant of 2g, the leveling agent of 1g and the diluent of 15g, high-speed stirring mixes Material, get material B2.

[0073] In this embodiment, the base material is 316 stainless steel ...

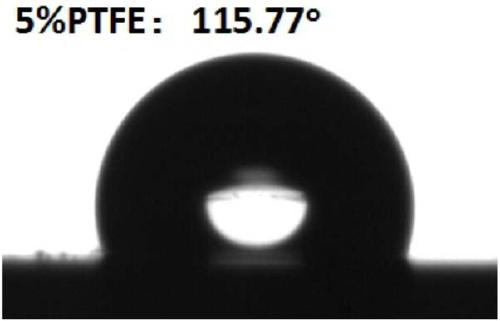

Embodiment 3

[0077] In this embodiment, the components and mass percentages of the anti-icing coating are as follows:

[0078] Dimethicone resin 55%

[0079] PTFE micropowder 5%

[0080] Nano Ceramic Particles 5%

[0081] Nano Silica 10%

[0082] Titanium dioxide 5%

[0083] Organomodified bentonite 2%

[0084] Dispersant 2%

[0085] Leveling agent 1%

[0086] Thinner 15%

[0087] The preparation method of this anti-icing coating is as follows:

[0088] (1) Mix 55 g of polydimethylsiloxane resin and 5 g of polytetrafluoroethylene micropowder with a high-speed mixer at a stirring speed of 500 rpm to obtain material A3.

[0089] (2) Add the nano-ceramic particle of 5g in the material A3, the nano-silica of 10g, the pigment of 5g, the anti-sedimentation agent of 2g, the dispersant of 2g, the leveling agent of 1g and the diluent of 15g, high-speed stirring mixes Material, obtain material B3.

[0090] In this embodiment, the substrate material is completely the same as that in Embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com