Telescopic aluminum strip positioning and compressing device for hollow glass molecular sieve filling machine

A pressing device and molecular sieve technology, which is applied in the field of glass processing, can solve the problems of molecular sieve splashing, reduced practicability, unfavorable integrated molding, etc., and achieve the effect of improving connection strength and stability, reducing contact area, and improving mobile flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

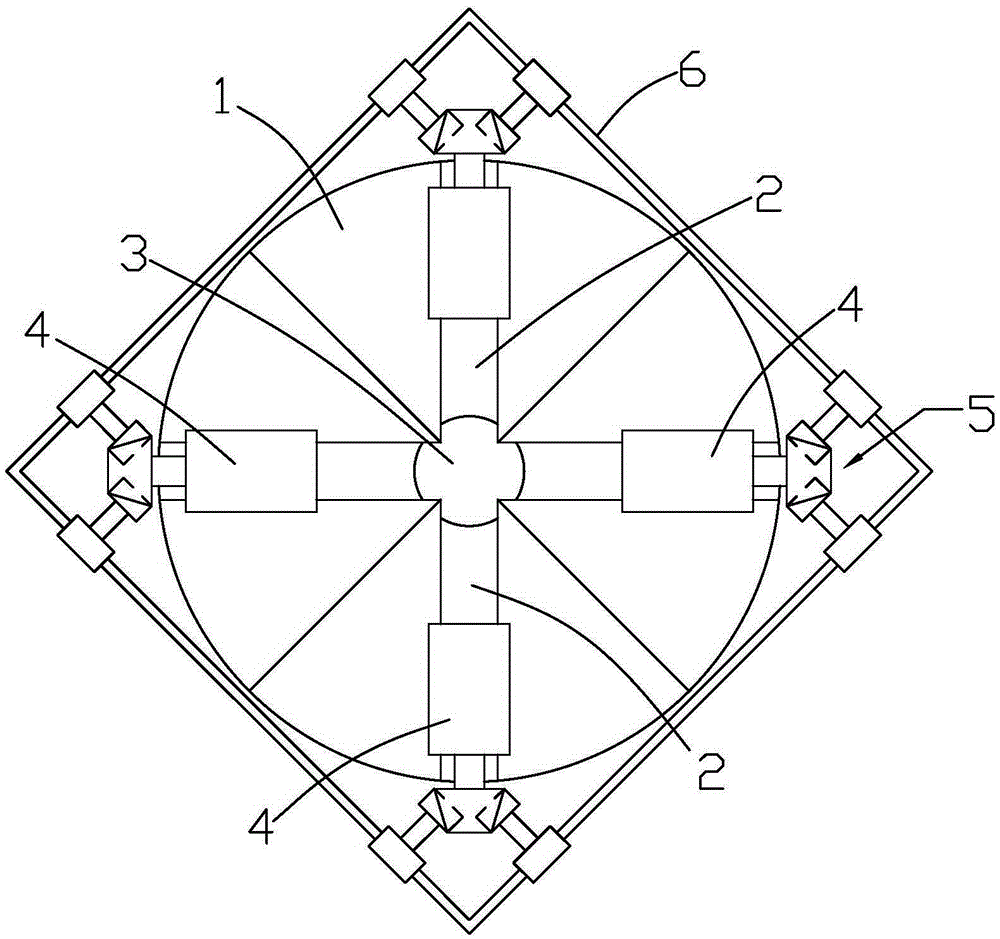

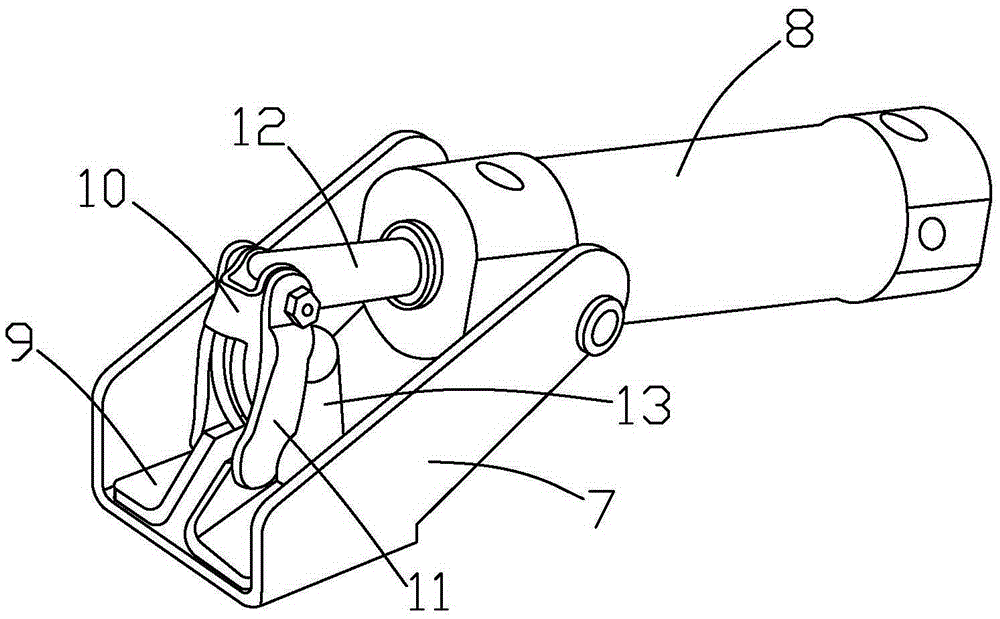

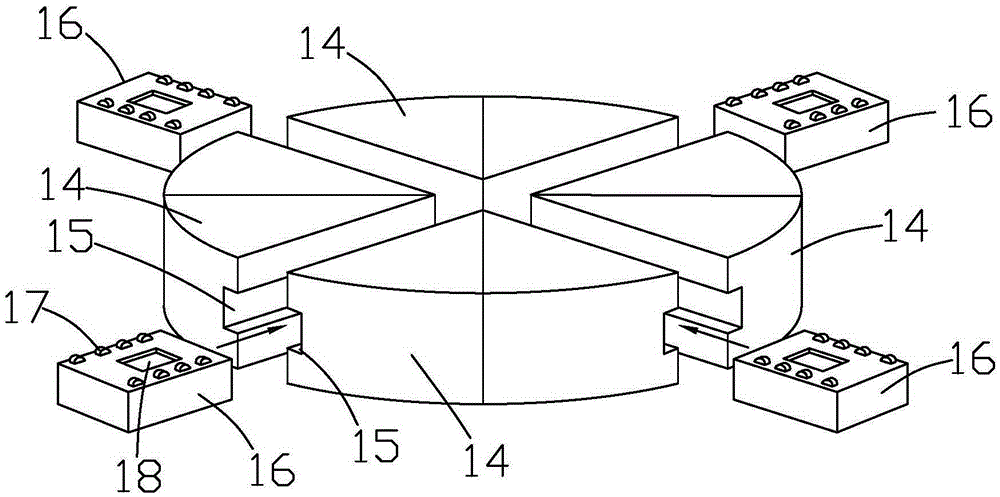

[0027] Such as Figure 1 to Figure 5As shown, it is a telescopic aluminum bar positioning and pressing device for a hollow glass molecular sieve filling machine of the present invention, which includes a rotary table 1, a hydraulic jacking device 4 and a positioning and pressing mechanism 5. The rotary table 1 is connected to the molecular sieve through a rotating shaft 3 On the filling machine, through the design of the rotating table 1, the filling of the aluminum strip frame 6 of different shapes can be satisfied, and the position and direction of the aluminum strip frame 6 can not be adjusted manually, and the filling hole on the aluminum strip frame 6 can be directly rotated to The bottom of the filling pinhole improves the molecular sieve filling efficiency, prevents the molecular sieve from splashing out, and shortens the filling time. Positioning guide groove 2 is arranged, and positioning guide groove 2 is provided with mutually parallel limit chute 15, and limit chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com