Patents

Literature

65results about How to "Save filling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

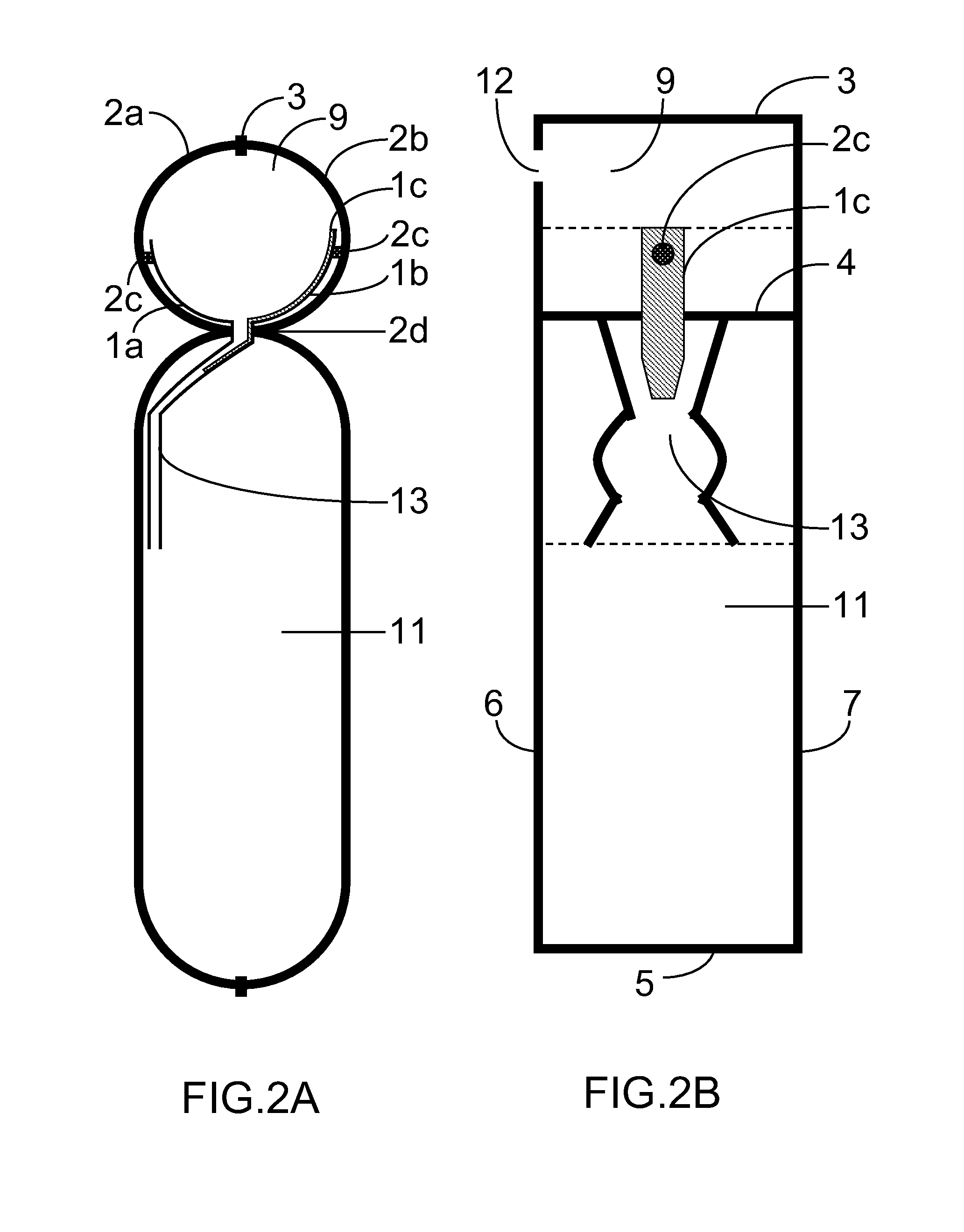

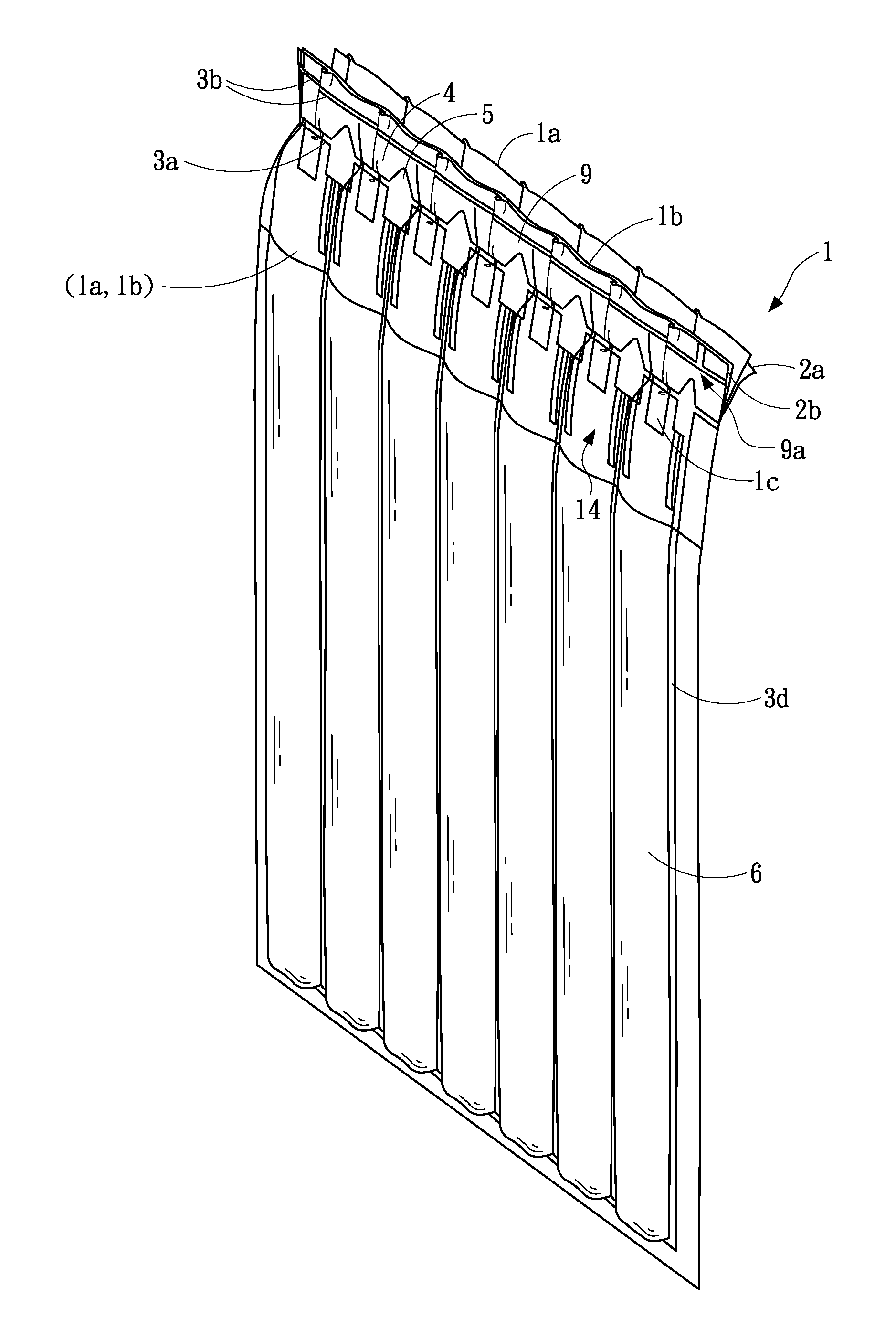

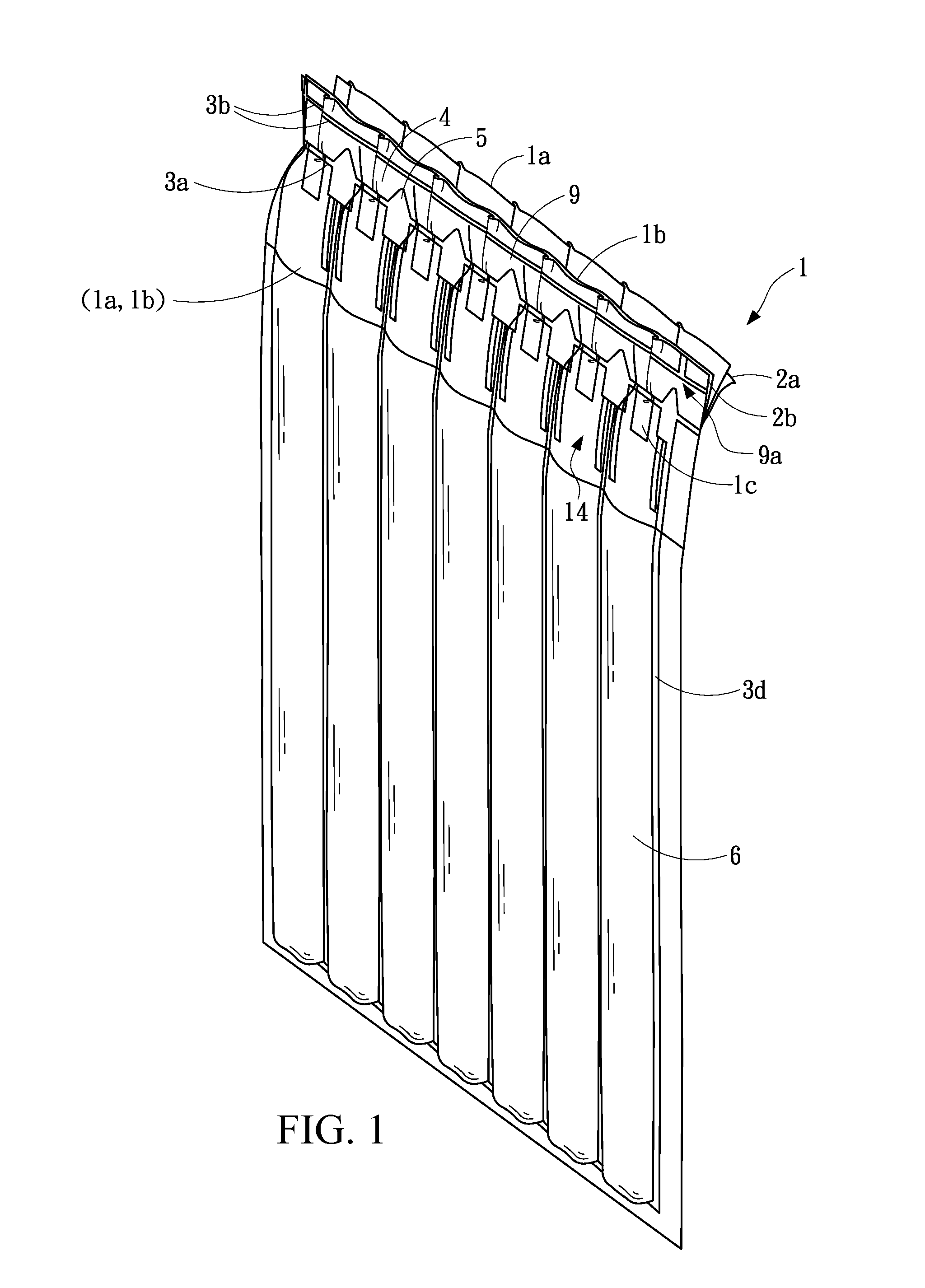

Inflatable pneumatic bag and the manufacture method thereof

ActiveUS7568508B2Effectively overcome reverse air flowPrevent air escapeLiquid fillingWrapping material feeding apparatusAirflow

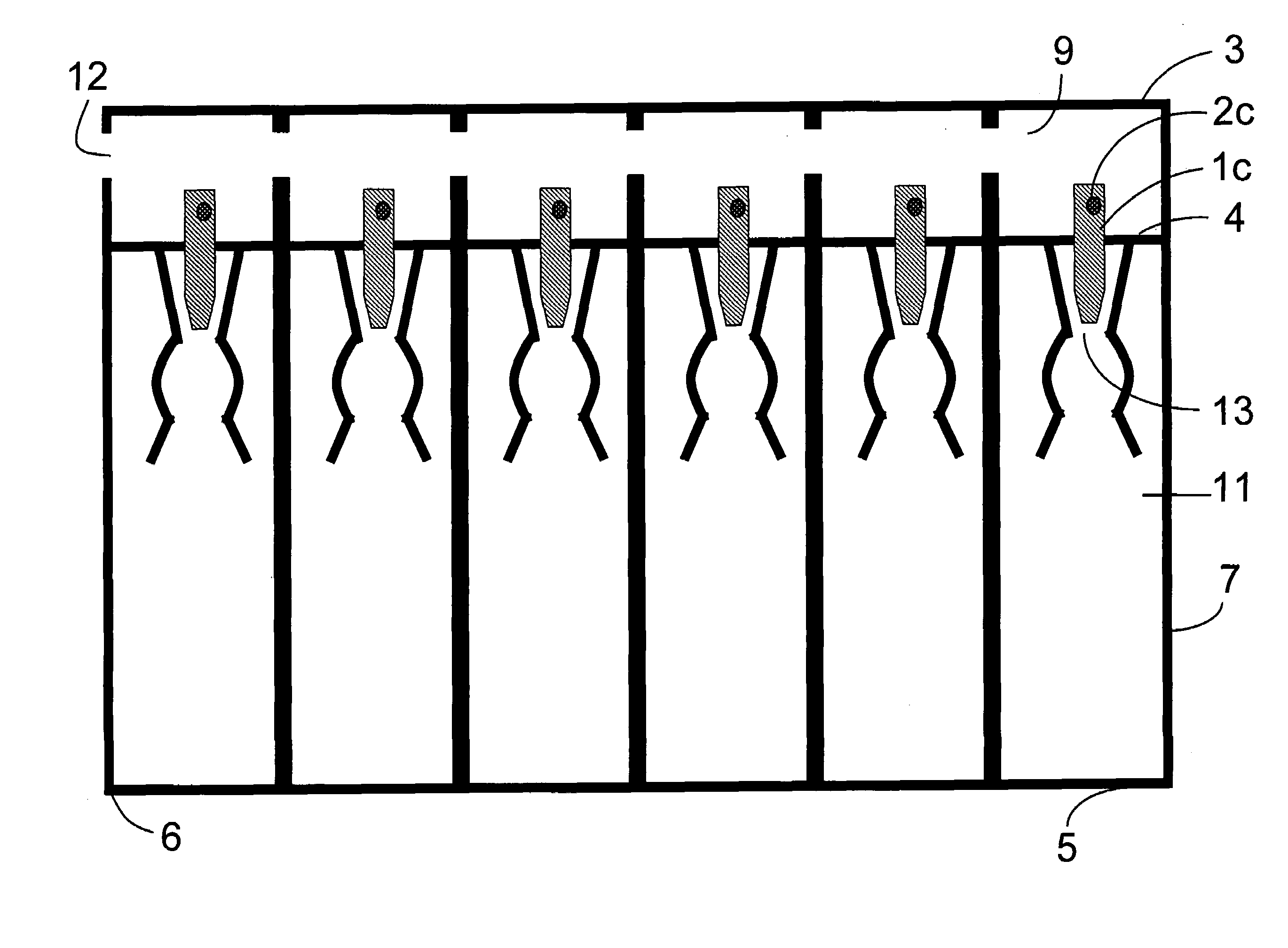

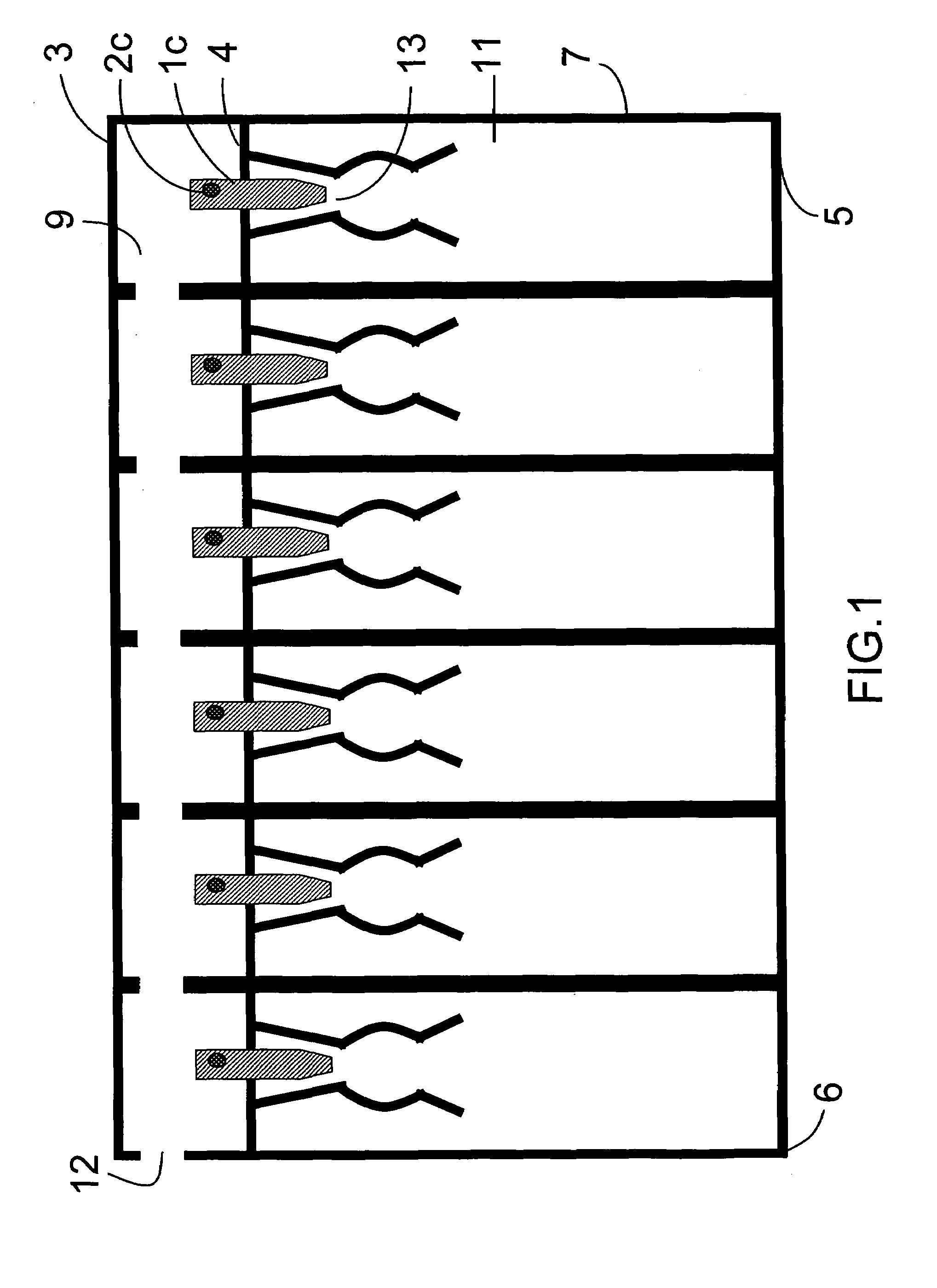

An inflatable pneumatic bag is disclosed. An inflatable pneumatic bag includes a pneumatic hole disposed at one end of a pneumatic channel. Air, which is applied to the pneumatic hole, moves along the pneumatic channel, then through air ingress holes covered with inner layers which are removed by the expansion of the outer layers to fill all the air tubes. When the air tube is filled with air, one or more inner layers cover and then close the air ingress hole to overcome reverse air flow. Then, a curve-shaped air passage in the air tube narrows to further prevent air escape. With the inner layer, effectively overcoming reverse air flow, and the air passage, further preventing air escape, the inflatable pneumatic bag filled with air may last for a substantial long period of time.

Owner:LIAO CHIEH HUA

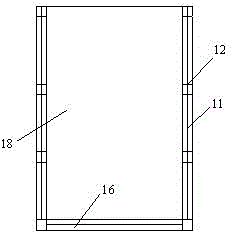

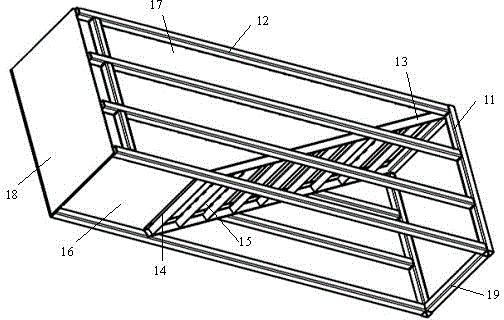

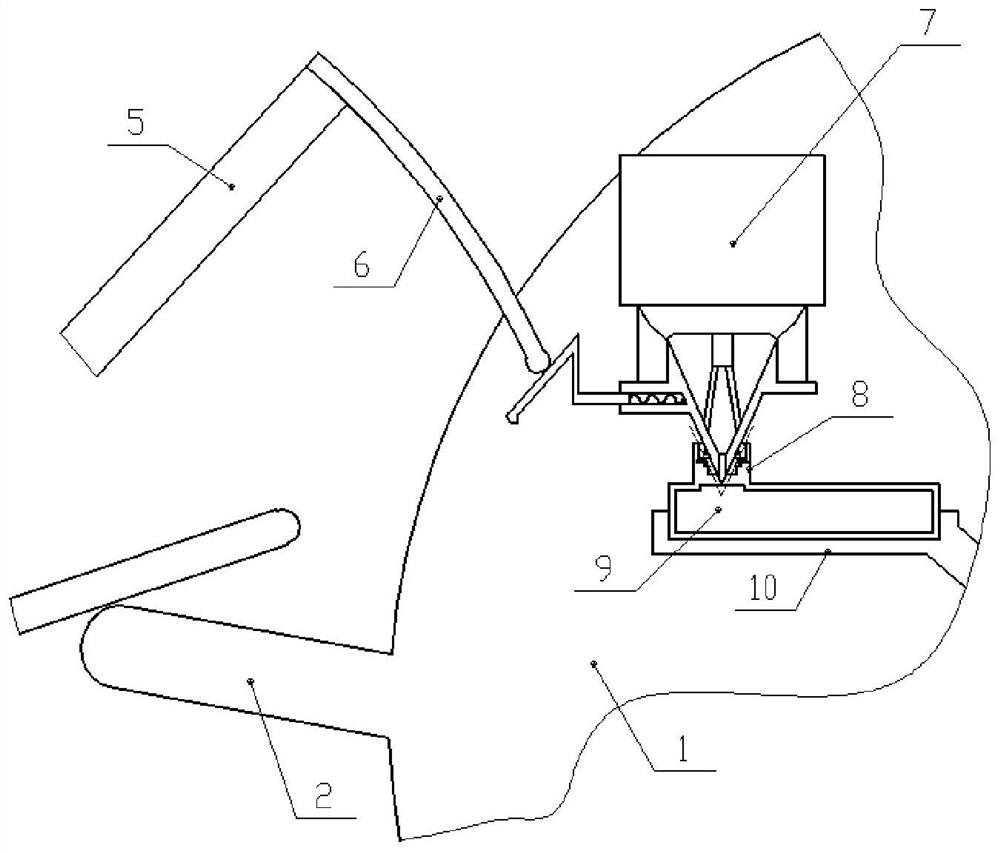

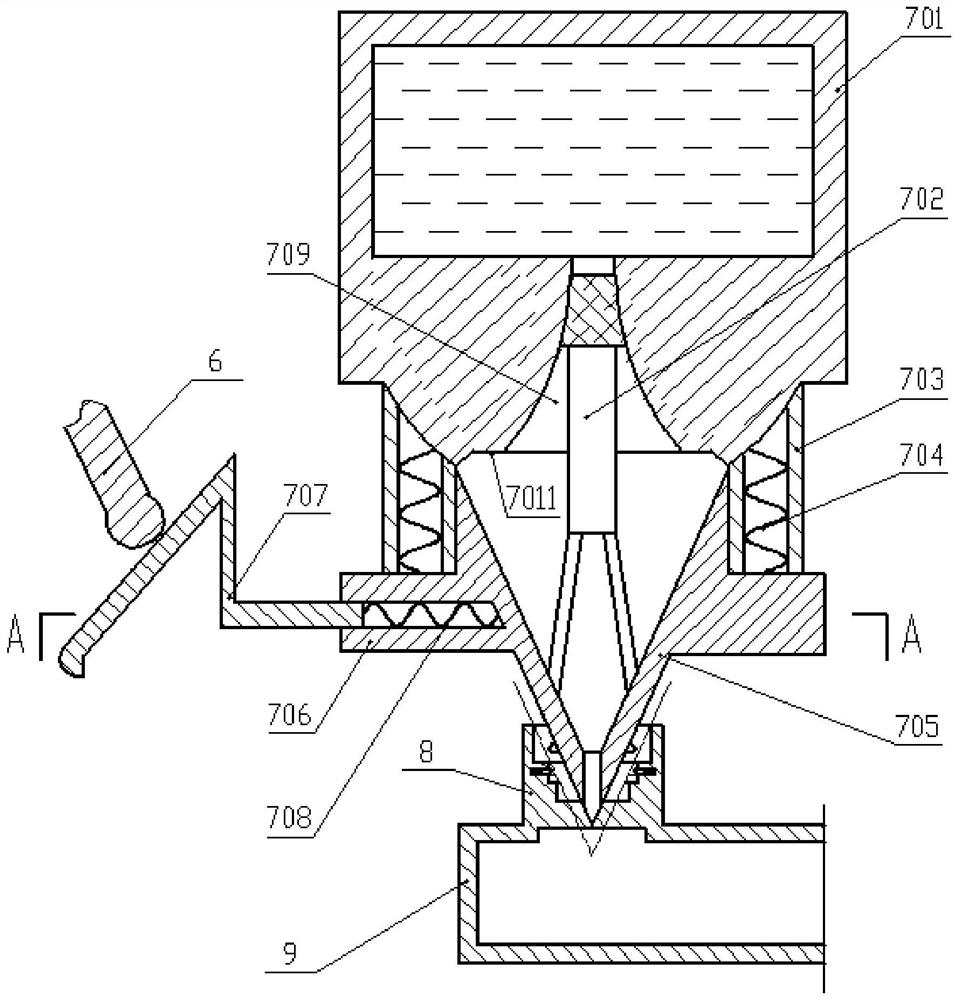

Expansive-soil slope hygroscopic deformation model experiment method and system

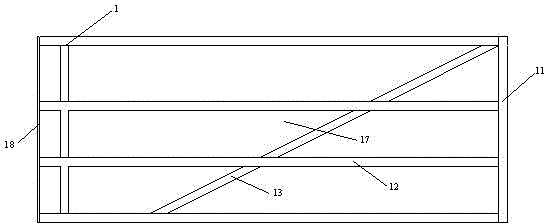

InactiveCN103954740AReduce penetrationTo achieve the test effectEarth material testingSoil scienceSimulated rainfall

The invention discloses an expansive-soil slope hygroscopic deformation model experiment method and a system. The expansive-soil slope hygroscopic deformation model experiment method comprises following steps: A, soil samples are turned and subjected to sun drying so as to control water content and soil filling thickness; B, soil filling is carried out by layers, slope cutting is carried out uniformly, and a part of monitoring components are buried; C, an obtained soil slope is allowed to stand until cracks are generated, and a displacement sensor is arranged; D, physical quantity initial values are recorded; E, a rainfall simulator is used for realizing dropping-pouring type concentrated rainfall, and rainfall amount is controlled; F, physical quantities and rainfall amount are monitored according to rainfall stages; G, a rainfall-evaporation cycle is carried out repeatedly so as to stimulate drying and watering cycle; and H, slope morphologic change is recorded, and results are analyzed. The system comprises a model case, monitoring components, and a rainfall simulator; the monitoring components are arranged in the model case; and the rainfall simulator is arranged on the upper part slope shoulder of the model case. The expansive-soil slope hygroscopic deformation model experiment method and the system are suitable for a plurality of expansive-soil slope hygroscopic deformation model experiments, and possess significant importance for researches on expansive-soil slope stability and catastrophe mechanisms.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

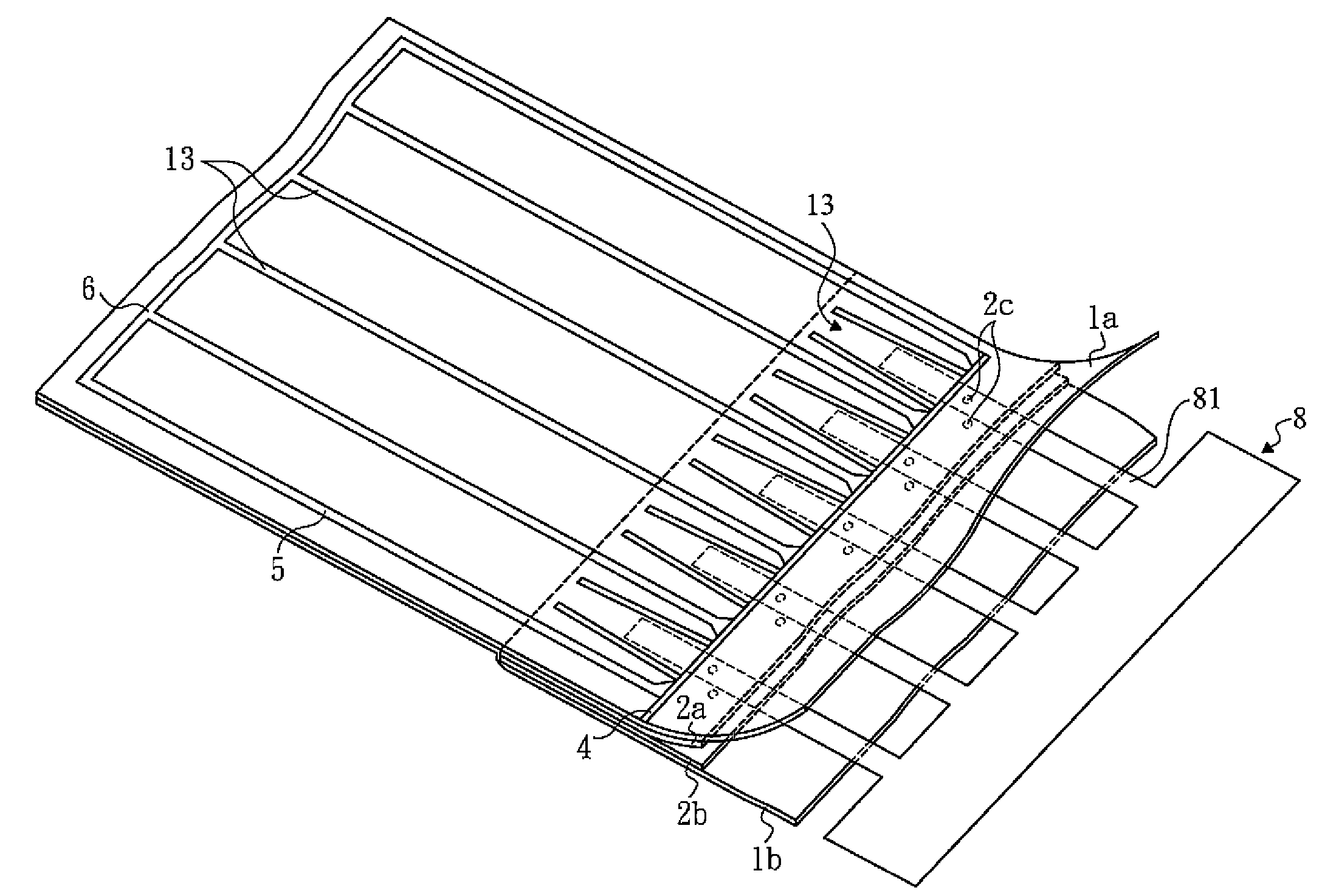

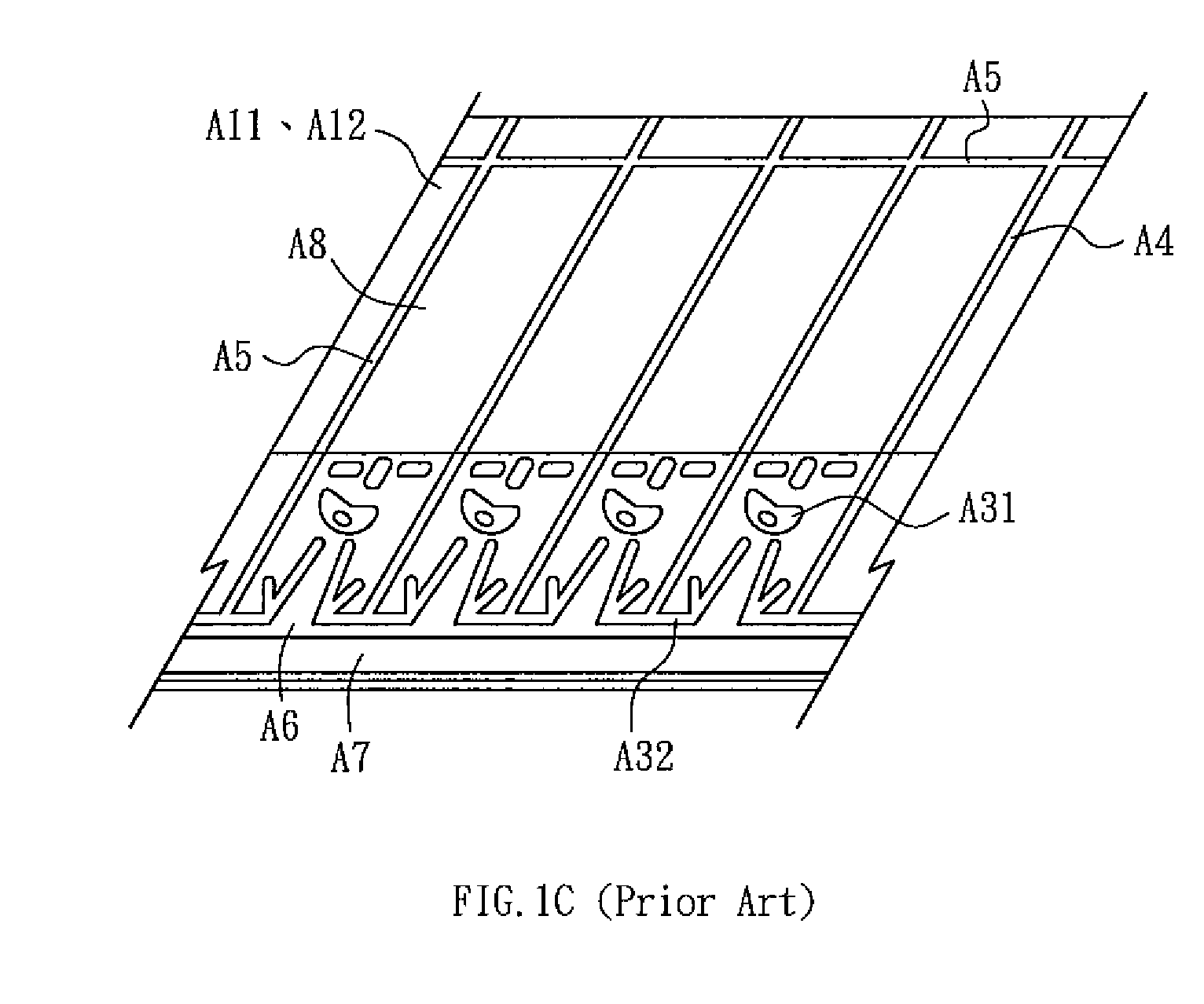

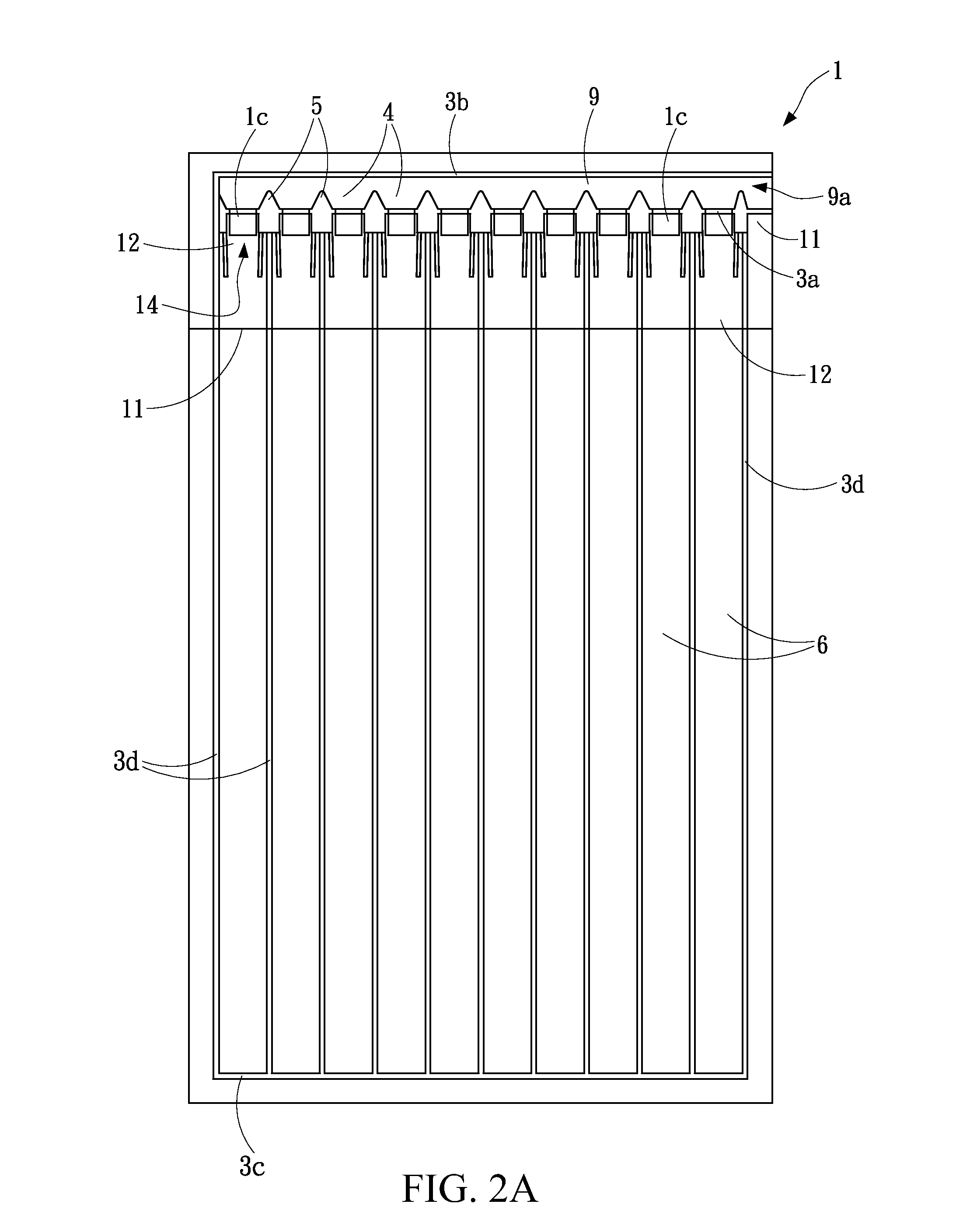

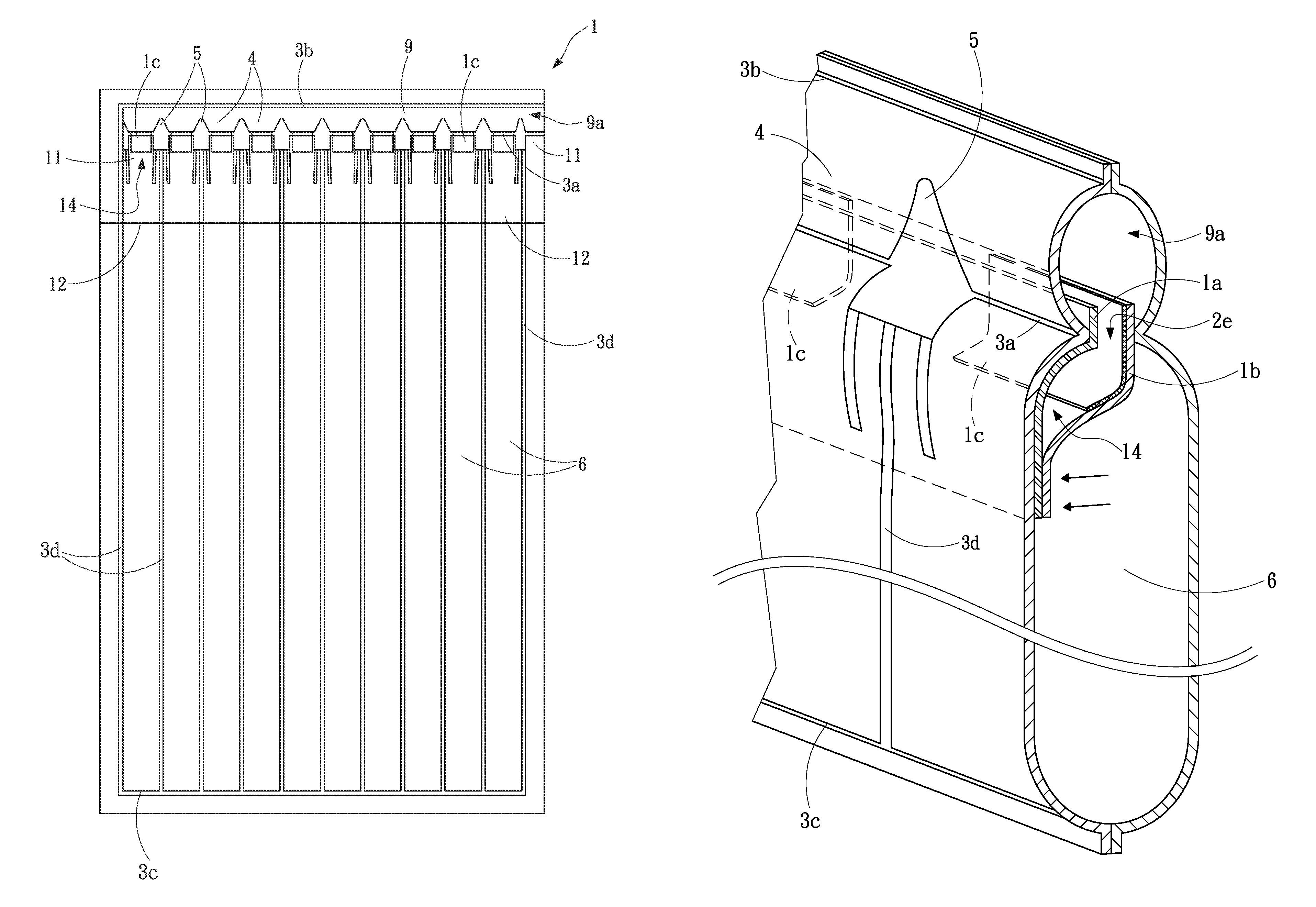

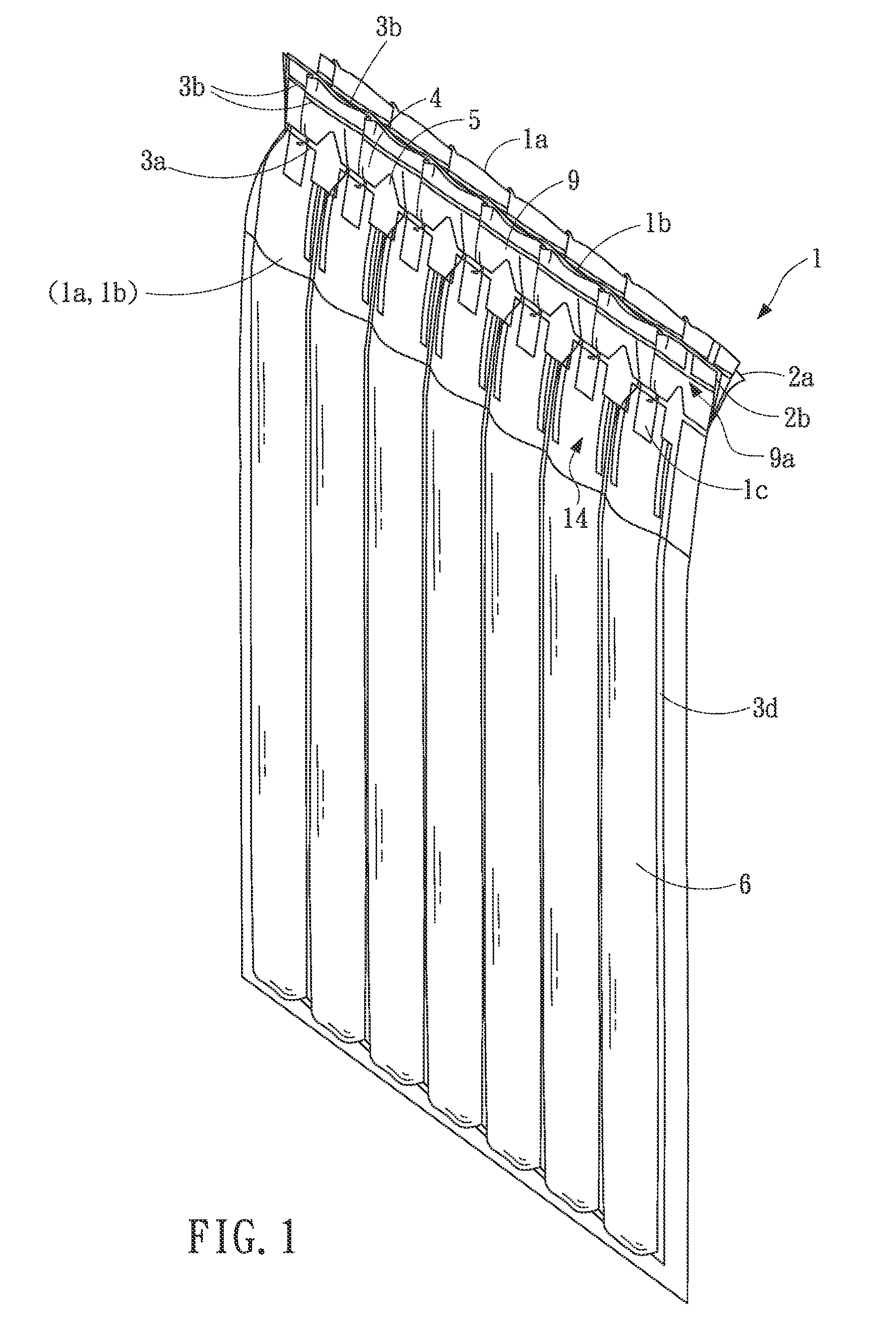

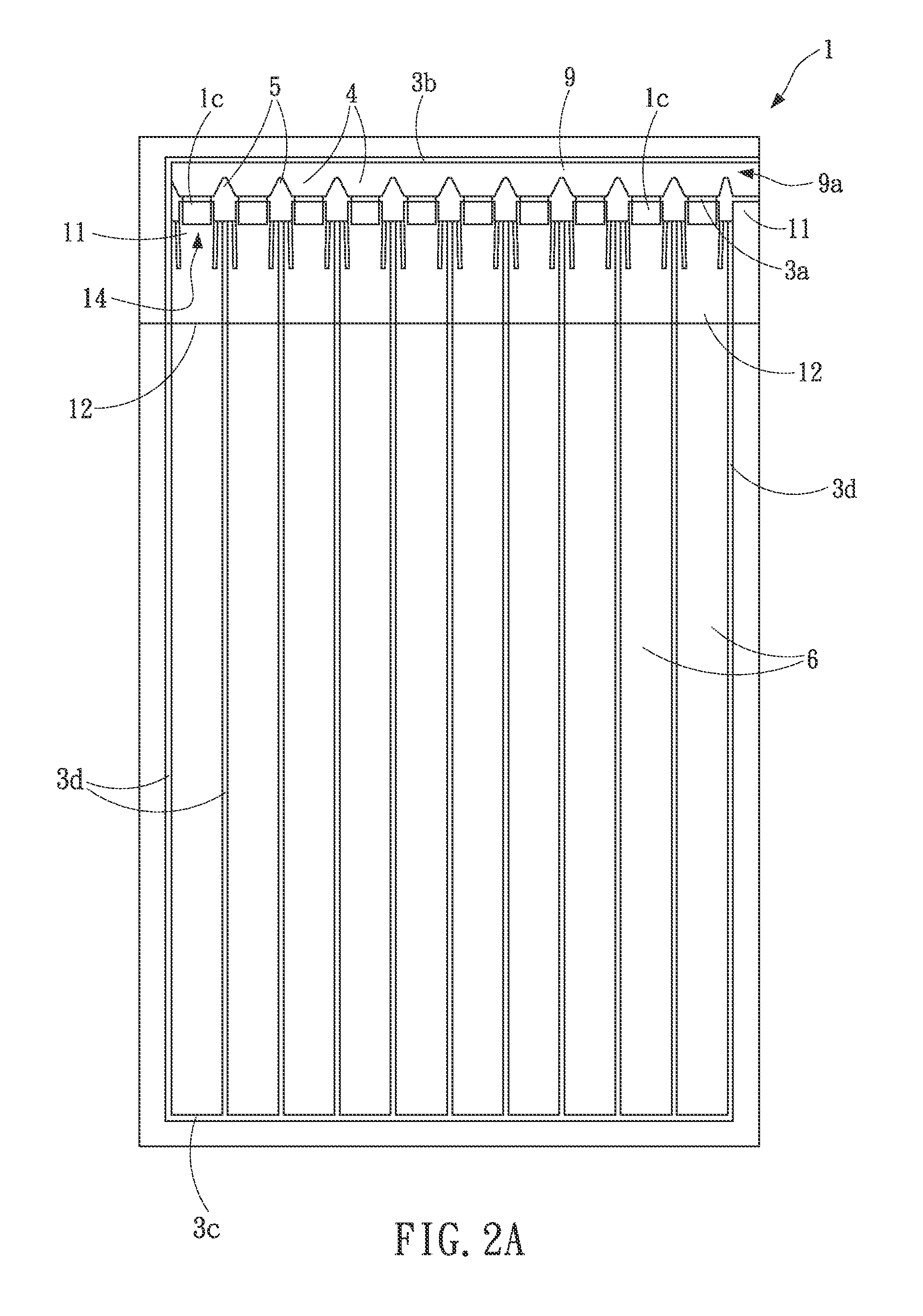

Air enclosure without heat resistant material and manufacturing of same

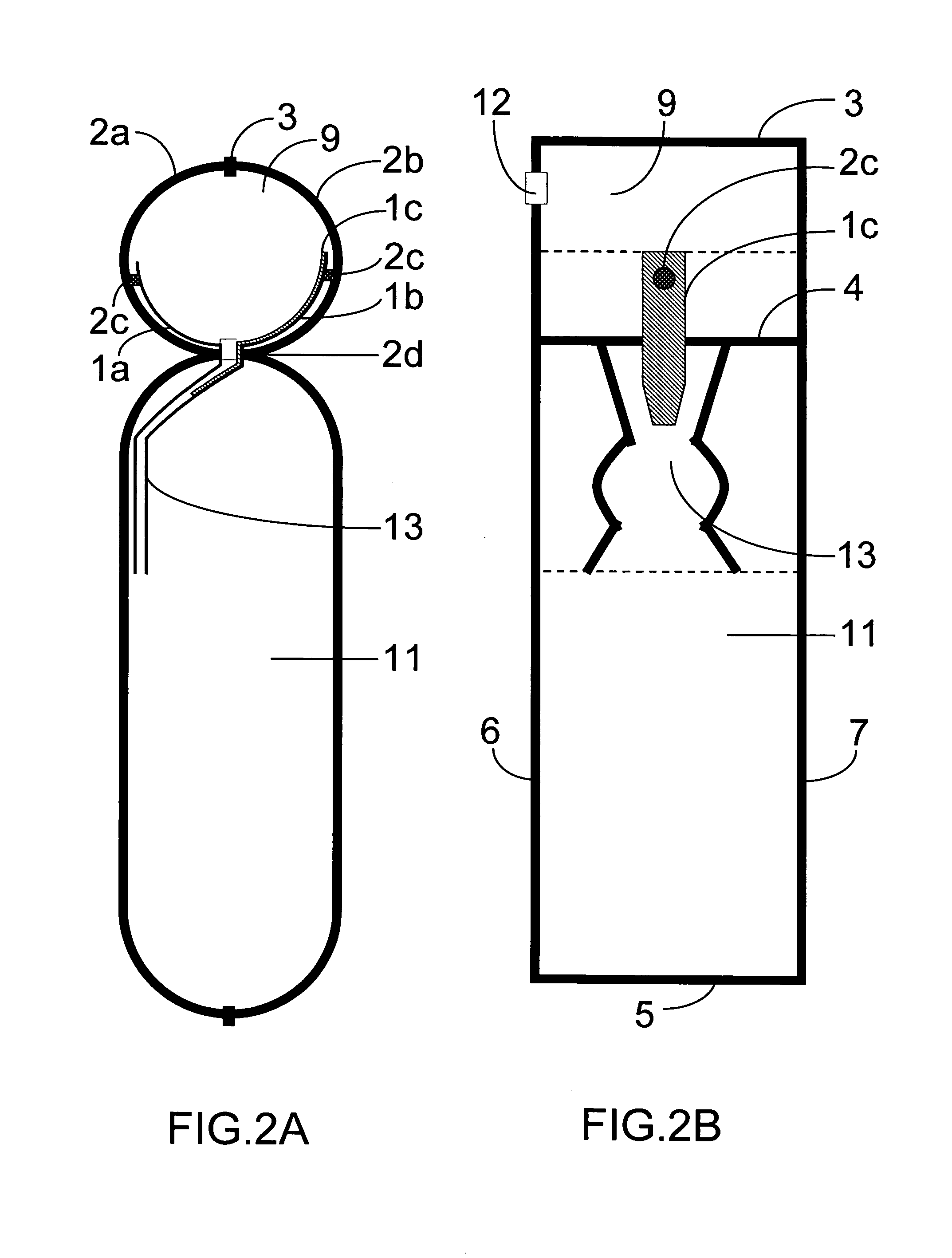

InactiveUS20090239006A1Save air filling timeLow costEnvelopes/bags making machinerySynthetic resin layered productsEngineeringAir compression

An air enclosure without a heat resistant material is formed by stacking two outer films and two inner films, allowing the two inner films to be lain in between the two outer films, placing a heat resistant pad between the two inner films, adhering the two outer films and the two inner films to each other to form at least one air inlet between the two inner films and at least one air cylinder between the two outer films, and thereafter, taking out the heat resistant pad, and filling air into the air cylinder via the air inlet to cause the air cylinder to be filled with air and expanded, where the air in the air cylinder compresses the two inner films to cover the air inlet to shield the air cylinder.

Owner:LIAO CHIEH HUA

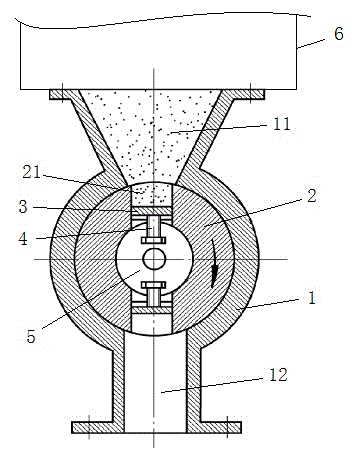

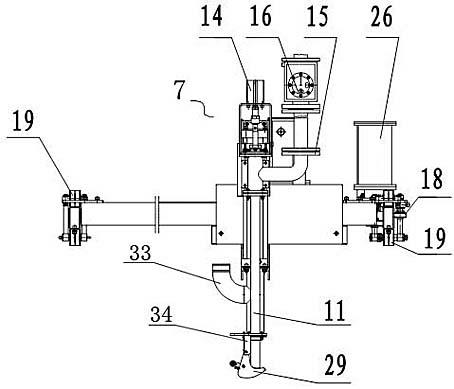

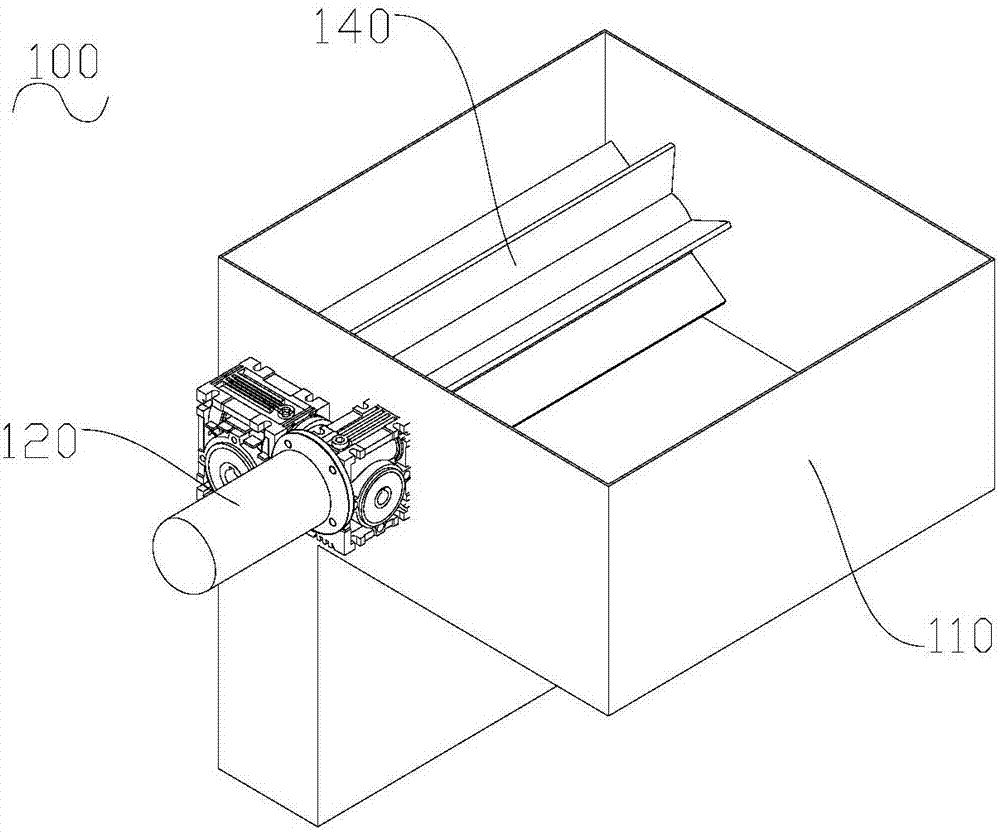

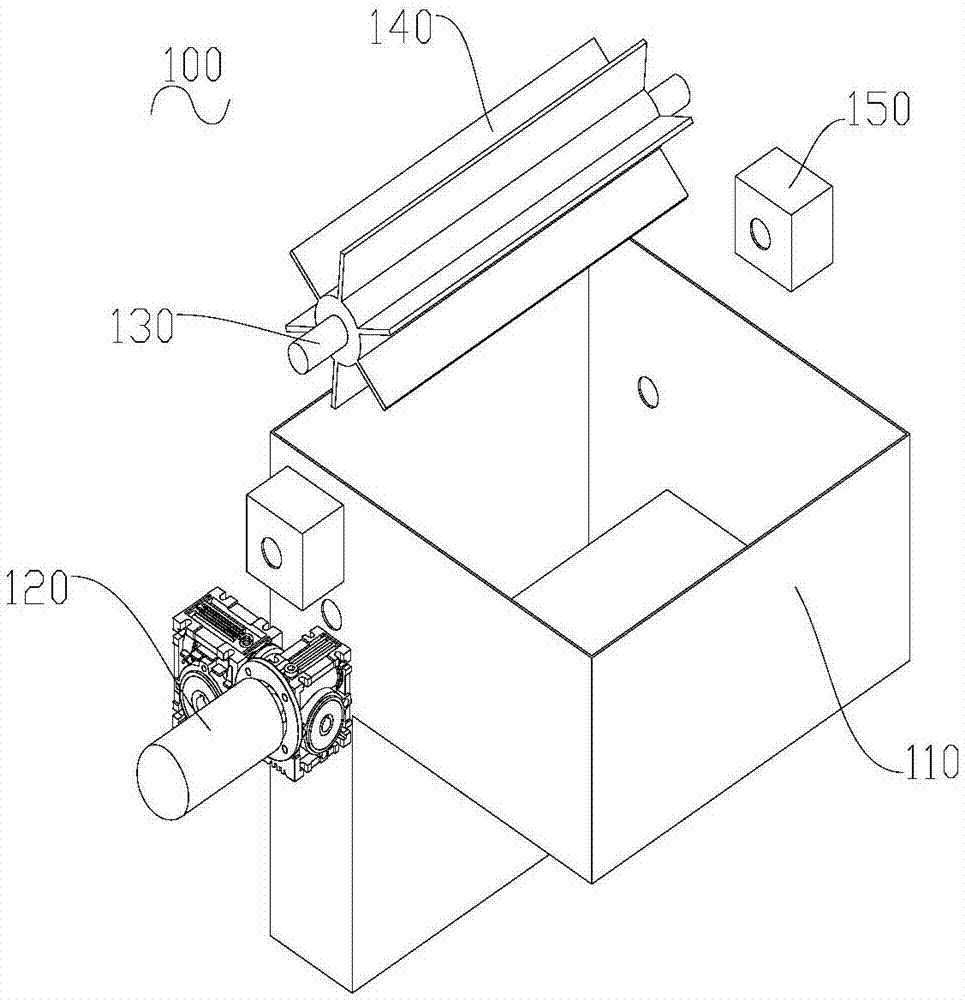

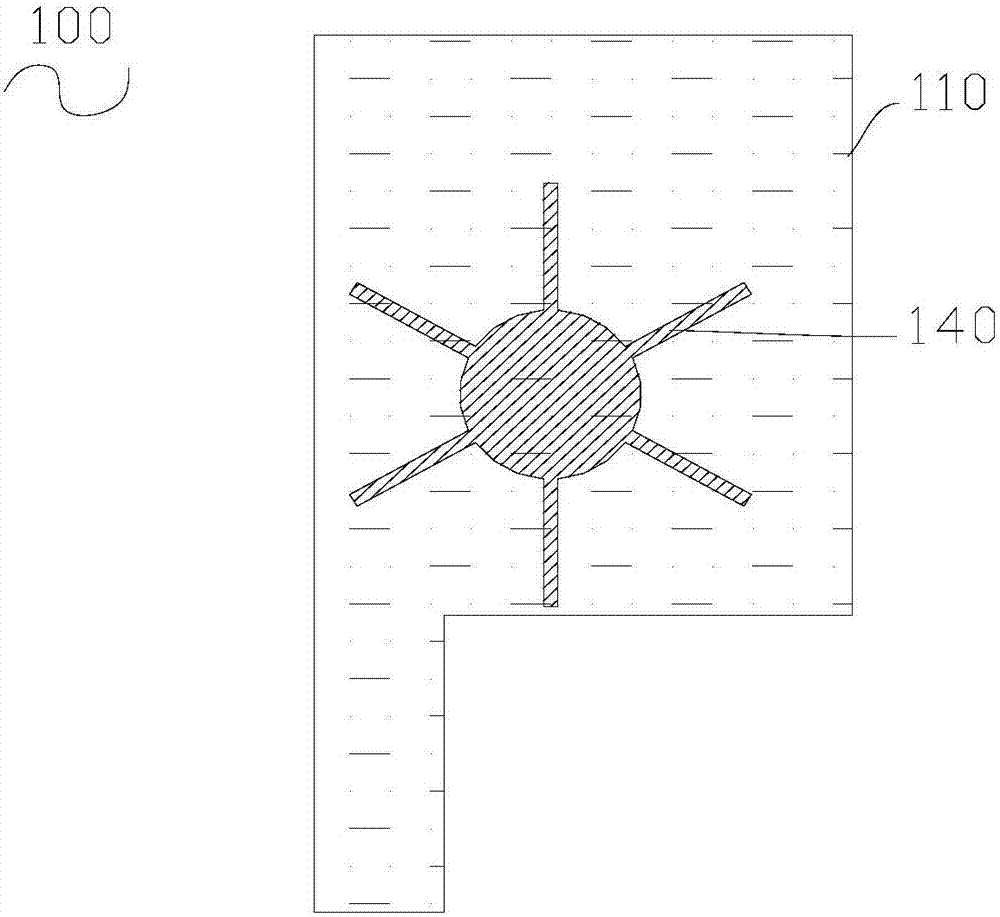

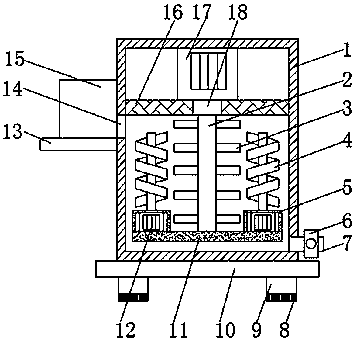

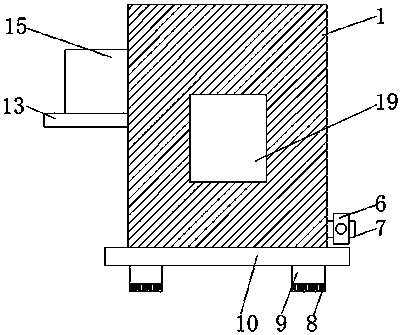

Powder measuring device

The invention discloses a powder measuring device. The powder measuring device comprises a hopper and is also provided with a valve body, a rotating shaft and a cylindrical revolving drum, wherein the middle part of the valve body is provided with a through hole for cooperatively inserting the revolving drum; the outer wall of the revolving drum is attached to the through hole; the two sides of the valve body are provided with a feed hole and a discharge hole which are communicated with the through hole respectively; one side of the feed hole of the valve body is communicated with the bottom of the hopper; the included angle of the feed hole and the discharge hole is 90-270 degrees; the rotating shaft is coaxially connected with the revolving drum; the revolving drum is radially provided with a plurality of powder cavities. According to the powder measuring device, a fixed amount of powder can be quickly measured, and the filling time is saved.

Owner:CHONGQING DAYE FOOD

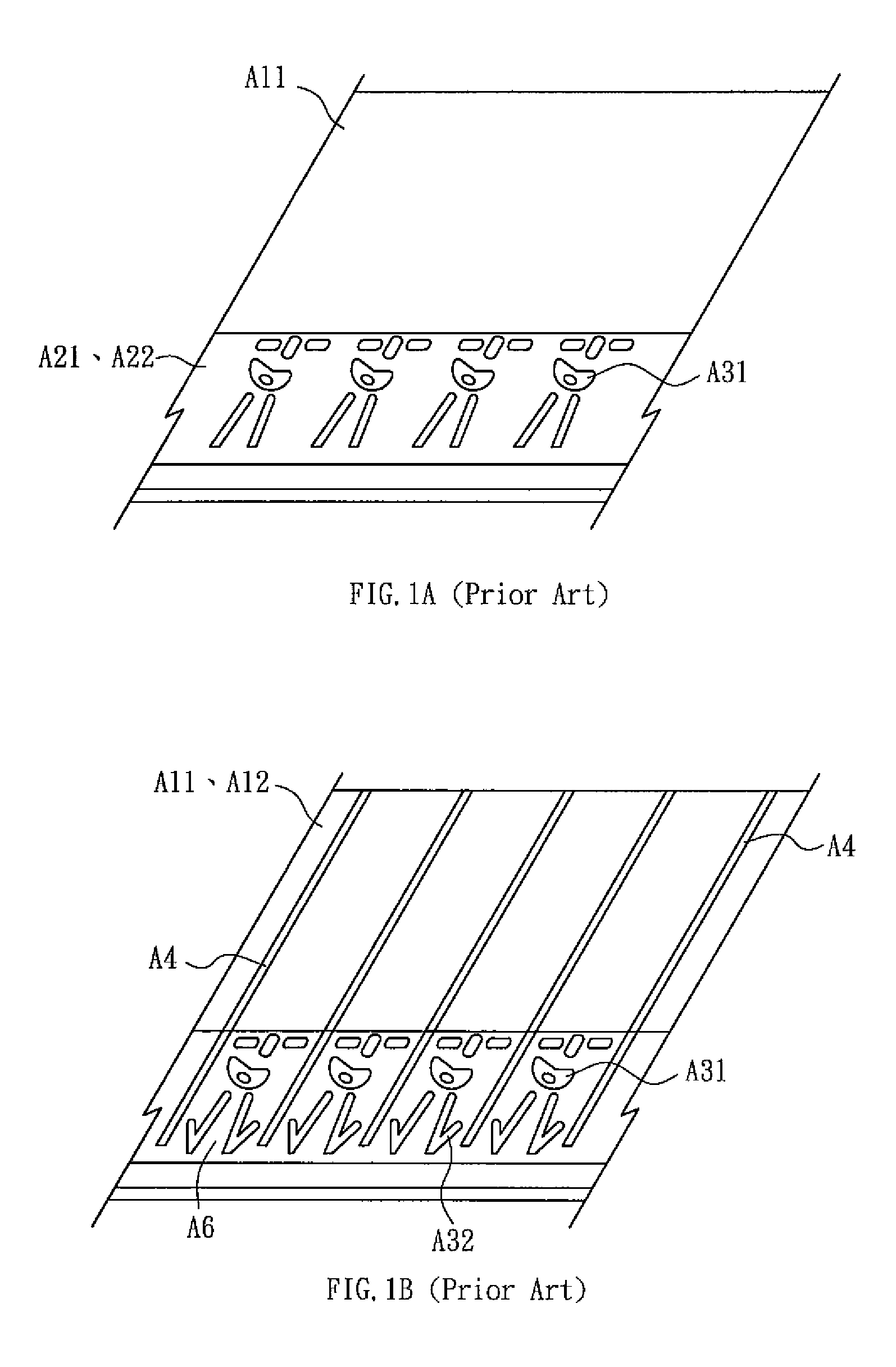

Inflatable pneumatic bag and the manufacture method thereof

ActiveUS20090297068A1Effectively overcome reverse air flowPrevent air escapeEnvelopes/bags making machineryLiquid fillingEngineeringAirflow

An inflatable pneumatic bag is disclosed. An inflatable pneumatic bag includes a pneumatic hole disposed at one end of a pneumatic channel. Air, which is applied to the pneumatic hole, moves along the pneumatic channel, then through air ingress holes covered with inner layers which are removed by the expansion of the outer layers to fill all the air tubes. When the air tube is filled with air, one or more inner layers cover and then close the air ingress hole to overcome reverse air flow. Then, a curve-shaped air passage in the air tube narrows to further prevent air escape. With the inner layer, effectively overcoming reverse air flow, and the air passage, further preventing air escape, the inflatable pneumatic bag filled with air may last for a substantial long period of time.

Owner:LIAO CHIEH HUA

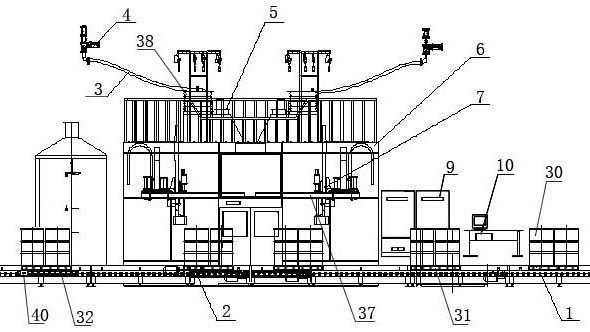

Visual-addressing double-barrel compatible filling system and filling method thereof

InactiveCN102674224AImprove compliance rateAccurate measurementBarrels/casks fillingEngineeringMachine

The invention discloses a visual-addressing double-barrel compatible filling system and a filling method thereof. The filling system comprises a machine body, a conveying mechanism, a filling mechanism, a visual addressing and locating mechanism, a sliding mechanism, a weighing measurement mechanism, a rechecking measurement mechanism and a tray; the visual addressing and locating mechanism comprises electric eyes, a processor and a controller, wherein the electric eyes are arranged at the upper end of the machine body, the processor is connected with the electric eyes, and the controller is connected with the processor; the filling mechanism is arranged on the sliding mechanism; the tray is arranged on the conveying mechanism; and the weighing measurement mechanism, the rechecking measurement mechanism, the filling mechanism and the sliding mechanism are respectively connected with the processor. According to the filling system and the filling method thereof, disclosed by the invention, a plurality of material barrels can be located once by adopting high-tech electric eye equipment, so that the filling time is greatly shortened, and the working efficiency is increased.

Owner:CHANGCHUN BEIFANG INSTR EQUIP

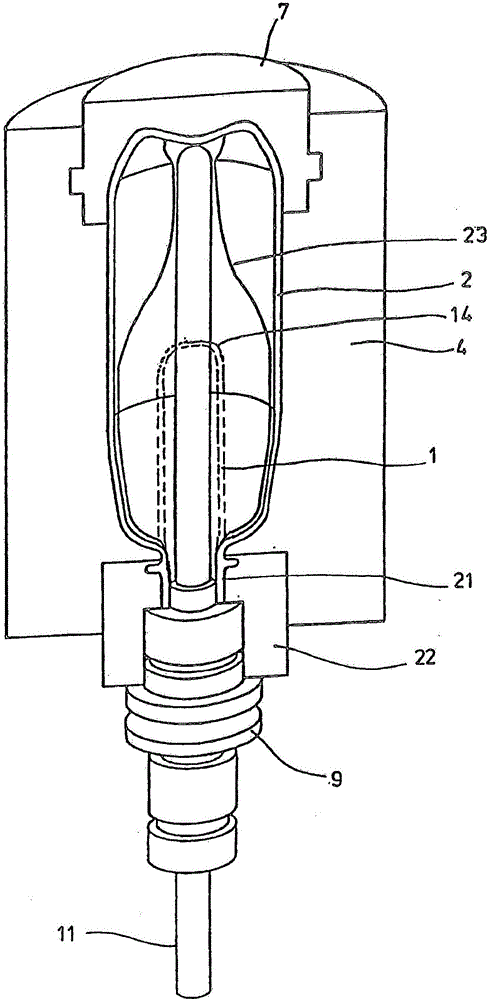

Method and device for producing a container filled with filling medium

ActiveCN106103044AEasy to understandRapid coolingDomestic articlesLiquid materialLiquid stateEngineering

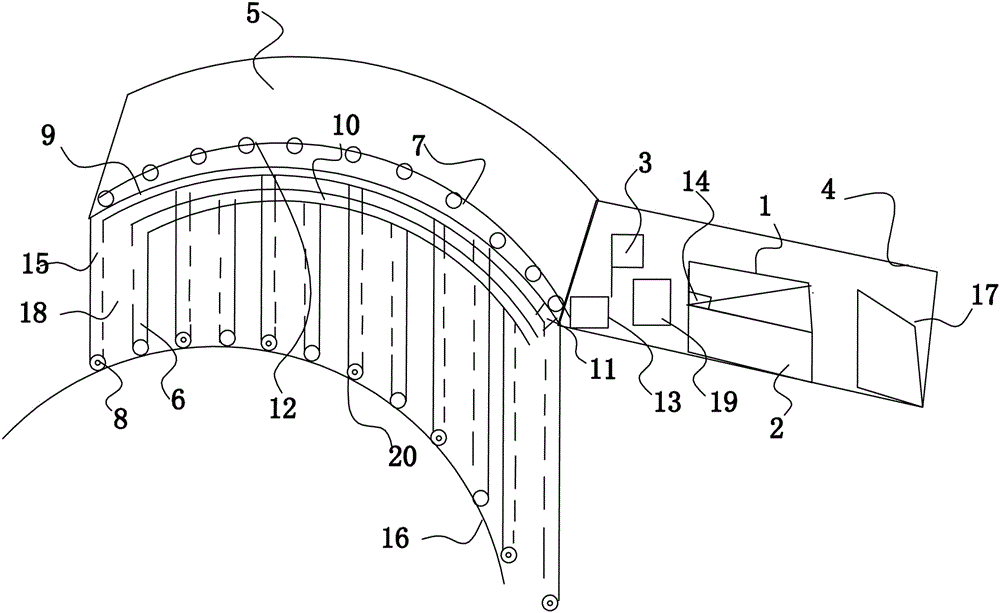

The invention relates to a method for producing a container (2) filled with a liquid filling medium, wherein a preform (1) made of a thermoplastic material is stretched after thermal conditioning by means of a stretching rod (11) and is transformed into the container (2) in an inflation process, wherein the inflation process comprises a pre-blowing phase, in which a fluid at a first pressure level is used for inflation, and a main blowing phase, in which a fluid at a second pressure level higher than the first pressure level is used for inflation. The invention is characterised in that the fluid used in the pre-blowing phase is a blowing gas, and that the fluid used in the main blowing phase is the filling medium. The invention further relates to a device for carrying out a method according to the invention.

Owner:KHS GMBH

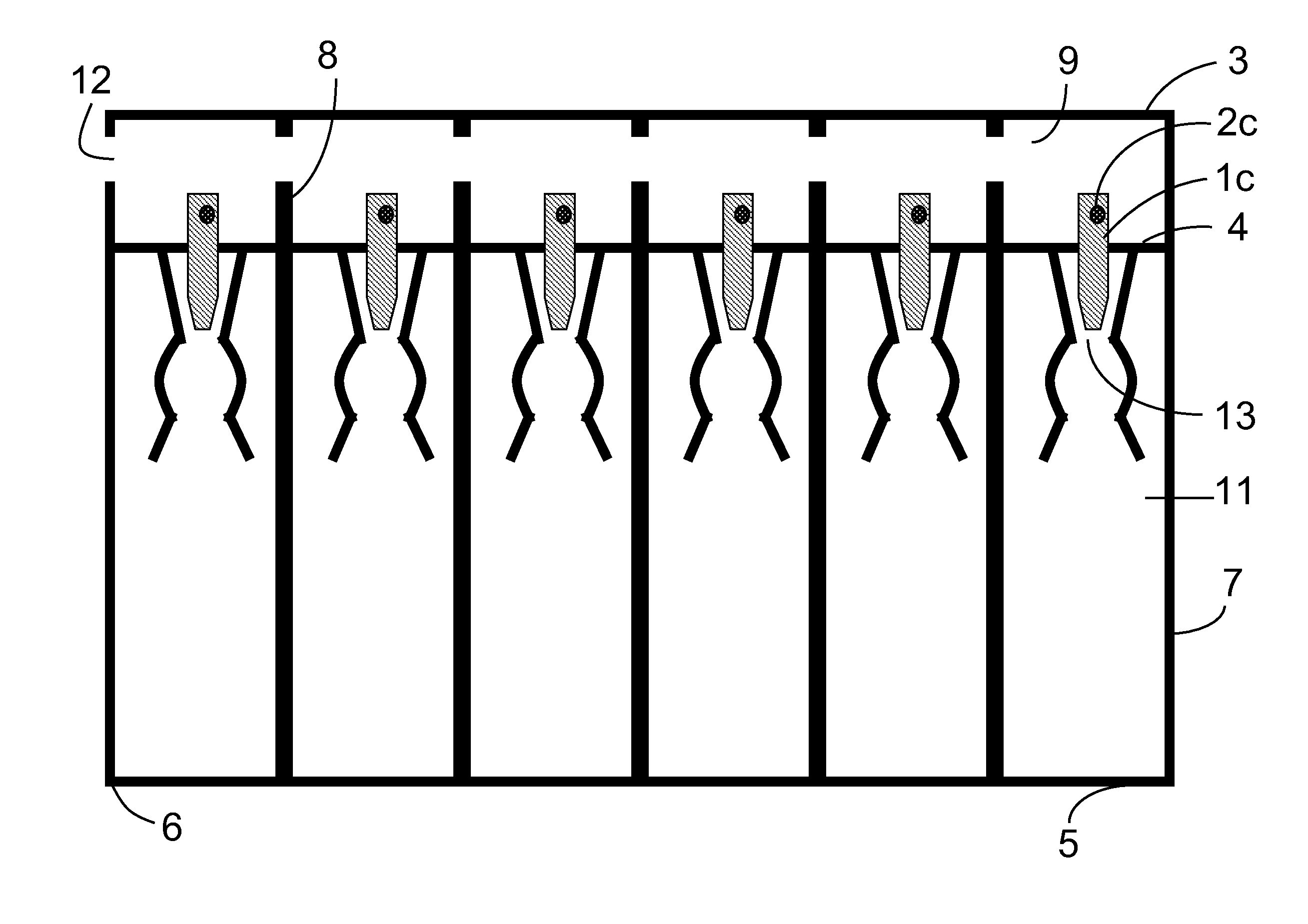

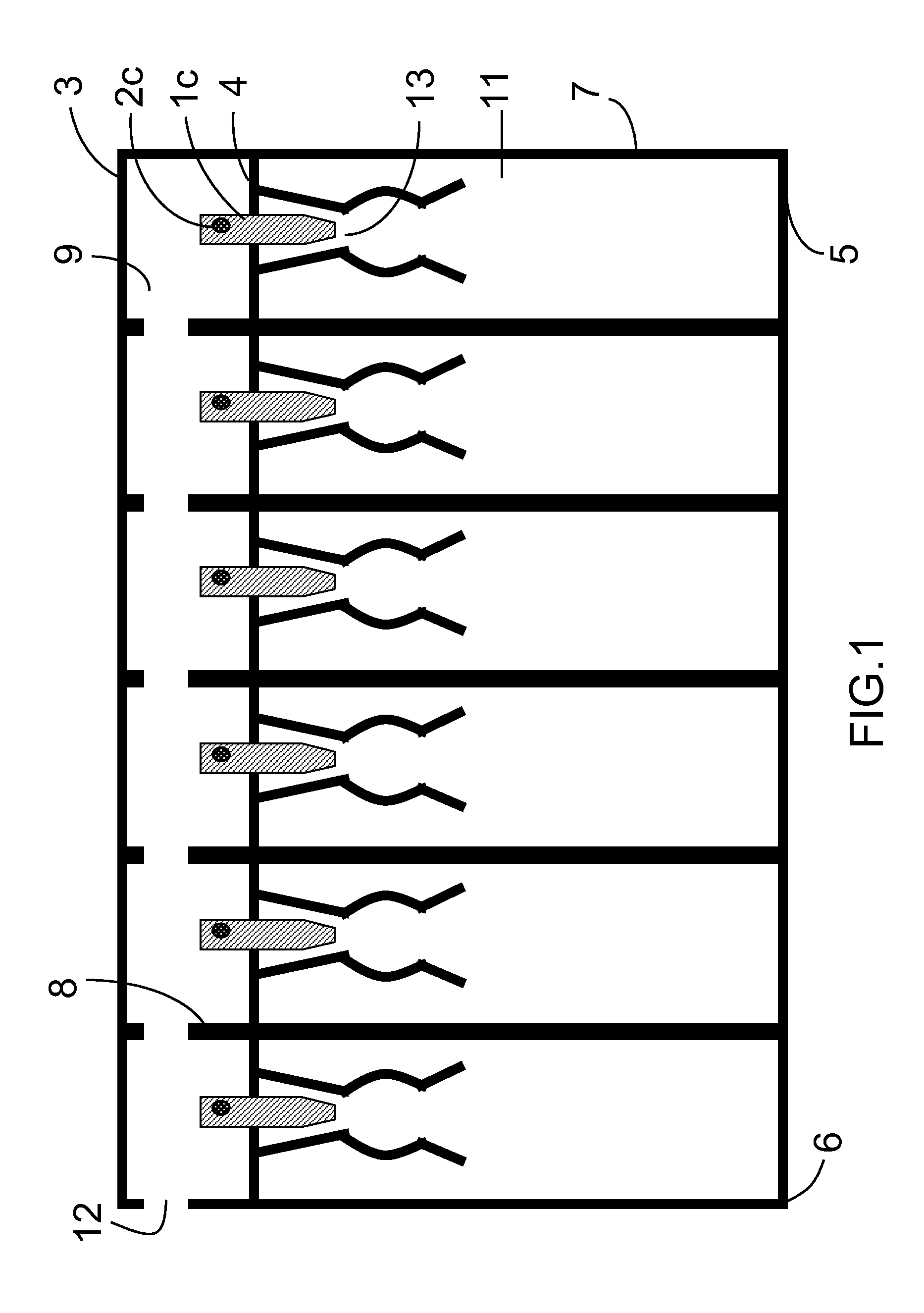

Air-sealed body with automatically opened air value

InactiveUS20120027969A1Save filling timeEasy to manufacturePaper-makingBox making operationsEngineeringOpen air

Owner:LIAO YAW SHIN

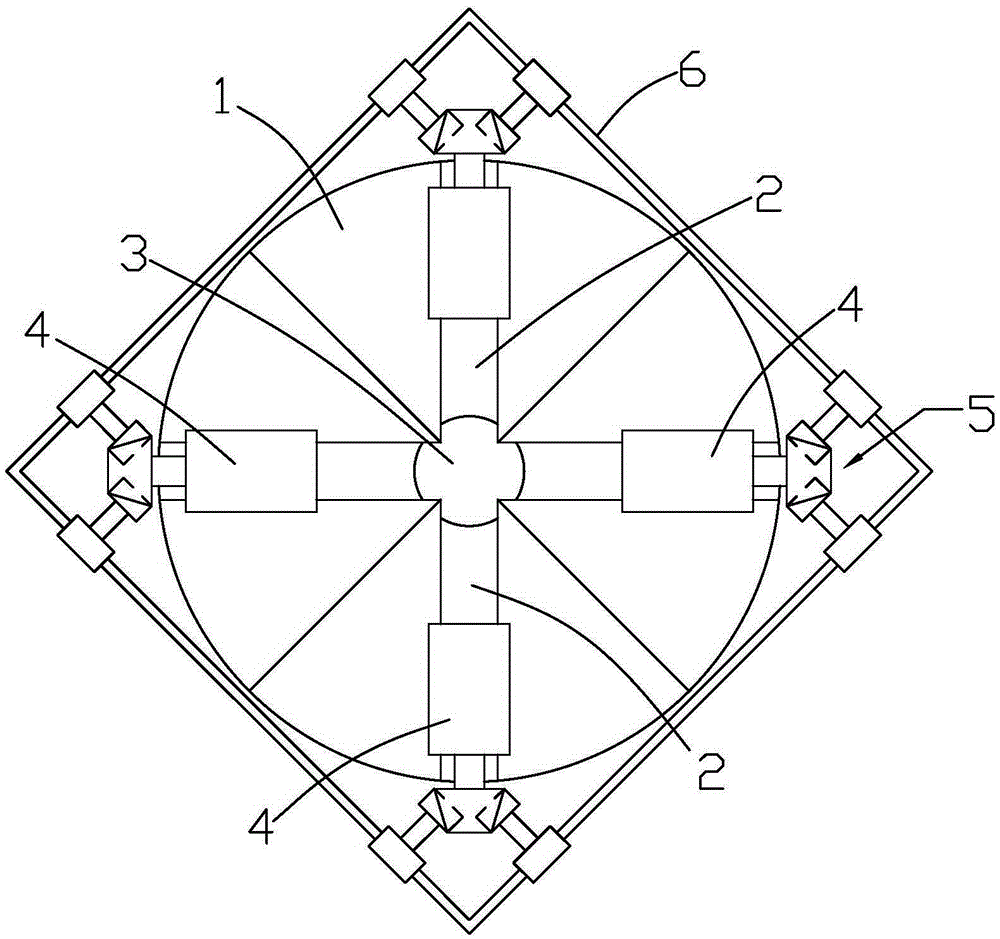

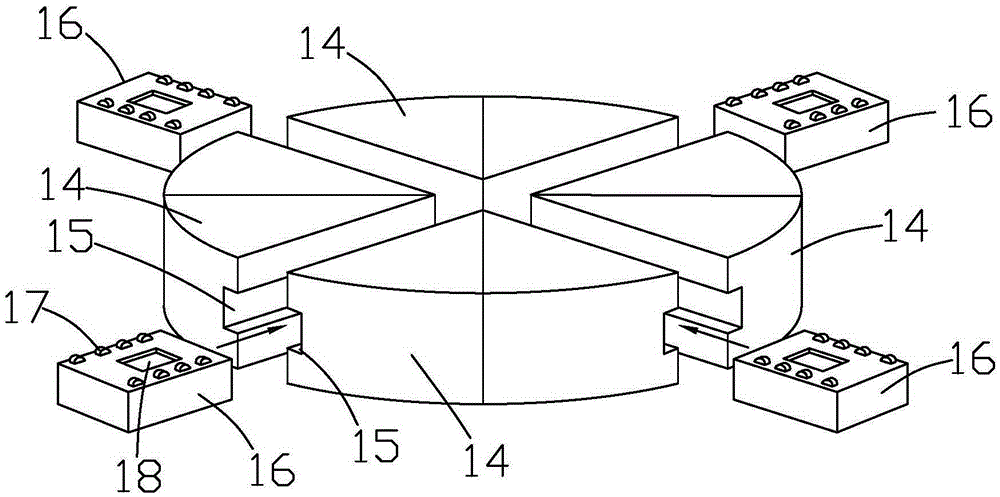

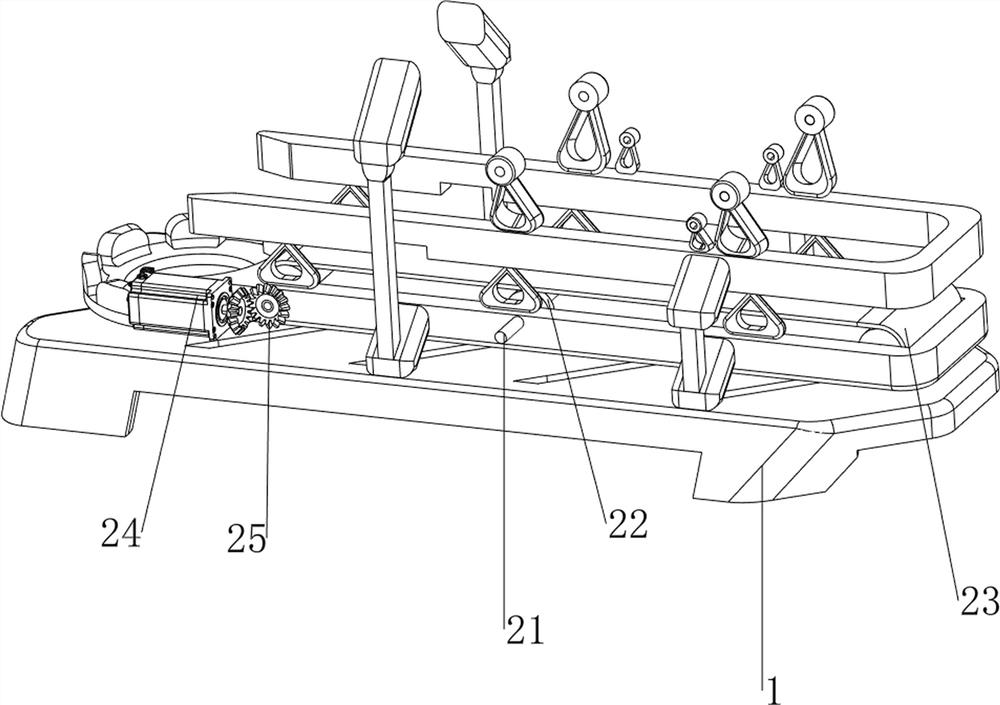

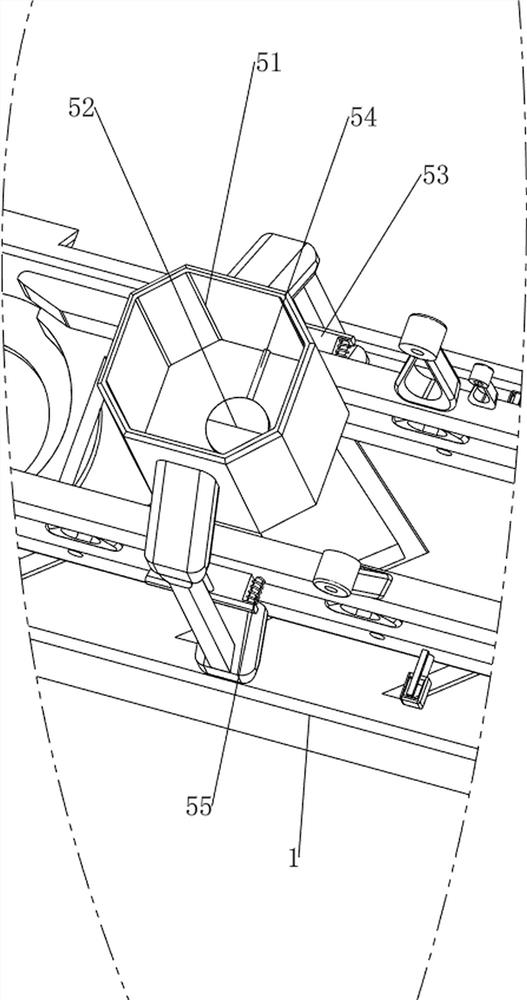

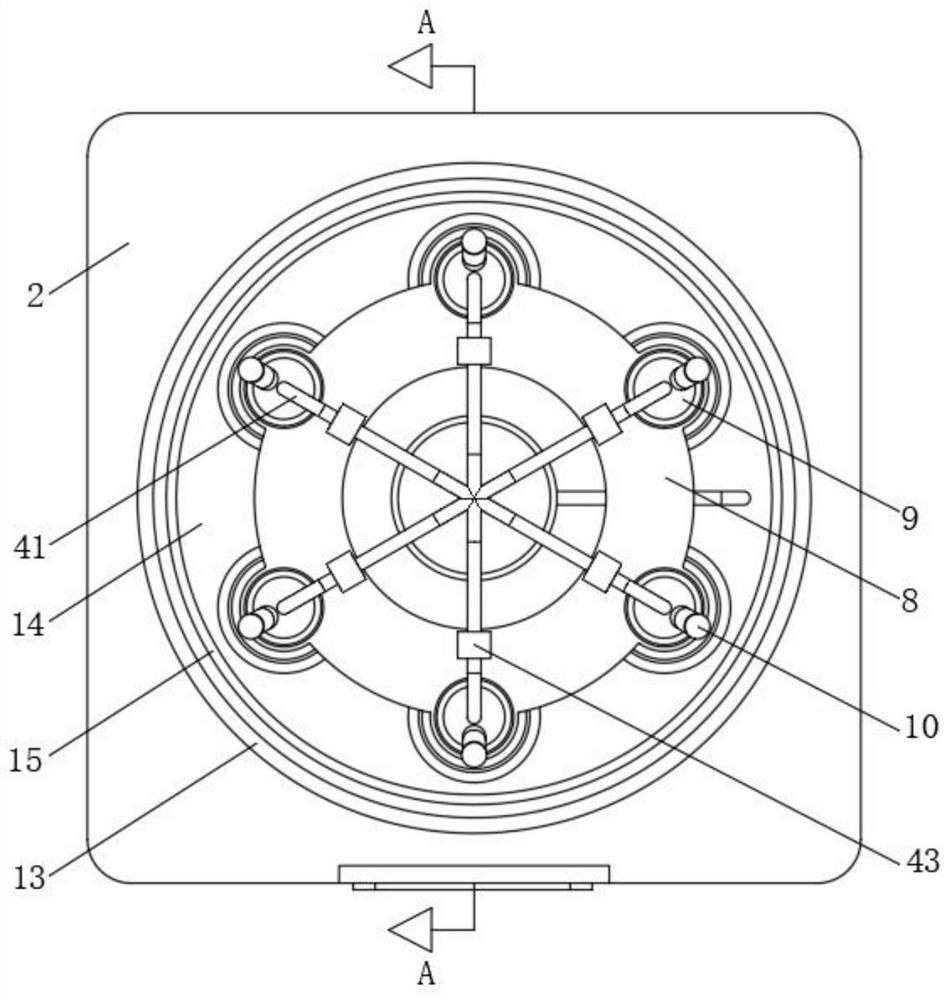

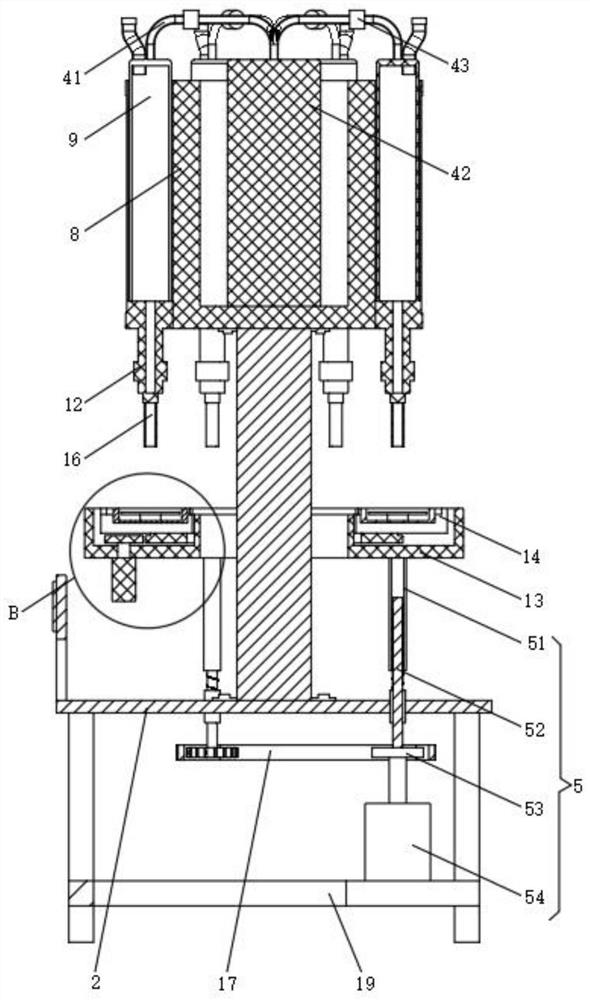

Telescopic aluminum strip positioning and compressing device for hollow glass molecular sieve filling machine

The invention discloses a telescopic aluminum strip positioning and compressing device for a hollow glass molecular sieve filling machine. The device comprises a turning table, a hydraulic ejecting and extending device and a positioning and compressing mechanism, wherein the turning table consists of four fan-shaped expansion plates, a positioning guide groove is arranged between every two adjacent fan-shaped expansion plates, limiting sliding grooves which are mutually parallel are arranged in the positioning guide grooves, the limiting sliding grooves are respectively located at the side surfaces of every two adjacent fan-shaped expansion plates, synchronous sliding blocks are connected into the limiting sliding grooves in a sliding manner, the top surfaces of the synchronous sliding blocks are provided with catching grooves, the hydraulic ejecting and extending device is connected to the turning table through the synchronous sliding blocks in a moving manner, the positioning and compressing mechanism is connected to the end part of the hydraulic ejecting and extending device, and every two opposite fan-shaped expansion plates are provided with one group of synchronous travel mechanisms. The device provided by the invention is simple in structure and high in practicability, not only is the molecular sieve filling of aluminum strip frames of different shapes and sizes met, but also the clamping and positioning can be automatically realized, the filling of each through hole of molecular sieve is realized, and the working efficiency of the filling machine is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

Air-sealed body with automatically opened air value

InactiveUS8701888B2Save filling timeEasy to manufactureBox making operationsPaper-makingOpen airVALVE PORT

Owner:LIAO YAW SHIN

Preparation method of Balsa wood core material of wind driven generator blade web

ActiveCN111958711AMass does not increaseLow moisture absorptionFinal product manufactureWood veneer joiningWind drivenEngineering

The invention relates to the technical field of wind driven generator blades, and particularly relates to a preparation method of a Balsa wood core material of a wind driven generator blade web. The preparation method comprises the steps of slicing, accurate grinding, dehumidification, double-end sawing treatment and gluing, and after pretreatment, shallow groove forming, punching, cloth pasting,deep groove forming, finished product inspection, template manufacturing, line drawing, edge cutting, mark writing, chamfering, IPQC process inspection, plate separation, dehumidification, laying inspection and packaging and warehousing are sequentially conducted. According to shallow groove forming, a plurality of shallow grooves are formed in at least one surface of the core material and are staggered on the surface of the core material to be arranged in a rectangular grid shape, and through holes penetrating through the upper surface and the lower surface of the core material are punched inthe intersection points of the multiple shallow grooves. According to the preparation method, three times of humidity detection are set, the moisture absorption possibility of the core material in the preparation process is further reduced, the risk of corrosion of bacteria and the like sealed in the core material in the operation process is reduced, and therefore the defects of the Balsa wood core material are effectively overcome.

Owner:常州兆庚新材料有限公司

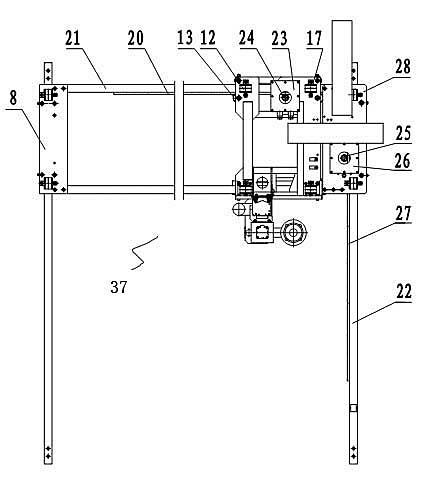

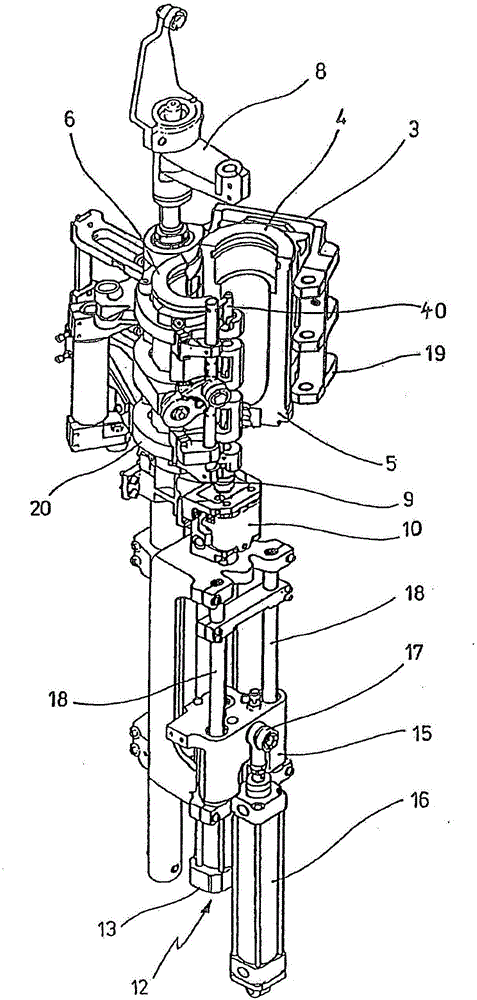

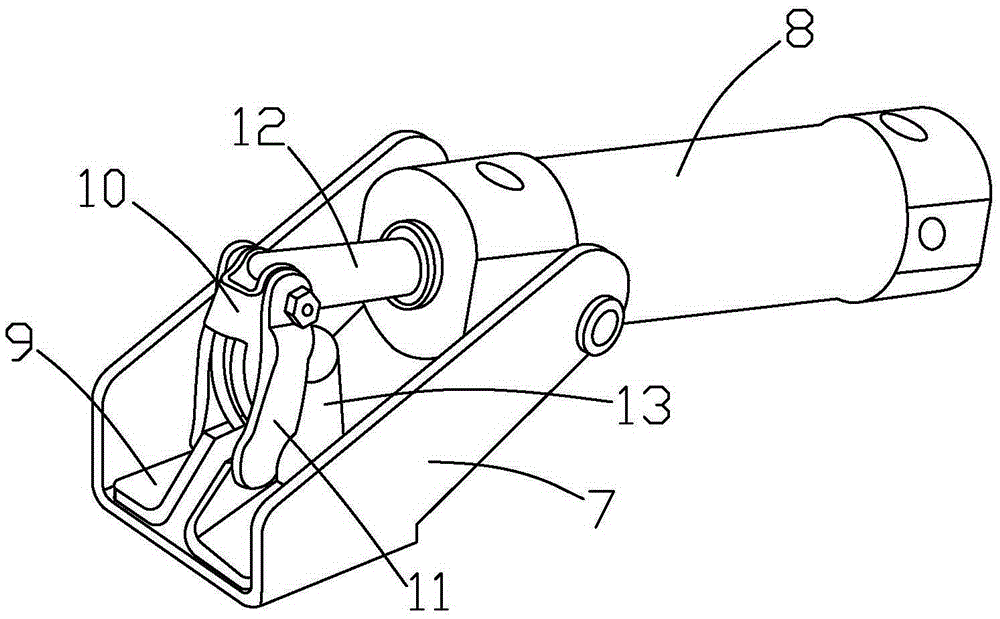

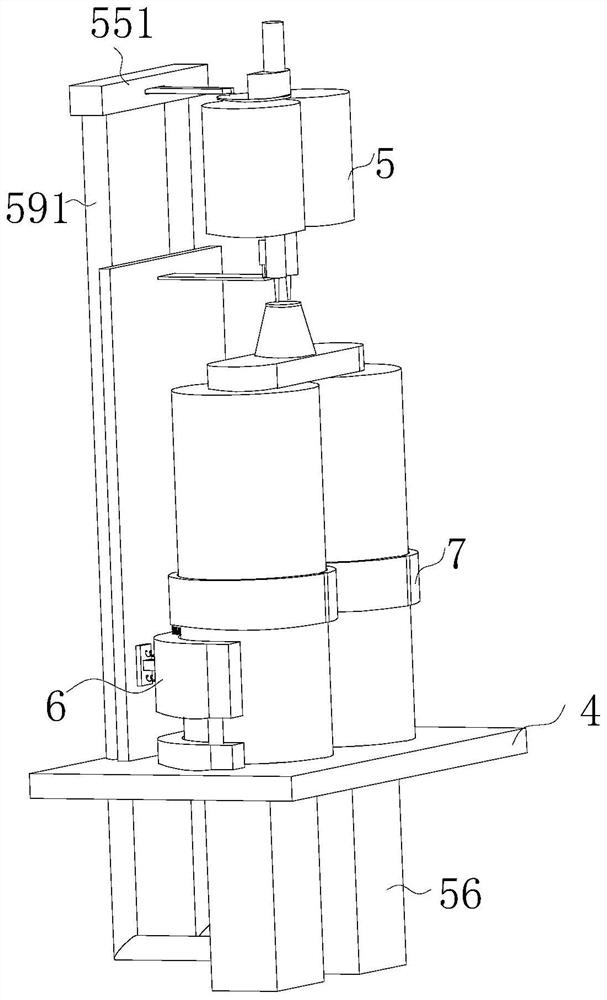

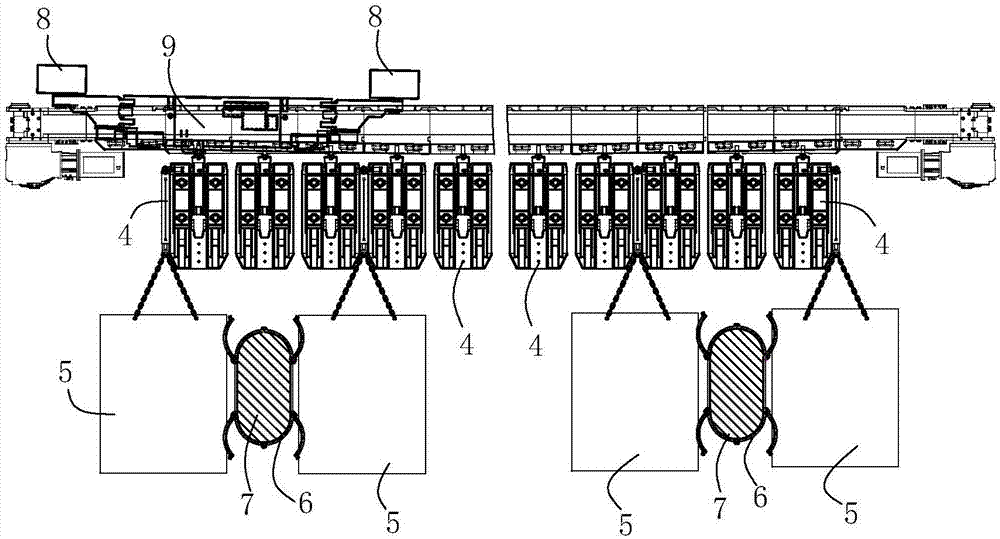

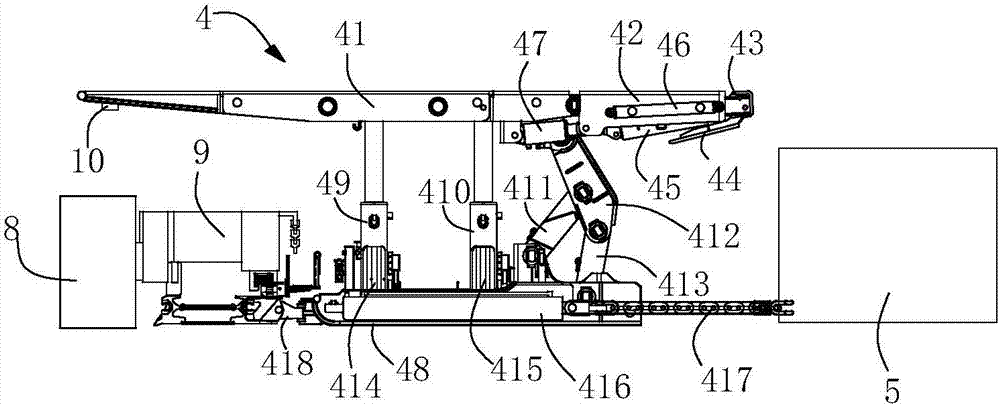

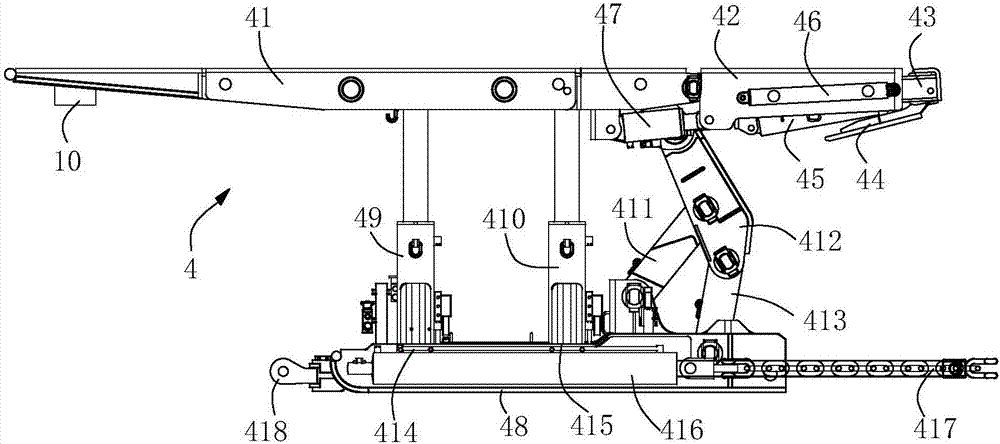

Filling head following lifting mechanism and working method thereof

PendingCN111924195ASave filling timeImprove work efficiencyPackaging automatic controlEngineeringMechanical engineering

The invention belongs to the technical field of filling machines, and particularly relates to a filling head following lifting mechanism and a working method thereof. The mechanism comprises a bracket, a traction mechanism arranged on the bracket and a lifting mechanism arranged on the traction mechanism. The traction mechanism is suitable for driving the lifting mechanism to move synchronously with packaging materials, and while the lifting mechanism moves, the lifting mechanism is suitable for driving a feeding nozzle mechanism to descend into the packaging materials for filling. The fillinghead following lifting mechanism uses the traction mechanism to drive the lifting mechanism to follow the movement of the packaging materials, and at the same time, the feeding nozzle mechanism is driven by the lifting mechanism to lower into the packaging materials for filling. Therefore, the filling can be completed in the process of conveying the packaging materials by a packaging material conveyor chain, the packaging materials do not need to be stopped, the filling time is shortened and the work efficiency is improved.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

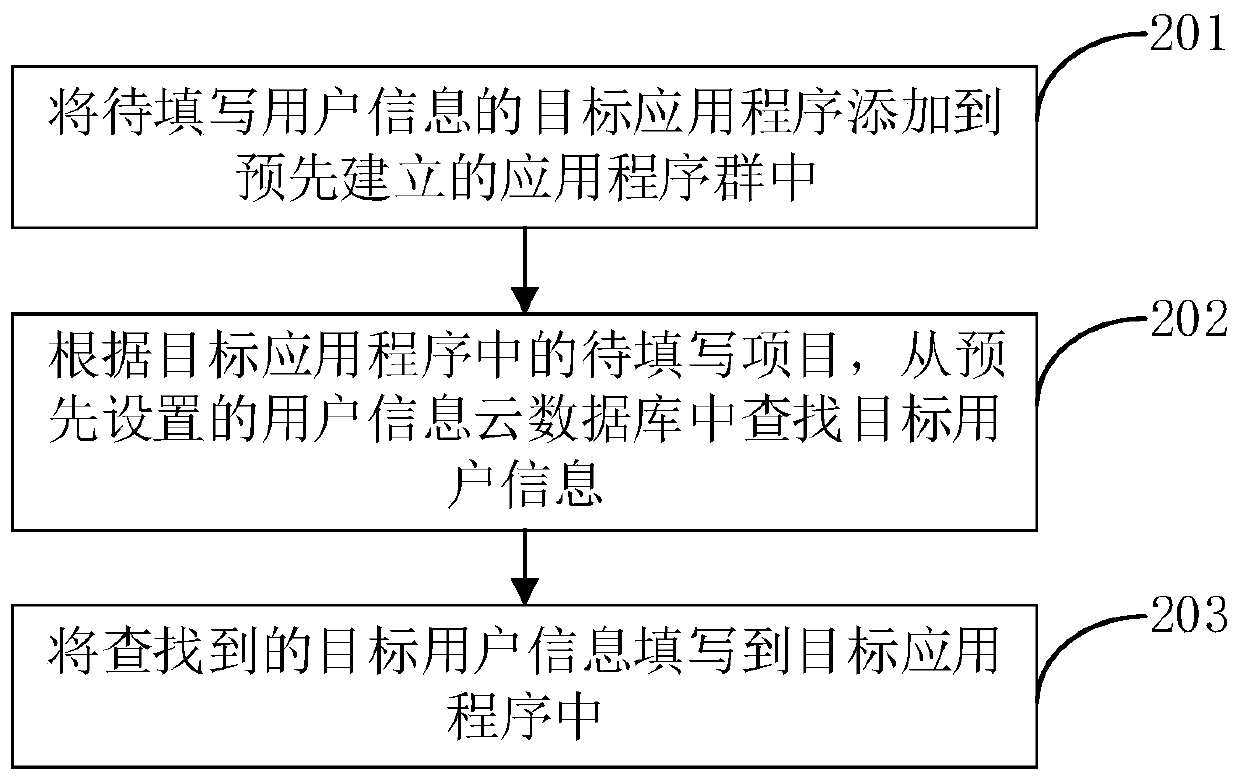

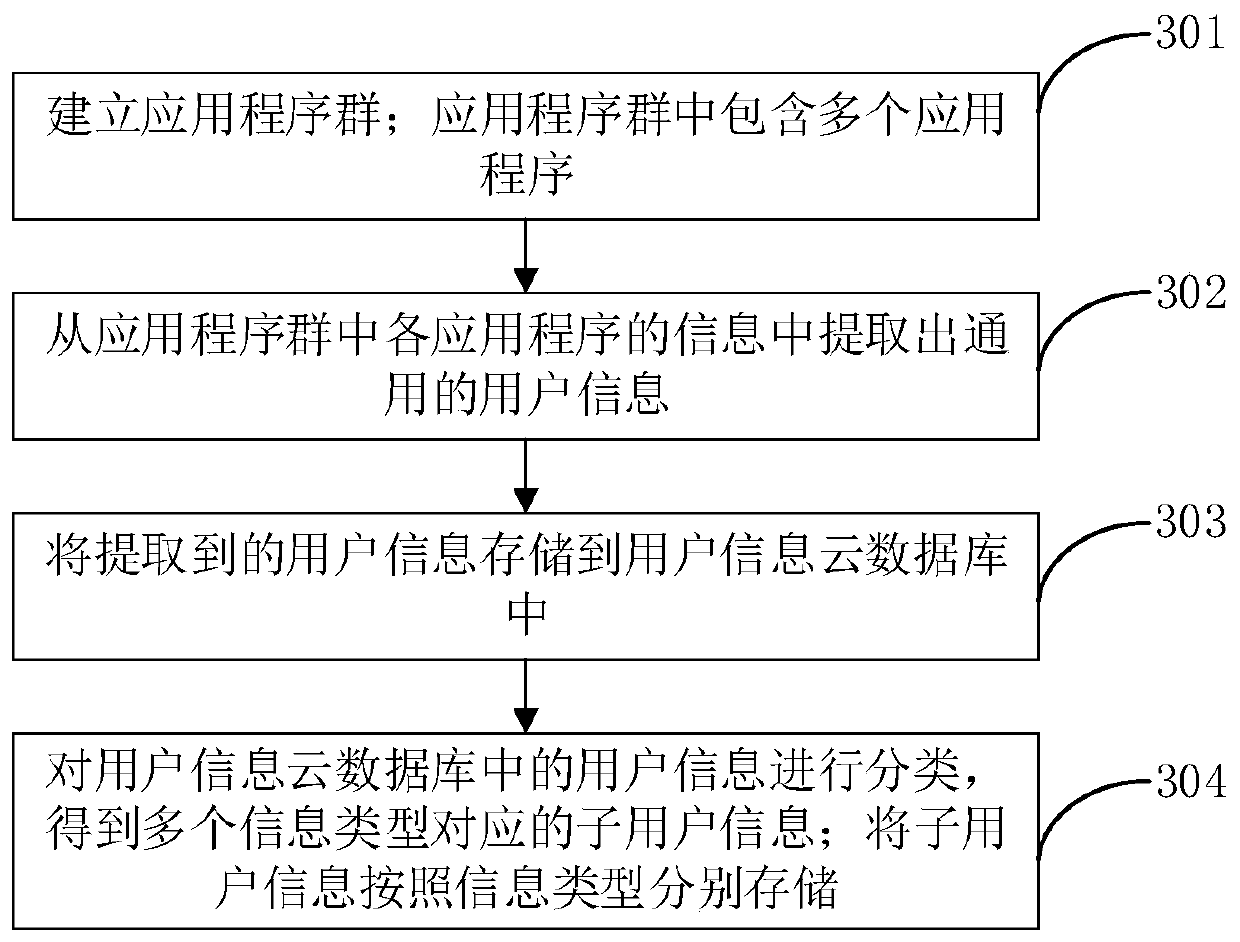

User information filling method and device, computer equipment and storage medium

PendingCN111209061ASave filling timeAvoid filling mistakesData processing applicationsDatabase management systemsComputer equipmentCloud database

The invention relates to a user information filling method and device, computer equipment and a storage medium. The method comprises the following steps: adding a target application program in which user information is to be filled into a pre-established application program group; searching target user information from a preset user information cloud database according to to-be-filled items in thetarget application program; wherein universal user information in different application programs is stored in the user information cloud database; and filling the searched target user information into the target application program. Through the embodiment of the invention, the filling time of the user information can be saved, and filling errors are avoided.

Owner:GUANGDONG DECHENG NETWORK TECH CO LTD

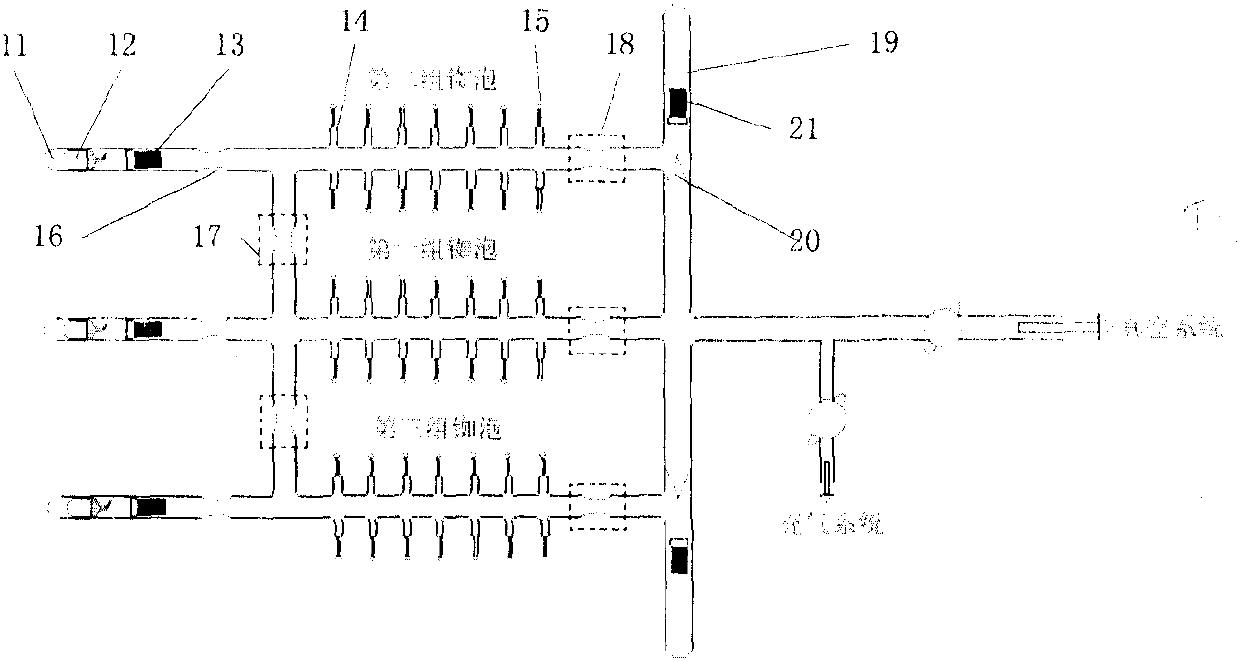

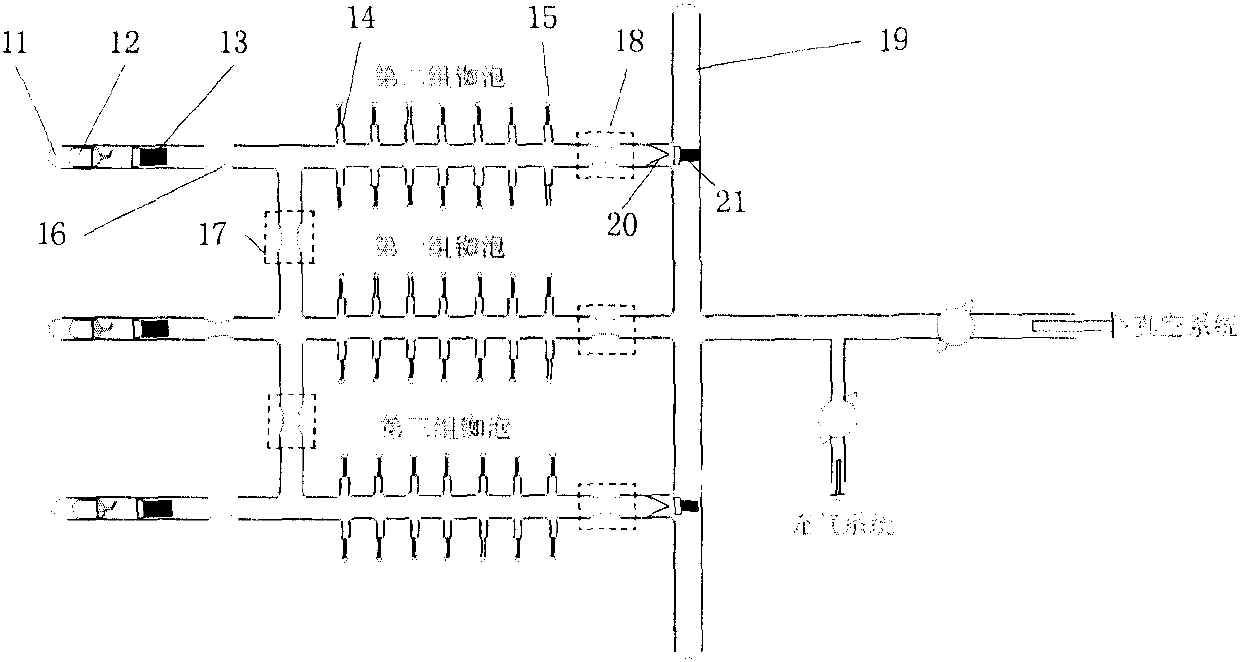

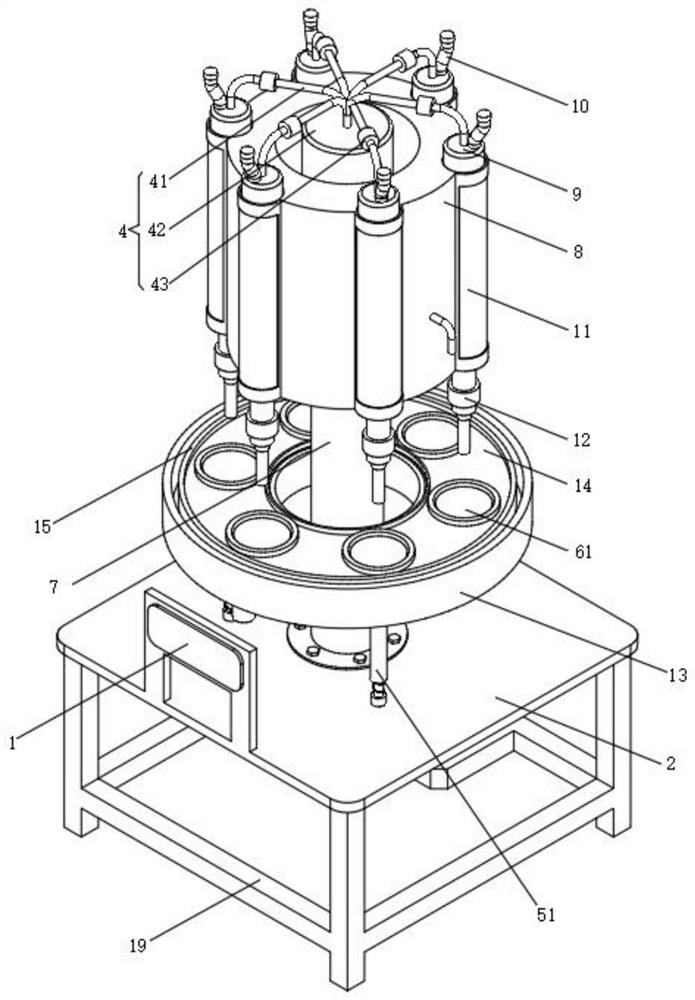

A filling device and method for a cascaded alkali metal gas chamber

ActiveCN110972564BHigh control precisionImprove reliabilityElectric discharge lampsCold cathode manufactureGas chamberMetal

In the filling device of the cascaded alkali metal gas chamber of the present invention, the alkali metal foam filling sub-pipes are placed side by side, and each alkali metal foam filling sub-pipe passes through the second glass shrinking pipe and the filling main pipe. The pipeline is connected; except for one of the alkali metal foam filling sub-pipelines, the other alkali metal foam filling sub-pipelines are equipped with breakable components at the connection with the filling main pipeline; the alkali metal foam is realized through the breakable components The closed and connected state of the filling sub-pipeline and the filling main pipeline is changed. The initial state is closed; the connecting pipeline is used to further connect all the alkali metal foam filling sub-pipelines, and every two alkali metal foam filling pipes The first glass reducing pipes are arranged between the sub-pipes; the connecting point of the connecting pipe is located between the alkali metal source and the alkali metal filling part in the alkali metal billet filling sub-pipeline; the vacuum system and the inflation system are connected to the main filling pipe . The invention can ensure that the alkali metal gas chambers with different filling parameters can be filled in one vacuum system.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Filling discharge device

InactiveCN107284716AIncrease the output speedSave filling timeRotary stirring mixersLiquid materialEngineeringViscosity

The invention relates to a filling discharge device. The filling discharge device comprises a tank, and a stirring device mounted in the tank. The stirring device comprises a rotating shaft, and multiple stirring blades mounted on the rotating shaft and uniformly distributed in the peripheral direction. Each stirring blade extends to the inner wall of the tank in the axial direction of the rotating shaft. When materials with high viscosity are filled, the stirring device works, so that the materials reach a certain initial velocity, the discharge speed is accelerated, the filling time is shortened, and the filling discharge device is higher in filling efficiency.

Owner:江苏首达机械有限公司

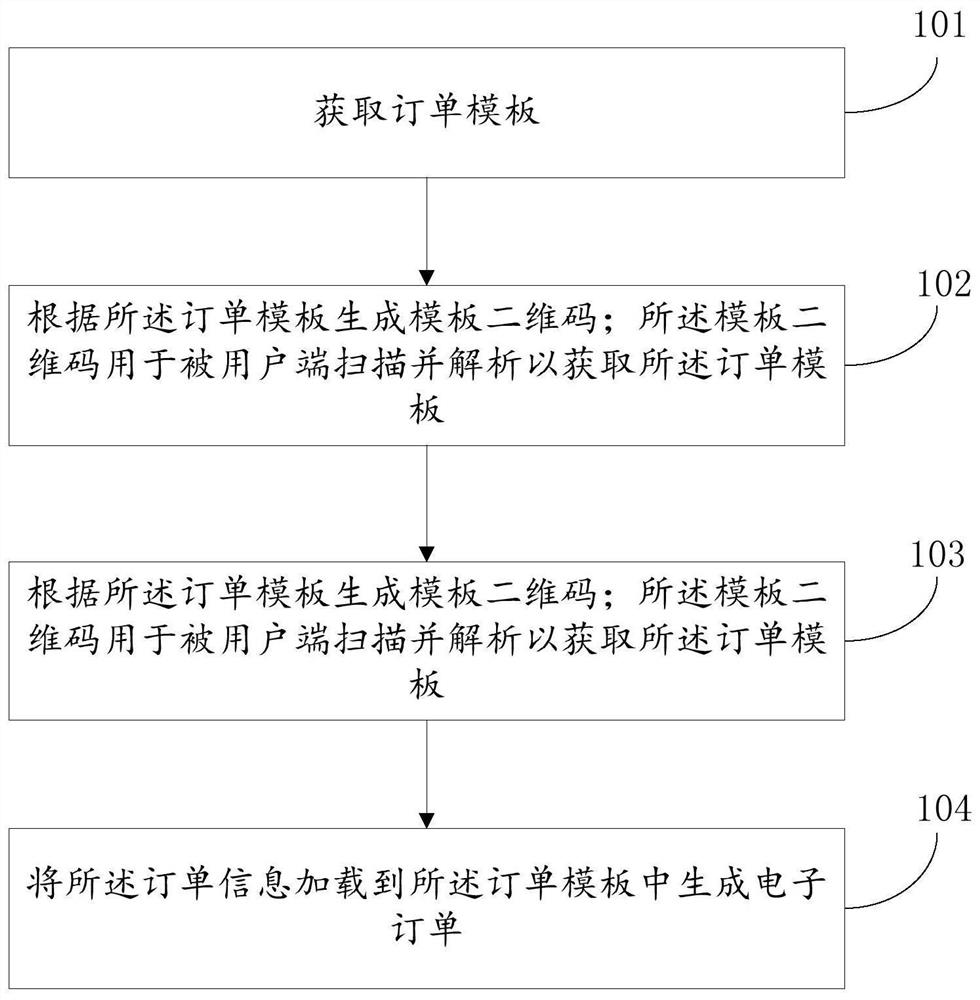

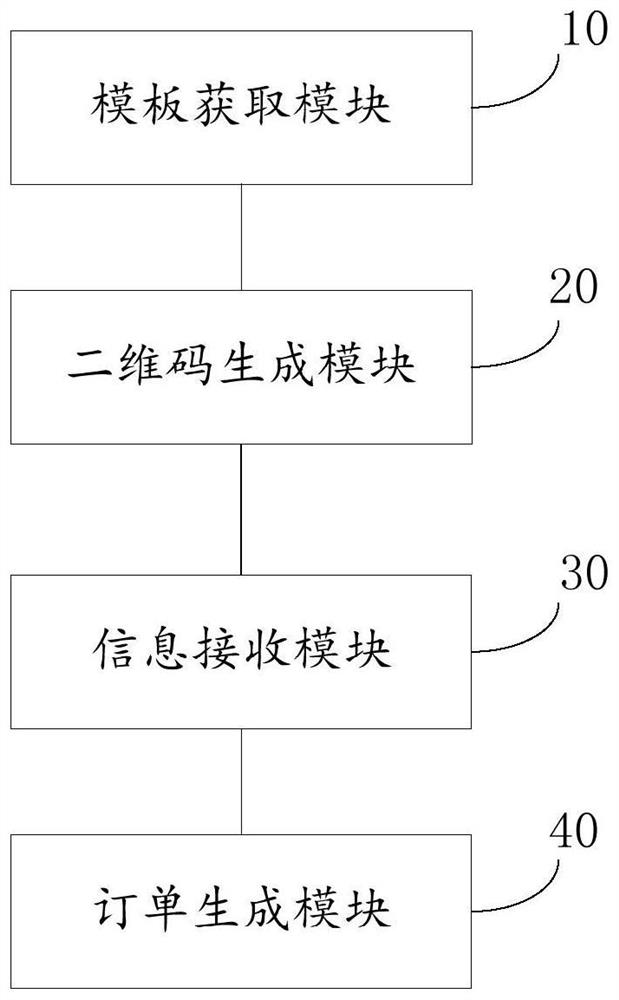

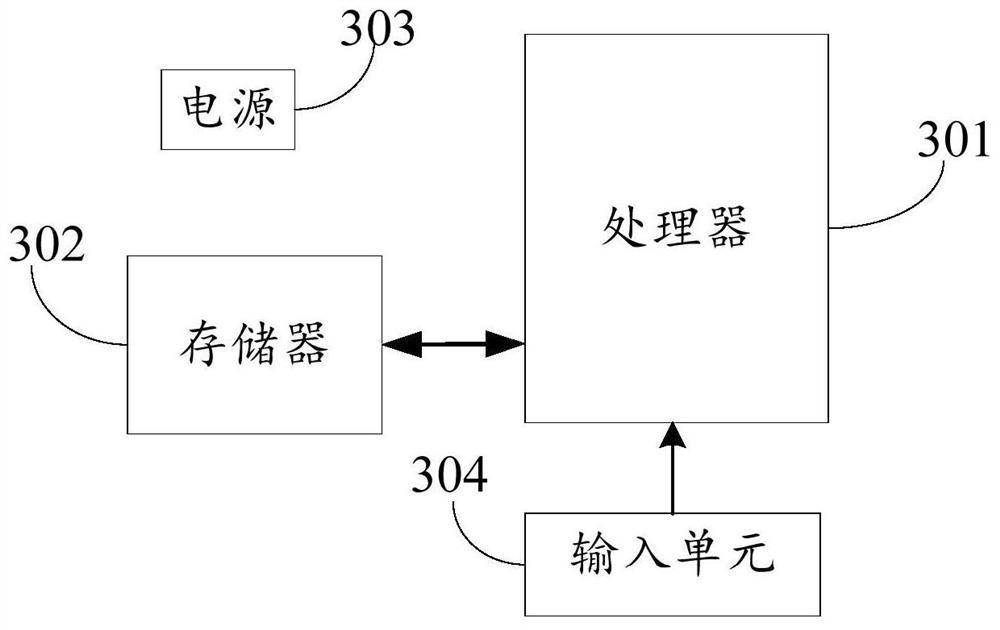

Electronic order generation method and device, terminal and storage medium

PendingCN111985984AImprove production efficiencySave filling timeCo-operative working arrangementsBuying/selling/leasing transactionsComputer hardwareOrder form

The invention discloses an electronic order generation method and apparatus, a terminal and a storage medium. The method comprises the steps of obtaining an order template; generating a template two-dimensional code according to the order template; wherein the template two-dimensional code is used for being scanned and analyzed by a user side to obtain the order template; receiving order information sent by the user side; wherein the order information is information input into the order template by a user after the user scans the template two-dimensional code through the user side to obtain the order template; and loading the order information into the order template to generate an electronic order. According to the embodiment of the invention, the order generation efficiency can be improved, the order management is facilitated, and the user time is saved.

Owner:SF TECH

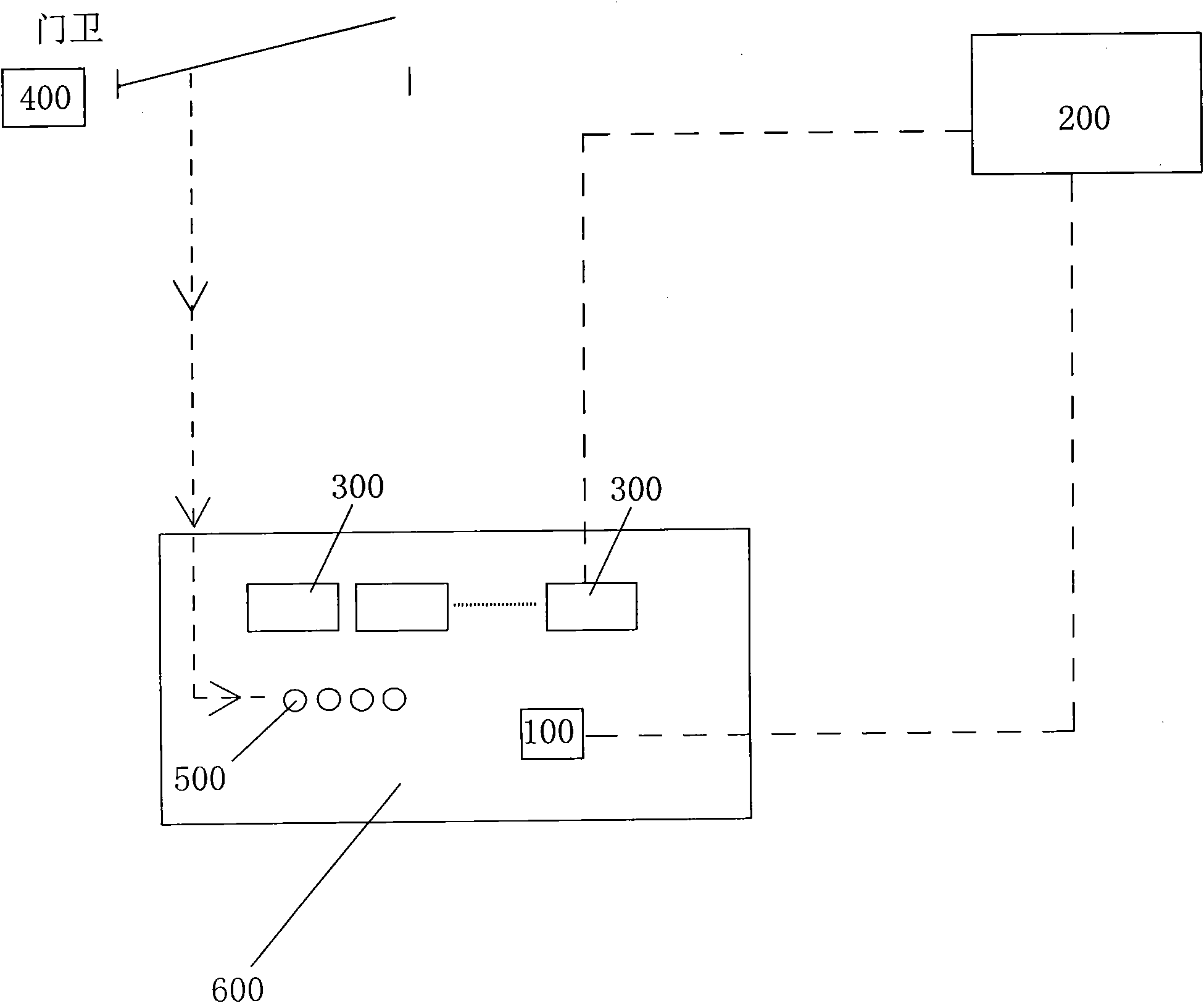

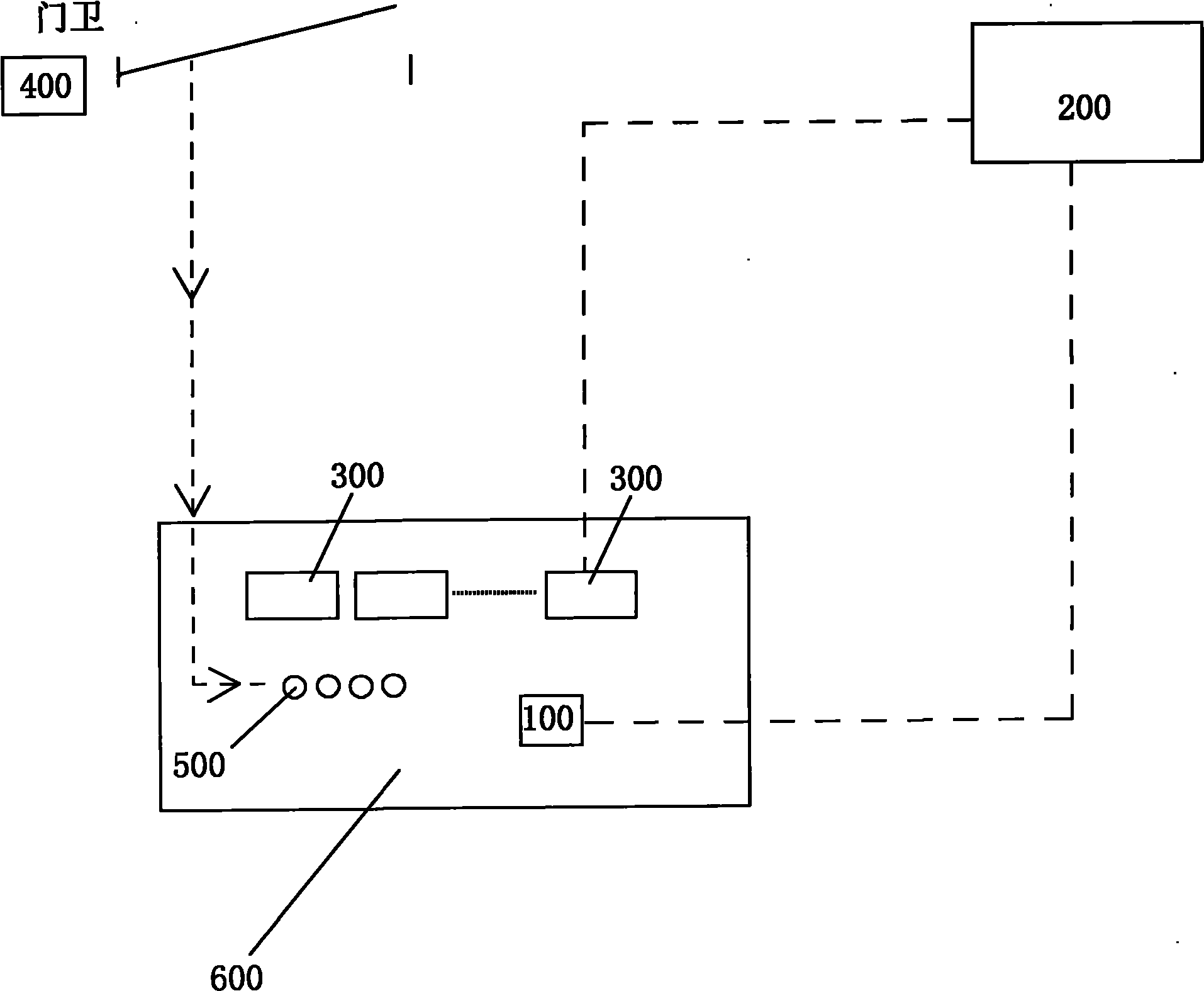

Active control filling system

The invention relates to the field of liquid filling, in particular to an active control filling system for changing the conventional liquid filling mode. The active control filling system comprises a filling machine and a computer console, wherein the computer console can be interactively communicated with the filling machine; the computer console edits filling information after finishing a billing program and transmits the filling information to the filling machine; and the filling machine fills a to-be-filled steel bottle according to the filling information. The system has the advantages that: the change in a field can be processed by using the computer console and a field billing machine at any time; customers are intelligently managed by a computer from entering a door to getting out of the door; a filling platform performs filling and filling personnel do not need to input data, so that human error factor can be avoided; in addition, personalized filling setting can be made for each steel bottle through the field billing machine and a label; and the field billing machine inputs a steel bottle number or reads a bar code or electronic tag with an unique identity on the steel bottle, edits the filling information and transmits the filling information to the filling machine for filling.

Owner:SHENZHEN LANYANG TECH

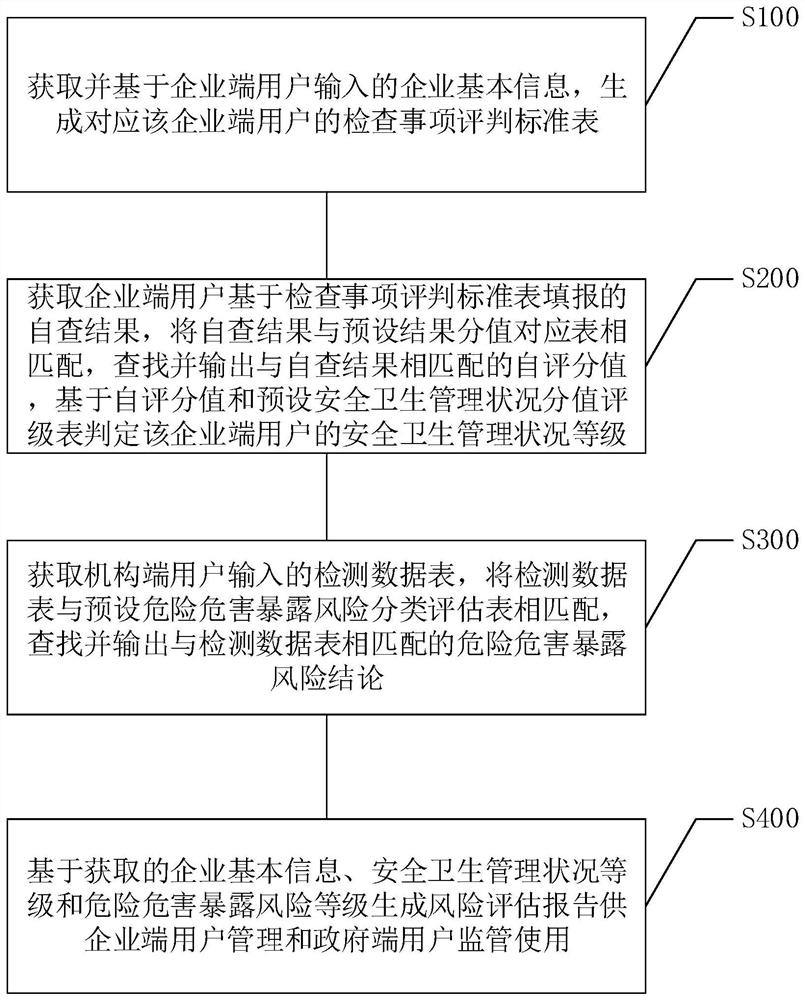

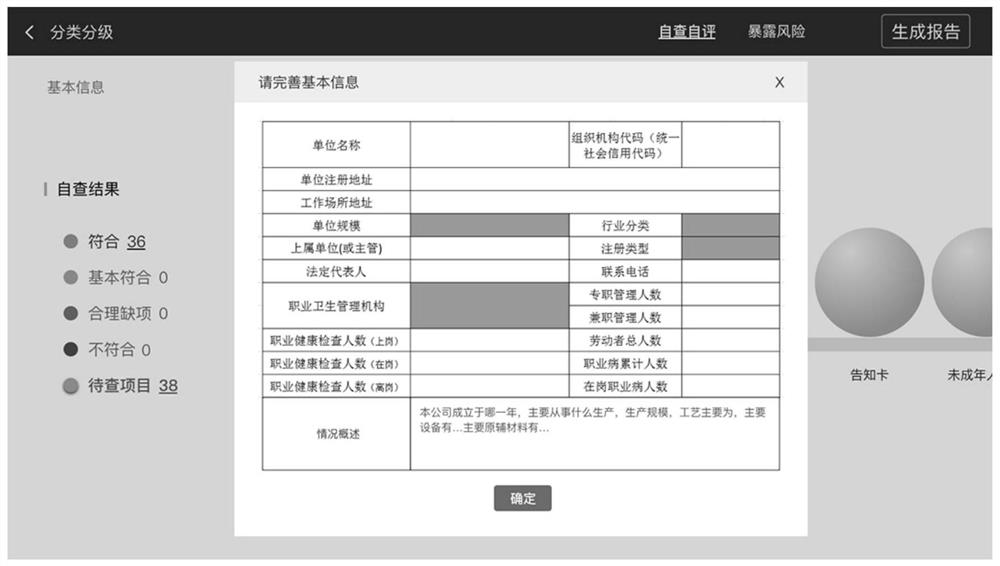

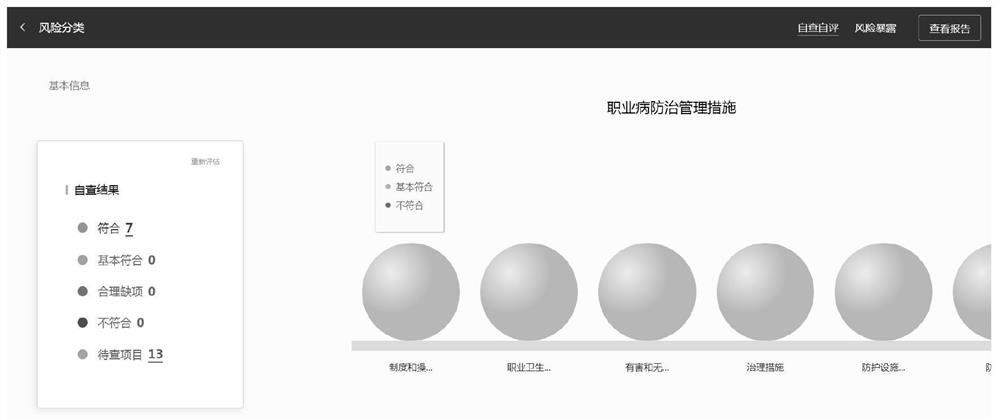

Enterprise safety and health risk classification and grading method

ActiveCN113256091AAvoid Statistical MistakesSimple processDigital data authenticationResourcesDatasheetRisk level

The invention discloses an enterprise safety and health risk classification and grading method, which comprises the following steps: acquiring enterprise basic information input by an enterprise terminal user, and generating an inspection item judgment standard table corresponding to the enterprise terminal user based on the enterprise basic information; obtaining a self-examination result filled by the enterprise terminal user based on the examination item evaluation standard table, searching and outputting a self-examination score value matched with the self-examination result, and judging the safety and health management condition grade of the enterprise terminal user based on the self-examination score value and a preset safety and health management condition score rating table; acquiring a detection (evaluation or auditing) data table input by a mechanism end user, and searching and outputting a dangerous hazard exposure risk conclusion matched with the detection (evaluation or auditing) data table; and generating a self-examination risk assessment report based on the obtained enterprise basic information, the safety and health management condition level and the danger hazard exposure risk level for enterprise end user to management and government end user to carry out supervision and use.

Owner:北京秒立方互联网科技有限公司

A full-automatic high-precision food processing filling equipment

ActiveCN111891430BImprove sufficiencySave filling timeLiquid materialPackaging machinesEngineeringMechanical engineering

The invention provides a full-automatic high-precision filling equipment for food processing, which includes a driving part, a filling part and an object stage, and the object stage can rotate intermittently around its center; the filling part includes a The filling assembly, and the bottom of the filling assembly has a filling needle that can elastically expand and contract toward the side of the clamping table that rotates to a predetermined position; The axis of rotation is coaxial with the axis of rotation of the stage and the driving disc is located behind the stage and the filling part; the active shaft and the drive rod are fixedly connected to each other to form an acute angle, and the active rod and the The driven rod is in contact with the driving disc to reversely rotate relative to the driving shaft. The full-automatic high-precision food processing filling equipment provided by the invention has high filling efficiency and can reduce filling waste.

Owner:SHANDONG GAOTANGYONGWANG FOOD CO LTD

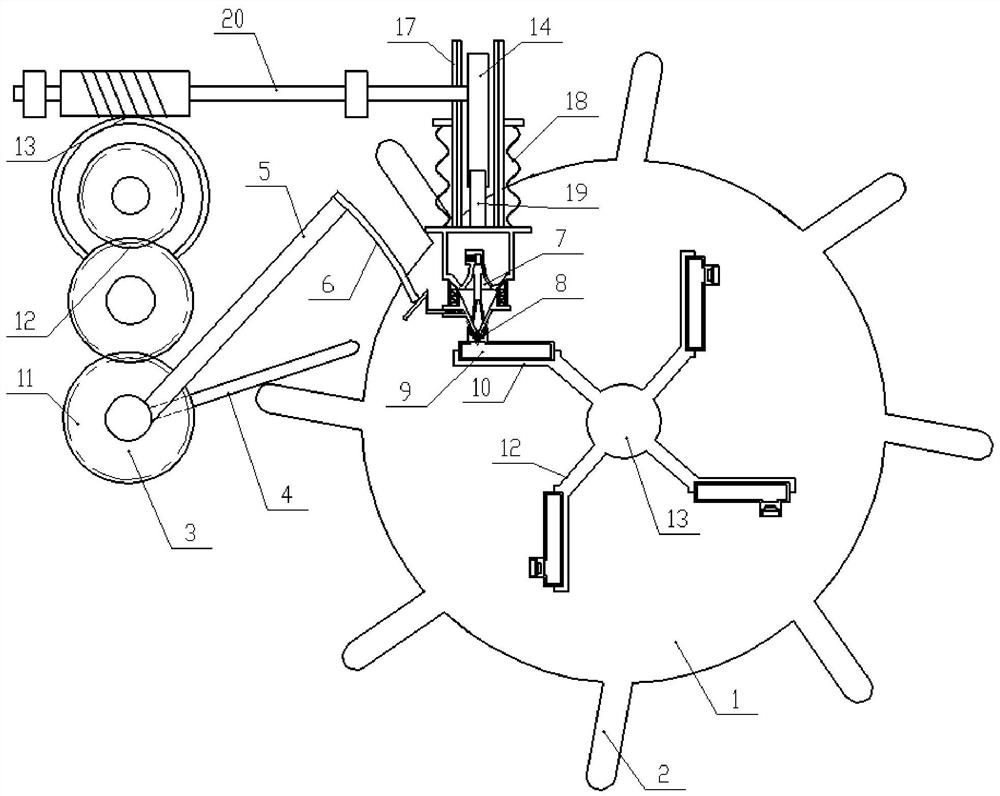

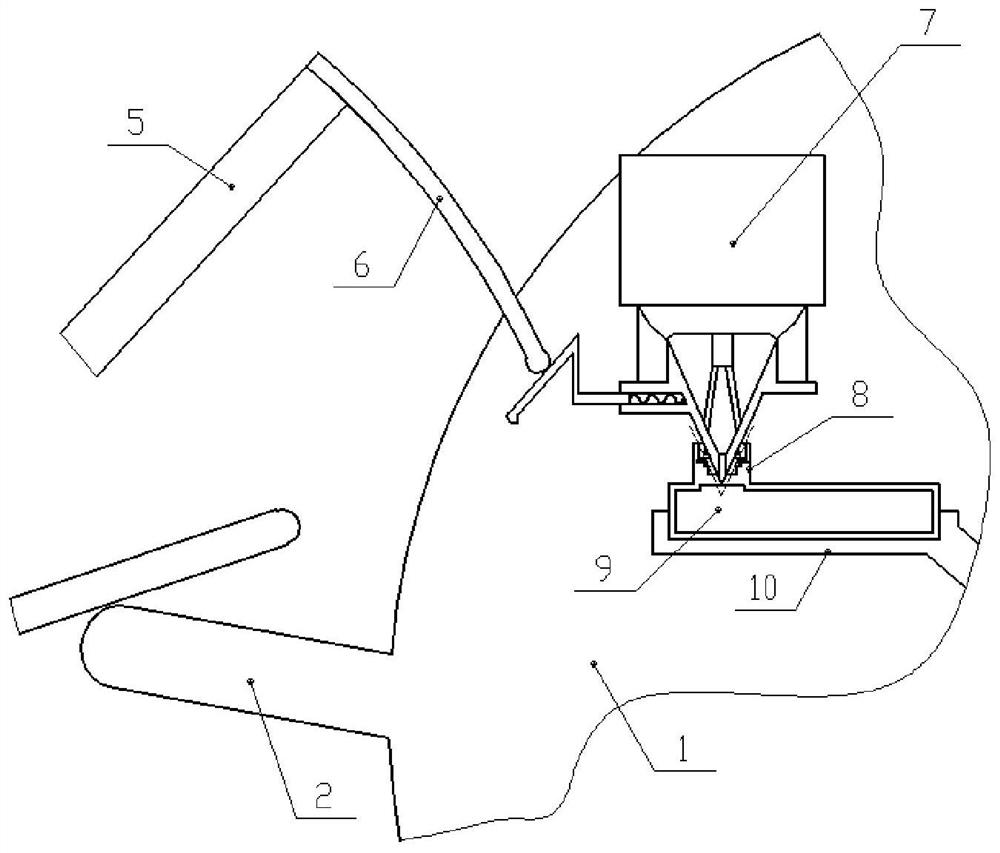

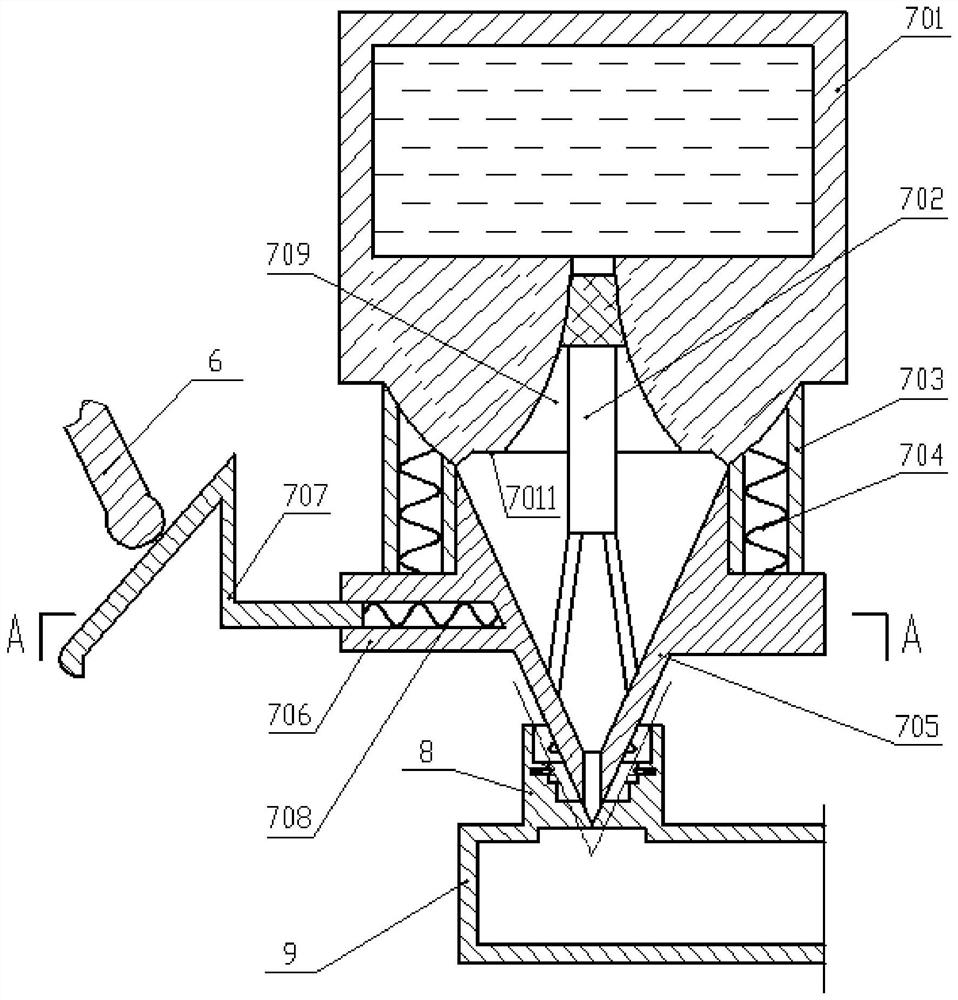

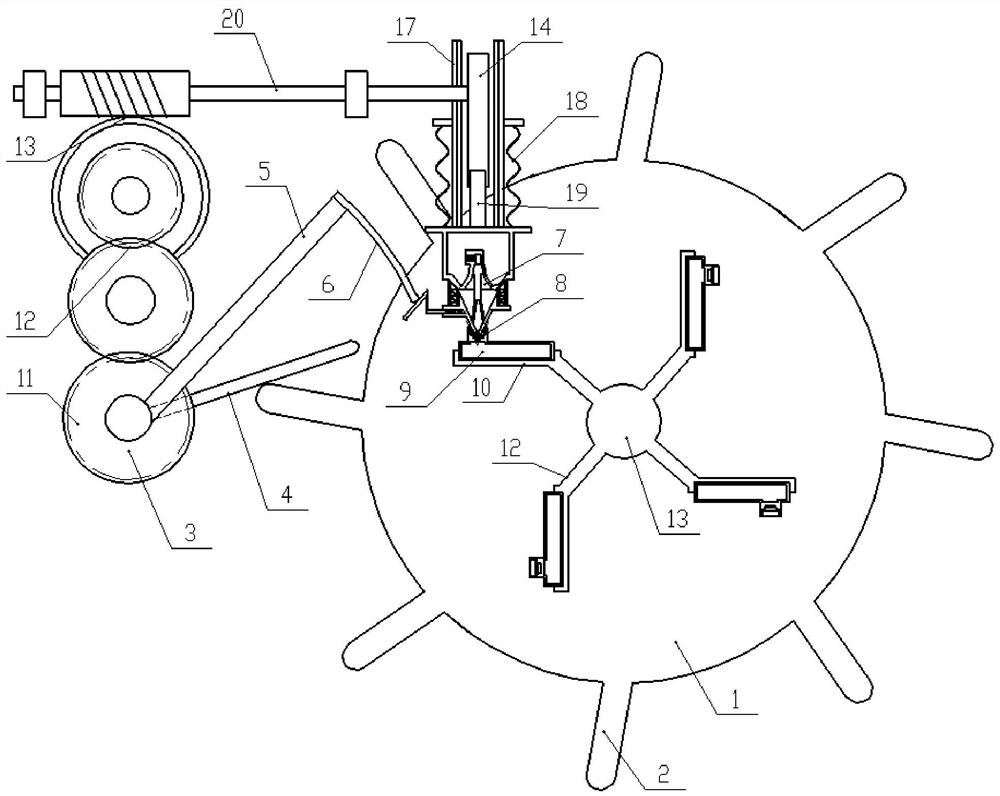

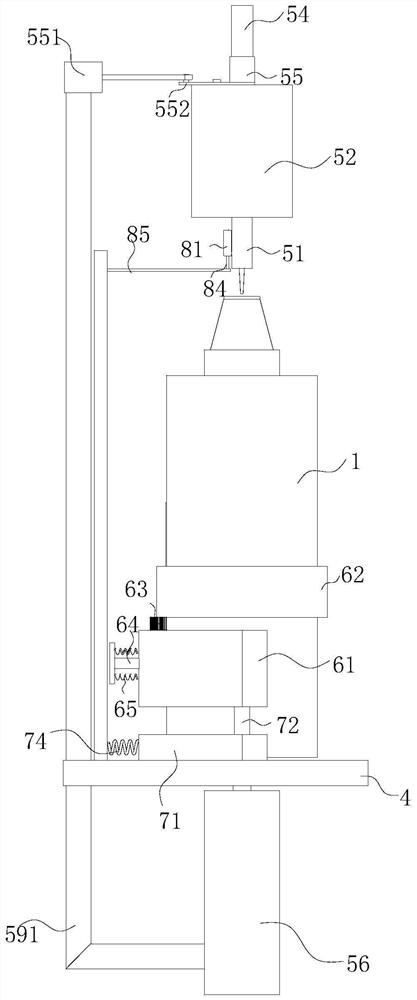

Full-automatic high-precision filling equipment for food processing

ActiveCN111891430AImprove sufficiencySave filling timeLiquid materialPackaging machinesAcute angleMechanical engineering

The invention provides full-automatic high-precision filling equipment for food processing. The full-automatic high-precision filling equipment for food processing comprises a driving part, a fillingpart, and an objective table, wherein the objective table can intermittently rotate around the center of the objective table; the filling part comprises a filing component which moves up and down through a pushing device; a filling needle which can be elastically stretched towards one side of a clamping table rotating to reach a predetermined position is arranged at the bottom of the filling component; the driving component comprises a driving disc which can autorotate and is coaxially and fixedly connected to the objective table, so that the autorotation axis of the driving disc and the rotation axis of the objective table are coaxial, and the driving disc is located at the backs of the objective table and the filling part; a driving rod and a transmission rod are fixedly connected to a driving shaft, and an included angle between the driving rod and the transmission rod is an acute angle; and the driving rod is in contact with a driven rod so as to move the driving disc to reverselyrotate relative to the driving shaft. The full-automatic high-precision filling equipment for food processing has high filling efficiency and can reduce filling waste.

Owner:SHANDONG GAOTANGYONGWANG FOOD CO LTD

Mixing device for production of building module

InactiveCN108284520AEasy to carryReduce labor costsCement mixing apparatusArchitectural engineeringComputer module

The invention discloses a mixing device for production of a building module. The mixing device comprises a mixing bin; the upper part of the left side surface of the mixing bin is provided with a feeding opening; the inside of the mixing bin is fixedly connected with a partition plate matched with the mixing bin; the upper surface of the partition plate is fixedly connected with a first motor; anoutput end of the first motor penetrates through the partition plate and extends out of the partition plate; the output end of the first motor is fixedly connected with a rotating rod; the outer surface of the rotating rod is fixedly connected with mixing rods which are arranged at an equal interval; and the bottom surface of the rotating rod is fixedly connected with a supporting plate. The mixing device for production of the building module can be conveniently transferred by a user by virtue of a forklift, so the labor cost generated when the user transfers the mixing device can be effectively lowered; the friction force between supporting legs and the ground can be effectively increased; the overall stability is improved; inclination, caused by external force, of the mixing device in ause process is prevented, and the overall mixing device realizes a relatively high mixing effect on cement and is simple to operate and beneficial for wide popularization.

Owner:江苏森鑫木业有限公司

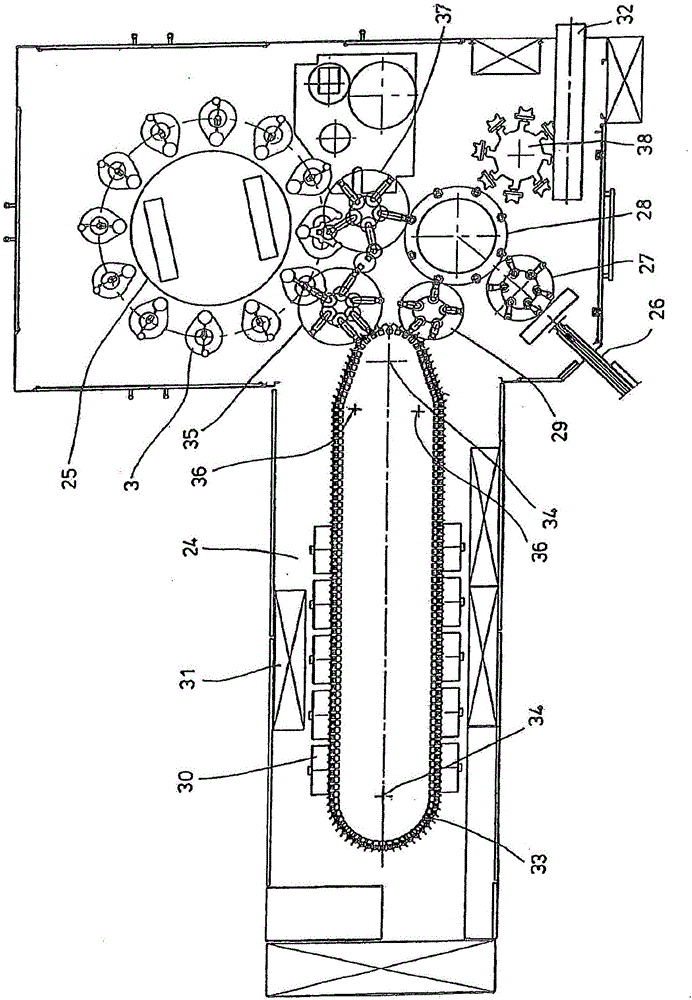

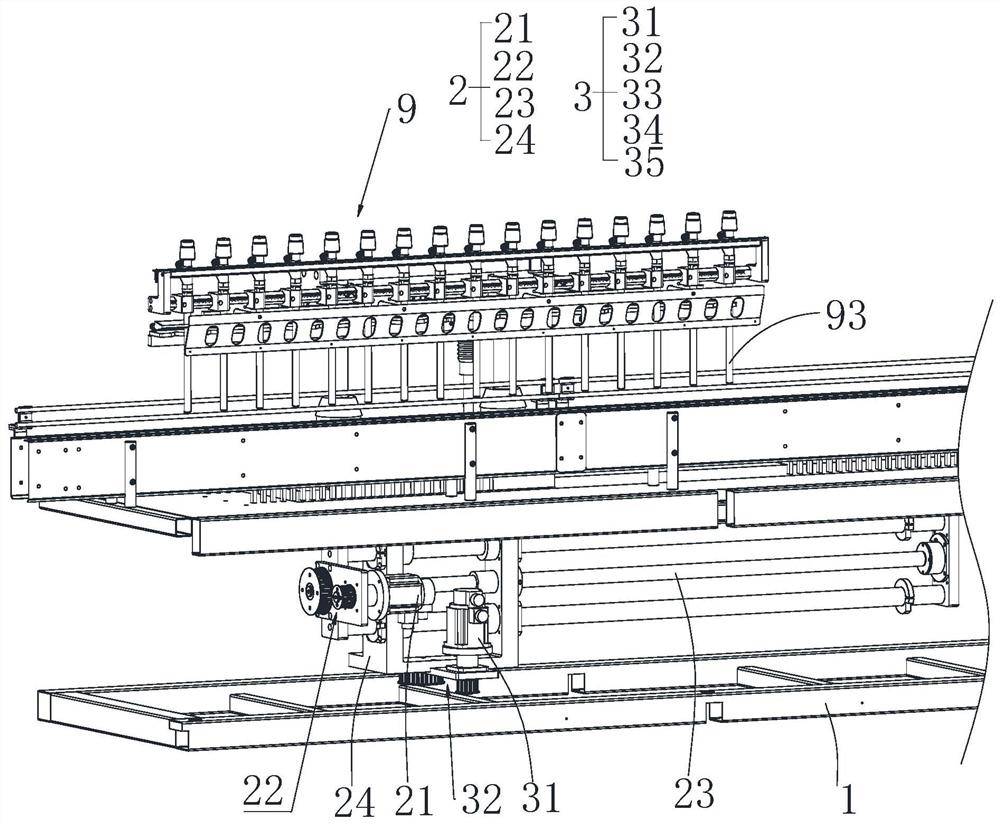

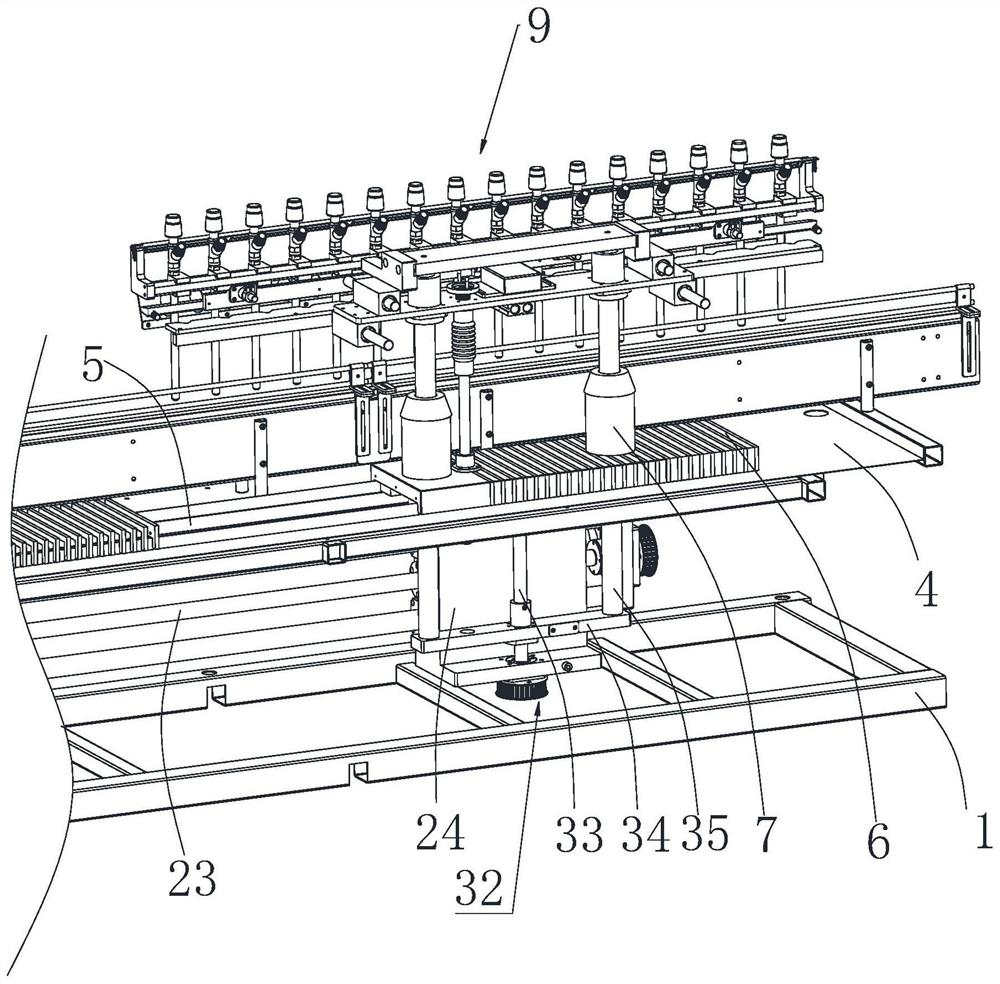

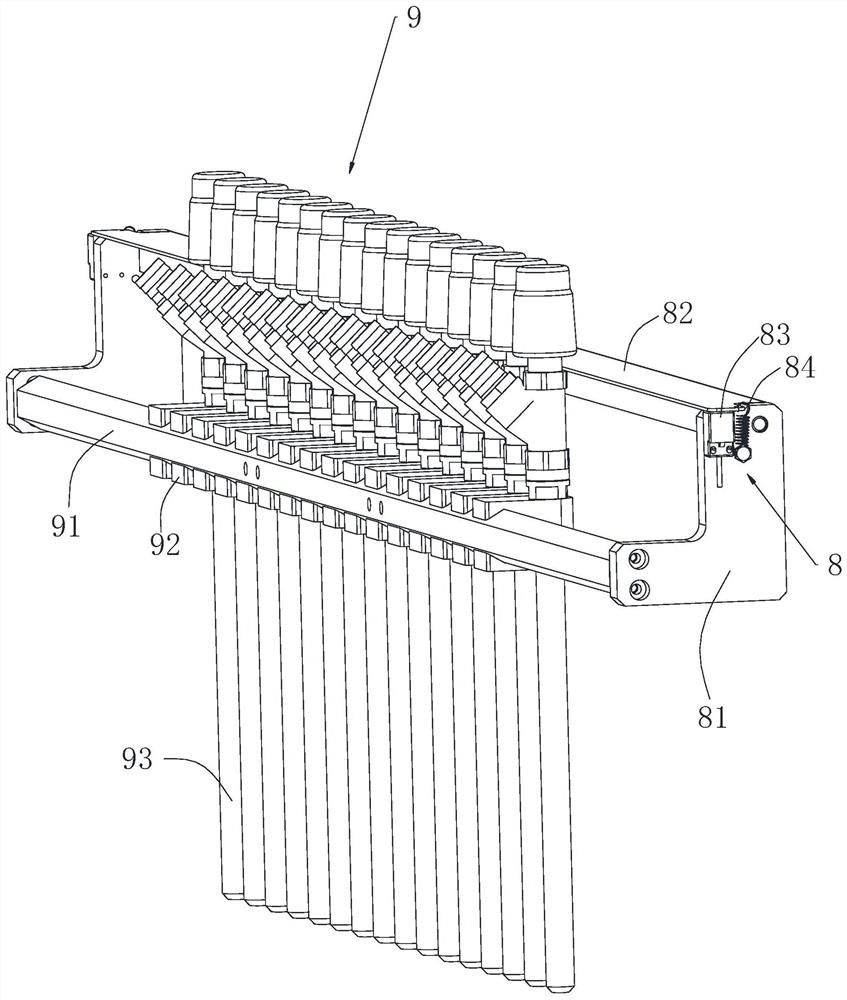

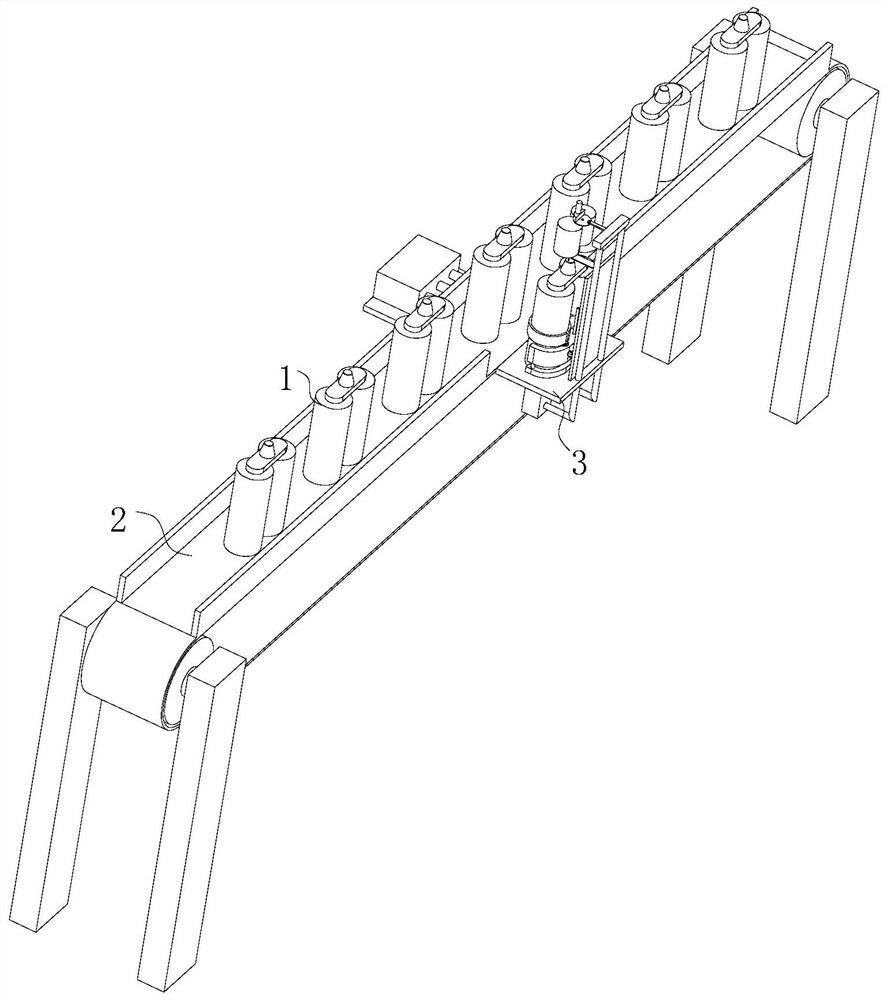

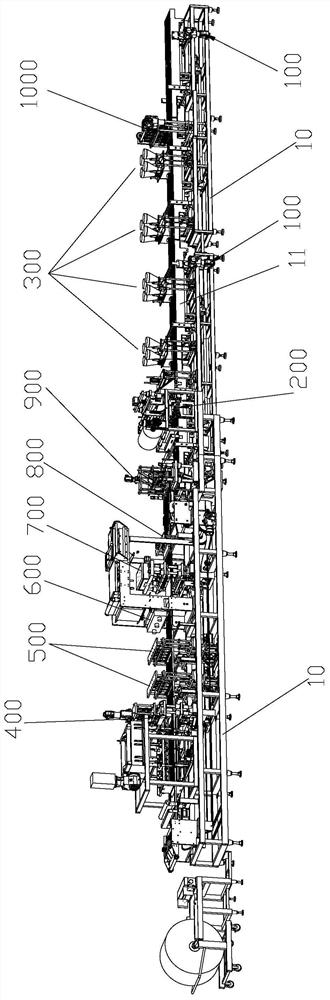

Seam beautifying agent filling production line

InactiveCN113371659AConsistent filling speedSave filling timeFilling using counterpressureBottle-handling machinesProcess engineeringManufacturing line

The invention discloses a seam beautifying agent filling production line in the field of seam beautifying agent production. The seam beautifying agent filling production line comprises a conveying line for conveying a two-component seam beautifying agent tank and a filling mechanism fixedly arranged on the side of the conveying line, wherein the filling mechanism comprises a mounting seat, a clamping unit, a cleaning unit and a filling unit are fixedly arranged on the mounting seat, and the filling unit is used for filling two tank bodies of the two-component seam beautifying agent tank fixed by the clamping unit at the same time and completing filling at the same time; and the cleaning unit is used for synchronously cleaning the surfaces of the two tank bodies of the two-component seam beautifying agent tank when the filling unit carries out filling. According to the seam beautifying agent filling production line, two tank bodies of the double-component seam beautifying agent tank can be filled at the same time, meanwhile, the surfaces of the two tank bodies can be synchronously cleaned during filling, so that the production time is shortened, and the production efficiency is improved.

Owner:东莞市欧尚自动化设备科技有限公司

Milk powder filling and film sealing equipment for food processing

PendingCN113212880ASave filling timeAvoid pollutionBottle/container closureSolid materialProcess engineeringManufacturing engineering

The invention relates to film sealing equipment, in particular to milk powder filling and film sealing equipment for food processing, and aims to solve technical problem about how to provide the milk powder filling and film sealing equipment which is used for food processing and is relatively low in equipment price, relatively low in use cost, relatively easy and convenient to operate and relatively high in automation degree. The milk powder filling and film sealing equipment for food processing comprises a supporting frame, a conveying mechanism, a sealing mechanism and a downward pressing mechanism; the conveying mechanism is arranged on the supporting frame; the sealing mechanism is connected to the supporting frame; and the downward pressing mechanism is arranged on the supporting frame. Through cooperation of a pushing mechanism and a discharging mechanism, automatic conveying and discharging of materials can be achieved, and the time for conveying the materials and filling milk powder by people is saved.

Owner:曾以南

Portable electric smart hair washing comb

The invention relates to a portable electric smart hair washing comb which comprises a comb body, comb teeth and a handle, wherein hair washing solution release teeth are arranged in the comb teeth and are communicated with a hair washing solution storage chamber; dirty water recycling teeth in the comb teeth are communicated with a dirty water recycling chamber; a water pump is arranged in the hair washing solution storage chamber, and a hair washing solution is pumped from the hair washing solution storage chamber into the hair washing solution release teeth through the pump; a micro water pump is communicated with a control box through a line; a dirty water recycling pipe is communicated with a water absorber, and dirty water is recycled into the dirty water recycling chamber through the water absorber; heat is generated by resistance heating, and hair is dried through air outlets distributed in a hot air pipeline. According to the portable electric smart hair washing comb provided by the invention, the water pump or the water absorber are simultaneously driven by an integrated module to supply or absorb water, hot air is provided by a hot air blower, and the hair washing solution can quickly touch and clean the hair as well as a scalp when the portable electric smart hair washing comb is in use; meanwhile, the dirty water can be quickly absorbed into the dirty water chamber; through matching of the hot air from the hot air blower, the hair can be quickly cleaned, absorbed and dried so as to achieve the purpose of washing hair.

Owner:陈平

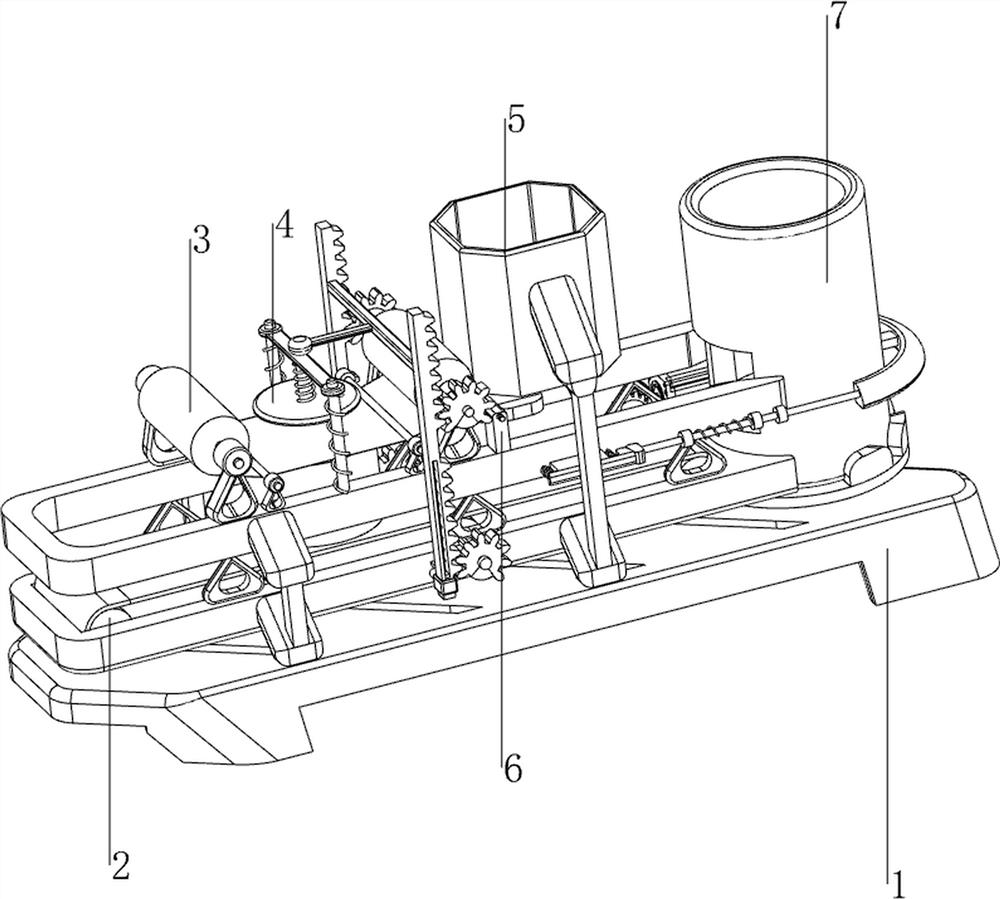

Seafood can ingredient quantitative filling equipment

InactiveCN111634877AChange distanceImprove filling efficiencyLiquid bottlingStructural engineeringMechanical engineering

The invention discloses seafood can ingredient quantitative filling equipment. A supporting plate, an auxiliary discharging device, a lifting drive device and a rotation drive device are included. A support is arranged at the bottom end of the supporting plate. A support column is arranged at the middle portion of the top end of the supporting plate. A material barrel is arranged at the top end ofthe support column. Six ingredient tanks are evenly arranged on the side face of the material barrel. Feeding pipes are arranged at the top ends of the ingredient tanks, filling heads are arranged atthe bottom ends of the ingredient tanks, and electromagnetic valves are arranged on the side faces of the filling heads. The auxiliary discharging device is arranged in the material barrel. The lifting drive device is arranged at the top end of the supporting plate. A lifting table is arranged at the top end of the lifting drive device. The top end of the lifting table is rotationally connected with a rotation table, the middle portions of the lifting table and the rotation table are provided with through holes, and six weighing devices are evenly arranged at the top end of the rotation table. By means of the ingredient quantitative filling equipment, six tanks can be filled at the same time, and the filling efficiency is high.

Owner:林贞妹

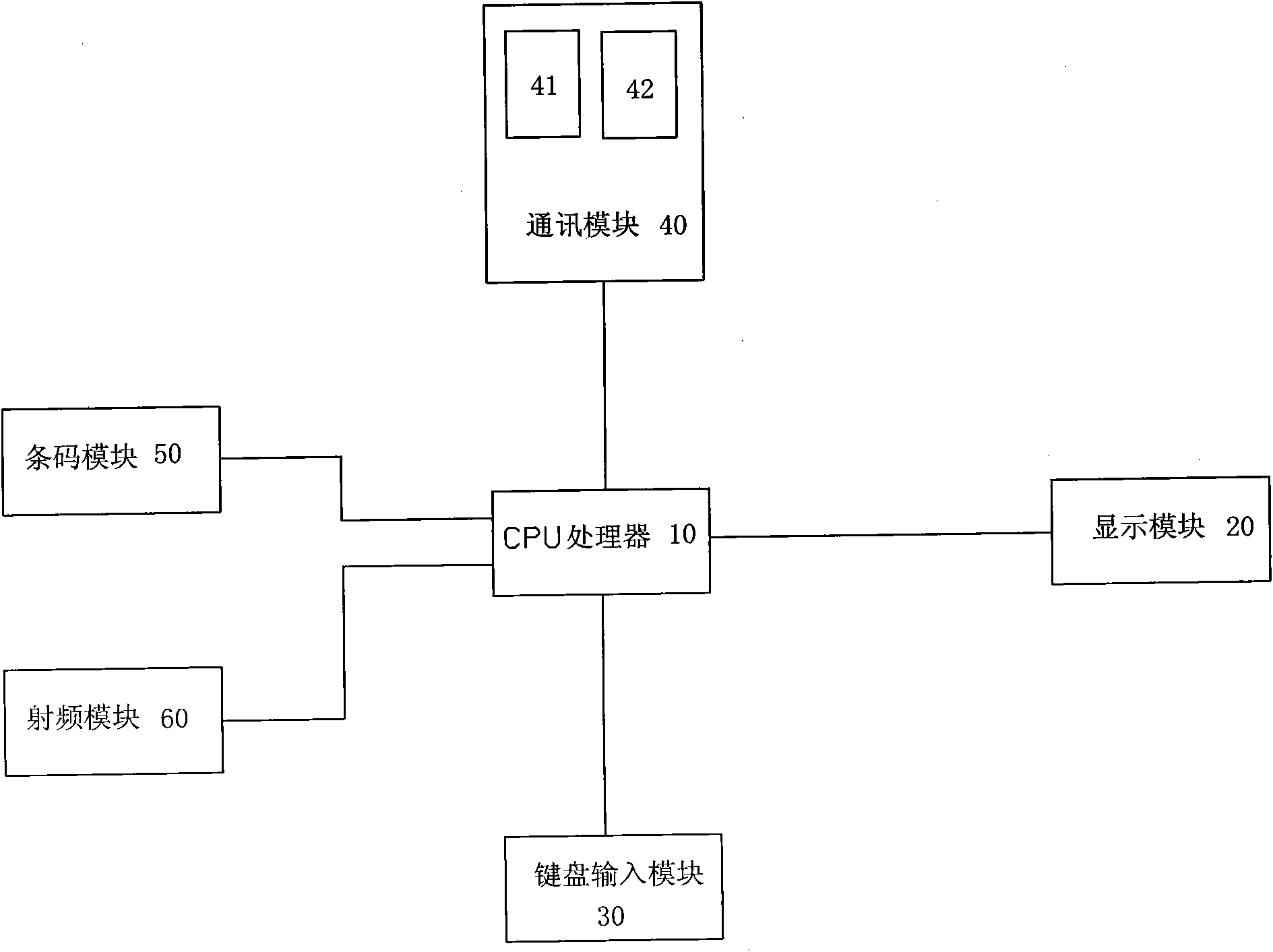

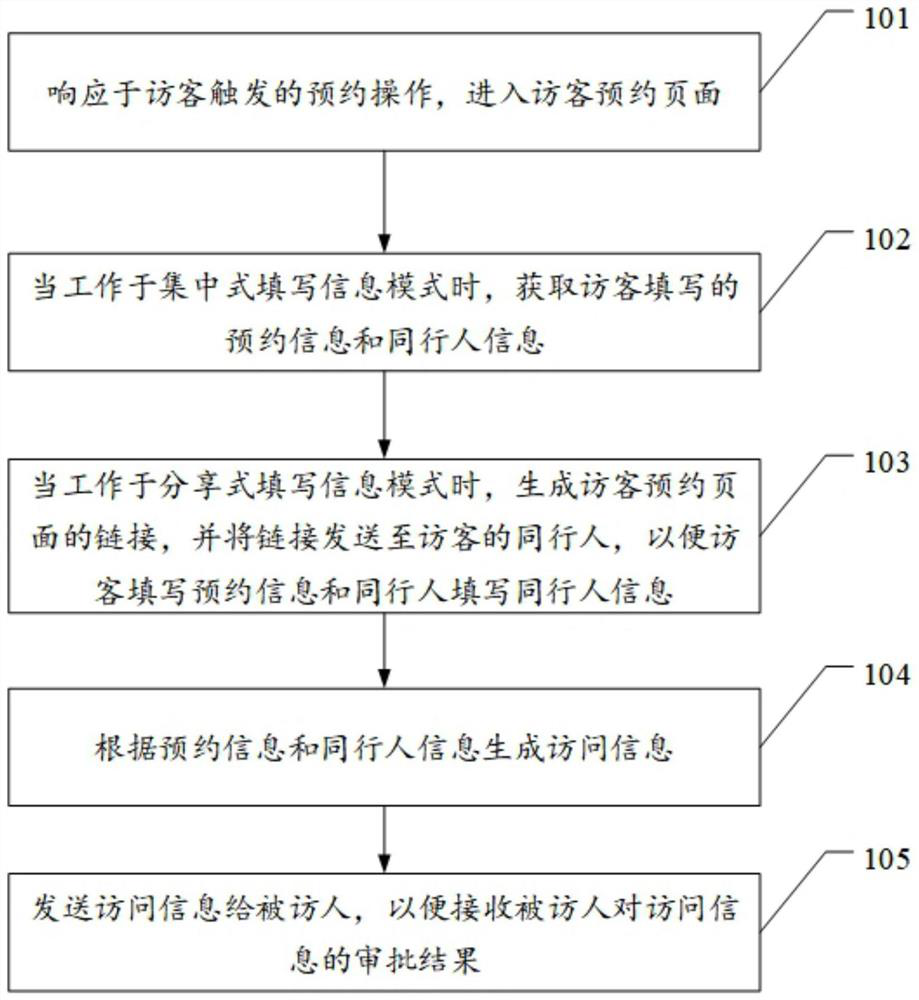

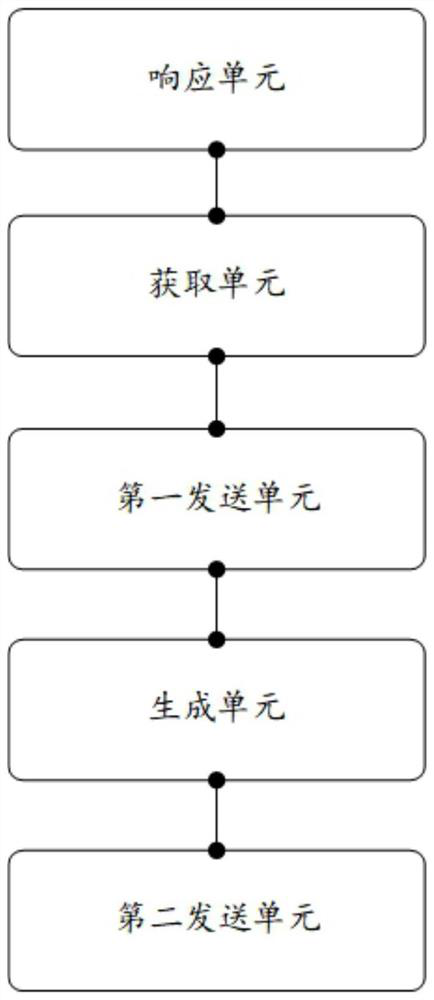

Multi-visitor collaborative reservation method, client, equipment and medium

PendingCN113096289ASave Appointment ProcessImprove booking efficiencyReservationsIndividual entry/exit registersInternet privacyEngineering

The invention discloses a multi-visitor collaborative reservation method, a client, equipment and a medium, wherein the method is applied to the client, and comprises the steps: responding to a reservation operation triggered by a visitor, and entering a visitor reservation page; when working in a centralized information filling mode, acquiring reservation information and partner information filled by the visitor; when working in a sharing type information filling mode, generating a link of a visitor reservation page, and sending the link to a partner of the visitor, so as to enable the visitor to fill the reservation information and the partner to fill the partner information; generating access information according to the reservation information and the partner information; and sending the access information to a visited person so as to receive an approval result of the visited person on the access information. The technical problem that an existing visitor reservation mode is low in efficiency is solved.

Owner:厦门熵基科技有限公司

Mining and filling combined hydraulic support system

The invention discloses a mining and filling combined hydraulic support system comprising filling auxiliary devices and filling auxiliary supports. The filling auxiliary supports are located in front of the filling auxiliary devices, connected with the filling auxiliary devices and used for pulling the filling auxiliary devices. Each filling auxiliary device comprises filling auxiliary units. Each filling auxiliary unit comprises a top beam, a base, a guide column and two hydraulic vertical columns, wherein the guide column and the hydraulic vertical columns are connected between the top beam and the base, and the guide column is located between the two hydraulic vertical columns; filling pipe seats are arranged at the front ends of the bases; and hanging pieces used for hanging filling moulds are arranged on the sides of the top beams. Mined areas do not need to be overall filled, room-column type filling is adopted, the moulds are filled with mixtures capable of being rapidly solidified, mining and filling can be conducted simultaneously, the filling time can be shortened, the filling cost can be reduced, and the filling efficiency is improved.

Owner:SHANDONG MINING MASCH GRP CO LTD +1

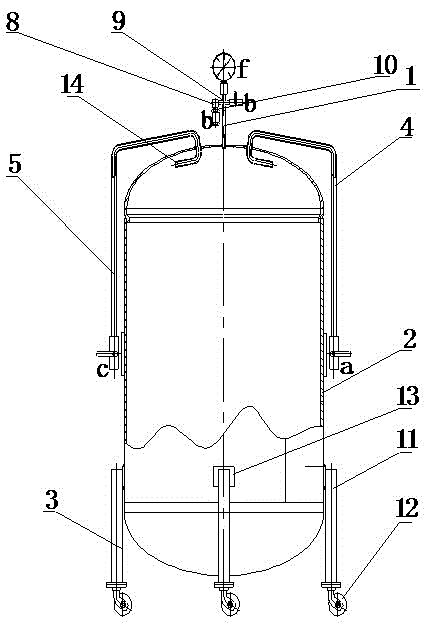

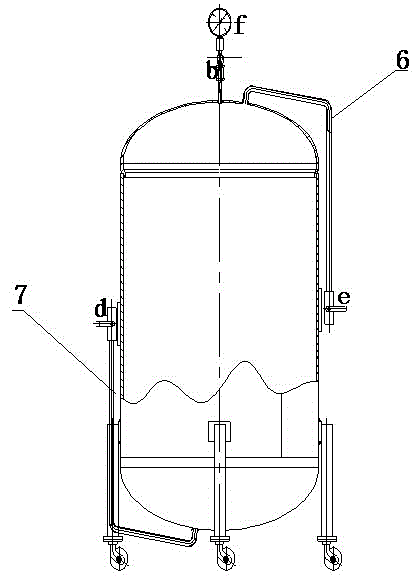

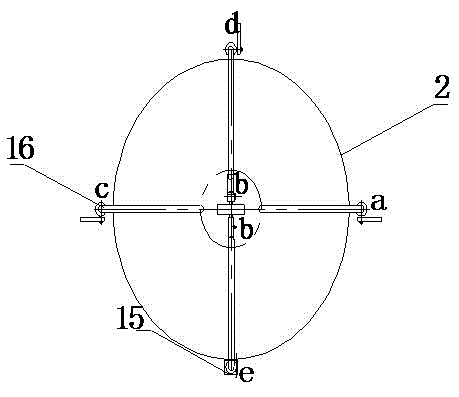

Molecular sieve pressure transport tank

ActiveCN105438673ARealize deliveryAvoid dangers such as explosionsLarge containersTank wagonsMolecular sieveDust collector

Provided is a molecular sieve pressure transport tank. The molecular sieve pressure transport tank comprises a pressure safety device, a tank body and a tank bottom support part. The pressure safety device is installed at the top of the tank body. The tank bottom support part is arranged in the low half part of the tank body and has a support effect on the tank body. A first stainless steel pipe, a second stainless steel pipe, a third stainless steel pipe and a fourth stainless steel pipe are arranged on the tank wall, closely pressing the tank body. Heads of the first stainless steel pipe, the second stainless steel pipe, the third stainless steel pipe and the fourth stainless steel pipe stretch into the top surface of the tank body in the forms of bending pipes. The tail of the first stainless steel pipe is a dust collector joint. The tail of the second stainless steel pipe is a molecular sieve suction inlet. The tail of the third stainless steel pipe is a pressurized port. The head of the fourth stainless steel pipe is a molecular sieve outlet. The molecular sieve pressure transport tank has following beneficial effects: delivery efficiency of the molecular sieve is increased; quality of the molecular sieve during transport is ensured; by means of the pressure safety device, potential safety hazards of the transport tank are eliminated; and the molecular sieve pressure transport tank has excellent usage effect.

Owner:江苏利旺车辆部件有限公司

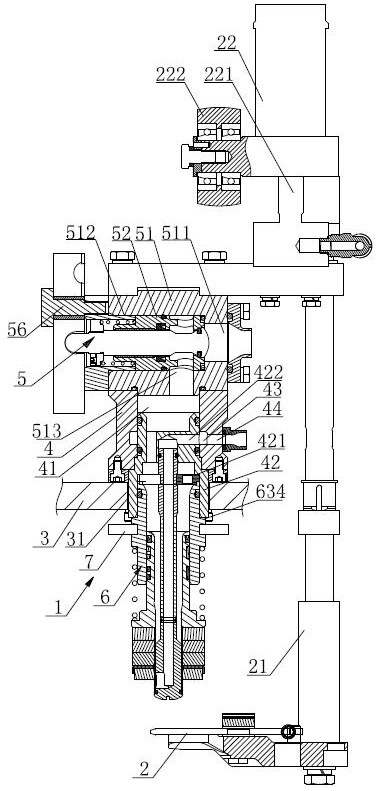

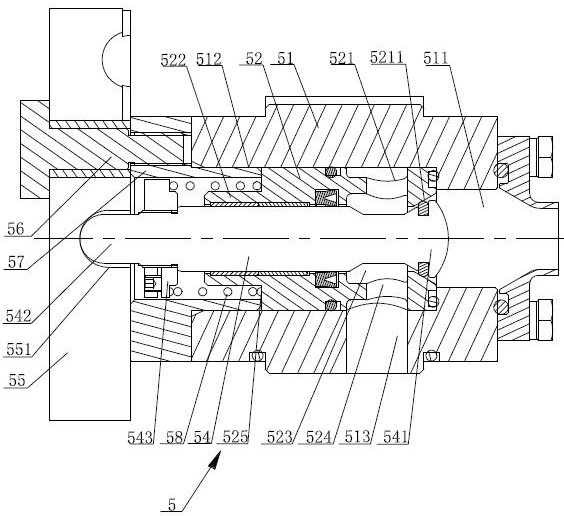

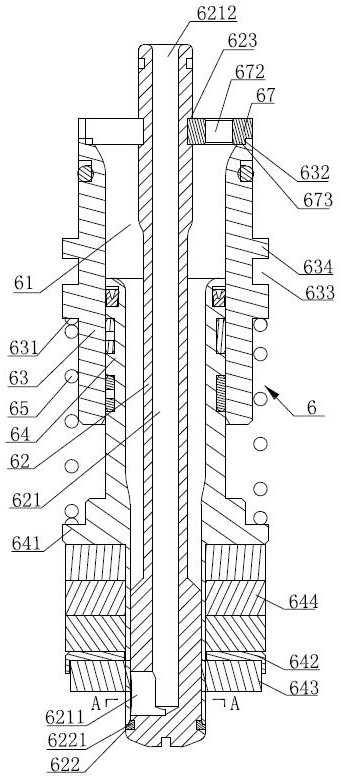

Filling device in filling machine

ActiveCN114014243AEasy maintenanceReduce back flowSynchronising machinesLiquid bottlingEngineeringBottle

The invention discloses a filling device in a filling machine, which comprises a filling valve, a bottle clamp is arranged below the filling valve, the structure of the filling valve comprises a valve seat fixedly arranged on a mounting rack, an upper valve cavity is arranged in the valve seat, a liquid inlet control mechanism is arranged at the top of the valve seat, and the bottom of the valve seat is detachably connected with a filling valve body for filling a bottle. The filling valve body comprises a filling valve cavity and a filling valve element, the filling valve cavity is communicated with the upper valve cavity, the filling valve element is hollow to form a backflow channel, and the backflow channel is communicated with a valve seat backflow hole channel in the valve seat. The filling device has the advantages that firstly, a liquid inlet control mechanism is arranged and can control the filling amount of materials, the surplus filling amount is reduced as much as possible on the premise that the filling requirement is met, and therefore the backflow amount is reduced, and the filling efficiency is improved; and secondly, the liquid inlet control mechanism is detachable, and the filling valve body can be integrally mounted and dismounted, so that the mounting and the maintenance of the filling valve are greatly facilitated.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

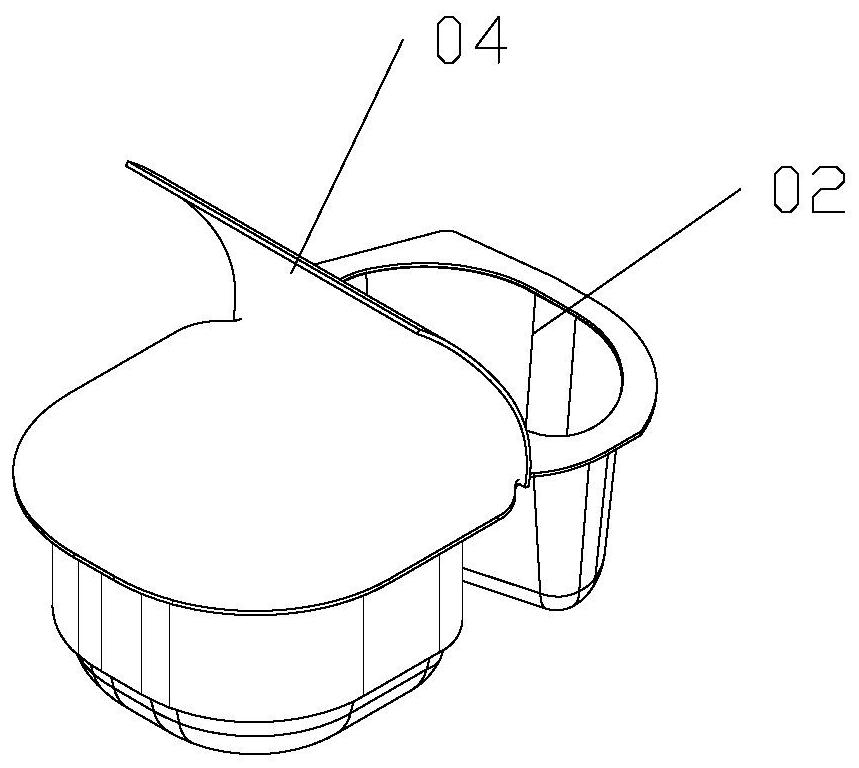

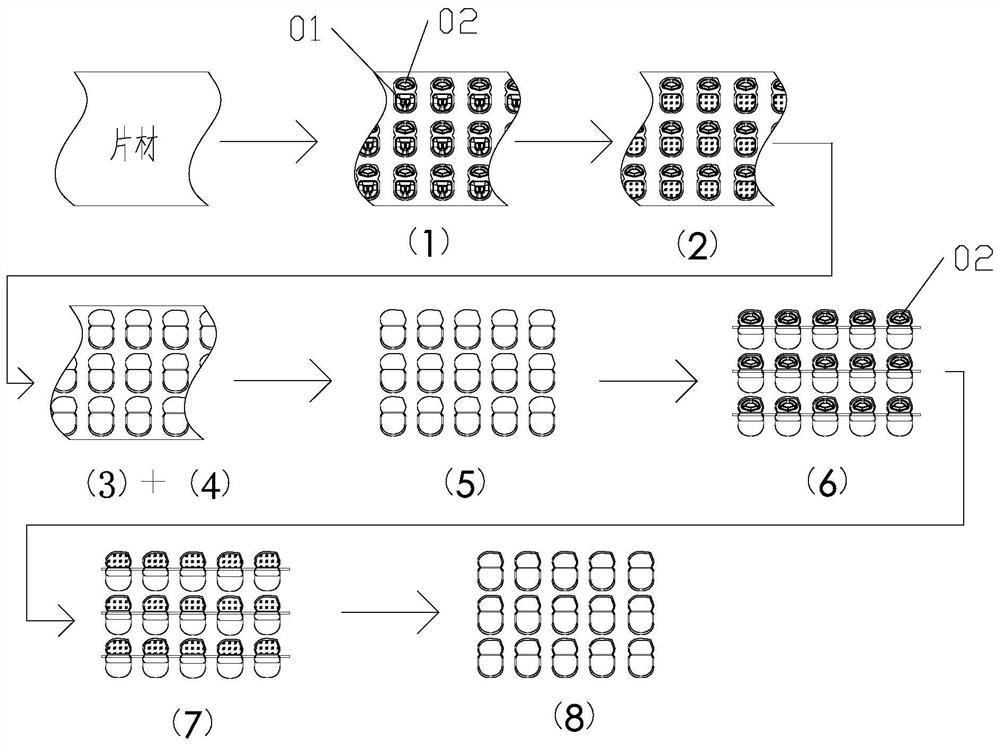

Primary-secondary cup food production method and production line

ActiveCN112722357AAvoid the phenomenon of falling into the first cavityAvoid pollutionWrapping material feeding apparatusWrapper twisting/gatheringPunchingManufacturing line

The invention discloses a primary-secondary cup food production method. A primary-secondary cup comprises a cup body and a cover film covering the cup body, and the cup body is provided with a first cavity and a second cavity. The primary-secondary cup food production method comprises the following steps of (1) extrusion molding, specifically, extruding a sheet to obtain the cup body connected with the sheet into a whole; (2) first filling, specifically, filling the first cavity with a first material; (3) film covering, specifically, covering the first cavity and the second cavity with cover films; (4) first sealing, specifically, sealing the first cavity; (5) punching, specifically, punching the sheet to enable the cup body to be separated from the sheet so as to form the independent cup body; (6) uncovering the film, specifically, uncovering the cover film covering the second cavity; (7) second filling, specifically, filling the second cavity with a second material; and (8) second sealing, specifically, after the cover film is reset, sealing the second cavity. In addition, the invention further discloses a production line for producing primary-secondary cup food by adopting the production method.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com