Milk powder filling and film sealing equipment for food processing

A technology for food processing and milk powder, applied in packaging, application, closure and other directions, can solve the problems of complex operation, high price and high use cost, and achieve the effect of preventing pollution, saving filling time, and realizing automatic transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

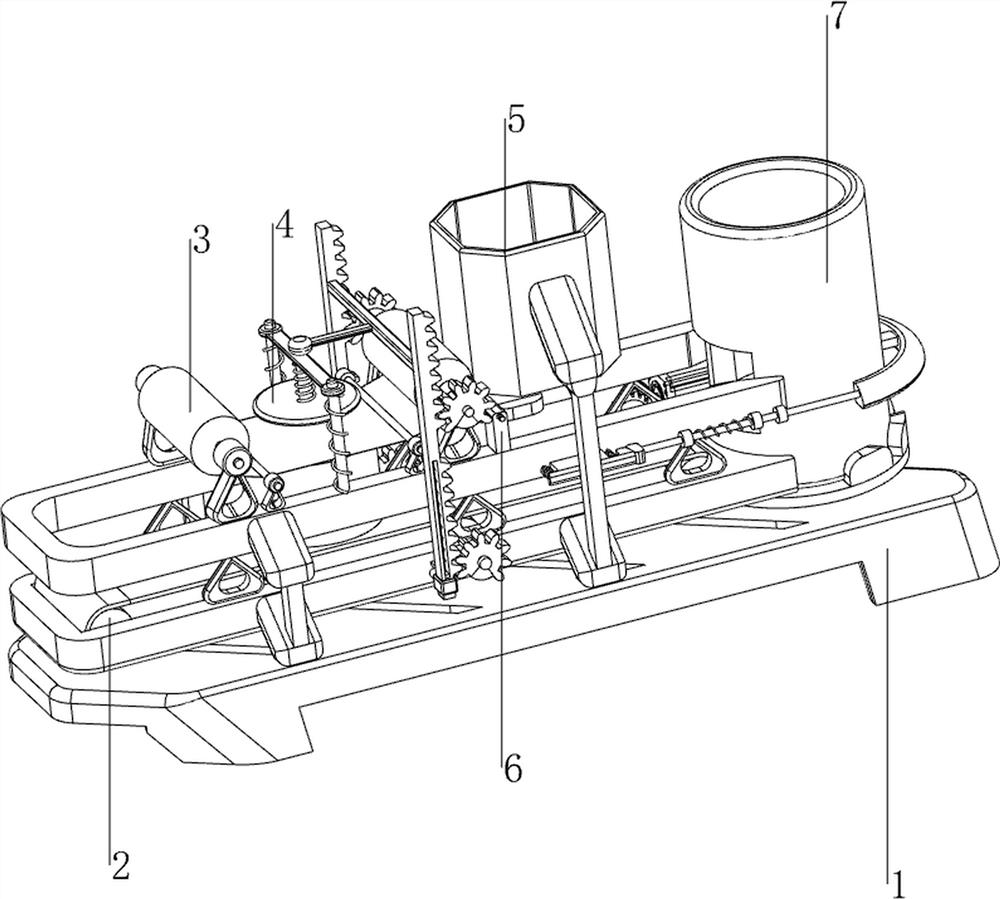

[0056] A kind of milk powder filling and sealing equipment for food processing, such as figure 1 As shown, it includes a support frame 1, a conveying mechanism 2, a sealing mechanism 3 and a pressing mechanism 4, the supporting frame 1 is provided with a conveying mechanism 2, the supporting frame 1 is connected with a sealing mechanism 3, and the supporting frame 1 is provided with a pressing mechanism Institution 4.

[0057] When people need to fill and seal the milk powder, the material is placed on the conveying mechanism 2, and after the material is manually filled with milk powder, the conveying mechanism 2 is started, and the conveying mechanism 2 drives the sealing mechanism 3 and the pressing mechanism 4 to move, that is The material can be sealed, and after the operation, the conveying mechanism 2 is closed, and the sealing mechanism 3 and the pressing mechanism 4 stop moving.

Embodiment 2

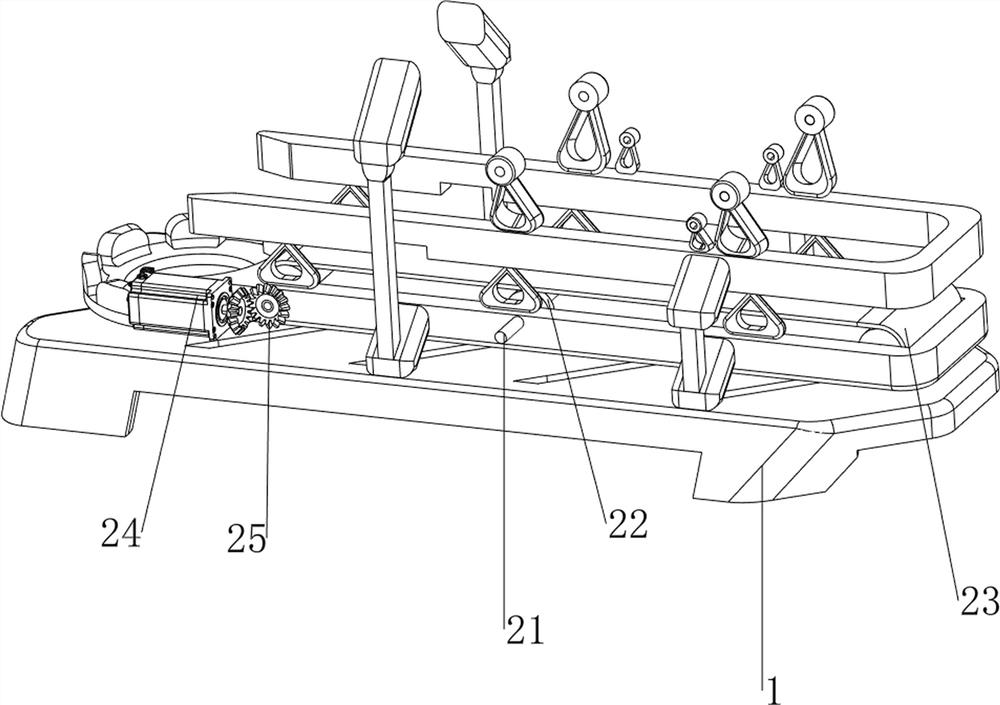

[0059] On the basis of Example 1, such as figure 2 As shown, the conveying mechanism 2 includes a first rotating shaft 21, a runner 22, a transport belt assembly 23, a servo motor 24 and a bevel gear set 25, and five first rotating shafts 21 are rotatably connected to the support frame 1, and three first The rotating shaft 21 is located at the bottom of the support frame 1, and the two first rotating shafts 21 are located at the top of the support frame 1. The front and rear sides of the first rotating shaft 21 on the lower side are provided with runners 22, and the first rotating shaft 21 on the left and right sides of the bottom is connected with a transport The belt assembly 23 is provided with a servo motor 24 at the right rear of the support frame 1, and a bevel gear set 25 is connected between the output shaft of the servo motor 24 and the first rotating shaft 21 on the left.

[0060] People place the material on the conveyor belt assembly 23, then start the servo motor...

Embodiment 3

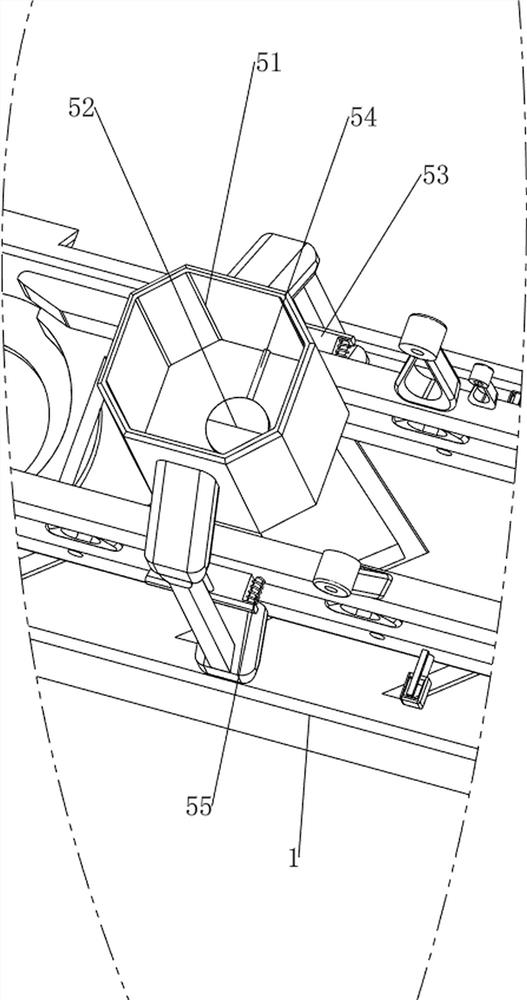

[0062] On the basis of Example 2, such as Figure 3 to Figure 7As shown, the sealing mechanism 3 includes a film winding wheel 31, a second rotating shaft 32, a missing gear 33, a rack 34, a first telescopic assembly 35 and a first fixed block 36, the front and rear sides of the first rotating shaft 21 in the lower part and the upper part The front and rear sides of the first rotating shaft 21 on the right side are provided with missing gears 33, and an overrunning clutch is provided between the front and rear sides of the first rotating shaft 21 on the upper right side and the missing gears 33, and the upper first rotating shaft 21 is provided with a film winding wheel 31 , the left and right sides of the upper part of the support frame 1 are rotatably connected with the second rotating shaft 32, the front and rear sides of the support frame 1 are slidingly connected with the rack 34, and the missing gears 33 are all meshed with the rack 34, and the front and rear sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com