Full-automatic high-precision filling equipment for food processing

A technology for food processing and filling equipment, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of high cost, large filling waste, inconvenient use and maintenance, and achieve low cost, improve adequacy, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means realized by the present invention, the creation features, the achievement of the purpose and the effect clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

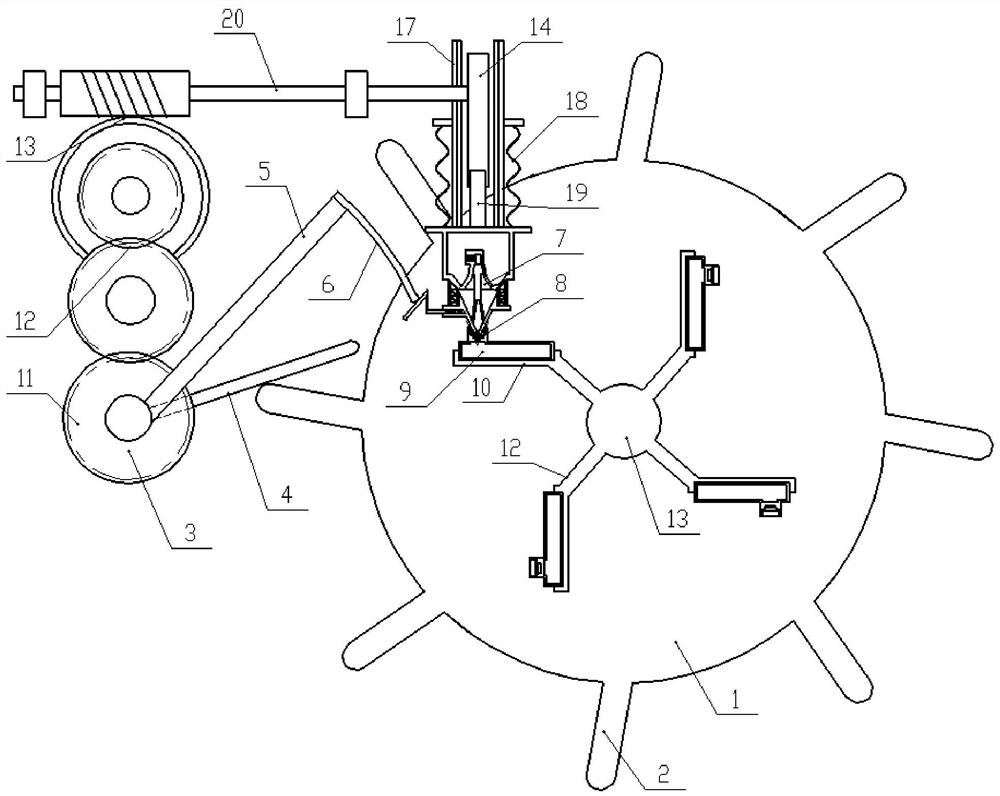

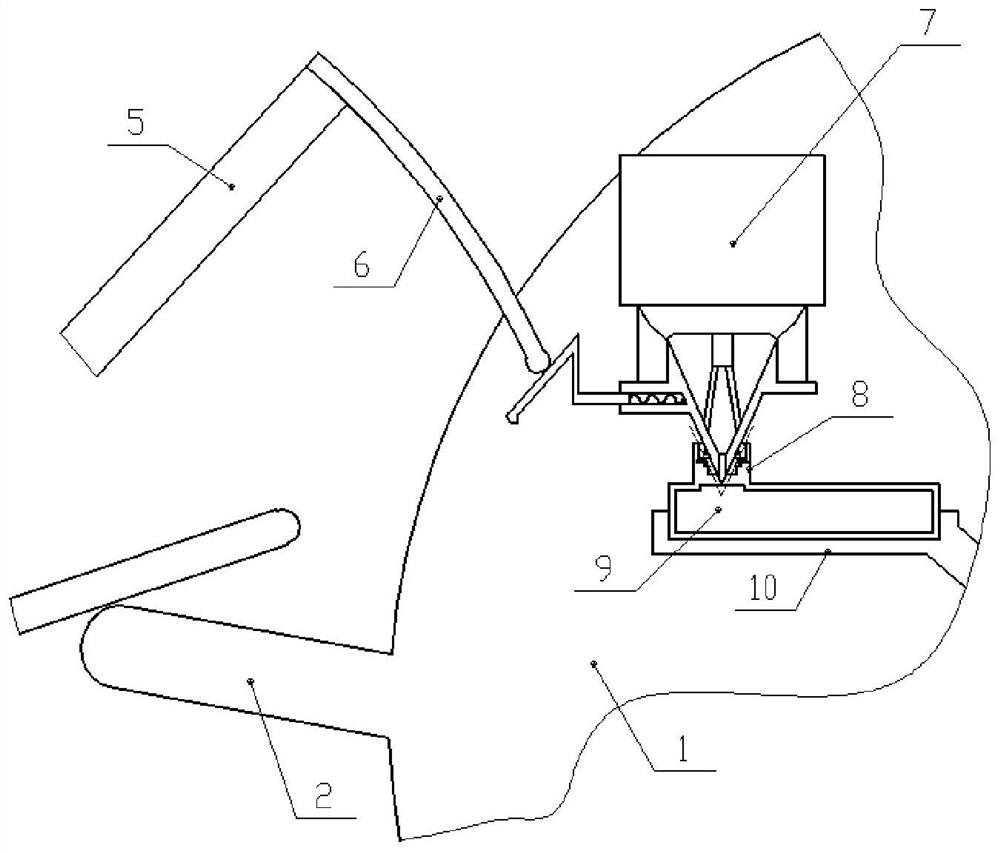

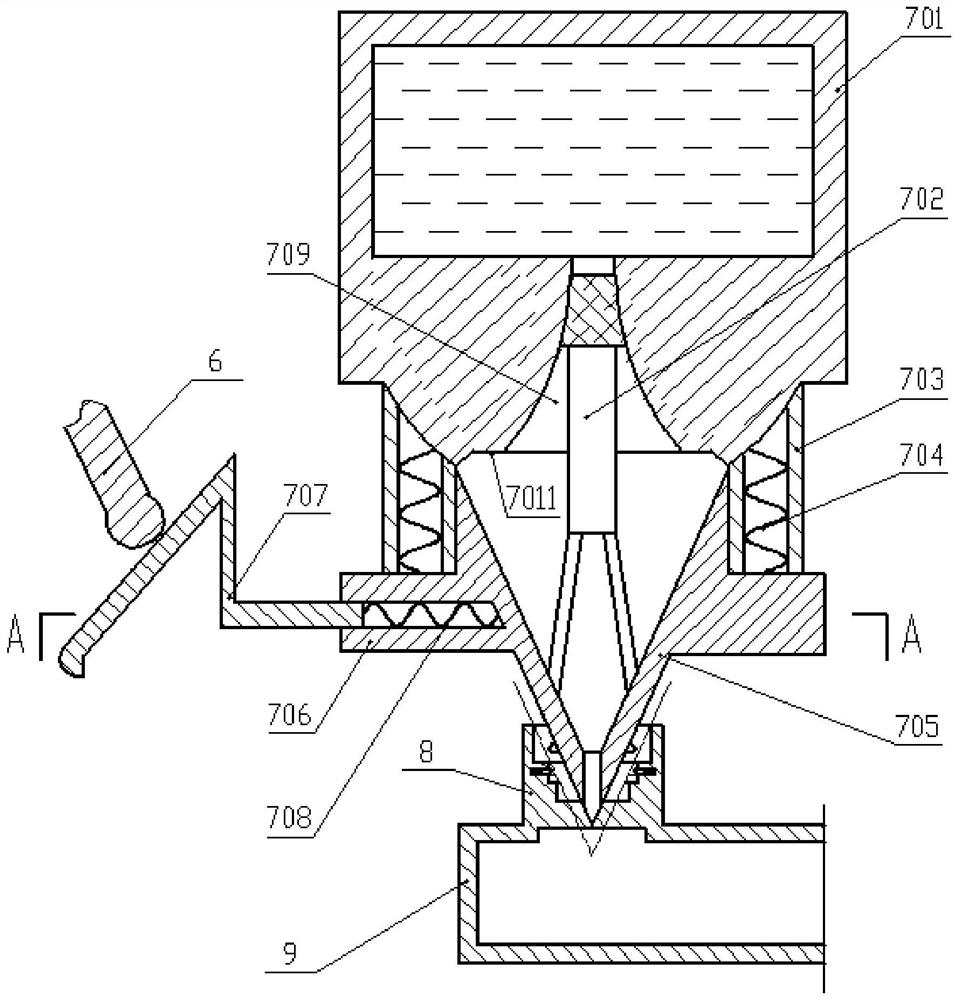

[0024] This embodiment discloses a fully automatic high-precision food processing filling equipment, including a driving part, a filling part and a stage, specifically, such as Figure 1-2 As shown in the figure, the carrier can rotate intermittently around its center, and the carrier is provided with several clamping tables 10 for fixing the liquid food boxes 9 to be filled, and all the clamping tables 10 rotate with the carrier The center is the center of the circle and is arranged in an annular array, and the clamping table 10 reaches a predetermined position intermittently and stays for a predetermined time when the stage rotates. A filling neck 8 for filling liquid f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com