A filling device and method for a cascaded alkali metal gas chamber

An alkali metal gas chamber and alkali metal technology, which is applied in the manufacture of discharge tubes/lamps, electrical components, cold cathodes, etc., can solve the problems of 48-hour preparation time and long cycle, and achieve saving filling time and reliability The effect of high reliability and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

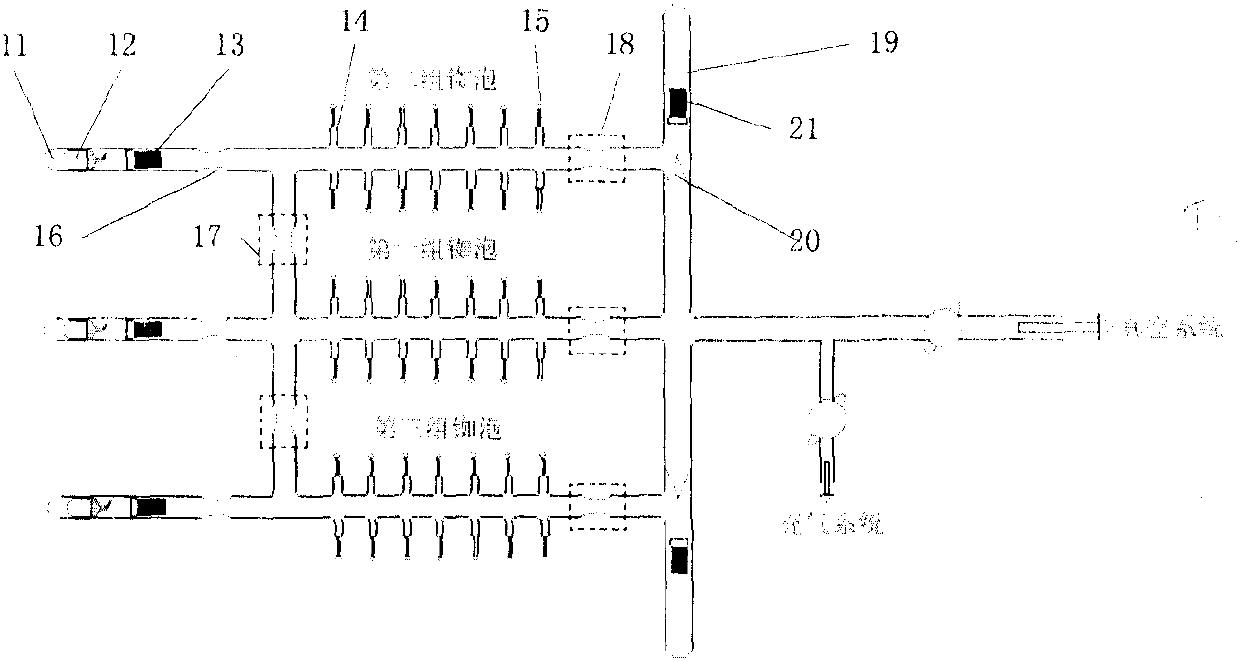

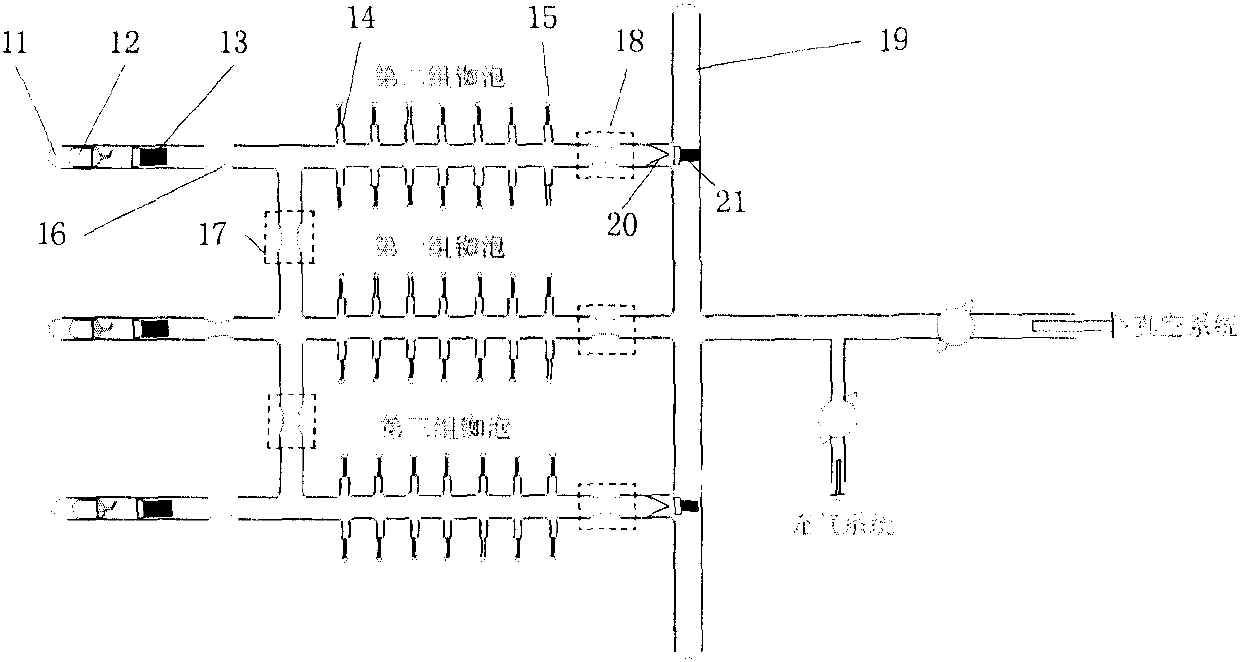

[0043] If the alkali metal is rubidium, with figure 1 Only three sub-pipelines are discussed as examples.

[0044] Turn on the vacuum system to pump air to seal the filling device, detect leaks, and degas;

[0045] If the sub-pipe in the middle is a sub-pipe not provided with breakable components, the first glass reducing pipe 17 between the sub-pipe and the other two sub-pipes will be sealed off to stop the current alkali metal foam filling Sub-pipelines and other alkali metal foam filling sub-pipelines are connected, and then rubidium is filled. After filling, the alkali metal foam that is currently being filled is filled by sealing off the second glass shrinking pipe 18 Branch pipeline is taken off from filling main pipeline 19.

[0046] Then carry out the following treatment to any one of the other two sub-pipelines: first move the second magnetic hammer 21 through the magnet to break the broken glass ampoule 20, so that the current alkali metal foam is fully made into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com