Active control filling system

A filling system and active control technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problem that the system cannot be actively controlled, achieve flexible and convenient filling information, save filling time, and save human resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

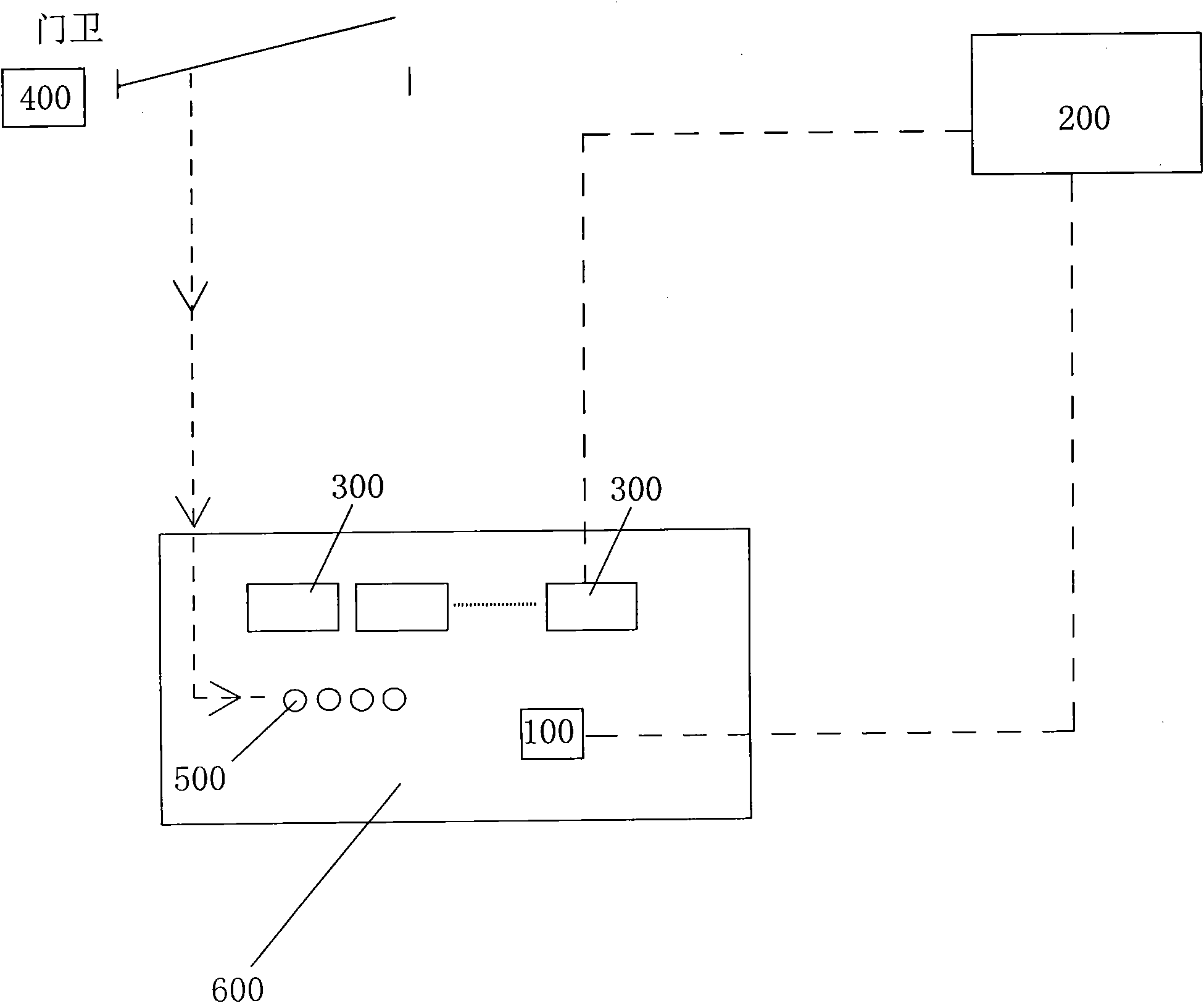

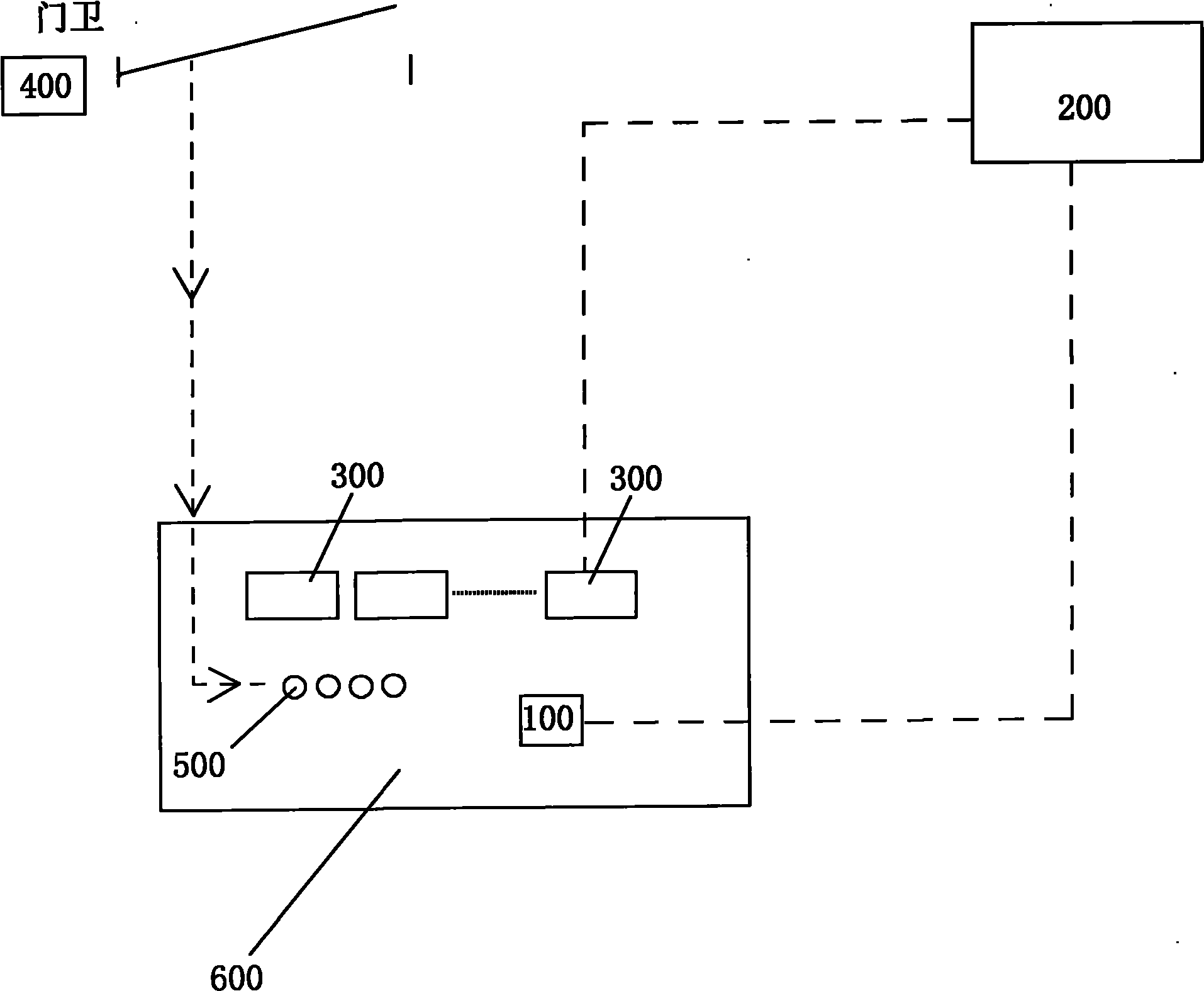

[0044] refer to figure 1 with figure 2 , the present invention is implemented like this:

[0045] exist figure 1 with figure 2 Among them, an active control filling system includes a filling machine 300 and a computer console 200, the computer console 200 and the filling machine 300 can communicate interactively, and the computer console 200 edits the filling information after completing the billing procedure, Then the filling information is sent to the filling machine 300, and the filling machine 300 fills the steel cylinder 500 to be filled according to the filling information.

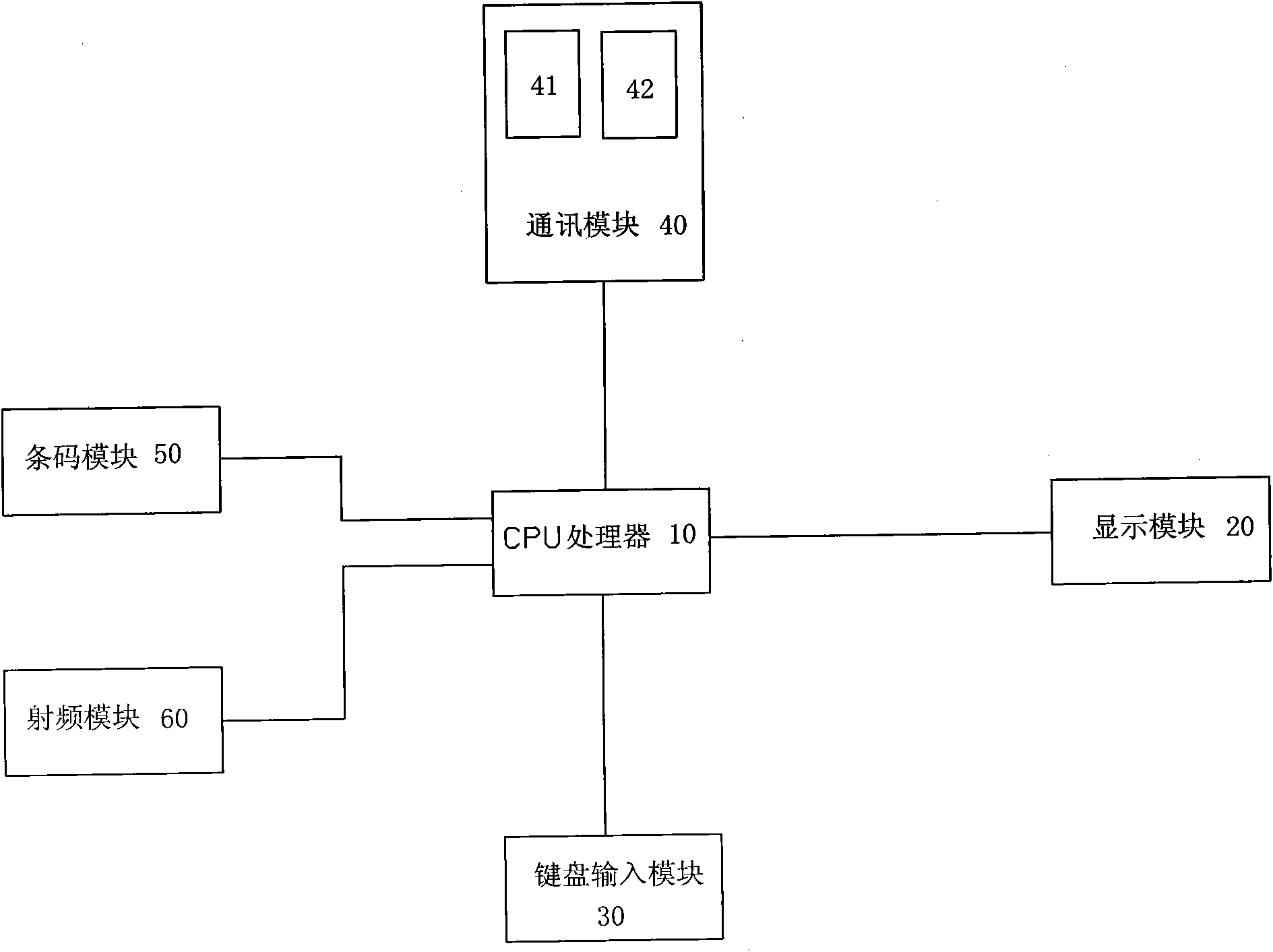

[0046] In this embodiment, the active control filling system also includes an on-site billing machine 100, which is used for counting steel cylinders at the filling site and setting individual filling volumes for each steel cylinder 500 on the spot. The on-site ticket issuing machine includes a CPU processor 10, and the CPU processor 10 is respectively connected to a display module 20 includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com