Method for preparing trimethylolethane through continuous condensation hydrogenation method

A trimethylolethane, condensation hydrogenation technology, applied in the preparation of carbon-based compounds, hydroxyl compounds, organic compounds, etc., can solve the problem that formate cannot be processed, the calcium method consumes more formaldehyde, and the process is complicated, etc. problems, to achieve the effect of high hydrogenation equipment and technical requirements, low production cost, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A method for preparing trimethylolethane by continuous condensation hydrogenation, comprising the following steps:

[0073] 1) Add 2 / 3 of the total volume of water or recover dilute formaldehyde solution in the impinging flow micro-mixing reactor, according to the following ratio; the molar ratio of formaldehyde, propionaldehyde, triethylamine and soft water is 2.5:1:0.6: The ratio of 20 is added to the condensation tank, and the temperature of the condensation tank is controlled at 30-40 ° C. The pH of the condensation liquid will fluctuate due to side reactions. The pH in the condensation tank is controlled at 8.5 to 8.9. The residence time is 8 to 12 hours. Contains 8%-18% 2,2-dimethylolpropanal, 1.5%-3% unreacted formaldehyde, 0.5%-1.5% alkali, 1%-3% mono-bis acetals and lipids compound, 75%-85% water;

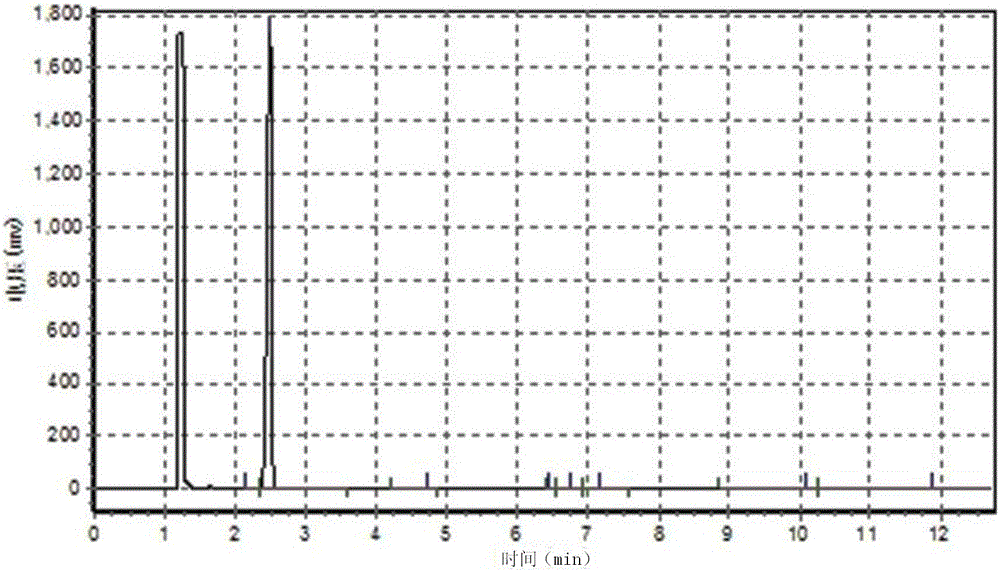

[0074] 2) Remove unreacted excess formaldehyde, organic base and water by distillation under reduced pressure from the condensation liquid prepared in step 1), and...

Embodiment 2

[0084] A method for preparing trimethylolethane by continuous condensation hydrogenation, comprising the following steps:

[0085] 1) Add 2 / 3 of the total volume of water or recover dilute formaldehyde aqueous solution as bottom water in the impinging flow micro-mixing reactor, according to the following ratio; the molar ratio of formaldehyde, propionaldehyde, ammonia water and soft water is 2.5:1:0.6 : 20 ratio into the condensation tank, the temperature of the condensation tank is controlled at 30-40 ° C, the pH of the condensation liquid will fluctuate due to side reactions, the pH in the condensation tank is controlled at 8.5 to 11, and the residence time is 8 to 12 hours. condensation liquid;

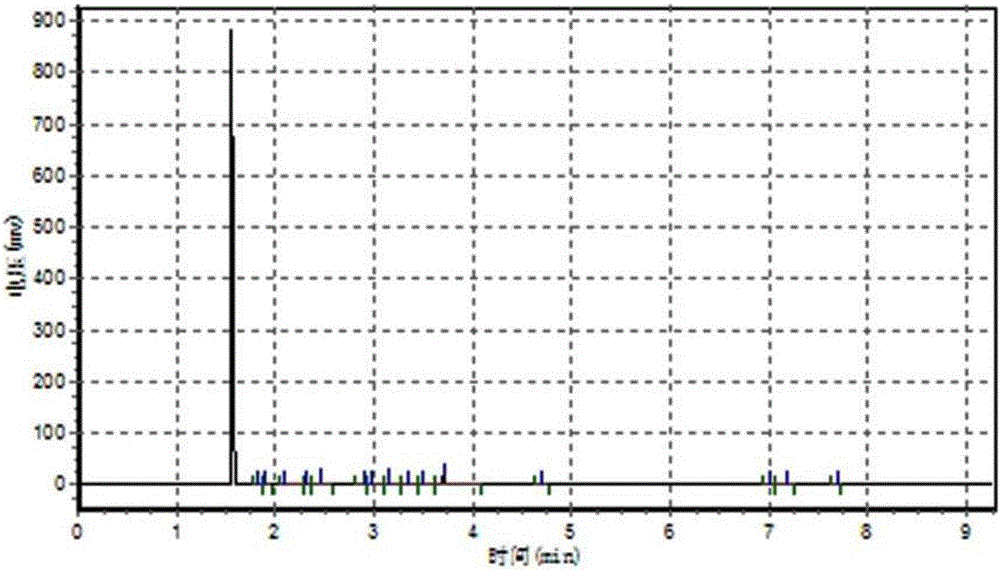

[0086] 2) The condensed liquid prepared by step 1) adopts the conditions of Example 1 to carry out underpressure distillation, and the concentrated liquid obtained contains a large amount of white solids, and the gas chromatogram ( image 3 ) analyzed that the white solid was urot...

Embodiment 3

[0088] In the four-necked flask, add 300ml of soft water, add 8g of aluminum magnesium hydrotalcite as a condensation catalyst, and charge 230ml of formaldehyde (37%) and 90ml of propionaldehyde (99.5%) into the pear-shaped separating funnel respectively. Allow stirring to fully disperse the catalyst in soft water, then slowly add formaldehyde and propionaldehyde dropwise, place the flask in a constant temperature water bath, and keep the temperature in the flask at about 35°C. Add propionaldehyde and formaldehyde dropwise in three to six hours, continue stirring after the dropwise addition, and add propionaldehyde and formaldehyde from the beginning to the end of a total of 10 hours. The above-mentioned reaction solution was placed in a rotary evaporator and evaporated under negative pressure to obtain a concentrated solution for chromatographic analysis. The results are shown in Figure 4 . Depend on Figure 4 It can be seen. . . . Hydrotalcite has a good catalytic eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com