Tear-resistant environment-friendly PBSeT copolyester material and preparation method thereof

A copolyester and anti-tearing technology, which is applied in the field of tear-resistant and environmentally friendly PBSeT copolyester materials and its preparation, can solve the problems of poor tear resistance and achieve the effect of improving tear performance and high market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

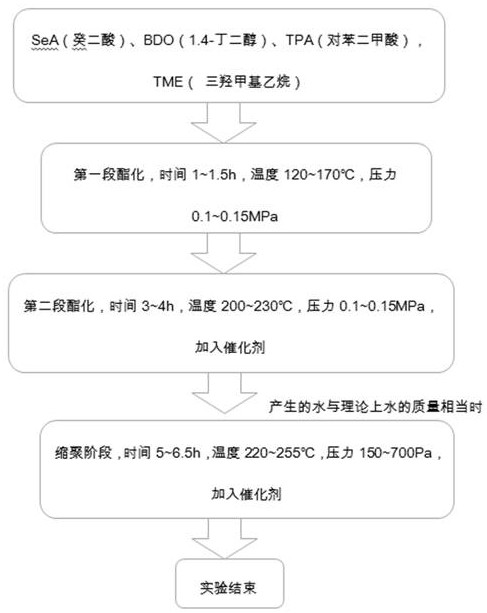

Method used

Image

Examples

Embodiment 1

[0027] Through the two-step esterification method, 707g of SeA (sebacic acid), 900g of BDO (1.4-butanediol), 581g of TPA (terephthalic acid), and 2.403g of TME (trimethylolethane) were weighed. Blending under the condition of adding a catalyst and at a temperature of 120-170°C, followed by the first stage of esterification, the pressure is 0.1-0.15MPa, after 1-1.5 hours of esterification; the second stage of esterification starts, and the temperature is raised When the temperature reaches 225°C, 6g of catalyst Tetrabutyl Titanate (tetrabutyl titanate) is added for esterification, and the reaction is about 3-4 hours. When the water produced is equivalent to the theoretical water quality (90-110%); the polycondensation stage begins , add catalyst Tetrabutyl Titanate (tetrabutyl titanate) 3g and raise the temperature to 225°C, the pressure is 600Pa, after polycondensation for 6.5h, when it is found that the torque on the equipment does not change, the polycondensation is complete....

Embodiment 2

[0029] Through the two-step esterification method, 707g of SeA (sebacic acid), 900g of BDO (1.4-butanediol), 581g of TPA (terephthalic acid), and 4.806g of TME (trimethylolethane) were weighed. Blending under the condition of adding a catalyst and at a temperature of 120-170°C, followed by the first stage of esterification, the pressure is 0.1-0.15MPa, after 1-1.5 hours of esterification; the second stage of esterification starts, and the temperature is raised When the temperature reaches 225°C, 6g of catalyst Tetrabutyl Titanate (tetrabutyl titanate) is added for esterification, and the reaction is about 3-4 hours. When the water produced is equivalent to the theoretical water quality (90-110%); the polycondensation stage begins , add catalyst Tetrabutyl Titanate (tetrabutyl titanate) 3g and raise the temperature to 225°C, the pressure is 600Pa, after polycondensation for 6.5h, when it is found that the torque on the equipment does not change, the polycondensation is complete....

Embodiment 3

[0031] Through the two-step esterification method, 707g of SeA (sebacic acid), 900g of BDO (1.4-butanediol), 581g of TPA (terephthalic acid), and 7.209g of TME (trimethylolethane) were weighed. Blending under the condition of adding a catalyst and at a temperature of 120-170°C, followed by the first stage of esterification, the pressure is 0.1-0.15MPa, after 1-1.5 hours of esterification; the second stage of esterification starts, and the temperature is raised When the temperature reaches 225°C, 6g of catalyst Tetrabutyl Titanate (tetrabutyl titanate) is added for esterification, and the reaction is about 3-4 hours. When the water produced is equivalent to the theoretical water quality (90-110%); the polycondensation stage begins , add catalyst Tetrabutyl Titanate (tetrabutyl titanate) 3g and raise the temperature to 225°C, the pressure is 600Pa, after polycondensation for 6.5h, when it is found that the torque on the equipment does not change, the polycondensation is complete....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com