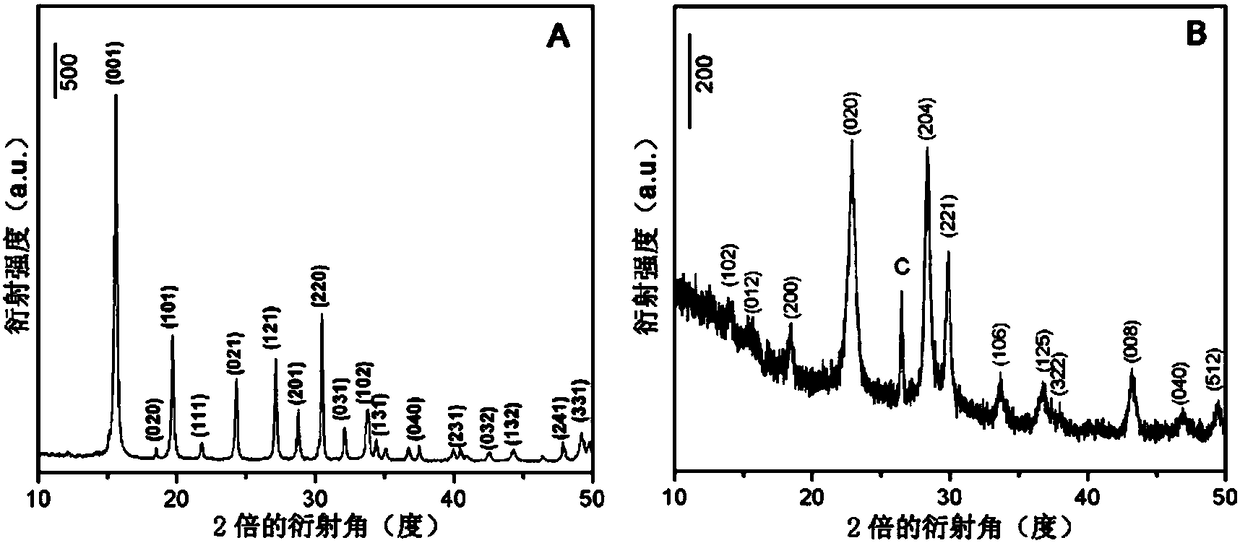

Vanadium phosphorus oxide catalyst for preparing maleic anhydride from n-butane through oxidation and preparation method thereof

A catalyst, vanadium phosphorus oxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve problems such as increasing the yield of maleic anhydride, achieve improved selectivity, increase specific surface area, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

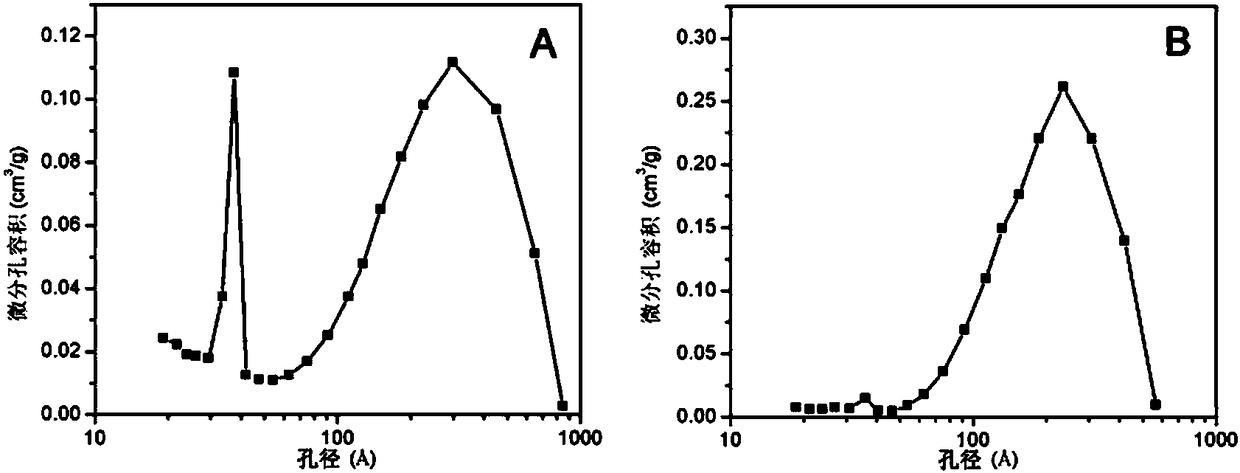

Embodiment 1

[0067] Add 127.2g V to a 3L round bottom flask 2 O 5 , the mixed solution of 1350mL isobutanol and 150mL benzyl alcohol was heated and stirred to reflux for 3 hours, 10.0g of polyethylene glycol with a molecular weight of 1500 was added to it, 150g of 105wt% phosphoric acid was added dropwise and heated and stirred to reflux for 16 hours, The V / P feeding molar ratio was 1 / 1.15, and the resulting pellet was centrifuged and washed with absolute ethanol and then dried at 120° C. for 12 hours. The dried catalyst precursor powder was added to graphite with a mass ratio of 3 / 97 to the catalyst precursor powder, mixed uniformly and heated in air at 250°C for 5 hours, and then the powder was pressed into a cylindrical structure with a height of 3mm and a diameter of 6mm. material, the density of this structure is 1.2g / cm 3 , the obtained catalyst precursor structure was heated to 375°C at a heating rate of 2.5°C / min in an air atmosphere, and then the atmosphere was changed to a mixe...

Embodiment 2

[0071] Add 127.2g V to a 3L round bottom flask 2 O 5 , the mixed solution of 1250mL isobutanol and 250mL benzyl alcohol was heated and stirred to reflux for 3 hours, 20.0g of polyethylene glycol with a molecular weight of 2000 was added to it, 156g of 105wt% phosphoric acid was added dropwise and heated and stirred to reflux for 20 hours, The V / P feeding molar ratio was 1 / 1.20, and the resulting pellet was centrifuged and washed with absolute ethanol and then dried at 120° C. for 12 hours. The dried catalyst precursor powder was added to graphite with a mass ratio of 3 / 97 to the catalyst precursor powder, mixed uniformly and heated in air at 250°C for 5 hours, and then the powder was pressed into a cylindrical structure with a height of 3mm and a diameter of 13mm. material, the density of this structure is 1.22g / cm 3 , the obtained catalyst precursor structure was heated to 375°C at a heating rate of 2.5°C / min in an air atmosphere, and then the atmosphere was changed to a mi...

Embodiment 3

[0075] Add 127.2g V to a 3L round bottom flask 2 O 5 , the mixed solution of 1250mL isobutanol and 250mL benzyl alcohol was heated and stirred to reflux for 3 hours, 10.0g of polyethylene glycol with a molecular weight of 6000 was added to it, 130g of 105wt% phosphoric acid was added dropwise and heated and stirred to reflux for 10 hours, The V / P feeding molar ratio was 1 / 1, and the resulting precipitate was centrifuged and washed with absolute ethanol and then dried at 120° C. for 12 hours. The dried catalyst precursor powder was added to graphite with a mass ratio of 5 / 95 to the catalyst precursor powder, mixed uniformly and heated in air at 250°C for 5 hours, and then the powder was pressed into a cylindrical structure with a height of 3mm and a diameter of 6mm. material, the density of this structure is 1.12g / cm 3 , the obtained catalyst precursor structure was heated to 375°C at a heating rate of 2.5°C / min in an air atmosphere, and then the atmosphere was changed to a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com