High-strength, anti-seepage and anti-corrosion concrete material and preparation method thereof

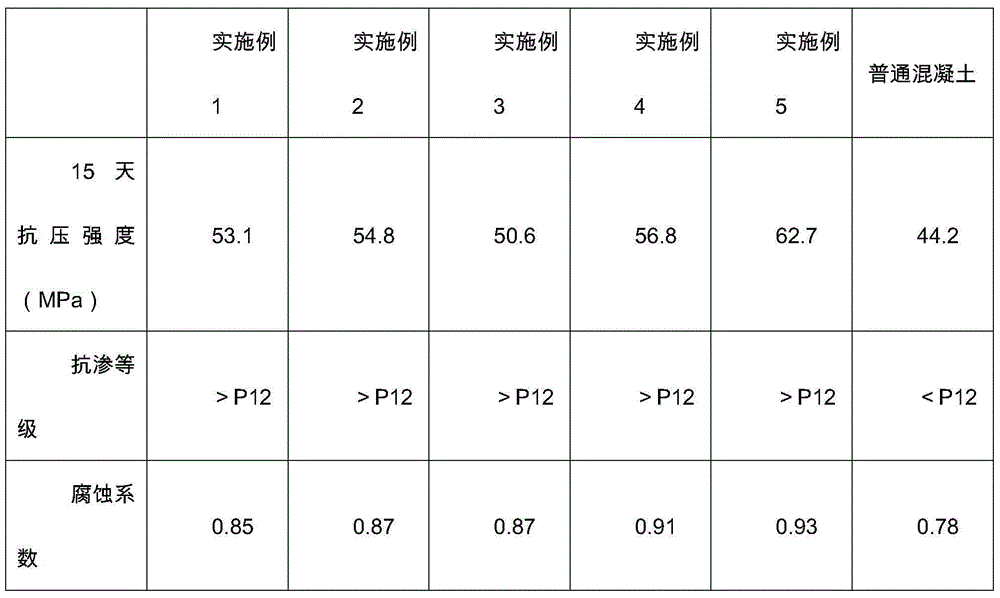

An anti-corrosion and concrete technology, applied in the field of concrete materials, can solve the problems of chloride corrosion, the decline of the durability of concrete structures, and the impact on engineering safety, and achieve the effect of good compressive strength, impermeability and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A high-strength anti-seepage and anti-corrosion concrete material, composed of the following components by weight: 180 parts of Portland cement, 10 parts of slag wool, 150 parts of crushed stone, 100 parts of glass flakes, 100 parts of fine sand, and 10 parts of calcium chloride 10 parts of magnesium silicate, 1 part of barium silicate, 1 part of sodium benzoate, 8 parts of calcium silicate, 4 parts of dialuminum hydrogen phosphate, 6 parts of strontium oxide, 4 parts of brucite powder, 2 parts of zinc powder, zinc oxide 10 parts, 2 parts of sodium metaaluminate, 2 parts of polyvinyl alcohol, 15 parts of dihydrate gypsum, 1 part of aluminum tripolyphosphate, 1 part of potassium tripolyphosphate, 1 part of potassium dihydrogen phosphate, bisphenol A epoxy acrylate 6 parts, 1 part of trihydroxymethylethane, 2 parts of polyacrylamide, 1 part of xylitol, 1 part of triethyl phosphate, 1 part of butyl methacrylate, 1 part of acrylonitrile, isobutyl triethoxy 2 parts of silane...

Embodiment 2

[0026] A high-strength anti-seepage and anti-corrosion concrete material, composed of the following components by weight: 200 parts of Portland cement, 20 parts of slag wool, 200 parts of gravel, 150 parts of glass flakes, 130 parts of fine sand, and 30 parts of calcium chloride 20 parts of magnesium silicate, 8 parts of barium silicate, 8 parts of sodium benzoate, 16 parts of calcium silicate, 12 parts of dialuminum hydrogen phosphate, 16 parts of strontium oxide, 12 parts of brucite powder, 10 parts of zinc powder, zinc oxide 20 parts, 10 parts of sodium metaaluminate, 10 parts of polyvinyl alcohol, 30 parts of dihydrate gypsum, 4 parts of aluminum tripolyphosphate, 4 parts of potassium tripolyphosphate, 4 parts of potassium dihydrogen phosphate, bisphenol A epoxy acrylate 8 parts, 3 parts of trihydroxymethylethane, 10 parts of polyacrylamide, 3 parts of xylitol, 4 parts of triethyl phosphate, 4 parts of butyl methacrylate, 4 parts of acrylonitrile, isobutyl triethoxy 4 part...

Embodiment 3

[0035] A high-strength anti-seepage and anti-corrosion concrete material, composed of the following components by weight: 180 parts of Portland cement, 10 parts of slag wool, 150 parts of crushed stone, 100 parts of glass flakes, 100 parts of fine sand, and 10 parts of calcium chloride 10 parts of magnesium silicate, 1 part of barium silicate, 1 part of sodium benzoate, 8 parts of calcium silicate, 4 parts of dialuminum hydrogen phosphate, 6 parts of strontium oxide, 4 parts of brucite powder, 2 parts of zinc powder, zinc oxide 10 parts, 2 parts of sodium metaaluminate, 2 parts of polyvinyl alcohol, 15 parts of dihydrate gypsum, 1 part of aluminum tripolyphosphate, 1 part of potassium tripolyphosphate, 1 part of potassium dihydrogen phosphate, bisphenol A epoxy acrylate 6 parts, 1 part of trihydroxymethylethane, 2 parts of polyacrylamide, 1 part of xylitol, 1 part of triethyl phosphate, 1 part of butyl methacrylate, 1 part of acrylonitrile, isobutyl triethoxy 2 parts of base s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com